- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

20K2000W American Transducer

short description part

The 20K 2000W ultrasonic transducer is an industrial-grade energy conversion device based on the piezoelectric effect, designed specifically for applications requiring stable, high-intensity ultrasonic vibrations. With a precisely locked operating frequency of 20kHz and an output power of 2000W, it efficiently converts high-frequency electrical energy into mechanical vibrations (ultrasonic waves), providing a continuous and reliable power source for processes such as welding, cleaning, and machining.

operating principle

Based on the piezoelectric effect, the ultrasonic generator generates high-frequency electrical energy and transmits it to the transducer. Under the action of high-frequency electrical energy, the core component, the piezoelectric ceramic plate, undergoes expansion and contraction deformation due to the piezoelectric effect, converting electrical energy into mechanical energy, that is, generating ultrasonic vibration. Subsequently, the transducer transmits mechanical vibration to the welding head of the welding tool. The welding head comes into contact with the material to be welded. The ultrasonic vibration causes microscopic friction and deformation on the material surface to generate heat, reaching the melting point or softening point. Under the action of static pressure, the material adheres closely together, and a firm connection is formed between the molecules.

product presentation

The 20K 2000W ultrasonic transducer is a core energy conversion device designed specifically for industrial applications. With its precise frequency control and powerful power output, it is an indispensable component in ultrasonic welding, cleaning, machining, and other processes. Its core function is to efficiently convert high-frequency electrical energy into mechanical vibrations (ultrasound) through the piezoelectric effect, providing stable and controllable ultrasonic power for various industrial production processes.

application area

Plastic Welding: Suitable for welding plastic components in the automotive manufacturing, electronics assembly, and medical device manufacturing sectors, such as automobile bumpers, plastic water tanks, and electronic product casings.

Metal Welding: Suitable for welding thin sheets of non-ferrous metals such as aluminum and copper, such as welding lithium battery tabs and butting and overlapping small metal components.

Non-woven Fabric Processing: Suitable for welding and embossing non-woven fabrics in mask production and home textiles, including sheeting and edge banding.

Other Applications: Suitable for ultrasonic cleaning, food processing, and chemical processing, such as cleaning precision machinery parts, assisting in homogenizing food ingredients, and wastewater treatment.

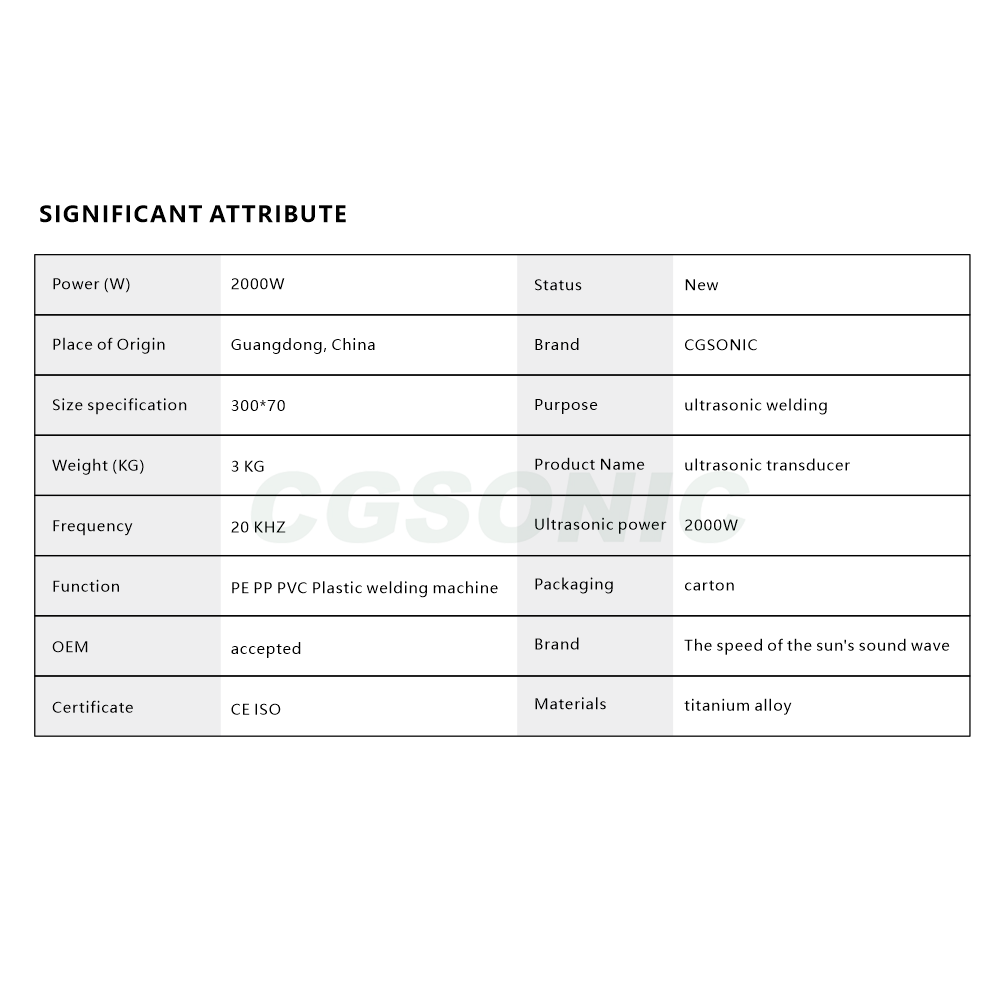

Product Parameter

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance