- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

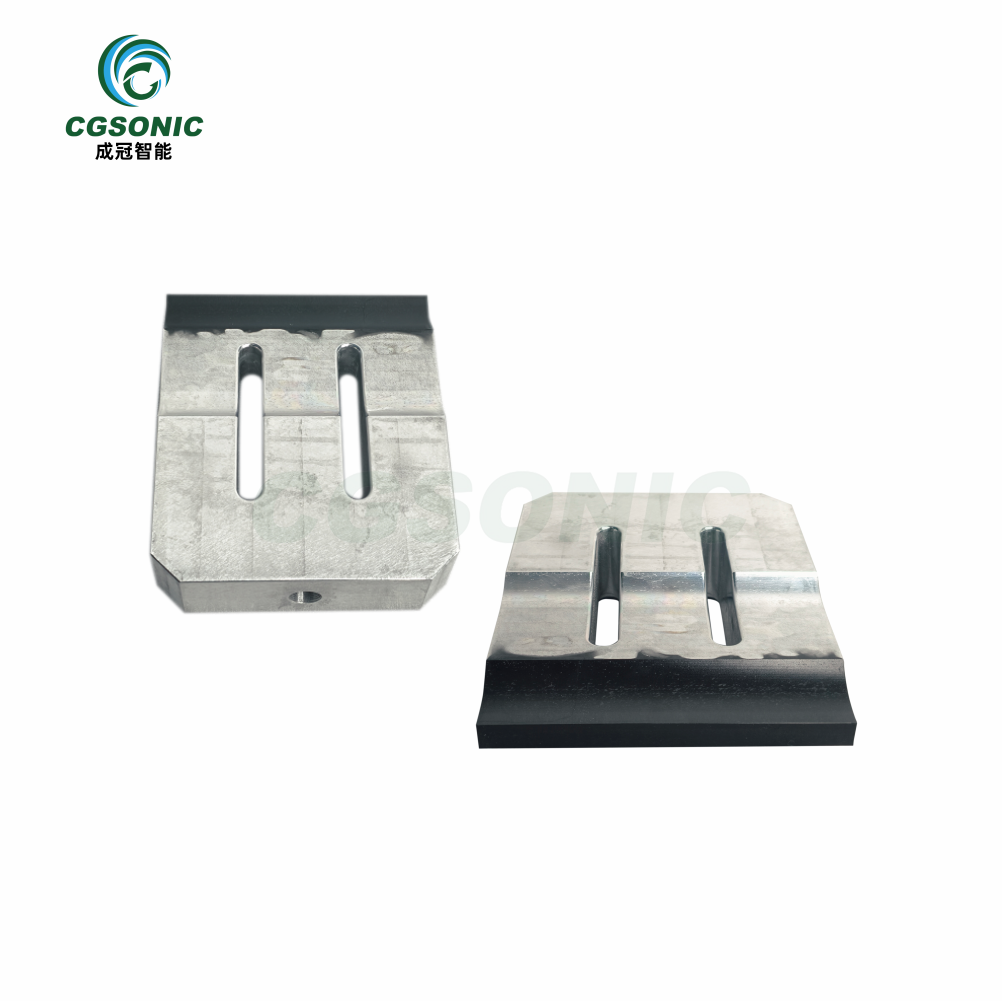

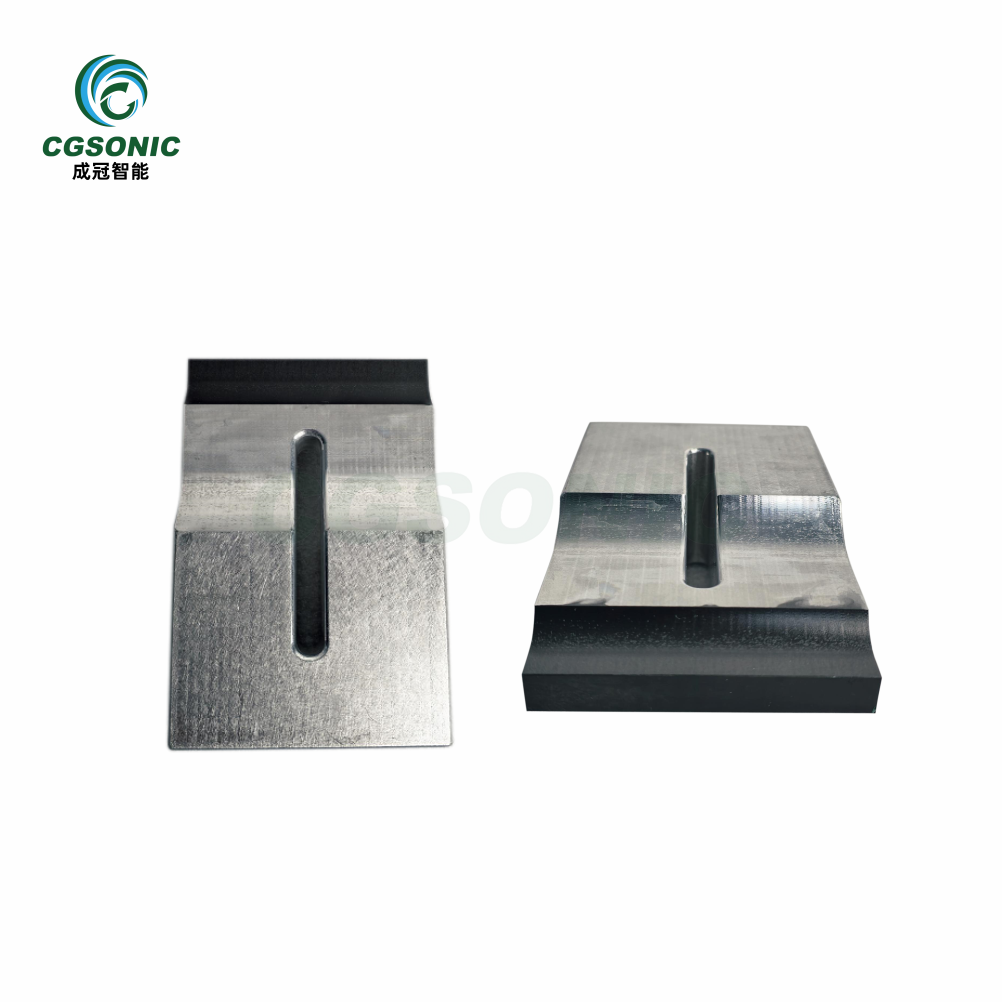

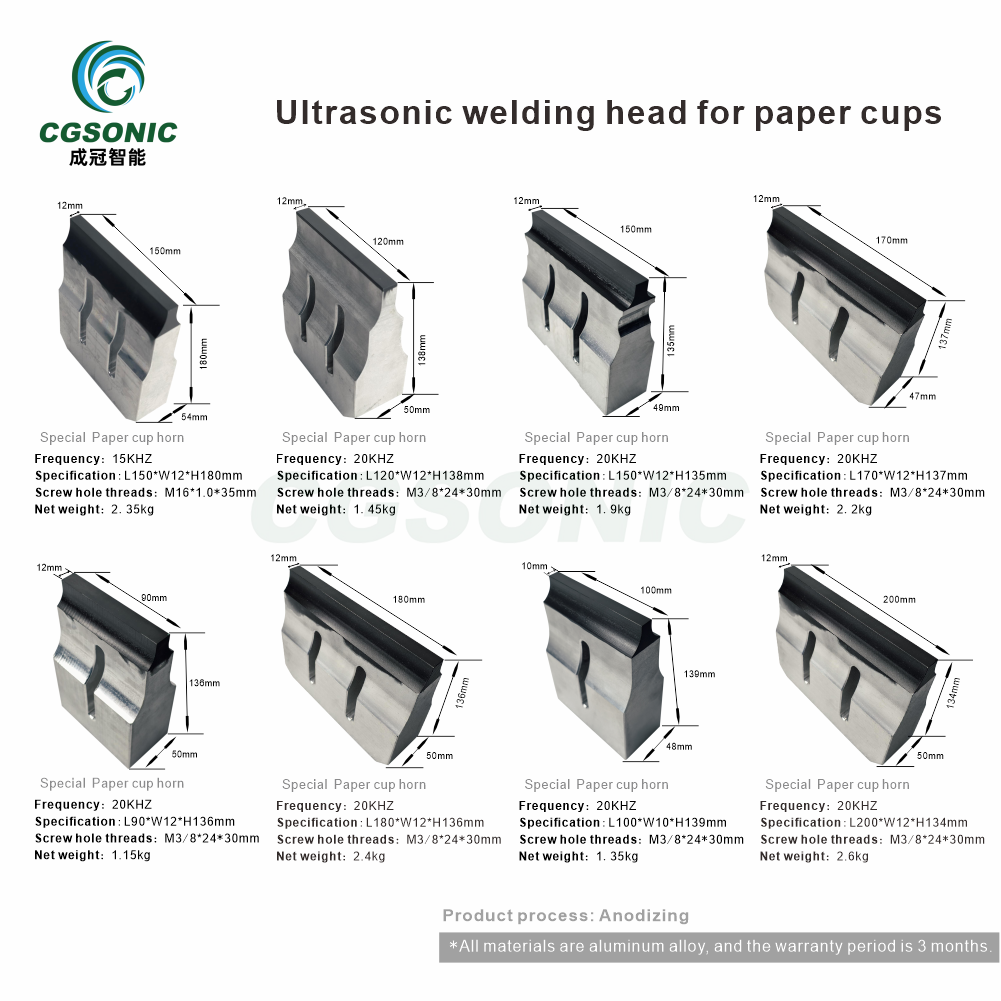

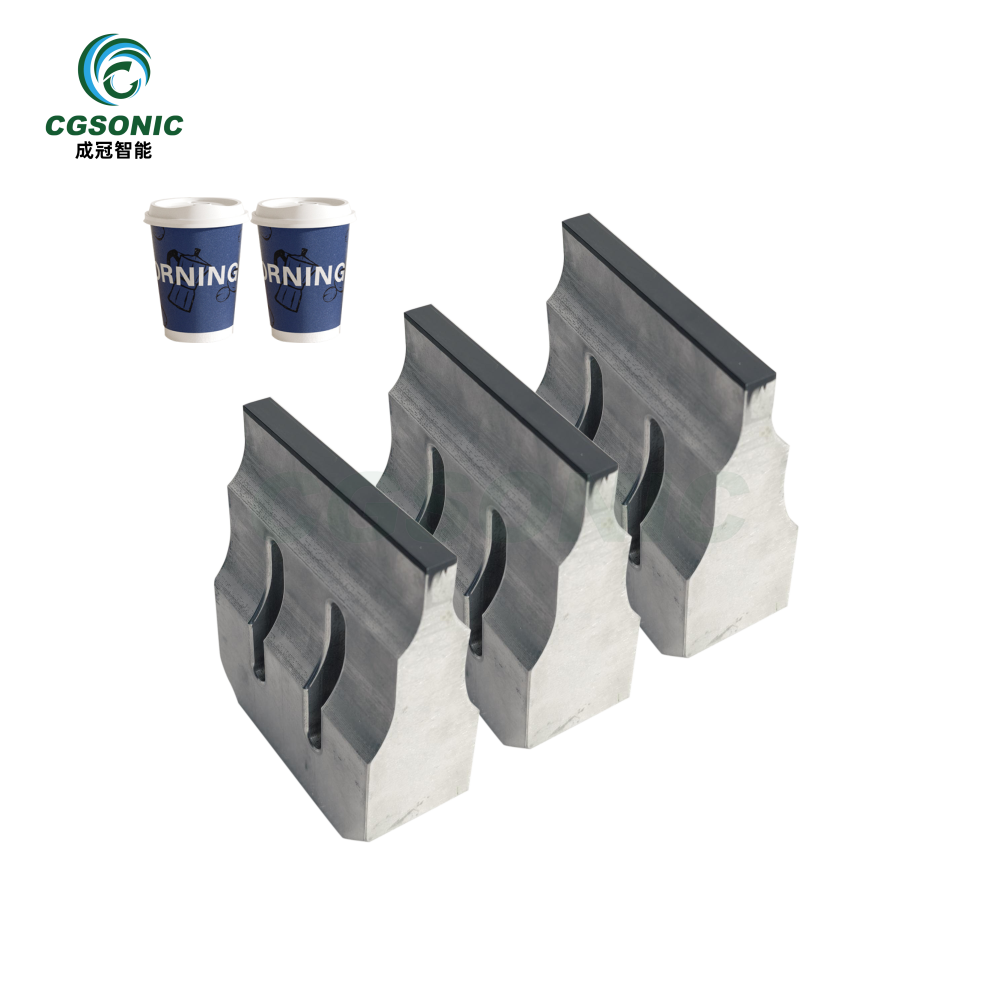

20kHz 2600W 220V Paper Cup Welding Head

Core Product Advantages

Precise power matching and high welding efficiency : The 2600W high-power output can quickly penetrate the paper cup coating layer, with a single welding cycle of only 1-3 seconds. It is compatible with high-speed automated production lines and can complete the welding of thousands of paper cups per hour, far exceeding the efficiency of traditional processes. The 20kHz frequency design balances welding strength and material adaptability, avoiding damage to the paper cup substrate caused by high frequencies.

Universal voltage compatibility and low maintenance costs : Designed with a standard 220V AC voltage, it requires no additional transformer and can be directly connected to the power grids in most parts of the world, reducing equipment adaptation costs. Core components are made of high wear-resistant alloy materials and are precision-machined, resulting in low vibration attenuation and long service life, reducing downtime losses caused by frequent replacements.

Glue-free welding is more environmentally friendly and safer than traditional glue bonding processes. The welding process leaves no chemical solvent residue, meeting food contact material safety standards and ensuring the safety of end consumers. No visible weld marks remain, maintaining the paper cup's clean and attractive appearance and enhancing the product's overall quality.

Excellent welding strength and reliable sealing performance : Welding is achieved through molecular-level fusion, and the joint strength is close to that of the substrate itself, effectively preventing liquid leakage and making it suitable for use in both hot and cold beverage paper cups. The welded surface is smooth and free of burrs and wrinkles, reducing the scrap rate caused by poor sealing.

Highly adaptable and easy to operate : Supports customized welding surface shapes according to different paper cup specifications (diameter 50-150mm, height 80-200mm), compatible with single-layer, double-layer, and sealing ring-equipped paper cups. Adopts a standardized interface design, allowing for quick connection with various ultrasonic welding equipment. Parameter adjustment is simple, requiring no professional technicians to operate.

Core Working Principle

This welding head utilizes ultrasonic welding technology, working in conjunction with an ultrasonic generator and transducer to convert electrical energy into 20kHz high-frequency mechanical vibration. This vibrational energy is precisely transmitted to the area of the paper cup to be welded via the welding head. The high acoustic resistance of the material in the welding area (paper cup coated plastic, PE film, etc.) generates localized, instantaneous high temperatures, rapidly melting the contact surface material. Simultaneously, under the pressure of the equipment, the molten material achieves molecular-level fusion. After the ultrasonic waves cease, pressure is maintained for several seconds to complete solidification, ultimately forming a strong and smooth weld joint. The equipment incorporates an intelligent automatic frequency tracking system that adapts to the 20kHz resonant frequency in real time, ensuring stable power output and preventing weak welds or material damage caused by frequency deviations.

Application Scenarios

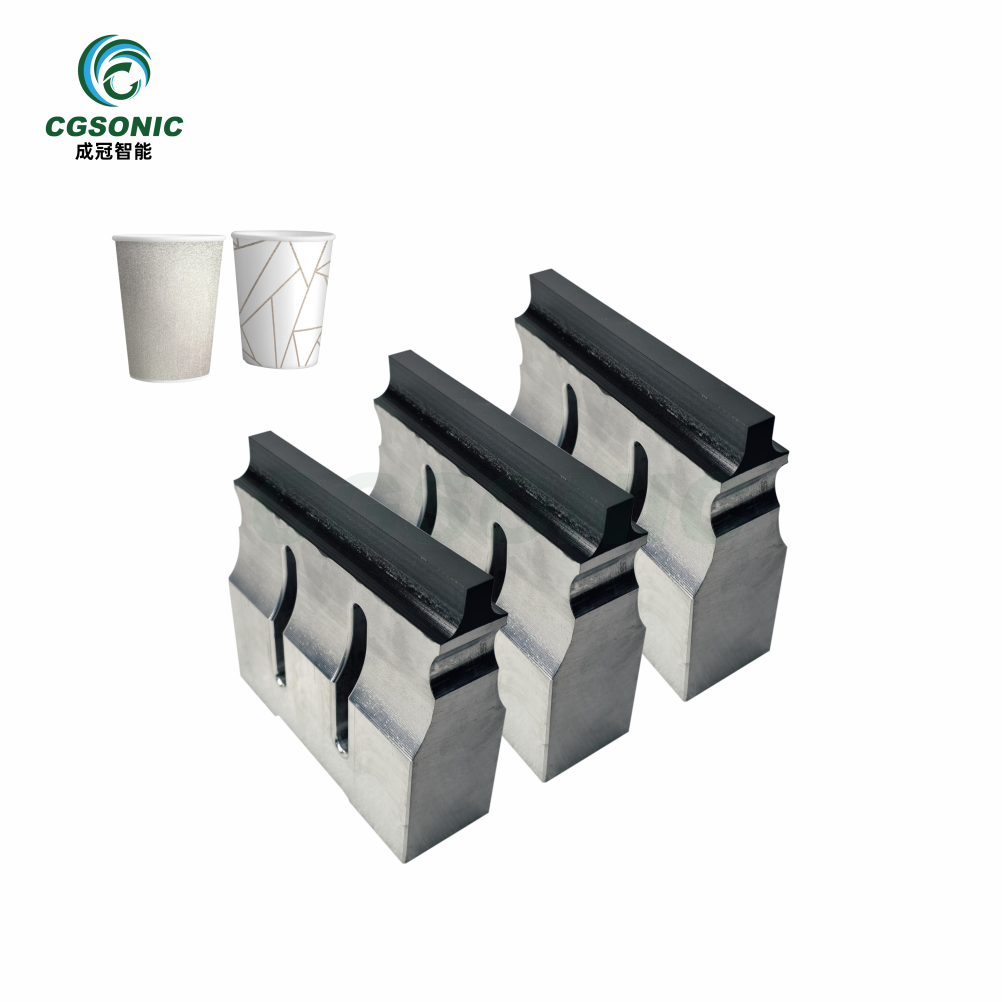

Thanks to its precise parameter design and wide adaptability, this welding head has been widely used in several core processes of paper cup and paper container production, with typical applications including:

For the disposable paper cup manufacturing industry : Suitable for side sealing and base fixing of disposable drinking paper cups such as milk tea cups, coffee cups, and soy milk cups. After welding, the sealing performance is excellent, which can effectively prevent the leakage of hot and cold drinks and meet the high-frequency use needs of catering chains, takeaway delivery and other industries.

Food packaging container industry : Welding of cup lids and cup bodies for food-grade paper cups (such as popcorn buckets, ice cream cups, soup buckets), and fixing of built-in sealing rings to ensure the airtightness and hygiene of food during storage and transportation.

In the paper lunch box manufacturing industry : suitable for edge welding and lid assembly of square and round paper lunch boxes, especially suitable for oil-proof lunch boxes with PE coating, and the welding strength can withstand the impact of external forces during the stacking and handling of lunch boxes.

Customized paper consumables production : For special-specification products such as holiday paper cups, advertising paper cups, and medical sampling paper cups, we achieve precise welding of irregular structures through customized welding surface design, taking into account both aesthetics and practicality.