- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

28K2000W Transducer

short description part

Frequency: 28kHz. Ultrasonic waves at this frequency ensure sufficient energy transfer for efficient cleaning or welding while avoiding issues such as increased cavitation and reduced welding precision caused by excessively high frequencies.

Power: 2000W. High power output ensures sufficient energy during operation to meet the demands of various high-intensity operations.

Power: 2000W. High power output ensures sufficient energy during operation to meet the demands of various high-intensity operations.

operating principle

Based on the piezoelectric effect, when an alternating voltage acts on the piezoelectric ceramic material inside the transducer, the piezoelectric ceramic will generate mechanical vibrations, thereby converting electrical energy into mechanical energy and generating 28kHz ultrasonic waves.

product presentation

Frequency: 28kHz, or 28,000 vibrations per second, suitable for a variety of industrial scenarios.

Power: 2000W, high power output meets the needs of high-intensity operations.

Working principle: Based on the piezoelectric effect, when alternating voltage acts on piezoelectric ceramic materials, the material will produce mechanical vibrations, thereby converting electrical energy into mechanical energy and generating 28kHz ultrasonic waves.

Structural composition: It mainly consists of a piezoelectric ceramic vibrator, front and rear covers, and electrodes. The piezoelectric ceramic vibrator is the core component, responsible for converting electrical energy into mechanical energy. The front and rear covers secure and support the vibrator, while also facilitating the transmission of ultrasonic vibrations. The electrodes are used to introduce alternating voltage into the piezoelectric ceramic vibrator, causing it to generate mechanical vibrations.

application area

Cleaning field: It is widely used in cleaning work in high-requirement fields such as electronic components, medical equipment, and precision mechanical parts. At the same time, it can also be used for precision maintenance of aerospace components and cleaning of key components in the new energy field.

Welding field:It has applications in fields ranging from automobile manufacturing to electronic device packaging, from medical devices to daily consumer products. Through high-frequency vibration, energy is transferred to the contact surface of the plastic material, causing the material to reach a molten state in an instant, thereby achieving seamless welding.

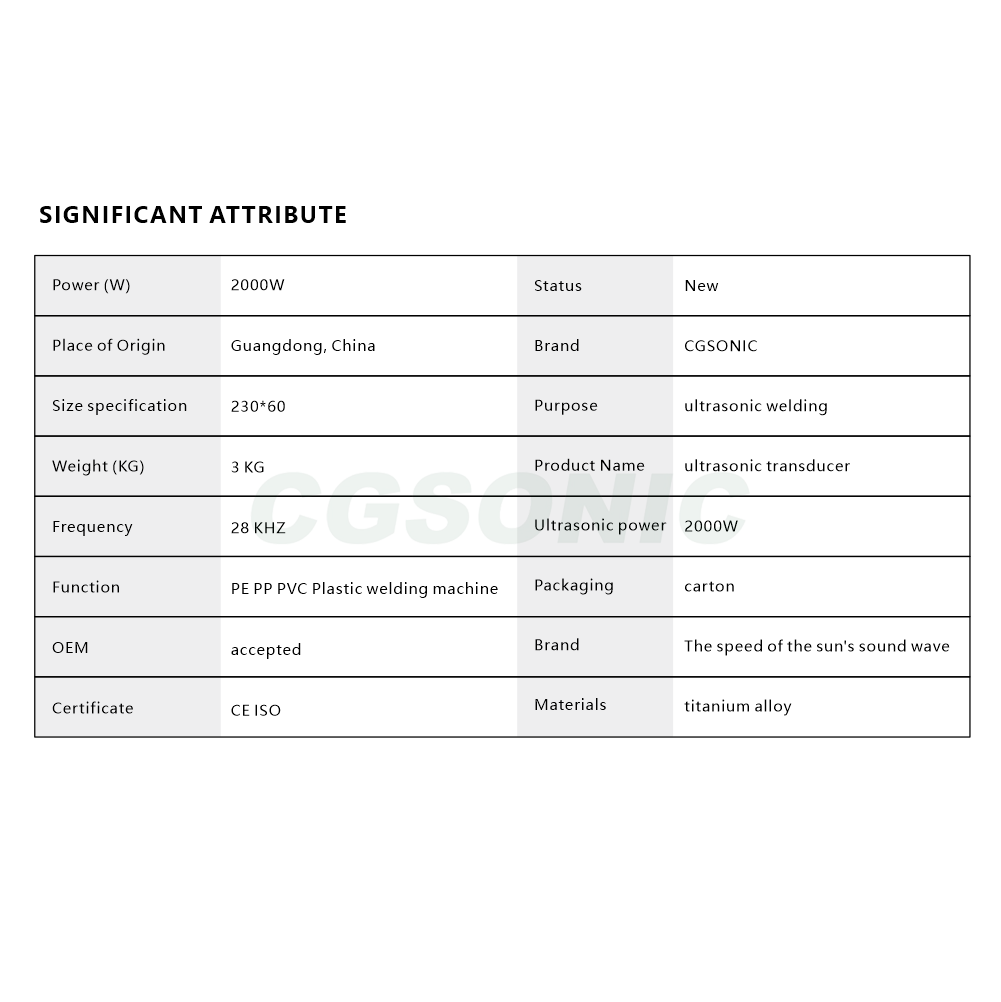

Product Parameter

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance