- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

28K400 watt transducer (red)

short description part

The 28K400-watt transducer is a high-frequency and highly efficient ultrasonic energy conversion device, with a fixed frequency of 28KHz and a powerful 400-watt output as its core advantages. Relying on the piezoelectric effect principle, it can efficiently convert electrical energy into high-frequency mechanical vibration, forming energy-dense ultrasonic waves. These waves can quickly penetrate thick media and reach complex areas such as micro-pores and crevices, powerfully breaking down stubborn dirt, grease and microorganisms. Military level of piezoelectric ceramics with high strength alloy materials, combined with precision encapsulation process, to ensure that in - 10 ℃ ~ 60 ℃ environment stable operation, low vibration attenuation rate to 5% / 1000 hours, using life over 8000 hours. The straight-handled handheld design is ergonomic, weighing only 0.9kg. It is equipped with a quick-plug interface, allowing connection to the main unit in just 3 seconds. It can support continuous high-intensity operation for 2 hours without getting hot. It is widely suitable for industrial cleaning, laboratory handling, food processing, and medical pretreatment scenarios, making it a high-performance tool that combines power and portability.

operating principle

The core working logic of the 28K400-watt transducer is the three-level conversion of electrical energy, mechanical energy and ultrasonic energy: after being connected to the 28KHz AC electrical signal, the internal piezoelectric ceramic vibrator generates the same frequency stretching vibration due to the inverse piezoelectric effect. The 400-watt power is focused on the front end through structural optimization, forming a high-frequency mechanical wave. Ultimately, it acts on the medium in the form of ultrasonic waves - triggering cavitation effects (bubbles bursting to generate impact forces) in the liquid, and converting them into thermal energy or mechanical force at the solid contact surface, achieving functions such as decontamination and welding.

product presentation

The 28K 400-watt transducer, with a frequency of 28KHz and a power of 400 watts as its core, achieves efficient energy conversion through the piezoelectric effect. Made of high quality material, strong stability, can continue to work in a variety of environments. The design is ergonomic, easy to operate and can be quickly connected to the main unit. Is suitable for industrial cleaning, lab processing scenarios, can effectively remove stubborn stains, improve work efficiency.

application area

Industrial cleaning: Deep decontamination of automotive parts, electronic components and molds;

Laboratory handling: Non-destructive cleaning of precision vessels such as test tubes and beakers;

Food processing: Removal of oil stains and microorganisms from the surface of packaging containers;

Medical field: Pre-treatment cleaning of surgical instruments (in combination with dedicated cleaning agents).

show details

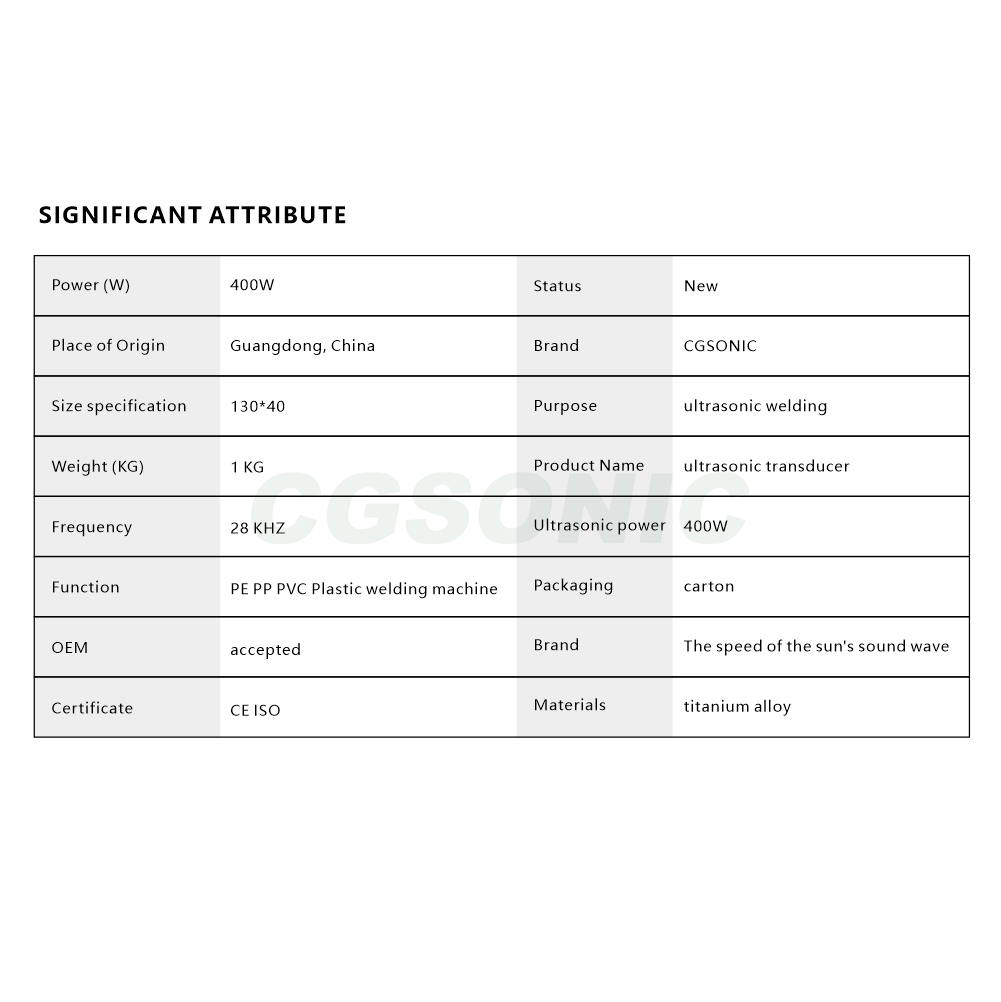

Product Parameter

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance