- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

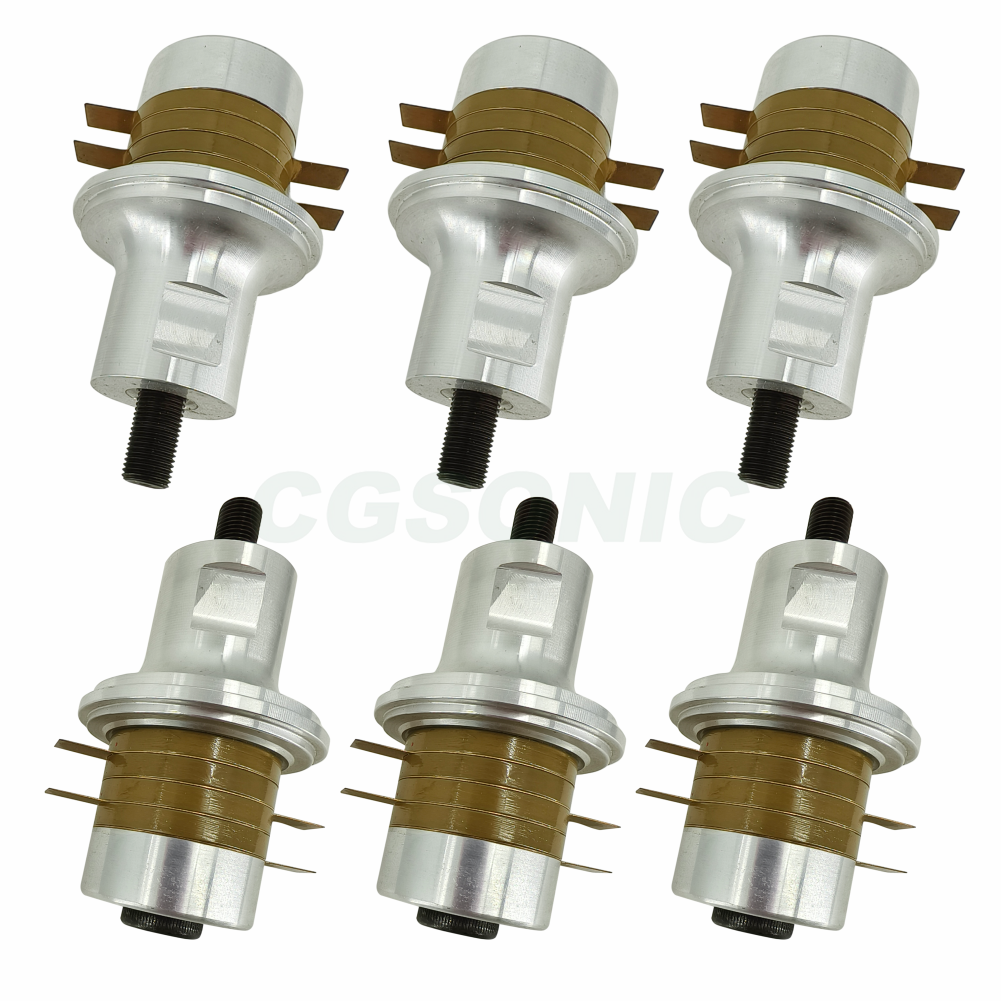

30K 1000W Transducer

short description part

The 30K 1000-watt transducer is a high-frequency and high-power ultrasonic energy conversion device, with a 30KHz frequency and a powerful 1000-watt output as its core. Relying on the piezoelectric effect, electrical energy can be efficiently converted into high-frequency mechanical vibrations, forming energy-intensive ultrasonic waves with strong penetration and high intensity. It can quickly handle stubborn stains and achieve efficient material welding, etc. Adopting piezoelectric ceramics with high quality and durable alloy materials, through precision process, can be in relatively wide temperature and humidity range and stable operation, low vibration attenuation rate, long service life. The design takes into account both stability and operability, is compatible with various hosts, and is widely used in scenarios such as heavy industrial cleaning, large parts welding, and high-strength material processing. It is a high-performance industrial-grade tool.

operating principle

The working principle of the 30K 1000-watt transducer is as follows: After a 30KHz electrical signal is connected, the internal piezoelectric ceramic vibrates at the same frequency due to the inverse piezoelectric effect. The 1000-watt power is focused by the structure to form ultrasonic waves. When acting on the medium, functions such as decontamination and welding are achieved through cavitation effect or mechanical force.

product presentation

The 30K 1000-watt transducer is a high-frequency and high-power ultrasonic energy conversion device, with core parameters of 30KHz frequency and 1000-watt power. It adopts high quality materials refined but become, relying on the piezoelectric effect to realize efficient energy conversion, strong ultrasonic can stable output. The equipment design emphasizes practicality, is compatible with various hosts, and is easy to operate. With high frequency and high power characteristics, are widely used in heavy duty industrial cleaning, large parts of welding, high strength material handling scenarios, such as it can be finished efficient decontamination, welding and other operations, improve work efficiency.

application area

Industrial cleaning: Deep decontamination of automotive parts, electronic components and molds;

Laboratory handling: Non-destructive cleaning of precision vessels such as test tubes and beakers;

Food processing: Removal of oil stains and microorganisms from the surface of packaging containers;

Medical field: Pre-treatment cleaning of surgical instruments (in combination with dedicated cleaning agents).

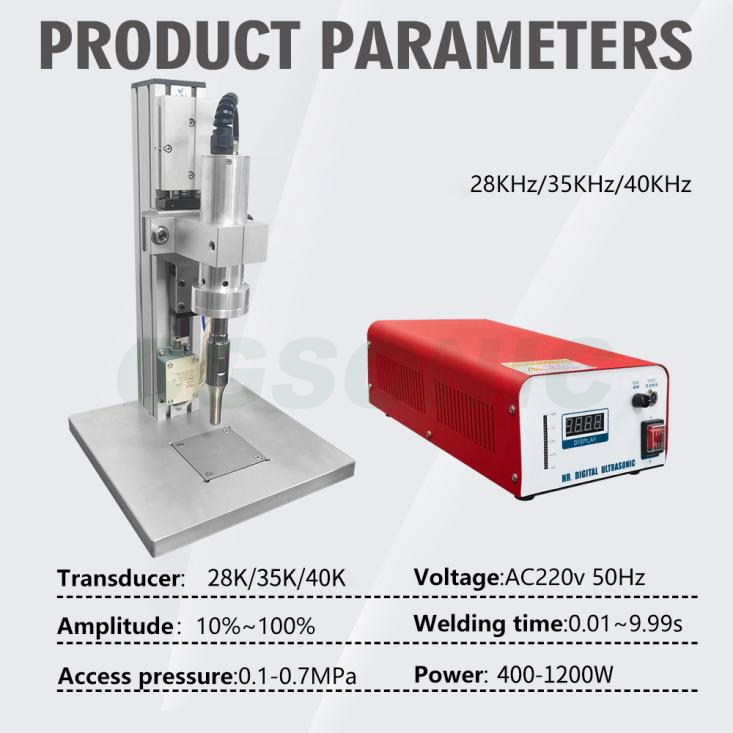

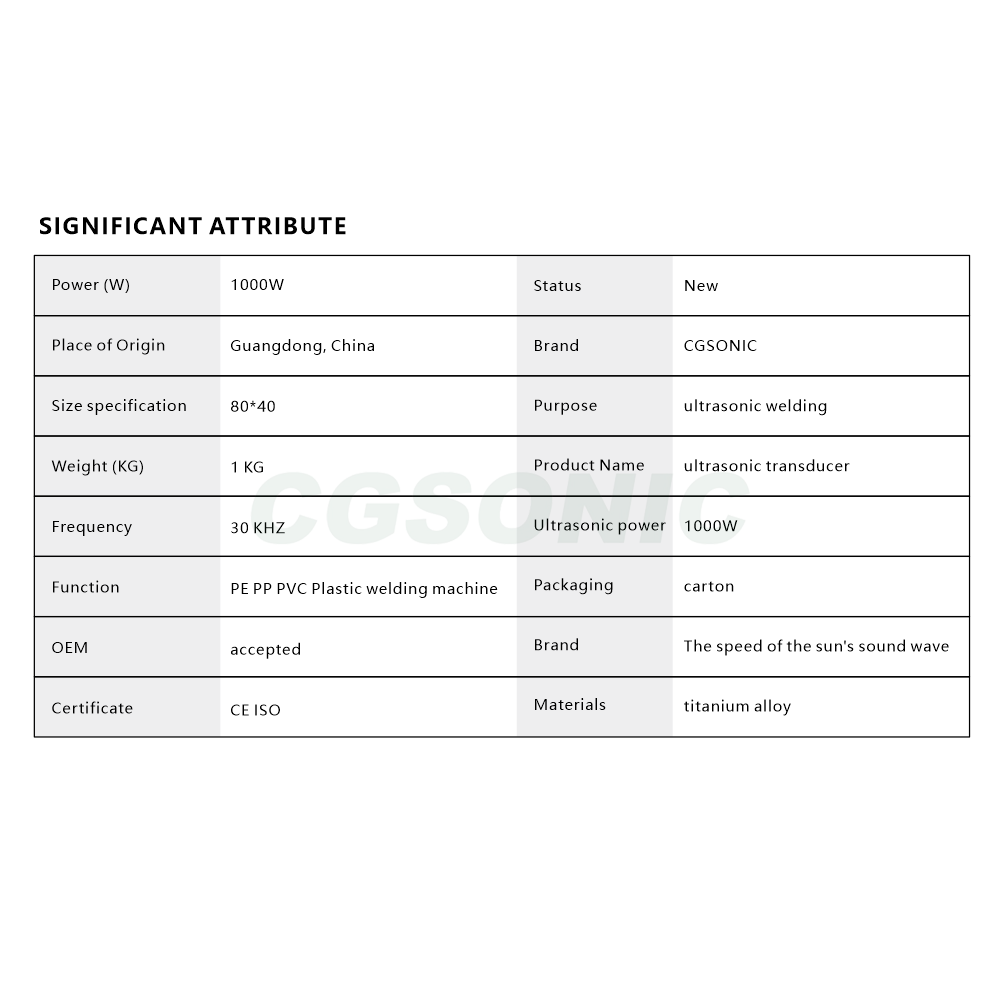

Product Parameter

Product Parameter

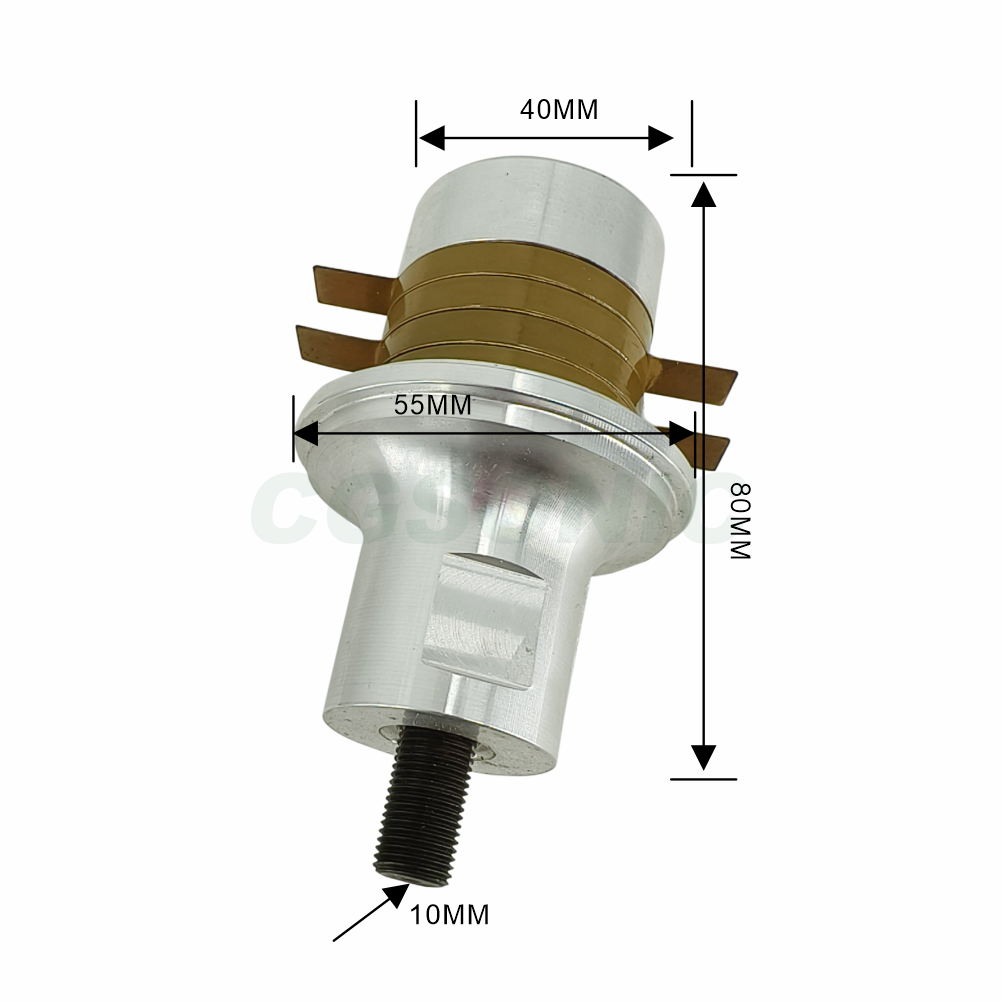

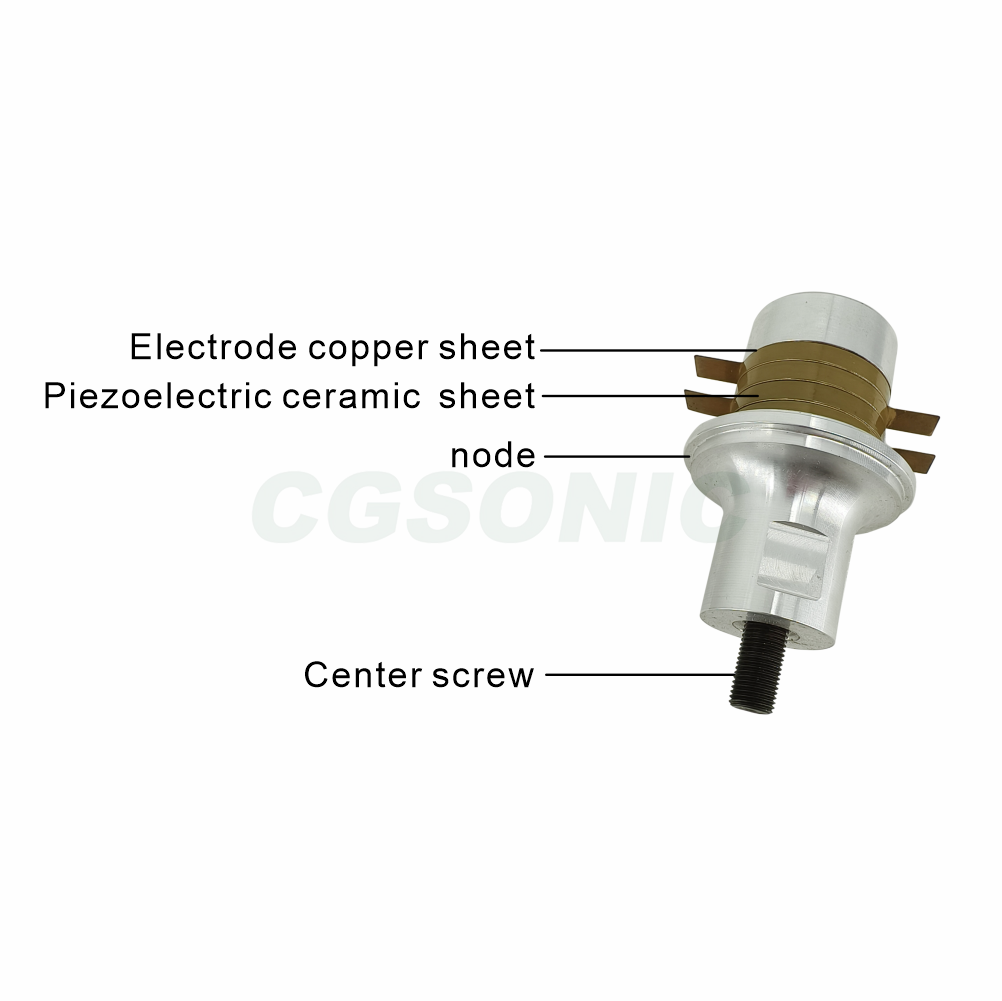

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance