- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

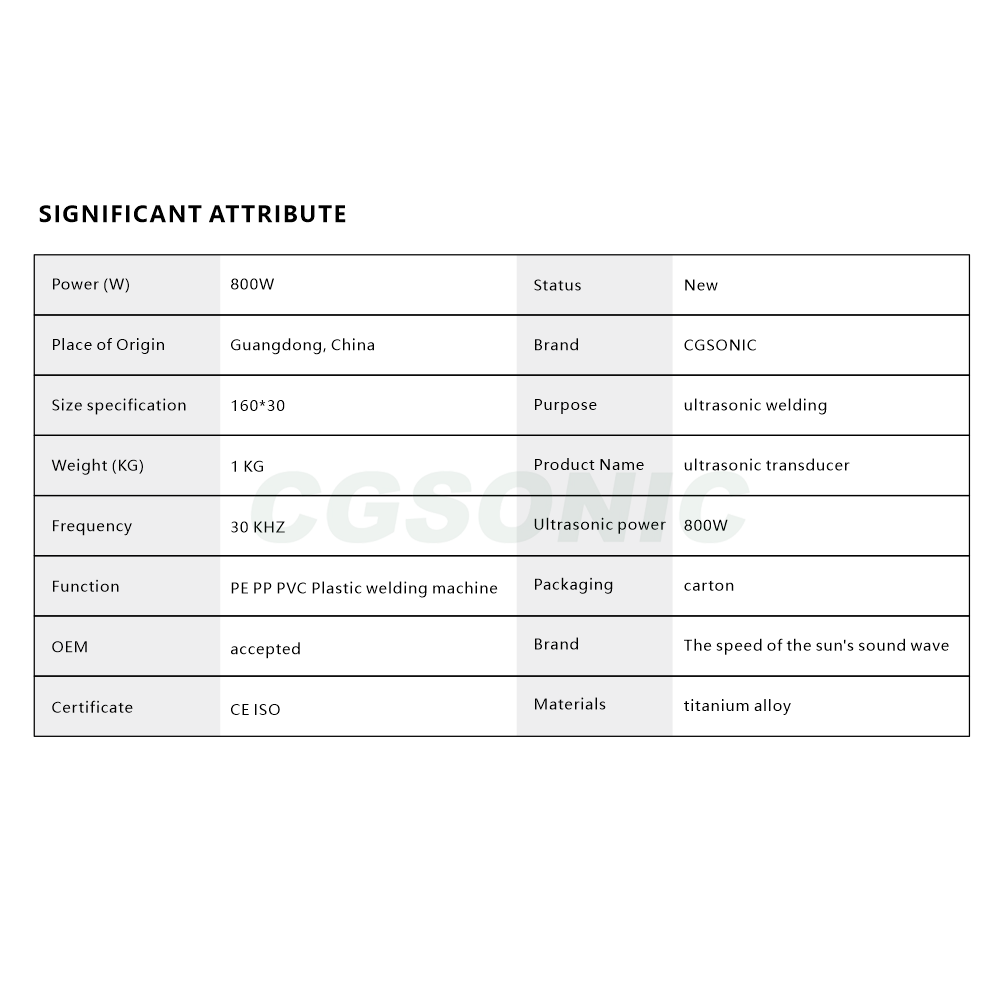

30khz800W Transducer

short description part

The 30K800W transducer is an ultrasonic transducer with a working frequency of 30kHz and a power of 800W. It achieves energy conversion based on the piezoelectric effect and features high efficiency and moderate amplitude. It is widely used in industrial cleaning, welding, medical atomization, environmental water treatment and other scenarios. When in use, attention should be paid to installation standards and avoid empty vibration.

working principle

The 30K800W transducer generally operates based on the piezoelectric effect. When an alternating voltage is applied to piezoelectric materials, the materials undergo periodic deformation due to the inverse piezoelectric effect, thereby generating mechanical vibrations and emitting ultrasonic waves. Conversely, when ultrasonic waves act on piezoelectric materials, the materials generate charges due to the positive piezoelectric effect, which can convert acoustic energy into electrical signals.

product presentation

High-efficiency conversion: It can efficiently convert the input electrical energy into mechanical energy (acoustic energy), with a relatively high conversion efficiency, ensuring less energy loss during operation and outputting stable ultrasonic waves with a power of 800W. Amplitude stability: under the condition of the working frequency of 30 KHZ, can produce stable and moderate amplitude, ensure the consistency of the strength and effect of ultrasonic, is conducive to the stable operation of the various application scenarios. High reliability: the quality of piezoelectric materials and advanced manufacturing technology, makes the transducer has high stability and reliability, and can work continuously for a long time under the condition of keep good performance, reduce the probability of failure. Strong adaptability, can adapt to a range of work environment change, such as temperature, humidity, etc., has a good environmental adaptability, can be in different industry, medical environment stable work, etc.

application area

Used in the field of industrial automation, such as ultrasonic welding, cleaning, etc. It can be used in the medical industry for phacoemulsification, nebulization therapy, etc. It can also be used in water treatment equipment (sterilization and disinfection) and air purification equipment in the environmental protection industry, etc.

Product Parameter

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance