- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

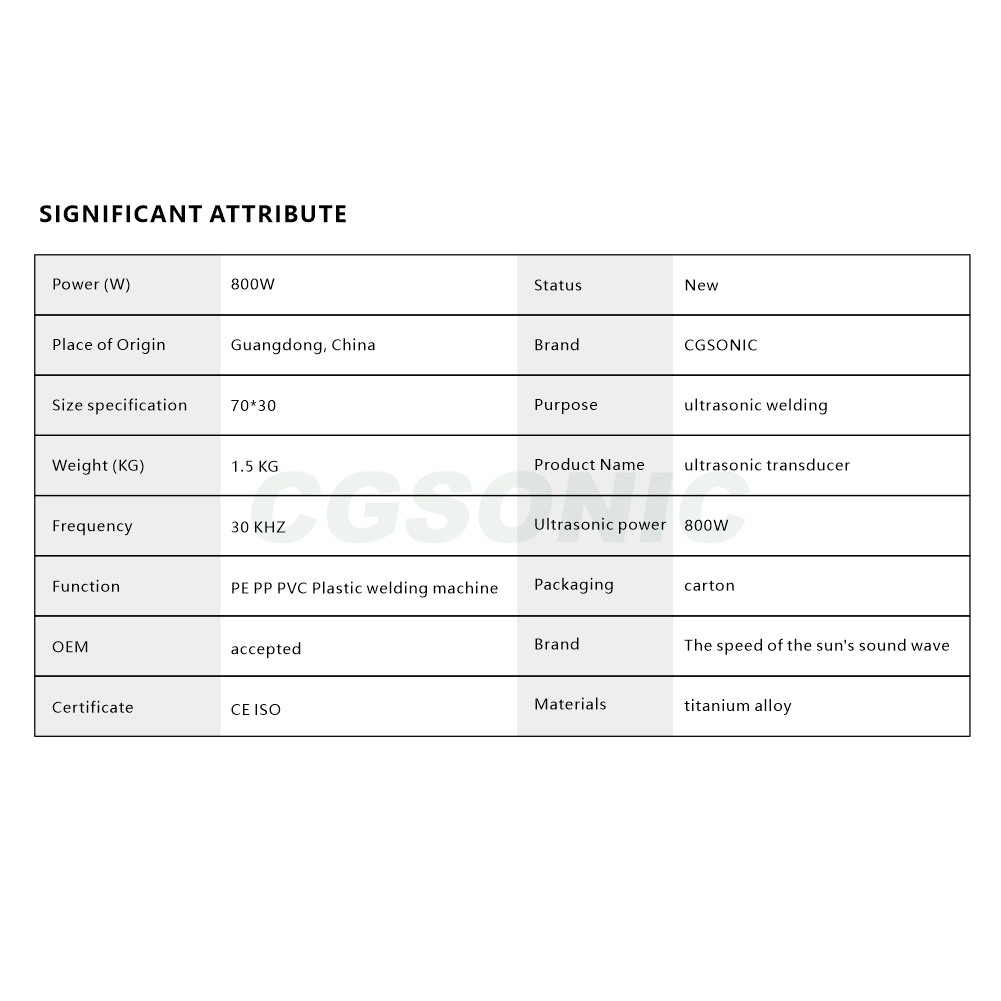

30KHZ800W Transducer

short description part

The 30KHZ 800-watt transducer is a core component of ultrasonic equipment, capable of efficiently converting high-frequency electrical signals into mechanical vibrations. With a stable frequency of 30KHZ and a power of 800W, it is suitable for various medium-load operations, featuring high energy conversion efficiency and uniform amplitude. It has excellent heat resistance and can work continuously for a long time. It is suitable for scenarios such as plastic welding and small component processing, ensuring processing quality and efficiency.

operating principle

The working principle of the 30KHZ 800-watt transducer is based on the piezoelectric effect. It works in conjunction with the ultrasonic electrical box, which converts electrical energy into a high-frequency electrical signal of 30KHZ and transmits it to the transducer. The piezoelectric ceramic plates inside the transducer undergo mechanical vibration under the action of high-frequency electrical signals, efficiently converting electrical energy into mechanical vibration energy of the same frequency to form ultrasonic vibration, providing energy for subsequent welding, processing and other operations.

product presentation

Its working principle is based on the piezoelectric effect and works in coordination with the ultrasonic electrical box. The ultrasonic electrical box first converts electrical energy into a high-frequency electrical signal of 30KHZ and transmits it to the transducer. Under the action of the high-frequency electrical signal, the piezoelectric ceramic plate inside the transducer generates mechanical vibration, thereby efficiently converting electrical energy into mechanical vibration energy of the same frequency, forming ultrasonic vibration, and providing energy for subsequent welding, processing and other operations. This transducer has many advantages. Its frequency of 30KHZ is stable and precise, and it can be well matched with related equipment. With a power of 800 watts, it is suitable for various medium-load operations, featuring high energy conversion efficiency and the ability to reduce energy loss. Meanwhile, it has a uniform amplitude, which can ensure the consistency of the processing effect. Moreover, it has excellent heat resistance and can adapt to long-term continuous operation, thus extending the service life of the equipment.

application area

Plastic processing industry

Welding of small plastic parts: such as plastic casings of electronic components, connectors and plugs, and small plastic accessories on toys, etc. Through the ultrasonic vibration generated by transducers, precise welding between parts can be achieved. The weld seams are firm and the appearance is smooth, avoiding problems such as deformation and glue overflow that may occur in traditional welding methods. Plastic sheet cutting: It is suitable for cutting thin plastic sheets, such as plastic films for packaging and small plastic gaskets. The cutting edge is smooth without burrs, with high precision, which can meet the requirements of fine processing.

Welding of small plastic parts: such as plastic casings of electronic components, connectors and plugs, and small plastic accessories on toys, etc. Through the ultrasonic vibration generated by transducers, precise welding between parts can be achieved. The weld seams are firm and the appearance is smooth, avoiding problems such as deformation and glue overflow that may occur in traditional welding methods. Plastic sheet cutting: It is suitable for cutting thin plastic sheets, such as plastic films for packaging and small plastic gaskets. The cutting edge is smooth without burrs, with high precision, which can meet the requirements of fine processing.

Medical device industry

It plays a significant role in the processing of some small medical devices, such as the welding of plastic interfaces on infusion sets and small medical plastic valves and other components. The welding process involves no high-temperature open flames and does not produce harmful substances. It can ensure the cleanliness and safety of medical devices and meets the strict hygiene standards of the industry.

It plays a significant role in the processing of some small medical devices, such as the welding of plastic interfaces on infusion sets and small medical plastic valves and other components. The welding process involves no high-temperature open flames and does not produce harmful substances. It can ensure the cleanliness and safety of medical devices and meets the strict hygiene standards of the industry.

The electronic and electrical industry

It can be used for the packaging and connection of electronic components, such as the plastic packaging of small sensors and the welding of plastic fasteners on electronic circuit boards. It can achieve reliable connection without damaging electronic components and ensure the stable performance of electronic devices.

It can be used for the packaging and connection of electronic components, such as the plastic packaging of small sensors and the welding of plastic fasteners on electronic circuit boards. It can achieve reliable connection without damaging electronic components and ensure the stable performance of electronic devices.

The handicrafts and ornaments industry

For the processing and assembly of some small handicrafts and ornaments made of plastic materials, such as plastic pendants and decorative pieces, this transducer can achieve fine welding or cutting, ensuring the beauty and integrity of the handicrafts and ornaments, and enhancing the quality sense of the products.

For the processing and assembly of some small handicrafts and ornaments made of plastic materials, such as plastic pendants and decorative pieces, this transducer can achieve fine welding or cutting, ensuring the beauty and integrity of the handicrafts and ornaments, and enhancing the quality sense of the products.

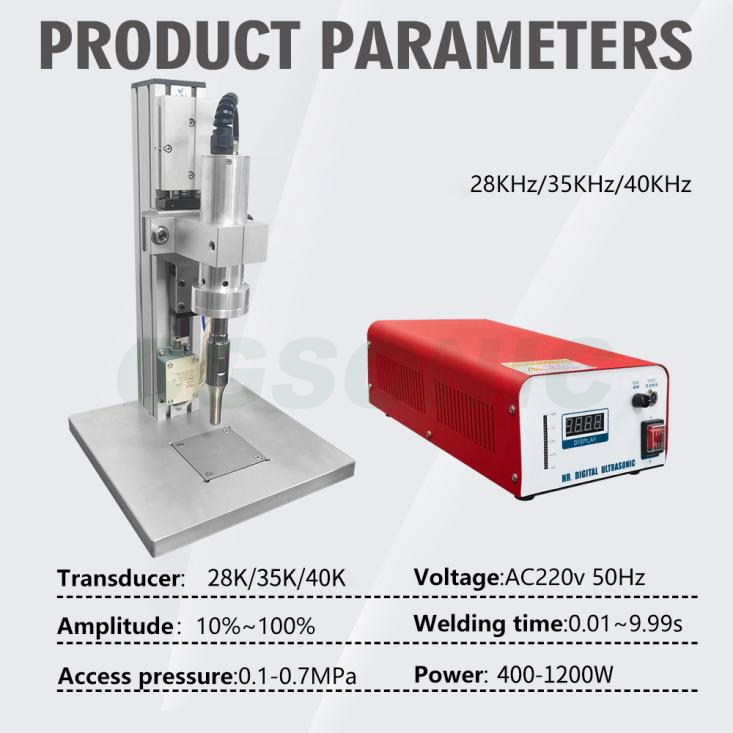

Product Parameter

Product Parameter

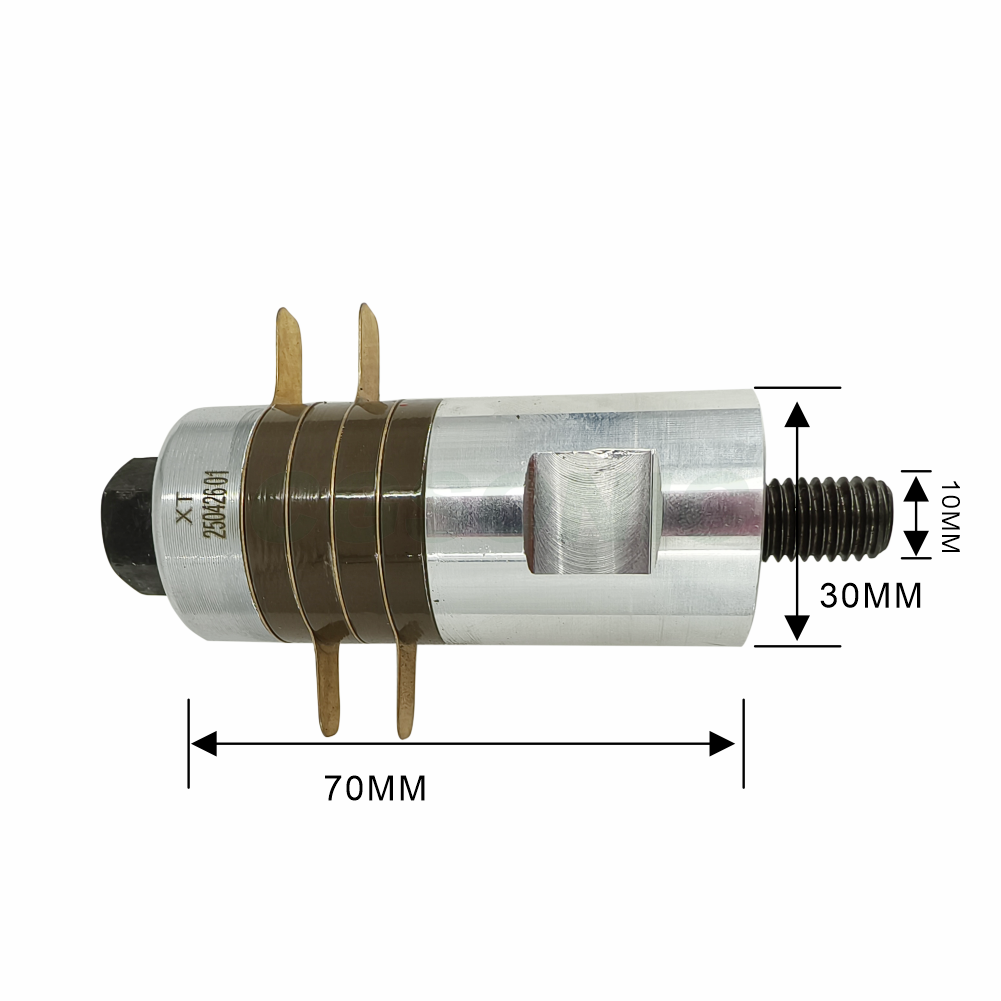

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance