- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

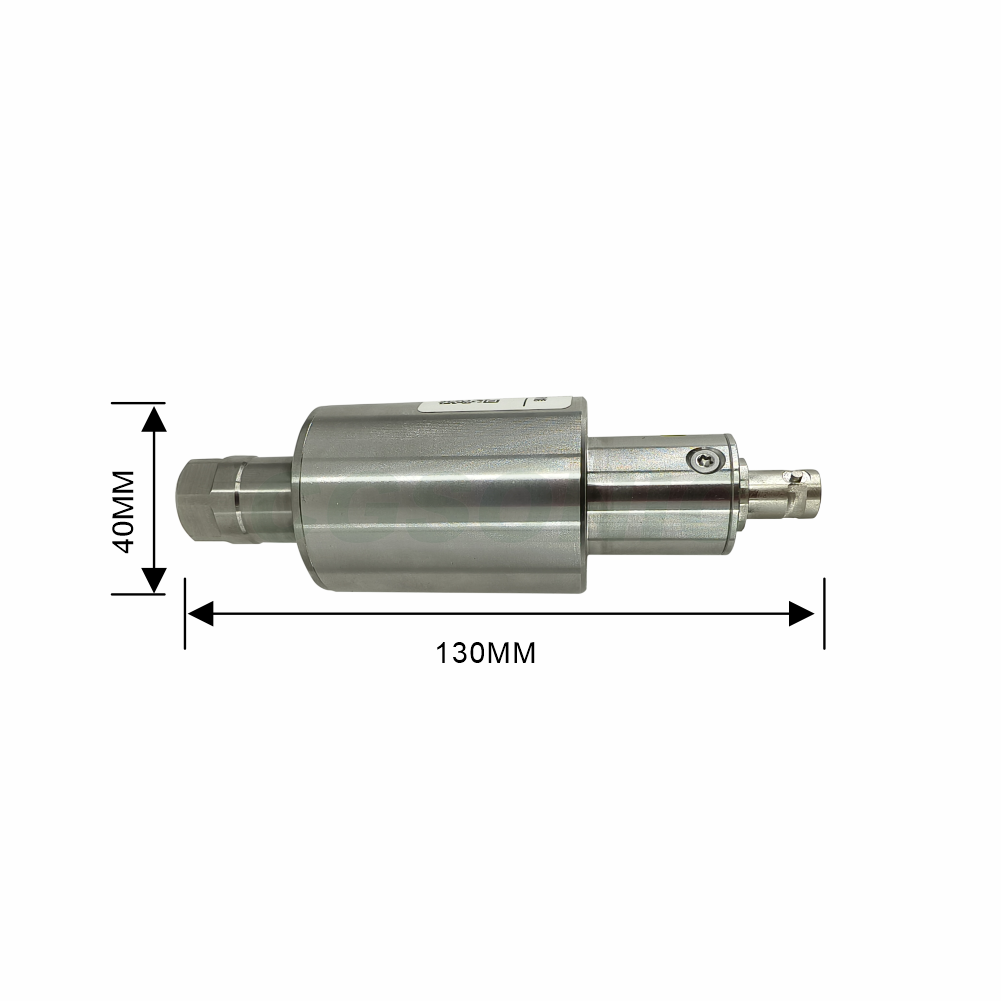

35KHZ1200W Transducer

short description part

The 35KHZ 1200-watt transducer, as the core component of ultrasonic equipment, operates stably at a precise frequency of 35KHZ and can output 1200 watts of power. It can efficiently convert the high-frequency and high-voltage signals from the ultrasonic electrical box into mechanical amplitude, achieving efficient conversion from electrical energy to mechanical energy. Its core advantages are significant. Not only does it have a high energy conversion efficiency, reducing energy waste, but it also features a stable and large amplitude, ensuring uniform processing effects. At the same time, it has good heat resistance and can work continuously for a long time, thus extending its service life.

operating principle

It is the core component of ultrasonic equipment and is used in conjunction with the ultrasonic electrical box. The ultrasonic electrical box converts electrical energy into high-frequency and high-voltage signals, and the transducer then converts these high-frequency and high-voltage signals into mechanical amplitudes, that is, it realizes the conversion from electrical energy to mechanical energy, thereby generating ultrasonic vibrations.

product presentation

High-efficiency conversion: It can efficiently convert the input electrical energy into mechanical energy. At a frequency of 35KHZ, it can stably output 1200 watts of power. With high energy conversion efficiency, it effectively reduces energy consumption and meets the requirements of energy conservation and environmental protection.

Amplitude stability: With a stable and large amplitude, it ensures the consistency of ultrasonic vibration during propagation and action, making the processing or treatment effect uniform and guaranteeing the quality stability of the product.

Excellent heat resistance: Under high-power and long-term working conditions, it has good heat resistance, can effectively dissipate heat, prevent performance decline or damage due to overheating, extend the service life of the transducer, and reduce equipment maintenance costs.

Frequency accuracy: The working frequency of 35KHZ has high accuracy and can always operate stably at the designed frequency, which is conducive to achieving the best matching with other equipment components such as ultrasonic electrical boxes, and improving the stability and reliability of the entire ultrasonic system.

application area

Plastic processing industry: Widely used in plastic welding, cutting and other processes, such as the welding of plastic components like bumpers and instrument panels in the automotive manufacturing industry, as well as the molding and assembly of plastic products like mobile phone cases and battery covers in the electronics and electrical industry. It can achieve efficient and firm welding, with high welding quality, beautiful appearance and no obvious weld marks.

Medical device industry: It can be used in the manufacturing of medical devices, such as welding and cutting of medical plastic pipes, containers, disposable syringes, etc. Due to its non-contact processing method, it can ensure the cleanliness and sterility of medical devices and avoid the contamination risks that may be brought by traditional processing methods.

Other industries: It also has important applications in the toy, stationery and daily necessities, sports goods, packaging and other industries. It can be used for the processing and assembly of various plastic parts, improving production efficiency and ensuring product quality.

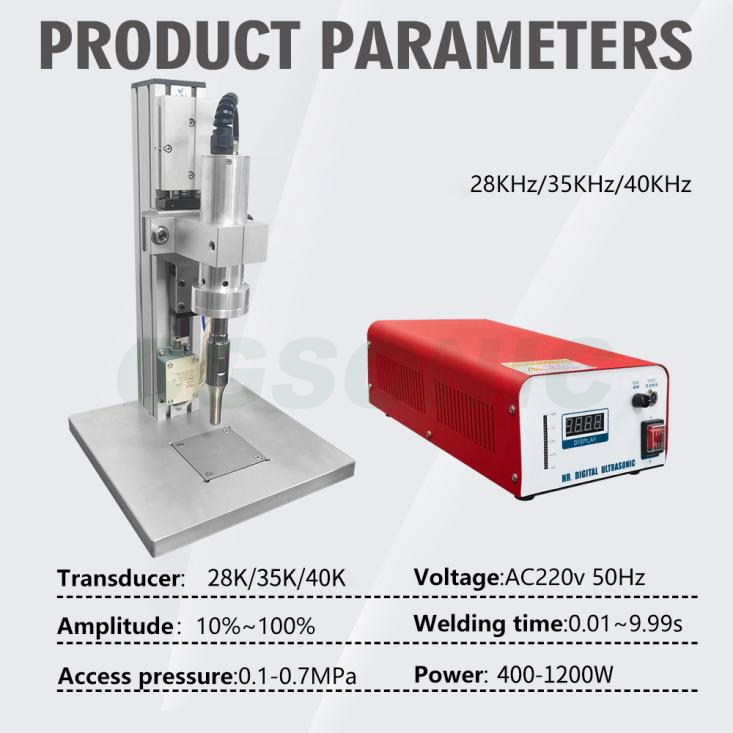

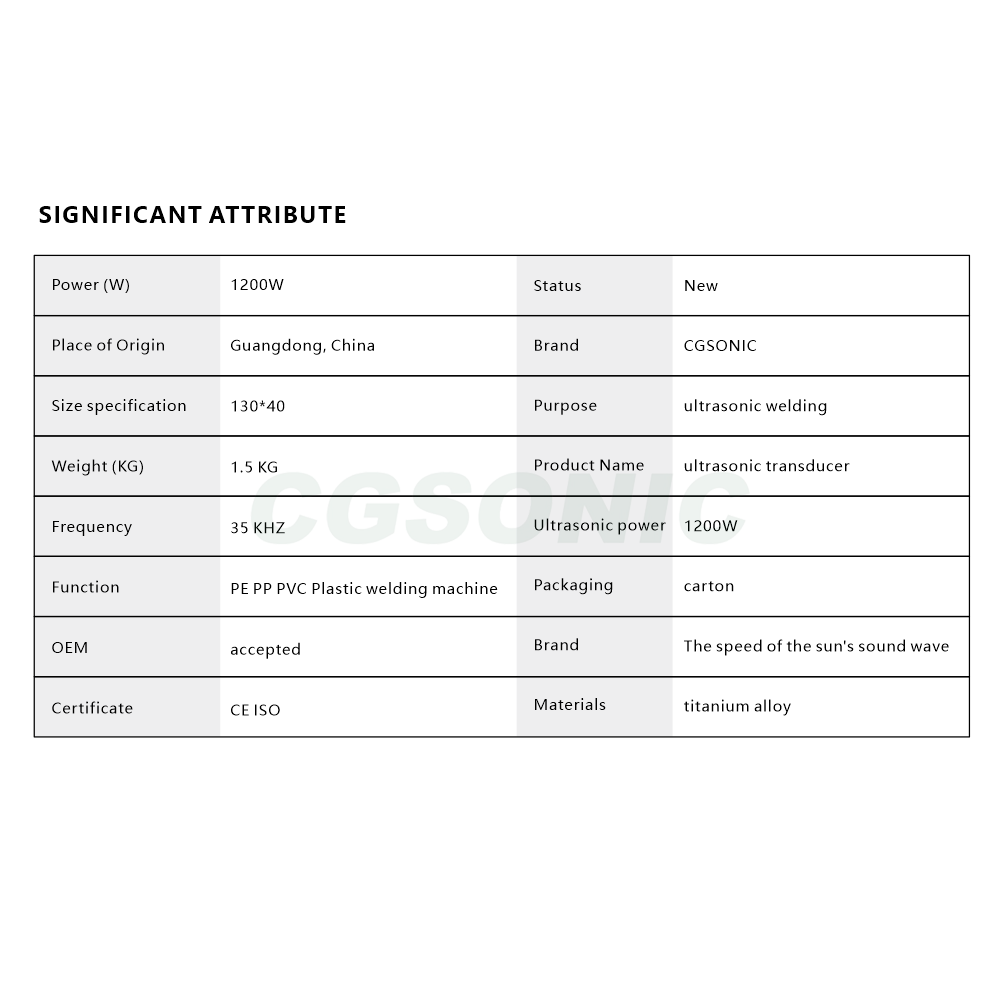

Product Parameter

Product Parameter

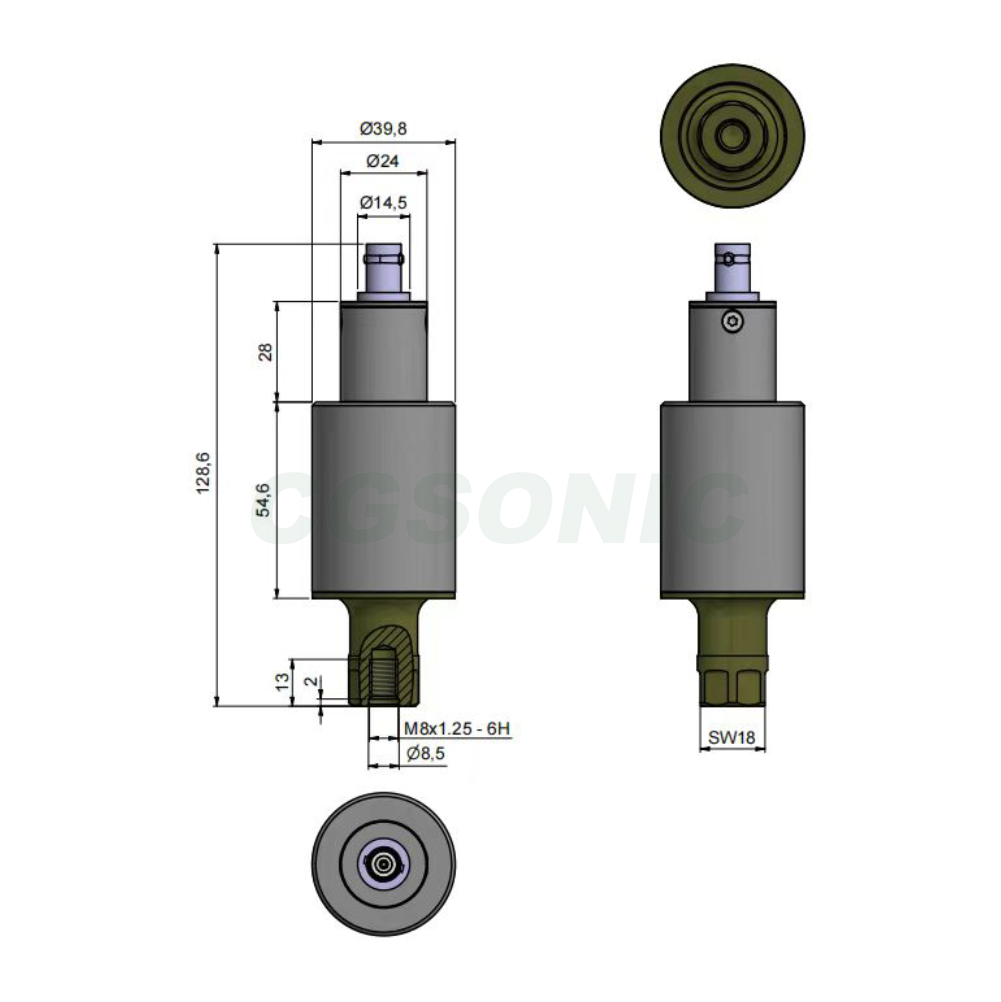

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance