- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

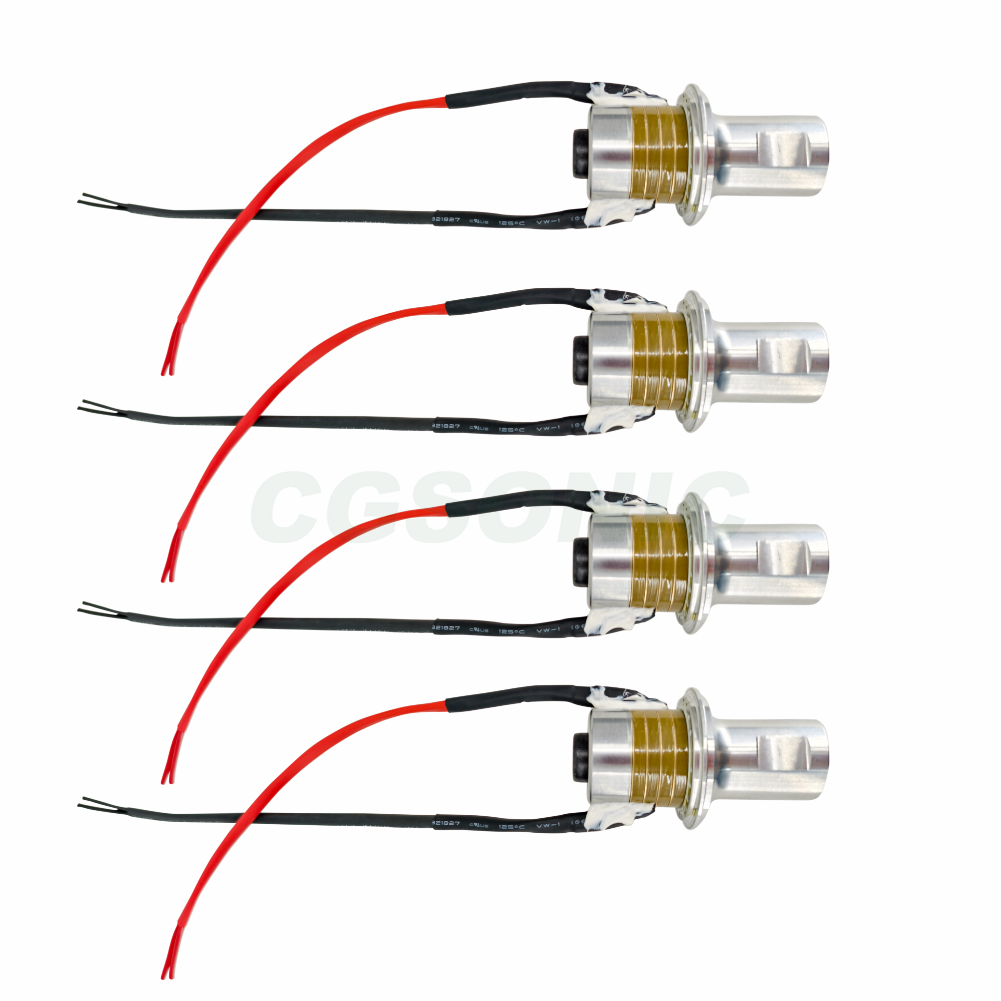

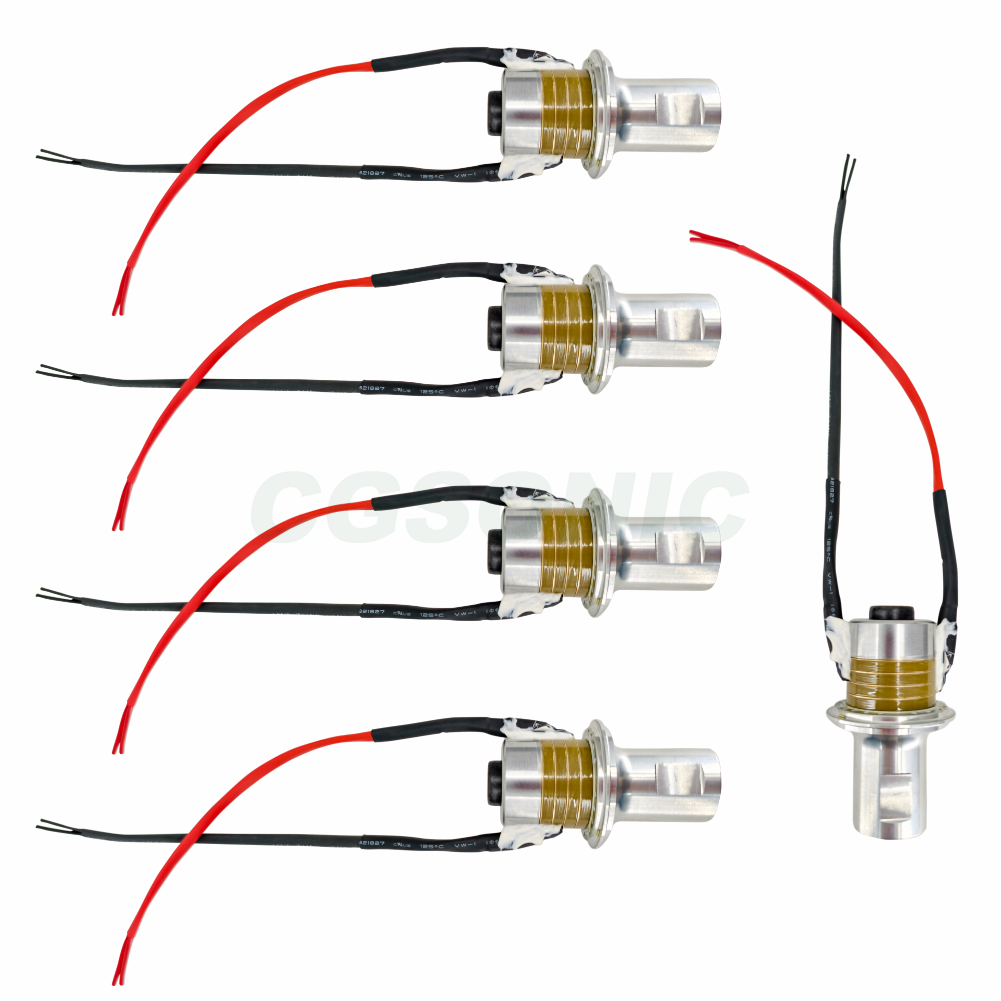

35KHZ800W Transducer

short description part

The 35kHz 800W transducer is a core component in ultrasonic precision machining. Operating stably at a high frequency of 35kHz and outputting 800W of adaptable power, it efficiently converts the high-frequency signal from the generator into precise mechanical vibrations.

Its outstanding performance, coupled with its high frequency characteristics, ensures a fine amplitude, making it suitable for machining micro and thin-walled components. Its high energy conversion efficiency reduces energy consumption. Its excellent heat resistance allows for long-term stable operation, resulting in precise and concealed welds, ensuring the precision and aesthetics of the machined parts.

It is suitable for applications in precision plastics machining, electronics and communications, medical device precision machining, and jewelry. It provides reliable energy support for ultrasonic machining of medium- to high-precision, miniaturized components, helping to improve product quality and production efficiency.

Its outstanding performance, coupled with its high frequency characteristics, ensures a fine amplitude, making it suitable for machining micro and thin-walled components. Its high energy conversion efficiency reduces energy consumption. Its excellent heat resistance allows for long-term stable operation, resulting in precise and concealed welds, ensuring the precision and aesthetics of the machined parts.

It is suitable for applications in precision plastics machining, electronics and communications, medical device precision machining, and jewelry. It provides reliable energy support for ultrasonic machining of medium- to high-precision, miniaturized components, helping to improve product quality and production efficiency.

working principle

The 35kHz 800W transducer operates at the core of its function, utilizing the piezoelectric effect. It works in conjunction with an ultrasonic generator, which converts incoming electrical energy into a 35kHz high-frequency electrical signal and transmits it to the transducer. This high-frequency signal causes the piezoelectric ceramic inside the transducer to rapidly stretch and vibrate, effectively converting the electrical energy into mechanical vibrations of the same frequency. This creates stable ultrasonic vibrations, providing precise energy for subsequent precision machining operations.

product presentation

The 35kHz 800W transducer is a core component in precision ultrasonic machining. Its high frequency and stability provide powerful energy support for precision manufacturing.

Leveraging the piezoelectric effect, it works with an ultrasonic generator to convert electrical energy into a 35kHz high-frequency electrical signal, which is then converted into mechanical vibrations of the same frequency, generating stable ultrasonic vibrations that power precision machining.

This transducer offers exceptional performance. The 35kHz high frequency ensures precise amplitude, making it ideal for machining micro and thin-walled components. Its 800W power conversion efficiency is high, while its energy consumption is low. Its excellent heat resistance allows for long-term stable operation, resulting in precise and concealed welds, ensuring both precision and aesthetically pleasing machining.

Leveraging the piezoelectric effect, it works with an ultrasonic generator to convert electrical energy into a 35kHz high-frequency electrical signal, which is then converted into mechanical vibrations of the same frequency, generating stable ultrasonic vibrations that power precision machining.

This transducer offers exceptional performance. The 35kHz high frequency ensures precise amplitude, making it ideal for machining micro and thin-walled components. Its 800W power conversion efficiency is high, while its energy consumption is low. Its excellent heat resistance allows for long-term stable operation, resulting in precise and concealed welds, ensuring both precision and aesthetically pleasing machining.

application area

Precision plastic processing: Welding of plastic casings for micro-electronic components such as smartwatch sensors, with small and firm weld seams. Small reagent bottles, cosmetic sample bottles and other thin-walled containers are sealed without deformation or leakage. Electronic communication: The Bluetooth headset shell and buttons are welded together, fitting neatly. The plastic component connection of the mobile phone data cable interface enhances durability. Medical devices: Welding of the push rod and piston of the micro-syringe, with a confidentiality seal and precision. The blood glucose test strips are plastic-encapsulated to prevent contamination.

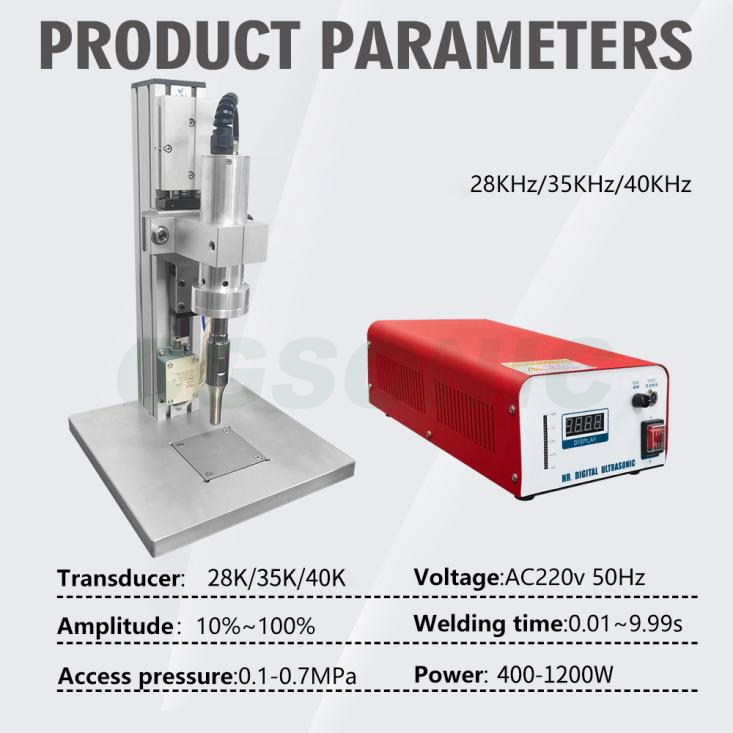

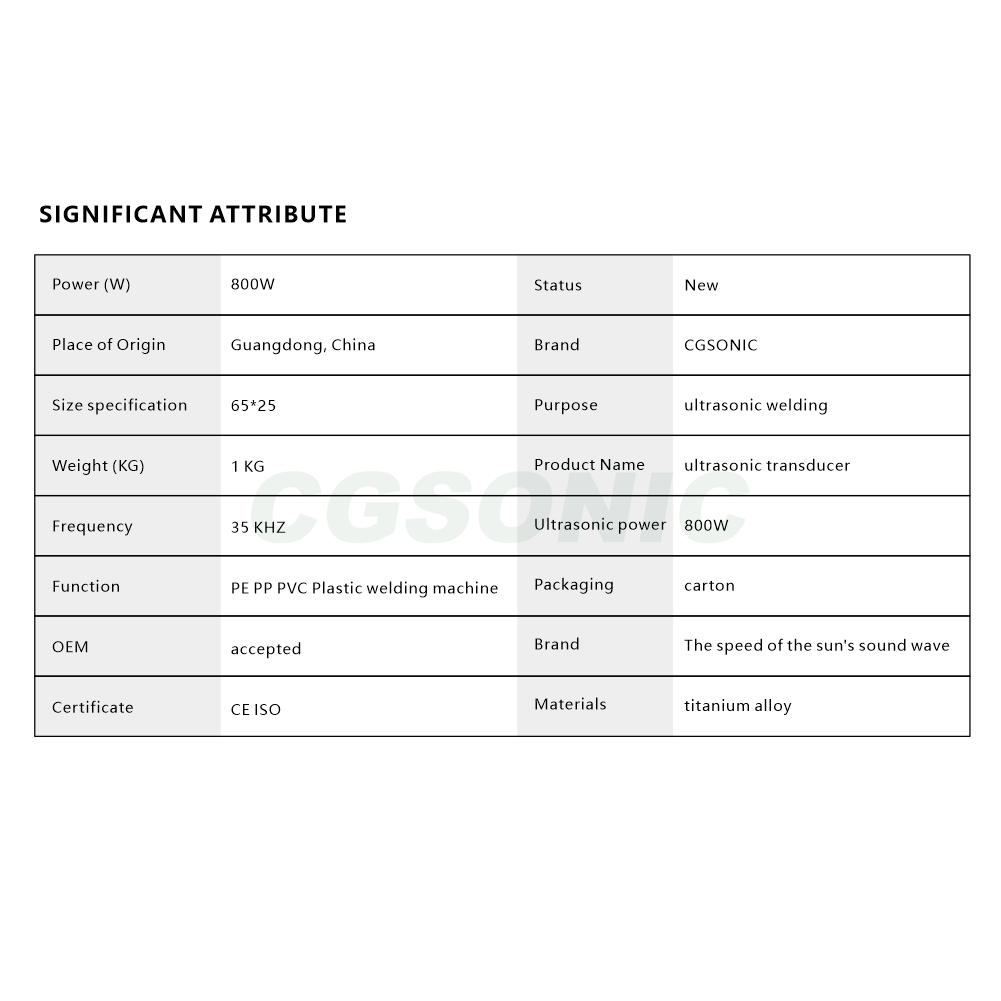

Product Parameter

Product Parameter

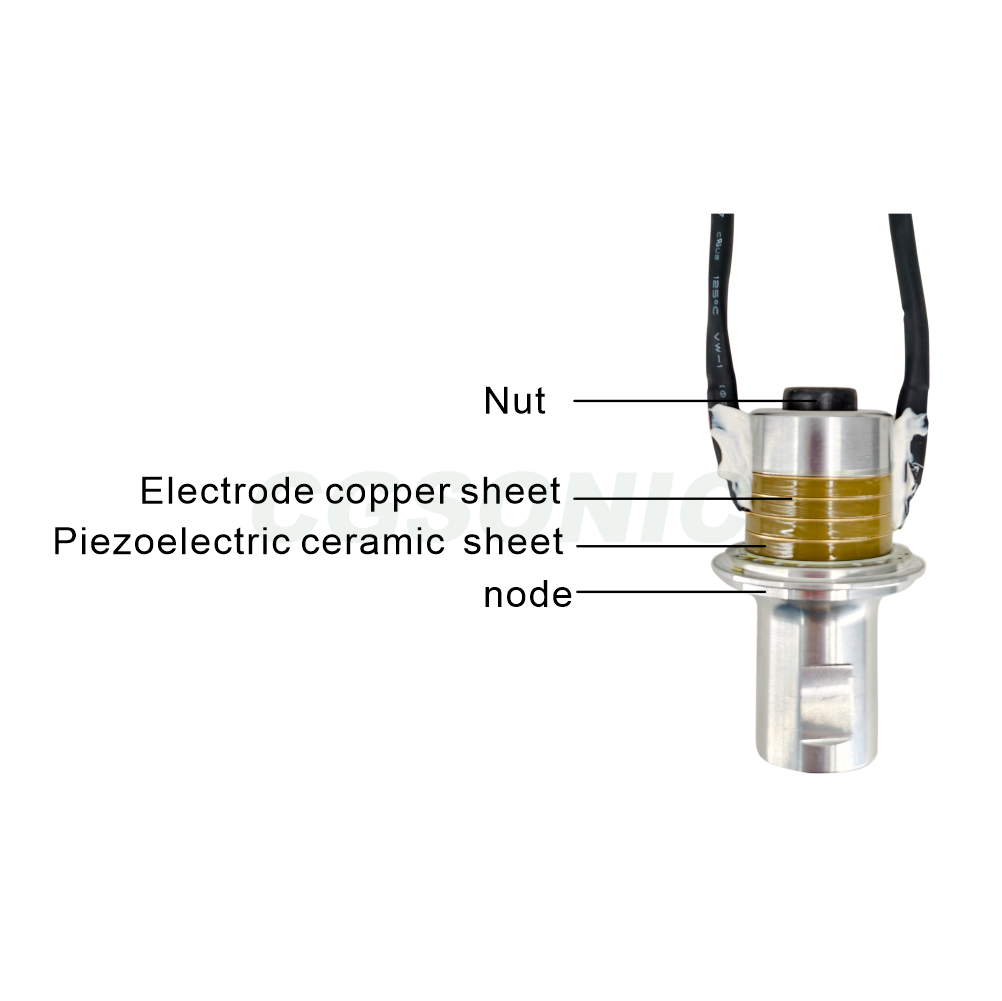

structure chart

Machine maintenance and upkeep

After the work is completed, clean the dust, oil stains and other debris on the surface of the transducer in a timely manner. A clean soft cloth dipped in an appropriate amount of neutral detergent can be used to gently wipe. Do not use strongly corrosive cleaners or hard objects to scrape, as this may damage the protective layer on the surface of the transducer. For transducers that have not been used for a long time, thorough cleaning is required before reuse to ensure that the surface is free of impurities and to prevent impurities from affecting energy transmission and working performance