For 20 years, we have focused on the field of ultrasonic plastic welding. So far, there are about 100,000 sets of ultrasonic plastic welding equipment produced by us, working diligently in factories allover the world.

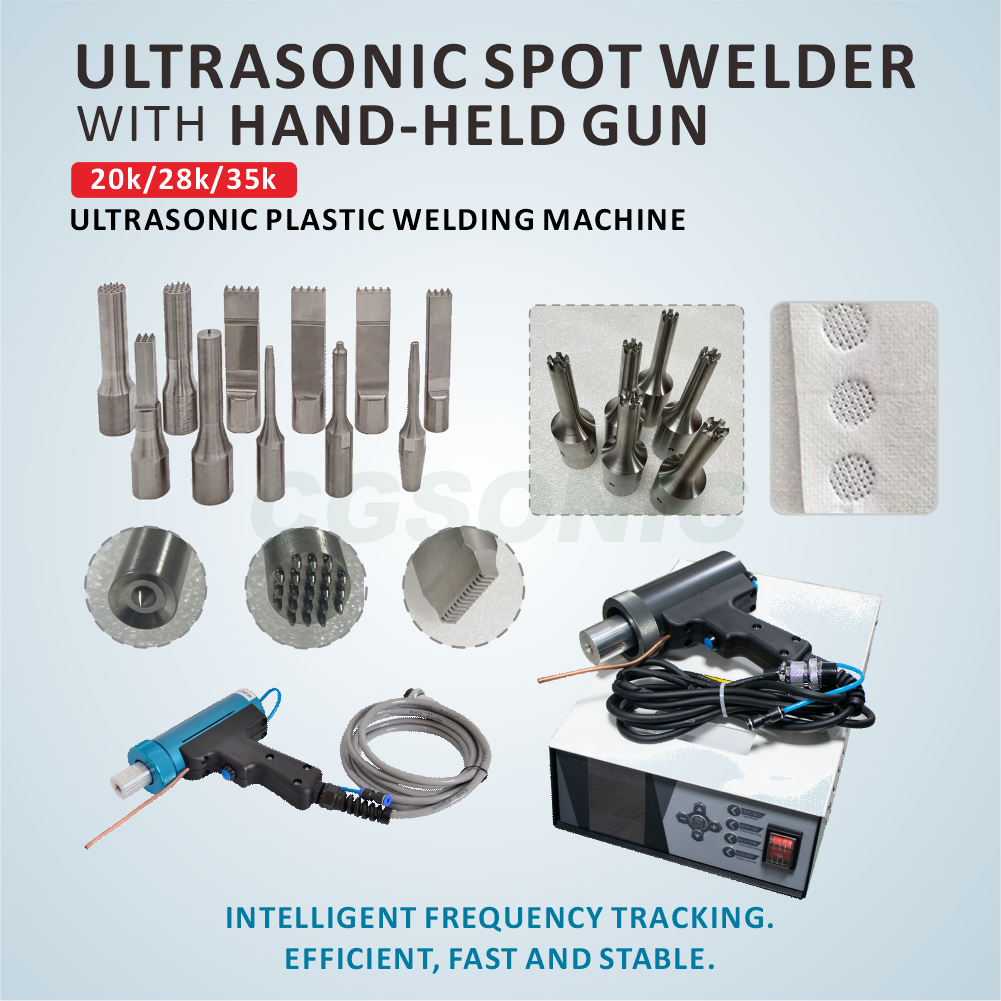

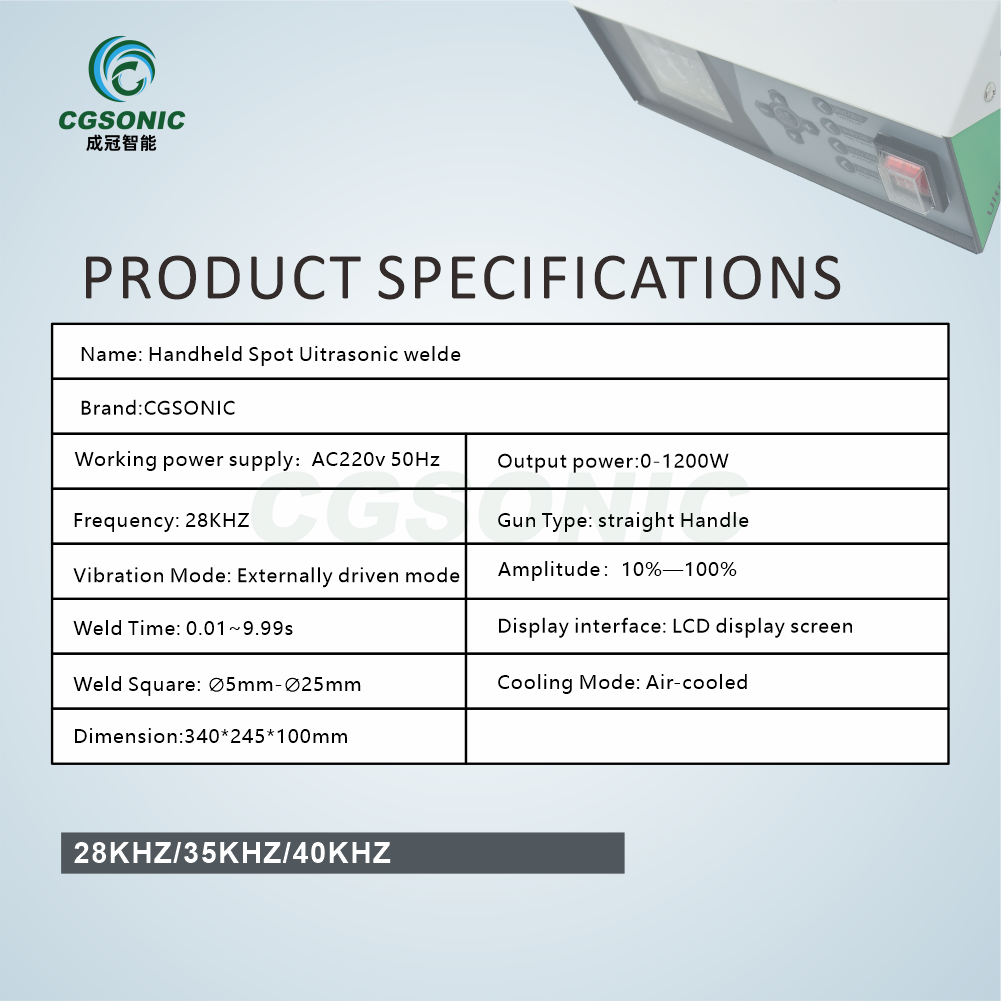

We provide customers in various industries: ultrasonic plastic welding systems, ultrasonic welding equipment, ultrasonic lace equipment, ultrasonic cutting equipment, ultrasonic extractor, ultrasonic homogenizer, ultrasonic generator, ultrasonic transducer and ultrasonic application tools, etc.

view more

OEM

Ultrasonic Transducer OEM:

OEM depending on the sample:

1. Customer supply sample

2. We customize depending on your sample

3. Customer test the customized transducer

4. If sample test passed, producing.

5. If sample test not passed update parameter depending on customer's advise.

OEM depending on the drawing and parameter:

1. Customizer test transducer by impedance analyzer

2. Customer supply dimension

3. We send drawing depending on supplied information

4. Drawing confrmed after discuss

5. Producing

01020304

Send Inquiry

We hope to explore and communicate with industry experts from all over the world, and we hope to grow rapidly with our customers.

Based in China, we hope to become the world's leading expert in the ultrasonic plastic welding industry.

Click for inquiryDirect Source Supply, High Cost-effectiveness

Chengguan Ultrasonic, as a direct source manufacturer, is a company integrating R&D, production and application. It precisely regulates the welding energy to ensure uniform weld strength and excellent sealing performance, suitable for precise welding of various materials such as plastics and metals. By eliminating the intermediate trading tache, it integrates equipment R&D, manufacturing and sales, without any additional charges. The products are of high quality and reasonable price, saving customers' procurement costs.

Efficient Customization

Rapid Delivery

Rapid Delivery

The factory has its own production line and professional technical team. It can quickly adjust the process according to the customer's product specifications and welding requirements. Customized equipment can be completed from order to shipment in the shortest 7 days. It can also quickly customize non-standard welding equipment according to the customer's product size, material and production scenario to meet urgent production needs.

Untroubled After-sales Service, Full Assurance

It is equipped with standardized production workshops and a professional after-sales team. It has a technical director with over 20 years of experience providing full technical support. It offers 24-hour fault response and lifetime maintenance services. At the same time, it supports free sample testing to help customers verify the welding effect in advance and reduce procurement risks. Regular follow-up inspections of the equipment status are conducted, and free operation training and technical upgrades are provided to ensure stable production.