Custom Auto Welding Machines from Reliable Factories and Manufacturers

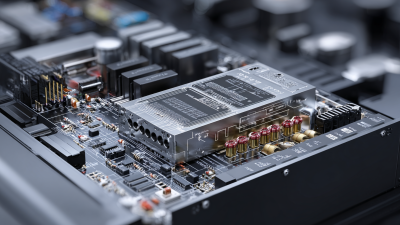

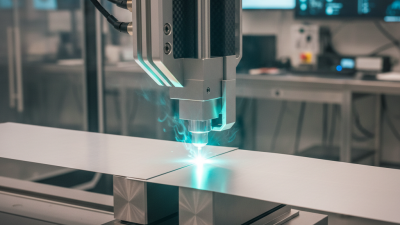

As a leading manufacturer in the automation industry, I offer top-quality Auto Welding Machines that are ideal for factories seeking efficient solutions. My experiences with ODM projects allow me to tailor machinery to meet specific production needs, ensuring optimal results. This cutting-edge equipment integrates advanced technologies for precise welding, enhancing productivity while reducing labor costs, At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we prioritize durability and reliability in our designs. Our auto welding machines are rigorously tested to meet industry standards, allowing businesses to operate smoothly without interruptions. Partnering with us means you get a direct line to manufacturers who understand the demands of the market, Whether you're scaling up production or upgrading your current setup, my team is here to support you with customized solutions that fit your budget and requirements. Reach out today to learn how our auto welding machines can elevate your manufacturing processes!

Avoiding Pitfalls Auto Welding Machine Your End-to-End Solution Leads the Global Market

In the rapidly evolving landscape of manufacturing, the importance of reliable and efficient technology cannot be overstated. Auto welding machines, particularly those employing ultrasonic technology, represent a significant advancement in the field of Plastic Welding. With 20 years of dedicated focus on this specialized area, companies can leverage proven ultrasonic systems that not only enhance production efficiency but also maintain high-quality standards across various industries. Understanding and avoiding common pitfalls in the procurement process of auto welding machines is crucial for global buyers looking to stay competitive. One of the primary challenges in selecting the right ultrasonic welding equipment lies in understanding the specific requirements of your production processes. Each application demands tailored solutions, and merely opting for the latest model available on the market may lead to inefficiencies or increased operational costs. Engaging with experienced suppliers who understand diverse industry needs can provide insights into the best configurations and equipment setups. Additionally, considering factors such as equipment scalability and maintenance requirements ensures that your production line can adapt to future demands without incurring significant downtime or costs. When investing in ultrasonic plastic welding systems, global purchasers should also prioritize suppliers with robust after-sales support and training programs. The right partner will not only supply high-quality equipment but will also ensure your team is adequately trained to operate and maintain the machines, further minimizing risks associated with improper handling and maximizing your investment's return. By navigating these potential pitfalls, businesses can successfully integrate ultrasonic technology into their operations, solidifying their place in the global market.

Avoiding Pitfalls Auto Welding Machine Your End-to-End Solution Leads the Global Market

| Machine Model | Welding Type | Power Source | Max Output (kW) | Weight (kg) | Warranty (Years) | Market Price (USD) |

|---|---|---|---|---|---|---|

| Model A | MIG | Electric | 300 | 150 | 2 | 1500 |

| Model B | TIG | Gas | 250 | 120 | 3 | 1800 |

| Model C | Stick | Electric | 200 | 100 | 2 | 1200 |

| Model D | Hybrid | Electric & Gas | 350 | 200 | 4 | 2500 |

| Model E | Plasma | Electric | 400 | 250 | 5 | 3000 |

Top Picks For Auto Welding Machine Global Reach Application

E

Emily Davis

The quality is unparalleled! I am also grateful for the professional assistance I received from the after-sales team.

10 May 2025

C

Chloe Hernandez

An excellent purchase! The support staff handled my inquiries with professionalism and care.

29 June 2025

J

Jack Nelson

Such a great product! The service personnel were well-informed and quick to assist.

06 July 2025

L

Liam Cooper

Thrilled with the quality! The after-sales team provided excellent support throughout.

08 June 2025

H

Henry Chapman

Very satisfied with my buy! Professional and knowledgeable staff made all the difference.

23 June 2025

I

Isaac Ramirez

Fantastic quality! The after-sales representatives were prompt and knowledgeable.

24 May 2025