Battery Shell Sealing Welding Solutions for OEMs, Factories, Manufacturers

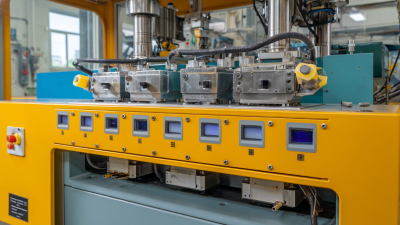

Are you in search of reliable solutions for Battery Shell Sealing Welding? Our high-quality ultrasonic sealing equipment is specifically designed for efficiency and durability, catering to the needs of various industries. As a leading factory in this field, we specialize in providing wholesale options to exporters and manufacturers worldwide, I understand how crucial it is to have dependable equipment that delivers consistent performance. Our products are engineered to ensure precision in sealing, making them an ideal choice for businesses looking to optimize their production processes. With Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. backing you, you can trust that you're getting cutting-edge technology paired with unrivaled customer support, Join the growing list of satisfied businesses who have made the switch to our advanced Battery Shell Sealing Welding solutions. Let’s elevate your production capabilities together!

How To Select Battery Shell Sealing Welding Is The Best Your End-to-End Solution

When selecting the best battery shell sealing welding solution for your production needs, it's vital to consider the precision, durability, and efficiency of the technology used. Ultrasonic Plastic Welding stands out as a premier method, especially for manufacturers looking to enhance their product quality while reducing cycle times. For over 20 years, Chengguan has dedicated itself to pioneering advancements in this field, ensuring that our ultrasonic welding systems and equipment meet the rigorous demands of various industries. Our extensive product range, including ultrasonic lacing, cutting equipment, and homogenizers, is designed to provide an end-to-end solution tailored to your specific requirements. Whether you are in the automotive, electronics, or energy sector, our high-performance ultrasonic extractors and welders ensure that battery shells are sealed with impeccable accuracy, resulting in superior strength and longevity. By integrating our cutting-edge technology into your production line, you can optimize operational efficiency and product reliability, ultimately driving customer satisfaction. In an era where sustainable solutions are paramount, Chengguan’s ultrasonic welding systems not only enhance product integrity but also contribute to energy savings and minimized waste. Choosing the right welding technology is crucial, and with Chengguan at your side, you can be confident that you are making the best choice for your battery sealing applications. Discover how our decades of expertise can empower your production process and help you achieve unmatched results in the global marketplace.

How To Select Battery Shell Sealing Welding Is The Best Your End-to-End Solution

| Criteria | Options | Advantages | Disadvantages |

|---|---|---|---|

| Material Compatibility | Aluminum, Steel, Plastic | Durable, Corrosion Resistant | Costly for High-Quality Materials |

| Welding Technique | Laser, Ultrasonic, Resistance | High Accuracy, Good Penetration | Requires Skilled Labor |

| Sealing Type | Hermetic, Non-Hermetic | Effective for Different Environments | More Complex for Hermetic |

| Cost Consideration | Low, Medium, High | Flexible Budgeting | Quality May Suffer with Low Cost |

| Production Speed | Rapid, Standard, Slow | Meets Market Demand | Rapid May Compromise Quality |

Quick Tips To Battery Shell Sealing Welding in 2025 Is The Best

J

James Johnson

Impressive craftsmanship and excellent post-purchase support! The response from the service team was prompt and helpful.

14 May 2025

A

Amelia Price

Fantastic quality! The support team surpassed my expectations with their professionalism.

16 June 2025

A

Andrew Cook

Great product! I greatly appreciated the expert advice provided by the support team.

08 June 2025

L

Landon Bell

A fantastic experience! The quality is evident, and the support team exemplifies professionalism.

02 July 2025

Z

Zoe Martinez

Truly a remarkable product! The knowledge and professionalism of the support staff are unmatched.

01 June 2025

C

Carter Ward

Outstanding experience! The quality stands out, and the staff was highly professional and helpful.

24 May 2025