Battery Tab Welding | OEM Manufacturers & Factory Solutions

When it comes to Battery Tab Welding, I understand how critical high-quality solutions are for your production needs. That’s why I’m proud to offer products manufactured with precision and reliability at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. Our welding equipment stands out because it’s designed specifically for battery production, ensuring maximum efficiency and minimum defects. As an exporter, we cater to businesses looking to enhance their manufacturing processes with dependable equipment. I believe that investing in high-quality battery tab welding solutions is essential for achieving excellent results in your projects. With our commitment to superior craftsmanship and customer satisfaction, I’m confident that our products can meet your needs and exceed your expectations. Join other successful manufacturers who have already experienced the difference in quality and performance with our battery tab welding solutions. Let's work together to elevate your manufacturing capabilities!

Step-by-Step Guide To Battery Tab Welding Application Global Reach

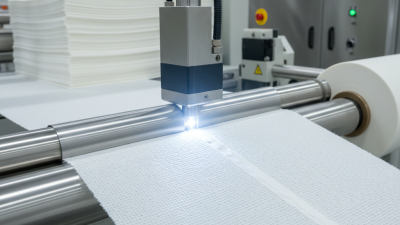

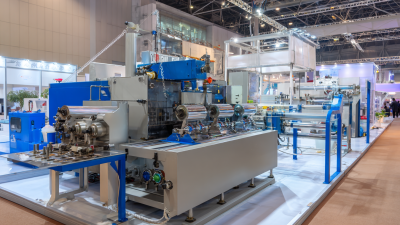

In today's rapidly evolving industrial landscape, battery tab welding stands out as a critical application that ensures the efficiency and safety of battery production. The process involves the precise fusion of metal tabs to battery cells, a task that demands both accuracy and speed. Understanding the nuances of battery tab welding can empower global buyers to make informed procurement decisions that enhance their production capabilities. This step-by-step guide not only illuminates the intricacies of the battery tab welding process but also addresses the growing demand for advanced ultraSonic Welding technology, which is revolutionizing manufacturing practices worldwide. The adoption of ultrasonic welding systems has escalated due to their ability to provide consistent and high-quality welds without the need for additional consumables. This technology operates through high-frequency sound waves that create localized heat, efficiently bonding materials such as aluminum and copper tabs to the battery cells. Manufacturers across various sectors can harness this technology to improve product integrity and reduce cycle times, ultimately leading to significant cost savings. By leveraging ultrasonic welding equipment, businesses can enhance their production lines and stay competitive in the global market. Moreover, the versatility of ultrasonic technology extends beyond battery tab welding applications. Industries ranging from automotive to consumer electronics can benefit from solutions like ultrasonic cutting and extraction systems. As global demand for reliable energy storage solutions continues to rise, businesses that invest in advanced manufacturing processes will likely see improved operational efficiency and product quality. Embracing these innovations positions companies to meet the challenges of an ever-expanding market while ensuring sustainability and profitability in their operations.

Step-by-Step Guide To Battery Tab Welding Application Global Reach

| Region | Application Type | Material Used | Welding Technique | Key Industries |

|---|---|---|---|---|

| North America | Electric Vehicle Batteries | Nickel-Cobalt-Aluminum | Laser Welding | Automotive, Renewable Energy |

| Europe | Consumer Electronics | Lithium-Ion | Ultrasonic Welding | Consumer Goods, Telecommunications |

| Asia-Pacific | Industrial Batteries | Lead-Acid | Resistance Welding | Manufacturing, Heavy Equipment |

| South America | Portable Power Banks | Lithium Polymer | Spot Welding | Technology, Communication |

| Middle East | Solar Energy Storage | Lithium-Ion | TIG Welding | Energy, Infrastructure |

Excellence in Battery Tab Welding Exceeds Industry Benchmarks Outperforms the Competition

O

Olivia Taylor

This purchase was worth every penny! The after-sales service team demonstrated professionalism and quick problem-solving skills.

15 June 2025

M

Mia Walker

This product is exceptional in quality! Plus, the after-sales staff were well-trained and very helpful.

29 June 2025

J

Jack Nelson

Such a great product! The service personnel were well-informed and quick to assist.

06 July 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

N

Nicholas Howard

Top quality! The support team was swift to respond and truly patient with my queries.

05 June 2025

T

Tyler Anderson

Remarkable product! The customer service representatives demonstrated incredible professionalism.

20 June 2025