You know, in today’s manufacturing world, after-sales support has really carved out its importance, especially when it comes to specialized fields like Metal Foil Welding. With the industry expected to grow by about 6.5% over the next five years, it’s super important to boost operational efficiency through smart after-sales services. This really helps keep repair costs down and productivity up. Take Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., for instance. They’ve been leading the way for over two decades in ultraSonic Welding solutions. Their dedication to quality means that a bunch of different industries can tap into advanced ultrasonic plastic welding systems. This not only delivers top-notch results but also helps save a good chunk of change on maintenance. Plus, it fits right into their vision of ‘World-Class Manufacturing, Chinese Pride, Exporting Globally,’ highlighting how critical a reliable after-sales support system is for keeping a competitive edge in such a fast-paced market.

You know, when it comes to welding metal foils, there are a ton of challenges, especially with those materials that don’t play nice together. A lot of the time, the existing techniques just can’t keep up, leading to weak joints that can really drive up repair costs. Take welding titanium and steel sheets, for example—it’s a real headache since these materials have such different properties. This can make joints brittle and pretty weak, which nobody wants. Then there’s the whole situation with laser welding. Sure, you can weld a lot of aluminum alloys, but throw in the need for filler material, and things can get tricky. Those pesky copper foils can mess with the mechanical properties, too, which is frustrating.

But here’s the good news: innovative methods are popping up, like Vaporized Foil Actuator Welding (or VFAW for short). This technique is not just clever; it uses about 80% less energy and creates bonds that are 50% stronger! How great is that? It makes welding a lot more efficient and helps tackle those pesky weak joint problems. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are really stepping up, developing specialized gear and techniques to cut down costs while boosting performance in this tricky world of Metal Foil Welding. So, there's a lot of exciting stuff happening!

This chart illustrates the impact of after-sales support on repair costs associated with metal foil welding. The data represents average repair costs (in USD) before and after implementing comprehensive after-sales support strategies.

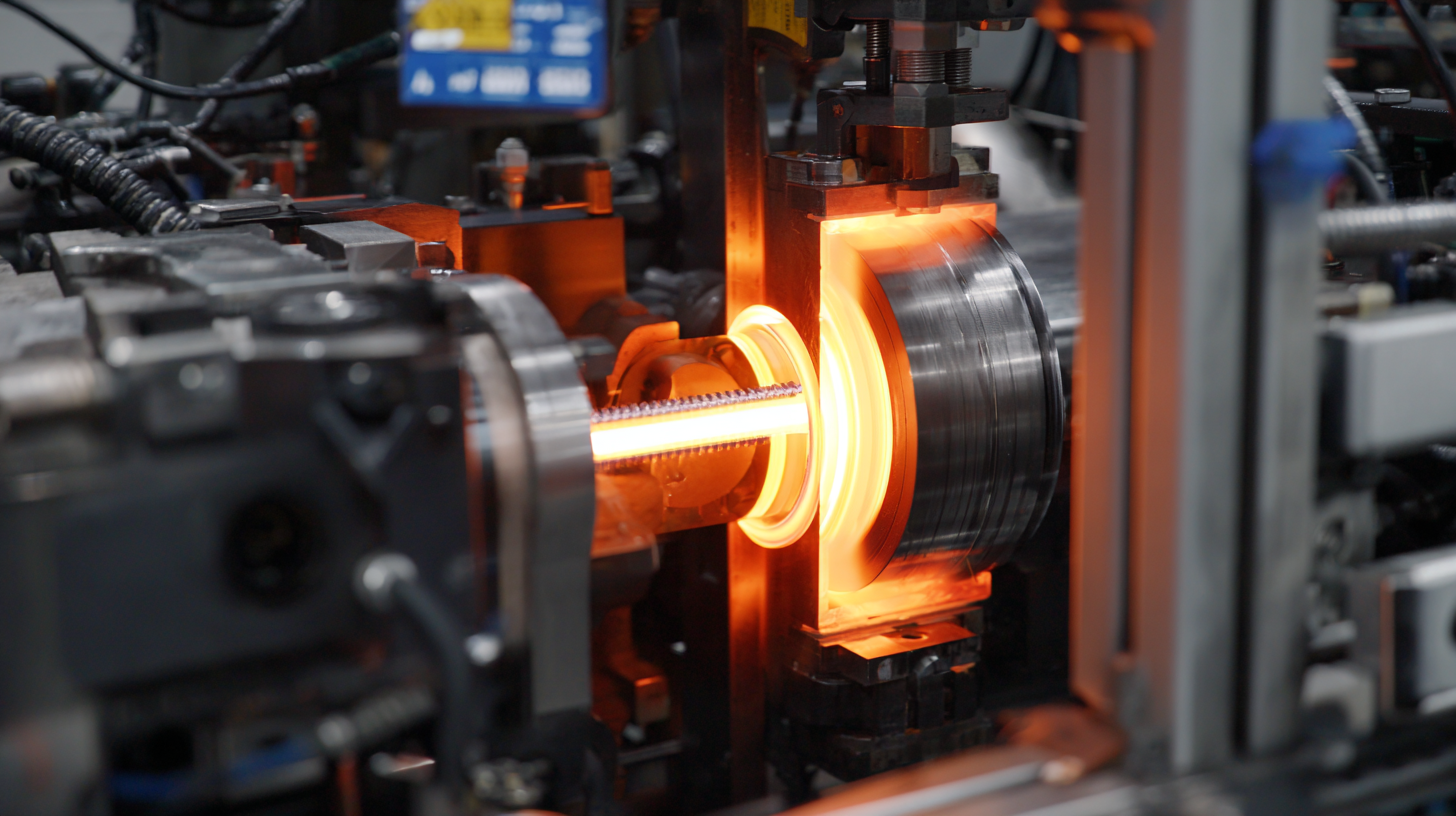

You know, in the world of metal foil welding, when equipment goes down unexpectedly, it can really hit the wallet hard. Recent studies have shown that unplanned downtime can cost manufacturers like, over $250,000 an hour! That just goes to show how super important it is to keep everything running smoothly. With the comeback of American-made ultrasonic welding machines, companies have a great chance to boost their productivity and really cut those costs. These cutting-edge machines don’t just make the welding process faster; they also help keep production steady and reliable.

Now, here’s a tip: if you stay on top of regular maintenance for your ultrasonic welding gear, you can really cut down the chances of those sudden breakdowns. Setting up a predictive maintenance schedule can help you catch potential problems before they escalate into major downtime, ultimately saving you both time and cash.

Don’t forget about solid after-sales support, either! Trust me, investing in quality customer service is crucial if you want to keep everything running efficiently. Numerous industry reports have shown that companies that focus on comprehensive after-sales care tend to see their equipment lasting longer and lower repair costs. This means they can keep producing at a good pace, which leads to a quicker return on investment. By taking these insights to heart, manufacturers can really step up their operational game.

Let’s face it: when it comes to welding equipment, figuring out whether to fix what you've got or just bite the bullet and buy new can seriously hit your wallet. The laser welding market is buzzing—it's expected to jump from $2.03 billion in 2022 to a whopping $2.79 billion by 2029! So, for businesses out there, it’s all about making smart choices about costs. Sure, fixing up your current machines usually costs less upfront than picking up brand new ones. But things get a bit tricky when you start thinking about the perks that come with a solid after-sales support system and how that could sway repair expenses over time.

A recent study on mining machinery maintenance found that having a top-notch after-sales support framework can really slash downtime and keep repair costs down. If companies stick to regular maintenance and thorough inspections, they can really stretch out the life of their gear. This proactive method not only ramps up productivity but also acts as a safety net for those surprise breakdowns that nobody wants to deal with. In the end, deciding whether to repair or replace should come down to a careful cost analysis, weighing the benefits of after-sales services against the potential savings of patching up what you already have.

You know, after-sales support is super important for making welding equipment last longer, especially when it comes to the nitty-gritty of metal foil welding. I came across this report by the American Welding Society, which says that good after-sales service can actually extend the life of welding machines by as much as 30%! Can you believe that? It’s all about being proactive—timely maintenance and expert advice really do help keep everything running smoothly.

And here’s something interesting: companies that focus on after-sales support tend to spend way less on repairs. Research shows that businesses with solid after-sales services can cut downtime by around 20%, which means fewer hiccups in production. Regular check-ups and training workshops on how to use the equipment really help welders boost their productivity while dodging those annoying costly repairs. So, this forward-thinking approach not only makes the equipment last longer but also leads to pretty significant savings over time.

Hey there! So, in the competitive world of metal foil welding, there's something super important that's been gaining a lot of attention—after-sales support. Believe it or not, it can really make a difference when it comes to boosting efficiency and cutting down on repair costs. A recent industry report actually showed that companies with solid after-sales strategies can slash repair expenses by up to 30%! This just goes to show that it’s not only about keeping your equipment running but also making sure it’s as reliable as possible. For industries that depend on high-precision welding, every minute of downtime can hurt production schedules and profits—definitely not something anyone wants to deal with, right?

Now, take Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., for instance. With two decades of experience in ultrasonic plastic welding, they’re really leading the way in making after-sales support better than ever for manufacturing operations. By using data-driven strategies, Chengguan is able to improve their service offerings, which means their customers experience fewer repair issues, all thanks to predictive maintenance and timely assistance. And get this—industry analysis indicates that companies that embrace proactive service models can see a whopping 50% drop in unexpected equipment failures! That’s huge and can lead to some serious cost savings and more efficient operations.

Plus, integrating real-time data monitoring systems lets manufacturers keep a close eye on their equipment’s performance. This not only helps with making smart choices about repairs and upgrades but also boosts the longevity of ultrasonic welding systems. In the end, this kind of approach helps companies stay competitive by really driving down those operational costs. It’s all about working smarter, not just harder!

| Dimension | Data Type | Value |

|---|---|---|

| Average Repair Cost | USD | $1,200 |

| After-Sales Support Satisfaction | Rating (1-5) | 4.5 |

| Average Response Time | Hours | 2 |

| Reduction in Downtime | Percentage | 30% |

| Training Sessions Conducted | Count | 15 |

| Customer Retention Rate | Percentage | 85% |

You know, having solid after-sales support can really change the game when it comes to repair outcomes in the metal foil welding industry. It's pretty amazing how much money companies can save and how much better their operations can run. A report from the International Welding Institute even showed that businesses that took a proactive approach to after-sales support managed to cut repair costs by 30%! How did they do it? Well, their technical support teams stepped in early to tackle issues before they turned into bigger headaches. Success stories even highlight how some companies have dedicated teams ready to help out in real-time, making sure their equipment is always running at peak performance.

So, here’s a little tip: it’s super important to set up a feedback loop with customers. Regularly checking in through surveys or follow-up calls can really shed light on the common hiccups and training needs. This way, companies can tweak their services to fit what their customers actually need. And honestly, offering thorough training sessions for operators can really help them handle the equipment better, which translates to fewer repairs down the line.

Another cool approach is using predictive maintenance techniques, which can seriously cut down on sudden repairs. A study by the Manufacturing Performance Management found that businesses that embraced predictive analytics saw their machine downtime plummet by up to 25%. Integrating such tech into after-sales support can really up the ante on repair outcomes, showing just how vital efficient support is for maximizing operational efficiency in metal foil welding. It’s all about making the support system work for everyone involved!

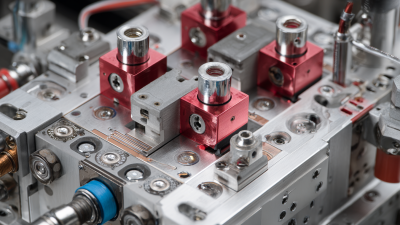

The advent of CGSF Servo Ultrasonic Plastic Welding Machines is setting a new standard in the manufacturing sector, focusing on efficiency and precision. One of the standout features of these machines is their high welding precision. By employing a sophisticated servo system, manufacturers can achieve unparalleled accuracy in the control of welding position, depth, and other critical parameters. According to a study by the International Journal of Advanced Manufacturing Technology, advancements in control technology can enhance product consistency by up to 30%, highlighting the importance of precision in maintaining quality standards.

Moreover, these machines deliver a stable energy output, which is essential for adapting to various plastic materials and welding requirements. As noted in a report by the Society of Manufacturing Engineers, consistent ultrasonic energy plays a crucial role in ensuring superior quality and minimizing defects during the welding process. With the ability to support preset welding parameters and recall functions, these systems embody high intelligence, facilitating easier operation and automating production lines.

The efficiency of CGSF Servo Ultrasonic Plastic Welding Machines is particularly noteworthy, with fast welding speeds and shortened cycle times reported to increase productivity by as much as 50%, as outlined in the latest manufacturing efficiency report by McKinsey & Company. This remarkable improvement in operational workflow not only benefits manufacturers in terms of output but also reflects a broader trend towards automation and smart manufacturing practices in the industry.

: Unplanned downtime can cost manufacturers upwards of $250,000 per hour, highlighting the importance of maintaining operational efficiency.

Regular maintenance of ultrasonic welding equipment and implementing a predictive maintenance schedule can significantly reduce unexpected breakdowns.

Effective after-sales support can extend the operational lifespan of welding machines by up to 30%, reducing wear and tear through timely maintenance and expert guidance.

Organizations with strong after-sales services can reduce downtime by approximately 20%, leading to fewer disruptions in production.

Companies that implement proactive after-sales strategies have seen a 30% reduction in repair costs and improved operational performance.

Establishing a feedback loop through regular surveys and follow-up calls helps identify common issues and training needs, allowing companies to enhance their services.

Businesses utilizing predictive maintenance techniques can decrease unexpected repairs, significantly improving operational efficiency and reducing downtime.

Offering comprehensive training sessions for operators can lead to better equipment handling, which minimizes the need for repairs.

Proactive after-sales strategies reduce repair costs and equipment downtime, leading to significant cost savings and a faster return on investment.

By leveraging insights from studies on after-sales support and predictive maintenance, manufacturers can take proactive steps to optimize their operational frameworks.