In the ever-changing world of energy storage, one thing that’s been getting a lot of buzz lately is Battery Tab Welding. It’s actually become a pretty big deal when it comes to making lithium-ion batteries work better. According to the 'Battery Industry Report 2023' by TechInsights, doing a good job with tab welding can boost a battery’s efficiency by up to 20%. That’s a big deal because it really affects how long batteries last and how safe they are. As more and more folks are demanding high-capacity batteries—think electric cars or those handy portable gadgets—the tech behind tab welding is more important than ever.

Dr. Laura Chen, an industry expert and researcher at PowerTech Solutions, points out, 'The quality and precision of battery tab welding really影响 whether a lithium-ion battery is reliable or not. It’s a key focus for manufacturers wanting to get the most out of their batteries.' Looking ahead to 2025 and beyond, the need for smarter, more advanced welding methods is only going to grow, especially to improve how batteries manage heat and pack in more energy. So, to sum it up, understanding and applying solid battery tab welding techniques isn’t just a good idea — it’s essential for meeting future energy needs and ensuring we keep developing better, more sustainable battery tech.

Battery tab welding plays a critical role in enhancing the energy density of lithium-ion batteries, an essential factor for the growing demand for high-performance energy solutions. According to a report by the International Energy Agency, improving energy density is pivotal as it directly impacts the battery life and efficiency of electric vehicles, with goals aiming for 300 Wh/kg by 2030. Efficient tab welding techniques ensure minimal resistance at the junction points, which is fundamental in maximizing charge and discharge capabilities, effectively contributing to the overall energy density.

Moreover, advancements in laser welding technology have demonstrated significant improvements in battery reliability and performance. A study published in the Journal of Power Sources indicates that precise welding methods can reduce heat generation, leading to better thermal management in cells. This enhancement not only increases the lifespan of the battery but also allows manufacturers to design lighter batteries without compromising on capacity. As the industry moves towards larger-scale production, the significance of optimal tab welding techniques cannot be overstated, as they are integral to achieving the ambitious energy density targets set by the automotive and electronics sectors.

| Parameter | Importance | Impact on Energy Density | Best Practices |

|---|---|---|---|

| Weld Quality | Ensures durability and reliability | Directly affects charge/discharge efficiency | Optimize parameters such as pressure and time |

| Material Selection | Reduces resistive losses | Higher conductivity leads to better performance | Utilize high-quality conductive materials |

| Process Control | Minimizes variability in welds | Consistent quality improves overall capacity | Implement real-time monitoring systems |

| Cooling Management | Prevents thermal degradation | Maintains optimal battery temperature | Use efficient cooling techniques |

| Environmental Control | Protects components from corrosion | Enhances longevity and reliability | Maintain a controlled manufacturing environment |

The quality of battery tab welding plays a pivotal role in determining the charge and discharge rates of lithium-ion batteries. Recent studies highlight that improper welding can lead to increased resistance at the connection points, which significantly impacts the overall energy efficiency and performance of the battery. For instance, the National Renewable Energy Laboratory (NREL) found that a mere 10% increase in contact resistance can decrease the discharge rate by over 15%, consequently affecting the longevity and reliability of the battery. This is particularly critical in applications where rapid charging and discharging are essential, such as in electric vehicles and portable electronics.

Furthermore, a report from the International Energy Agency (IEA) indicates that advancements in battery technology heavily rely on optimizing these welding processes. High-quality welding techniques ensure that the energy transfer between the cells is maximized, which can enhance the charge rate by up to 20%. This improvement not only contributes to faster charging times but also extends the cycle life of batteries, enabling manufacturers to meet the growing demand for efficient energy storage solutions. As the industry progresses, prioritizing the quality of battery tab welding will be essential for achieving better-performing lithium-ion batteries.

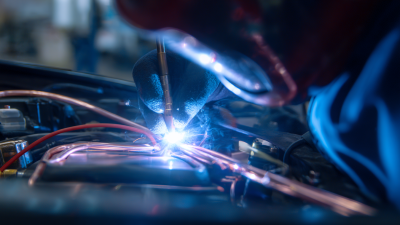

The efficiency of welding techniques plays a crucial role in optimizing lithium-ion battery performance, particularly when considering the two prominent methods: ultrasonic and laser welding.

Ultrasonic Welding utilizes high-frequency vibrations to create localized heat at the interface of the battery tabs, enabling a strong bond without affecting the surrounding materials. This method is favored for its speed and ability to handle delicate components, making it an ideal choice for manufacturing batteries where precision is key.

On the other hand, laser welding employs focused light beams to melt and fuse the materials together. This technique allows for deeper penetration and faster processing times, which can be particularly beneficial in high-volume production environments. While laser welding generally yields stronger joints and can be applied to various metal types, it requires careful temperature control to avoid damaging sensitive battery elements.

Ultimately, the choice between ultrasonic and laser welding will depend on specific manufacturing needs, emphasizing the importance of selecting the right technique to enhance the overall effectiveness of lithium-ion batteries.

Adhering to industry standards in battery manufacturing is critical for ensuring optimal performance and safety of lithium-ion batteries. According to a report by the International Electrotechnical Commission (IEC), approximately 25% of battery failures are attributed to non-compliance with established guidelines. These standards provide a systematic approach to materials selection, manufacturing processes, and quality control measures, reducing the likelihood of defects that can compromise battery life and safety.

One prominent standard is the IEEE 1725, which specifies guidelines for lithium-ion battery cell, module, and pack design. Compliance with such standards has been shown to enhance battery cycle life by up to 15%, and can significantly lower the risks of thermal runaway incidents. Proper battery tab welding, which connects cells together, is also vital; ensuring precise weld quality can lead to a 20% increase in electrical efficiency.

**Tips:** Always verify that your battery supplier complies with relevant safety and performance standards. Implement regular quality checks during the welding process to maintain optimal performance. Additionally, consider investing in training for employees responsible for manufacturing to familiarize them with best practices in battery production.

The chart below illustrates the correlation between the compliance rate of battery tab welding standards and the performance metrics of lithium-ion batteries, such as energy density, cycle life, and safety ratings.

As the demand for high-performance lithium-ion batteries continues to rise, advancements in battery tab welding technology play a crucial role in ensuring longevity and efficiency. Future trends suggest a shift towards more automated and precise welding techniques, such as laser welding and ultrasonic welding. These methods not only enhance the quality of the weld but also minimize potential defects that could compromise battery performance. Improved welding processes can lead to stronger connections between battery cells, ultimately increasing the overall lifespan and reliability of lithium-ion batteries.

Tips for optimizing battery tab welding include focusing on the materials used for tabs and electrodes. Choosing corrosion-resistant materials can extend the lifespan of the battery. Additionally, maintaining optimal welding parameters, such as energy input and speed, is essential to achieve solid, dependable connections. As technology evolves, embracing innovations in welding equipment can help manufacturers stay competitive while prioritizing battery integrity.

Looking ahead, the integration of smart welding systems equipped with real-time monitoring capabilities could revolutionize the industry. These systems promise to ensure consistency and quality in production while quickly identifying issues that could negatively impact battery performance. Staying informed about these trends will be vital for manufacturers aiming to enhance the lifespan and efficiency of their lithium-ion batteries.

In the realm of lithium-ion battery manufacturing, the welding process plays a crucial role in ensuring optimal performance and reliability. Among various welding techniques, resistance welding and ultrasonic welding are gaining prominence due to their efficiency and precision. The ultrasonic welding equipment market, valued at approximately $112 million in 2022, is expected to reach $198 million by 2030, highlighting a CAGR of 7.9% from 2024 to 2030. This significant growth underscores the increasing demand for advanced welding technologies in battery production, where even minor defects can impact battery performance and longevity.

Moreover, the cost-benefit analysis of these advanced welding solutions reveals compelling advantages. Resistance welding offers faster cycle times and reduced thermal damage, while ultrasonic welding provides control over heat input and minimized impact on material properties. As industries push for higher performance and safer lithium-ion batteries, companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are stepping up to meet these demands with their specialized ultrasonic welding systems. As the global welding market continues to evolve, the focus on automation and efficiency in welding technologies will be instrumental in advancing the lithium-ion battery sector, poised for substantial growth as it adapts to modern energy challenges.

: Battery tab welding is critical for improving energy density, which affects battery life and efficiency in electric vehicles, with goals aiming for 300 Wh/kg by 2030.

Efficient tab welding techniques minimize resistance at junction points, maximizing charge and discharge capabilities, which contributes to the overall energy density of the battery.

Advancements in laser welding technology have improved battery reliability and performance by reducing heat generation, leading to better thermal management and increased battery lifespan.

Future trends include automated and precise welding techniques, like laser and ultrasonic welding, which enhance weld quality and minimize defects, thereby increasing battery lifespan and reliability.

Manufacturers should choose corrosion-resistant materials for tabs and electrodes and maintain optimal welding parameters such as energy input and speed to achieve strong connections.

Smart welding systems with real-time monitoring capabilities can ensure consistency and quality in production while quickly identifying issues that could negatively affect battery performance.

The ultrasonic welding equipment market, valued at approximately $112 million in 2022, is expected to reach $198 million by 2030, indicating a CAGR of 7.9% from 2024 to 2030.

Resistance welding provides faster cycle times and reduced thermal damage, while ultrasonic welding offers control over heat input and minimizes the impact on material properties.

Advanced welding solutions reduce minor defects that can negatively impact the performance and longevity of lithium-ion batteries, making them crucial for efficient manufacturing.

Automation in welding technologies is essential for advancing the lithium-ion battery sector, ensuring higher performance and safety measures as industries adapt to modern energy challenges.

Battery Tab Welding plays a pivotal role in enhancing the performance of lithium-ion batteries by significantly improving energy density and impacting charge/discharge rates. The quality of the welding process directly influences the efficiency and reliability of batteries, underscoring the importance of choosing advanced techniques such as ultrasonic welding. This method stands out in comparison to others, offering superior precision and minimal thermal impact, leading to better overall battery performance and safety.

In the context of industry standards, adherence to these benchmarks not only ensures compliance but also enhances both the lifespan and reliability of battery systems. As trends in battery tab welding technology evolve, they promise to further optimize production processes and offer cost-effective solutions. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are at the forefront, providing innovative ultrasonic welding systems that cater to diverse manufacturing needs, thereby contributing to the advancement of battery technologies.