You know, with all these advanced tech innovations in manufacturing these days, it's totally changing how industries handle joining materials. One standout thing is the Acrylic Welding Machine—it's pretty impressive because it offers both precision and speed when welding acrylics. And honestly, there's been a real spike in demand for these machines, thanks to acrylic’s popularity across sectors like automotive, construction, and signage. If you look at the latest industry reports, the global acrylic market is expected to hit over $20 billion by 2025, growing at about 6.2% annually. That really shows how much people are relying on acrylic now, and how important it is to have solid welding solutions. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd.—who’ve got over 20 years of experiencein ultrasonic Plastic Welding—are leading the way. They’re offering some pretty advanced ultrasonic systems tailored for all sorts of applications, helping businesses make the most of these new welding techs like theAcrylic Welding Machine. This means better quality, faster production, and more efficient operations overall.

You know, with all these advanced tech innovations in manufacturing these days, it's totally changing how industries handle joining materials. One standout thing is the Acrylic Welding Machine—it's pretty impressive because it offers both precision and speed when welding acrylics. And honestly, there's been a real spike in demand for these machines, thanks to acrylic’s popularity across sectors like automotive, construction, and signage. If you look at the latest industry reports, the global acrylic market is expected to hit over $20 billion by 2025, growing at about 6.2% annually. That really shows how much people are relying on acrylic now, and how important it is to have solid welding solutions. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd.—who’ve got over 20 years of experiencein ultrasonic Plastic Welding—are leading the way. They’re offering some pretty advanced ultrasonic systems tailored for all sorts of applications, helping businesses make the most of these new welding techs like theAcrylic Welding Machine. This means better quality, faster production, and more efficient operations overall.

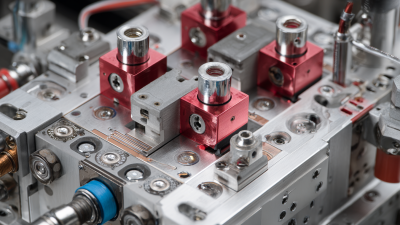

Acrylic welding machines have really taken off in modern fabrication lately, mainly because they're so versatile and offer a bunch of benefits when it comes to making strong and precise assemblies. One thing that folks in the industry often point out is how well these machines can join different acrylic-based materials—perfect if you're into projects that need transparency or a slick, aesthetic look. Not only does this boost the overall strength of the finished product, but it also opens doors for cool new applications, like in microfluidics, where low-cost yet accurate manufacturing is a game-changer.

Lately, making acrylic-based microfluidic devices has gotten a lot easier, which shows just how important dedicated welding machines are. With quick and straightforward methods—think polymerization in droplets—companies can whip up microfluidic chips that are great for biological uses. Plus, there have been some pretty exciting advances in dual-curing systems for 3D printing. These showcase how acrylic welding machines can improve joint strength by using innovative materials like carbon nanotubes, which is pretty remarkable for pushing industrial tech forward. All this really highlights how these machines are becoming essential tools in modern fabrication, helping companies stay ahead by meeting market demands with speed and precision.

In today's world of fabrication, having precise control really makes a huge difference—especially when you're working with acrylics. Using an acrylic welding machine can help you get those super clean, accurate bonds that are essential for detailed projects. Compared to old-school methods like gluing and clamping, which can take ages to dry, these welding machines give you instant results. That means your parts stay perfectly aligned without any risk of shifting while they cure.

One thing I love about these machines is how you can tweak the temperature and control how fast the welding happens. It gives you that extra bit of finesse that's so important when you're dealing with intricate designs—you really don’t want even a tiny mistake messing things up. Plus, as technology keeps getting better, acrylic welding is becoming more user-friendly. Whether you're a seasoned pro or just a hobbyist, it makes the craft way easier and more precise. All in all, moving towards this kind of precision welding not only speeds up the process but also really boosts the overall quality of what you end up with.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Precision Control | Allows for fine adjustments to welding parameters. | Improves joint accuracy and reduces waste. | Used in custom acrylic display cases and furniture. |

| Speed | Fast operation with quick setting times. | Increases production efficiency. | Ideal for high-volume fabrication projects. |

| Versatility | Can weld various thicknesses and types of acrylic. | Adaptable for different project needs. | Used in signage, lighting, and exhibits. |

| Quality of Finish | Provides a clear and polished bond line. | Enhances aesthetic appeal of finished products. | Suitable for decorative items and art installations. |

| Safety | Includes safety features to minimize risk. | Protects operator and work environment. | Necessary for industrial and workshop settings. |

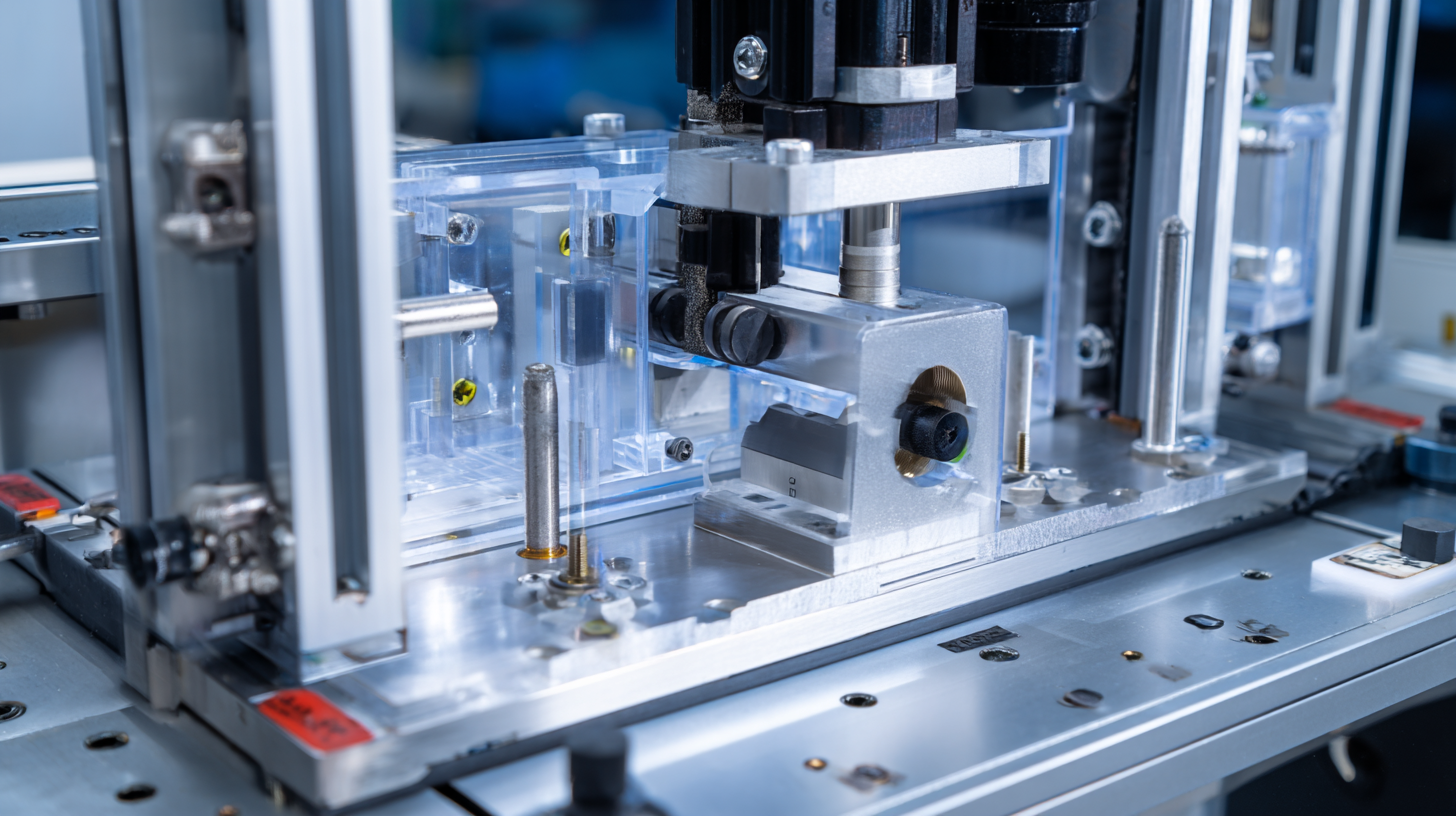

Acrylic welding machines have really changed the game in the fabrication world, mainly by making things way faster. You see, old-school methods of joining acrylic—like using mechanical fasteners or adhesives—could be pretty tedious and sometimes slow things down or lead to mistakes.

But with acrylic welders, it’s a whole different story. They use heat and some clever techniques to create seamless joints quickly, which means fabricators can get more done without sacrificing quality.

Because these machines speed up the process, manufacturers are able to hit tight deadlines and adapt more quickly to customer needs. The fact that they can achieve strong, durable bonds in no time is a real game-changer—projects move from the drawing board to finished products so much faster.

This boost in efficiency doesn't just cut down labor costs; it also ramps up overall productivity. Honestly, acrylic welders are becoming pretty much essential in modern workshops. As businesses aim to stay competitive, investing in these advanced tools isn’t just smart—it’s a strategic move to streamline workflows and stay ahead of the curve.

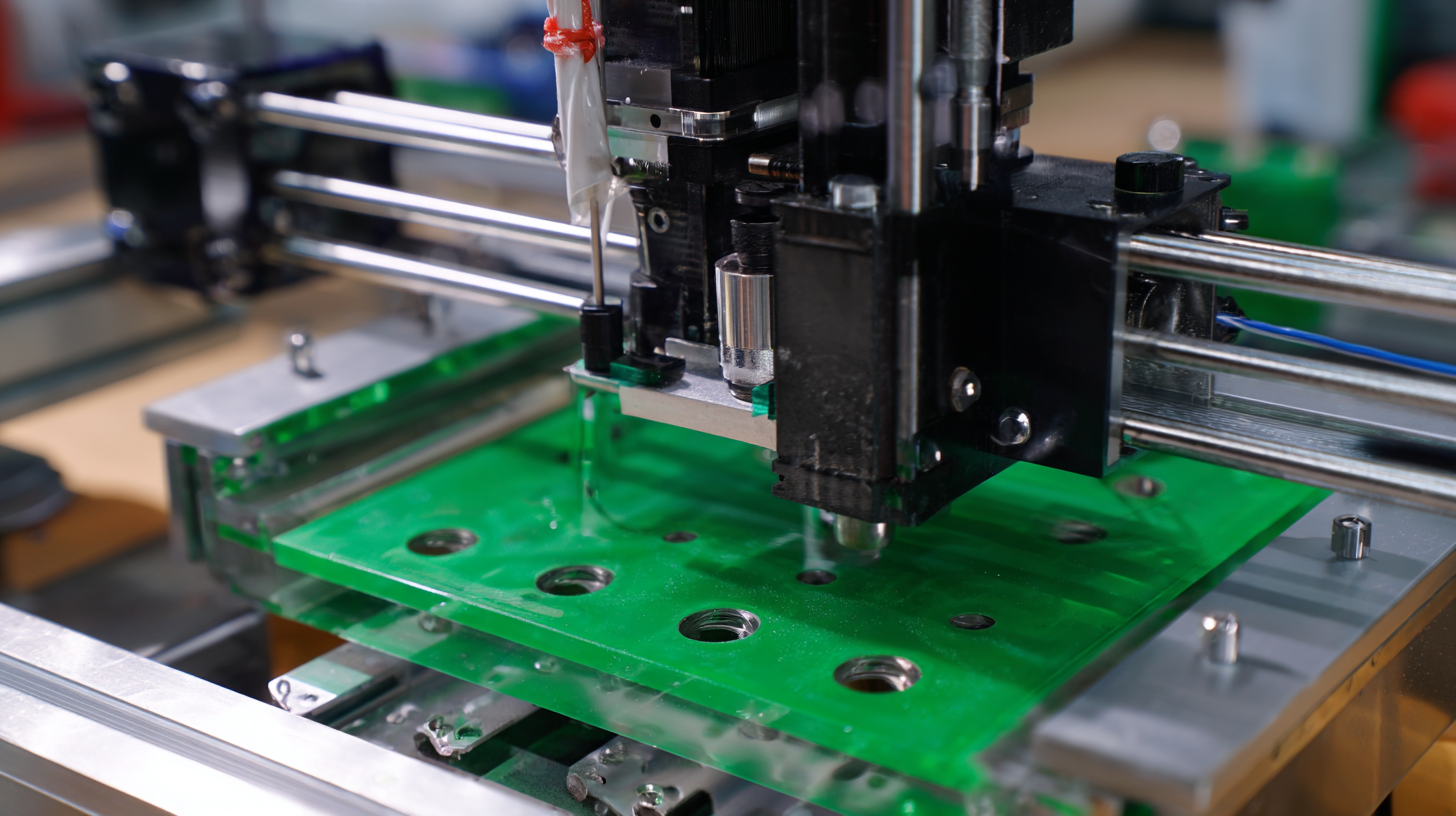

You know, acrylic welding machines have really become a must-have in today's manufacturing world. They’re super versatile and used in all sorts of industries—think automotive, signage, packaging—you name it. I recently read that the acrylic welding market is expected to grow at about 5.2% compound annual growth rate by 2025. That’s pretty significant and shows how much demand there is for reliable, efficient welding solutions. Part of the reason? Acrylic is lightweight, durable, and easy to mold, making it perfect for tons of different products.

Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we've been leading the way in ultrasonic welding tech for over 20 years. Our systems are built to boost productivity and ensure top-notch quality when it comes to acrylic welding. They’re designed to work with a whole range of materials, fitting nicely into different industries. Thanks to how flexible these acrylic welding machines are, manufacturers can adapt to new market trends without compromising on precision or efficiency. As businesses keep pushing the envelope with new applications, having the right equipment—like what we provide—is super important to making sure everything turns out just right.

Honestly, when you think about it, using acrylic welding technology in manufacturing really offers some big perks. These machines make the whole process way more efficient, letting you put together acrylic parts fast and smoothly. It’s a real game-changer—it helps cut down on labor costs and also reduces waste since the welds are so precise that you end up discarding less acrylic. For companies looking to keep their costs in check and stay competitive, adopting acrylic welding can really give them an edge.

Plus, the strength and durability of these welded acrylic pieces mean they last longer, which translates to saving money in the long run. By investing in good quality acrylic welding machines, manufacturers can produce sturdy products that don’t need replacing or fixing so often. Sure, the upfront cost might seem a bit steep, but in the end, the savings and benefits definitely outweigh that. And here’s a cool bonus — using this technology opens doors for creating more innovative and uniquely designed products that might have been too tricky or expensive with older methods. So, it’s kinda like future-proofing your business while boosting your creative game.

Modern acrylic welding tools really have come a long way! These days, they come packed with safety features that make working in the shop way better and more comfortable for fabricators. Compared to the old-school methods, which could kick out some nasty fumes and required bulky safety gear, today’s machines are way smarter about keeping stuff safe. A lot of them even have built-in ventilation systems that effectively blow away those hazardous fumes, making the workspace much healthier overall.

And it’s not just that—many of these newer machines are loaded with tech that helps prevent accidents. They often have automatic shutoff functions that kick in if things start to overheat or if electrical issues pop up, which is pretty reassuring. Plus, the user interfaces are simple enough that even someone new can easily follow instructions without messing up. All these safety features don’t just protect the folks operating the machines; they also boost productivity because workers can focus more on their work instead of worrying about safety hazards. With composite materials becoming more popular in different industries like automotive manufacturing, I think we’ll see demand for reliable, safe welding equipment just keep climbing. It’s clear that modern acrylic welding gear isn’t just about getting the job done—it’s about doing it safely and efficiently, too.

: Acrylic welding machines provide significant time efficiency by creating seamless joints quickly, reducing the production time compared to traditional methods involving mechanical fasteners or adhesives. This allows manufacturers to enhance their output and meet tight deadlines.

Acrylic welding technology streamlines production by allowing quick assembly of components and minimizing waste material. While the initial investment may be higher, the longevity and durability of welded products lead to lower long-term operational costs and enhanced profitability.

Yes, by speeding up the fabrication process, acrylic welding machines enable manufacturers to respond swiftly to changing customer demands, allowing projects to progress more rapidly from design to completion.

Modern acrylic welding equipment includes enhanced safety features such as built-in ventilation systems to disperse harmful fumes, automatic shutoff mechanisms to prevent overheating, and user-friendly interfaces that reduce operator error.

Acrylic welders increase overall productivity by reducing labor costs and allowing faster production cycles, enabling manufacturers to produce more in less time without compromising quality.

Businesses benefit from a significant reduction in operational costs due to the durability of welded acrylic products, which require less frequent replacements and repairs, leading to better long-term returns on investment.

Hey, I recently read an article about using acrylic welding machines in modern fabrication, and honestly, it was pretty eye-opening. These machines really pack a punch when it comes to precision and control, making sure that your bonding projects turn out perfect every time. Plus, they’re a huge time-saver — you can really speed up the whole manufacturing process with them, which is a game-changer in many industries.

What’s cool is how versatile these machines are, too. They can handle different materials and fit pretty much any project requirements without breaking a sweat. And let’s be honest, using this kind of tech can save a lot of money in the long run — lower costs but higher production output. Safety's also a priority here; most modern acrylic welding equipment comes with important safety features to keep operators safe and secure while working.

Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are leading the way with some pretty advanced systems that boost what you can do with acrylic welding across various industries. Overall, it’s clear that these machines are becoming essential tools — helping us work smarter and safer, no doubt about that.