Composite Material Welding has really become a game-changer in today’s manufacturing world. It offers some pretty unique benefits that cater to the complex needs of many industries. If you’ve seen the latest market reports, you'll know that the global market for composite materials is expected to hit around USD 38.7 billion by 2027, growing at roughly 9.5% a year from 2020 onwards. That kind of rapid growth definitely bumps up the demand for faster, more reliable ways to join materials— which is where composite material welding comes in and leads the charge.

Here’s a bit of good news: Shenzhen Chengguan, with over two decades of experience in ultrasonic plastic welding, is right at the heart of this innovation. Our top-notch ultraSonic Welding systems are tailored to meet all sorts of manufacturing needs, making sure joints are strong and products last longer. As more industries switch to composite materials because they’re lightweight but super strong, usingultrasonic welding becomes pretty much essential. It helps streamline production and saves costs at the same time. So, if you’re a manufacturer hoping to stay ahead in this fast-changing landscape, understanding the top benefits of composite material welding is more than just useful—it’s a must.

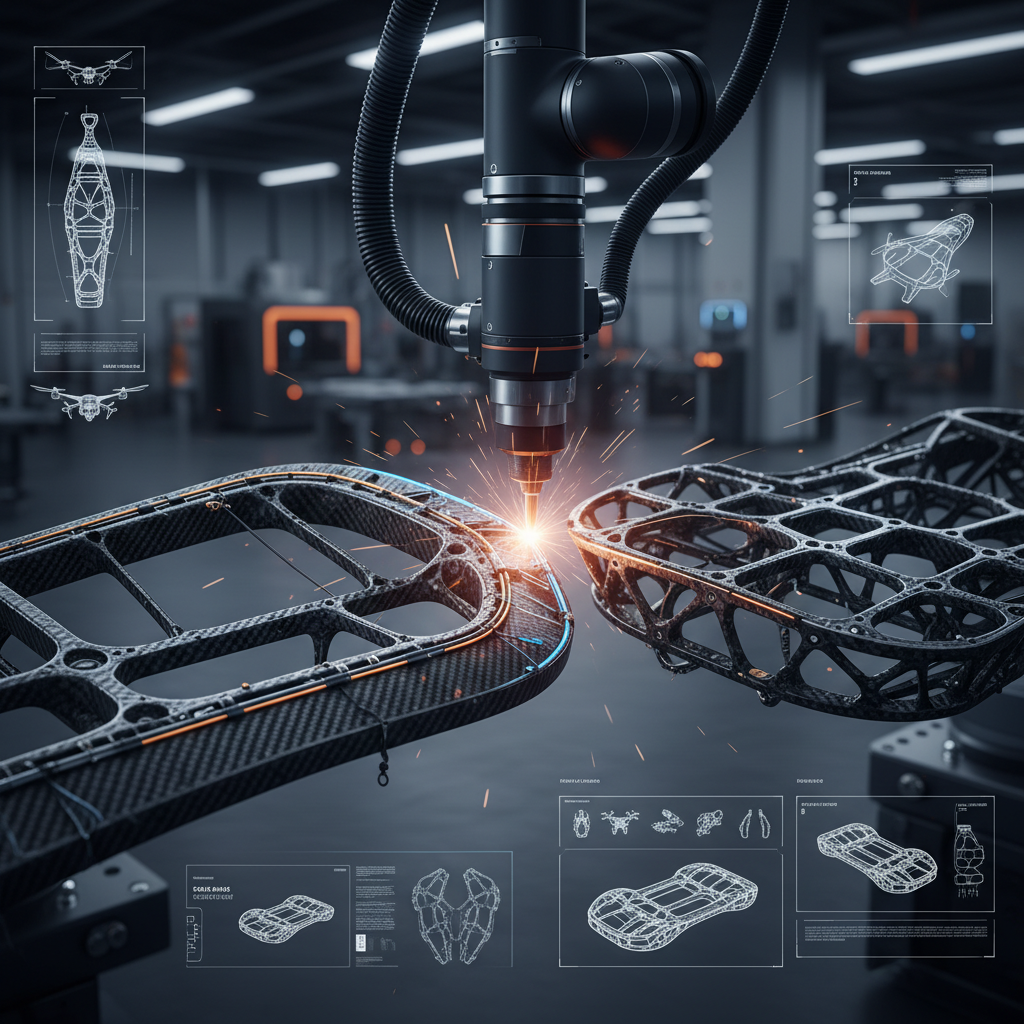

Composite material welding has revolutionized modern manufacturing by enhancing the strength and durability of products. One of the key benefits of utilizing composite materials is their ability to improve performance while maintaining lightweight characteristics. This is particularly important in industries such as automotive and aerospace, where manufacturers are increasingly seeking innovative materials that contribute to better fuel efficiency and reduced emissions. The recent introduction of advanced fibers opens up new possibilities for elevating the capabilities of traditional materials like glass and carbon fibers, providing manufacturers with an effective means to achieve design flexibility and visual appeal without compromising on structural integrity.

Moreover, the advancements in welding technology, particularly in high-power applications, are shaping the future of composite material welding. As manufacturers adopt these technological innovations, the challenges associated with welding lightweight materials, such as warping due to heat, are being effectively addressed. This enhances the overall manufacturing process, allowing for the production of more robust and durable components. With the relentless pursuit of excellence in manufacturing, composite material welding stands out as a critical component in driving efficiency, sustainability, and innovation across various sectors.

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Strength | Composite materials provide superior strength-to-weight ratios. | Lighter structures with increased load-bearing capacity. |

| Increased Durability | Resistance to corrosion and environmental degradation. | Longer lifespan of manufactured products. |

| Versatility | Can be tailored for various applications and industries. | Broader application in manufacturing sectors. |

| Cost-Effectiveness | Reduction in material and maintenance costs over time. | Overall savings in manufacturing processes. |

| Improved Safety | Minimized risk of breakage and failure in extreme conditions. | Safer working environments and product reliability. |

Composite material welding has emerged as a game-changer in modern manufacturing, particularly regarding cost efficiency. One of the primary advantages of utilizing composite welding is its ability to significantly reduce material waste. Traditional welding methods often involve excess filler materials and result in intricate waste due to the different thermal properties of metals and composites. In contrast, composite welding techniques are designed to optimize the joining process, allowing manufacturers to utilize the entire composite material without the need for excessive additional resources. This streamlined approach not only minimizes waste but also leads to a more sustainable manufacturing process.

In addition to reducing material waste, composite welding also lowers labor expenses. The simplicity and efficiency of composite welding methods often require fewer steps and less time for completion compared to conventional welding techniques. As a result, manufacturers can accomplish more in less time, leading to increased productivity. Furthermore, the adaptability of composite welding allows for easier training and a quicker learning curve for operators, which minimizes the labor costs associated with skilled workforce training. Overall, the combined effect of reduced waste and lower labor expenses positions composite material welding as an economically advantageous solution for modern manufacturing challenges.

The pursuit of lightweight materials in modern manufacturing is increasingly pivotal for enhancing fuel efficiency and reducing emissions in the automotive sector. With the European automotive composites market projected to reach approximately USD 2.98 billion by 2033, driven by the demand for innovative lightweight solutions, manufacturers are strategically leveraging composite materials. This shift not only supports stringent environmental regulations but also fosters advancements in electric vehicle technologies, which hinge on optimal weight-to-performance ratios.

As explored in recent industry analyses, companies are recognizing the importance of composites such as polyvinyl chloride (PVC) and polyurethane (PU). These materials provide significant advantages in weight reduction without compromising structural integrity. For instance, automotive manufacturers have reported improvements in fuel economy by as much as 30% when integrating lightweight composites into their designs.

Tip: When considering lightweight materials for your projects, focus on evaluating composite options that best meet your performance needs while also contributing to sustainability goals. It's essential to stay informed about market trends and technological innovations that can enhance your product offerings. Additionally, collaborating with specialized companies can lead to breakthroughs in both innovation and efficiency, ensuring that your solutions remain competitive in the evolving manufacturing landscape.

Composite material welding offers remarkable design flexibility, which is critical for modern manufacturing. This technique allows engineers and designers to create intricate shapes and configurations that traditional materials may not support. By utilizing composite materials, manufacturers can tailor the properties of a product, such as weight, strength, and durability, to meet specific application requirements. This level of customization opens up new possibilities for innovative designs, enabling companies to stay competitive in an ever-evolving market.

Tips for leveraging design flexibility in composite material welding include utilizing simulation software to visualize and test designs before production. This can help identify potential issues early in the development process, allowing for adjustments without incurring significant costs. Additionally, experimentation with varying composite material compositions can yield unique benefits tailored to the specific needs of a project, enhancing both performance and aesthetics.

Moreover, collaboration between designers and engineers is essential when working with composites. Encourage cross-functional teams to share insights and ideas throughout the design process, fostering an environment that values creativity and optimization. By leveraging the strengths of composite material welding, manufacturers can push the boundaries of what is possible, bringing innovative products to market more efficiently.

Welding composite materials has revolutionized the manufacturing sector, particularly due to their exceptional corrosion resistance. In harsh environments, where traditional materials often succumb to deterioration, composites provide a reliable alternative that can withstand extreme conditions. The inherent properties of composite materials, when welded together, create a strong barrier against corrosive agents, ensuring longevity and durability. This advantage is particularly critical in industries such as aerospace, automotive, and marine, where the costs associated with maintenance and replacement of corroded materials can be substantial.

Moreover, the process of welding composites not only enhances their resistance to corrosion but also improves their structural integrity. By joining different composite layers and materials, manufacturers can create products that are not only lightweight but also possess enhanced mechanical properties. This synergy results in components that are capable of enduring rigors that might compromise metals, such as saltwater exposure or chemical contact. As industries continue to seek innovative solutions for extreme environments, the adoption of composite material welding is poised to grow, solidifying its role as a cornerstone of modern manufacturing strategies focused on sustainability and efficiency.

This bar chart illustrates the key benefits of composite material welding in modern manufacturing. Each benefit is rated on a scale from 0 to 100, showcasing the significance of corrosion resistance as the leading advantage, followed by weight reduction and strength-to-weight ratio. These metrics highlight the importance of welding composites in enhancing product longevity and performance in harsh environments.

The aerospace and automotive industries are witnessing a transformative shift with the integration of composite materials and advanced welding technologies. As reported by the Composites Market Report 2023, the global composite materials market is projected to reach $140 billion by 2025, largely driven by the demand for lighter and more durable components in these sectors. Ultrasonic welding, a specialty of Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., plays a pivotal role in enhancing the manufacturing processes for composite materials, offering high precision and efficiency that is essential for producing intricate shapes without compromising structural integrity.

In aerospace applications, the ability to join composite components rapidly and reliably is crucial. According to a study by the Aerospace Industries Association, the use of composite materials in aircraft construction can reduce weight by up to 20%, translating to significant fuel savings and emissions reduction. Similarly, in the automotive sector, lightweight composites help manufacturers meet stringent CO2 emissions targets while improving performance and fuel efficiency. Chengguan's innovative ultrasonic welding systems enable manufacturers to harness these benefits, ensuring robust joints and smooth production flows. With 20 years of expertise, Chengguan is at the forefront of guiding industries through this transition toward more sustainable and efficient manufacturing paradigms.

In the competitive landscape of plastic manufacturing, maximizing efficiency is paramount. The CGSF Servo Ultrasonic Plastic Welding Machine stands out as a pivotal innovation that enhances productivity while ensuring superior quality. One of its standout features is the high welding precision enabled by its advanced servo system. This technology guarantees accurate control over welding parameters such as position and depth, ensuring product consistency across batches. As manufacturers strive to meet the increasing demand for reliable and uniform products, this precision becomes a significant advantage.

Moreover, the CGSF machine provides stable energy output, adapting seamlessly to various plastic materials and welding requirements. This adaptability is essential for maintaining superior quality in diverse production environments. The machine's high intelligence adds another layer of efficiency; with preset welding parameters and storage functions, operators can easily recall settings, streamlining the production process. This feature significantly reduces setup times, facilitating increased automation in manufacturing workflows. By combining high welding speed with short cycle times, the CGSF Servo Ultrasonic Plastic Welding Machine not only bolsters productivity but also positions manufacturers to meet future growth projections in the industry.

: Composite material welding enhances product strength and durability while maintaining lightweight characteristics, which is crucial for industries like automotive and aerospace that prioritize fuel efficiency and reduced emissions.

Composite welding significantly reduces material waste and labor expenses by optimizing the joining process, allowing manufacturers to use the entire composite material and requiring fewer steps and less time compared to conventional welding methods.

It addresses challenges associated with welding lightweight materials, such as warping due to heat, thereby improving the overall manufacturing process and enabling the production of more robust and durable components.

Designers can use simulation software to visualize and test designs before production, allowing for early identification of potential issues and adjustments without incurring significant costs.

Collaboration between designers and engineers is essential for sharing insights and ideas, fostering creativity and optimization throughout the design process, which can lead to innovative products.

Advancements in welding technology, particularly in high-power applications, are enhancing the capabilities of composite welding and helping to overcome challenges faced with traditional welding methods used on lightweight materials.

Reducing material waste contributes to a more sustainable manufacturing process by minimizing excess resources and environmental impact, which is increasingly important in modern production practices.

By allowing customized manipulation of properties such as weight, strength, and durability, composite material welding enables the creation of products that meet specific application requirements, enhancing overall performance.

Composite welding techniques have simpler methods that require fewer steps, leading to a quicker learning curve for operators and minimizing labor costs associated with training.

Experimentation with varying composite material compositions can lead to unique benefits tailored to specific project needs, enhancing both performance and aesthetic appeal of manufactured products.

Composite material welding is revolutionizing modern manufacturing by enhancing strength and durability, while also promoting cost efficiency. This innovative method significantly reduces material waste and labor expenses, making it a practical choice for industries striving for sustainability. Moreover, the lightweight nature of composite materials contributes to fuel efficiency and minimizes emissions, aligning with global environmental goals.

The design flexibility offered by composite material welding allows for extensive customization, catering to specific manufacturing needs. Additionally, the corrosion resistance of welded composites ensures longevity even in harsh environments, making them ideal for demanding applications. As seen in sectors like aerospace and automotive, the future of composite welding is bright, promising innovative applications that can transform production processes. At Chengguan, we understand the importance of advanced welding technologies, and our ultrasonic welding systems are at the forefront of promoting these benefits across various industries.