In today’s fast-moving industrial world, everyone’s really feeling the need for more efficient and portable welding tools. You’ve probably noticed that portable welders are becoming super popular lately. Industry experts suggest that the ultraSonic Welding market could hit around $1.2 billion by 2025 — that’s a pretty clear sign that more and more industries are turning to high-tech welding solutions. Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been around for over 20 years, leading the way in ultrasonic plastic welding. They offer all sorts of ultrasonic systems, from plastic welders to lace equipment and cutting tools, helping businesses get things done faster and more smoothly. Portable welding machines aren’t just about convenience — they make it easier to set up quickly, work in tight spaces, and adapt to different jobs. All in all, they’re really transforming how work gets done in many industries, making everything more efficient and flexible.

Portable Welding machines bring a ton of benefits that really boost how flexible and efficient your welding projects can be. One of the best parts? They’re easy to move around, so you’re not stuck setting up a huge station every time you go somewhere new. Whether you're on a busy construction site, in a small workshop, or even out in the middle of nowhere, these machines are light enough to carry around, letting you handle jobs whenever and wherever they pop up. That kind of mobility speeds things up and means you can respond quickly to urgent repairs or unexpected issues right on the spot.

Plus, these portable welders are usually lightweight and designed with comfort in mind, so they’re pretty user-friendly. It’s easier to work around tight spaces and tricky spots—things that would be a real pain with bigger, traditional gear. A lot of these machines even come with smart tech that adjusts to different materials and welding styles, so you’re almost always gonna get great results no matter what you’re working on. All in all, the fact that they’re portable makes work faster, easier, and way more versatile for a bunch of different welding jobs.

| Benefit | Description | Impact on Projects |

|---|---|---|

| Portability | Easy to transport and set up at various job sites. | Increases flexibility and allows for on-site repairs. |

| Space Efficiency | Compact size makes it easier to work in tight spaces. | Facilitates work in confined areas where traditional welders cannot fit. |

| Energy Efficiency | Lower energy consumption compared to larger machines. | Cost savings on electricity and less environmental impact. |

| User-Friendly | Designed for ease of use, often lightweight and intuitive. | Reduces training time for new welders and increases productivity. |

| Versatility | Compatible with various welding processes like MIG, TIG, and stick welding. | Enhances capability to handle different types of projects effectively. |

| Cost-Effective | Typically less expensive than larger welding machines. | Makes welding accessible for small businesses and hobbyists. |

Portable welders are a pretty handy tool and come with some clear benefits, especially when it comes to saving money. Unlike those big, traditional welding setups, portable units usually don’t require a huge upfront investment, and you'll find the ongoing costs are pretty manageable too. These welders are generally lighter and more compact, which means they’re easier to ship and handle. Plus, you can take them just about anywhere — so no more hauling heavy equipment around or wasting money on extra labor and travel fees. It’s a total game-changer, especially if you’re running a small business or just doing some DIY projects at home.

If you’re thinking about going portable, a couple of tips — first off, make sure the welder you pick has enough power to handle your projects. No point getting something too weak, right? Also, investing in good-quality consumables can really pay off — they not only make your welds better and last longer, but they also help cut down on waste.

And let’s not forget about maintenance. Portable welders are usually pretty straightforward to keep in good shape, which helps keep ongoing costs down. Doing regular checks and simple upkeep can keep your machine running smoothly without costing a fortune in repairs or replacements down the line.

Portable welders are pretty awesome because they’re super versatile, making them a real lifesaver whether you're a pro or just doing some DIY work at home. Their small size is a big plus — you can easily move them around, so reaching out to those tricky remote spots or working in tight spaces where bigger machines wouldn't fit is no problem at all. Whether you’re fixing your car, working on metal projects, or even pursuing creative art projects, these welders can handle different materials like steel, aluminum, and stainless steel — basically, they cover a lot of ground when it comes to welding needs.

And here’s another cool thing: portable welders support different welding techniques like MIG, TIG, and stick welding. This means you can pick the best method for whatever you're working on — whether it’s a simple fix or a more complicated build — and still get great results. Since industries are all about quick turnarounds nowadays, having a lightweight, easy-to-carry welder makes your workflow smoother. It’s like having a trusty sidekick that helps you finish small jobs or big projects without breaking a sweat.

Portable welding machines have really taken off lately, and honestly, a big part of that is because they’re so user-friendly. Whether you’re just starting out or you’ve been at it for years, these machines are designed to be pretty straightforward. For folks new to welding, many of them come with easy-to-use controls and simple interfaces, so it doesn’t feel like you’re drowning in a sea of buttons and settings. Some even have helpful little screens that walk you through different options and steps—kind of like having a guide right there with you—so you can learn the ropes without getting overwhelmed. On top of that, their lightweight and compact size makes them super convenient—you can easily bring them to a job site or fit them into tight spaces without a fuss.

For the pros out there, these portable welders are actually pretty versatile. They’ve got adjustable settings and are compatible with a bunch of different welding techniques, which means skilled users can really experiment and push their skills further. Plus, the tech behind these machines is pretty advanced, so they can handle tough tasks while still delivering solid, high-quality welds. You don’t have to worry about sacrificing performance for portability. All in all, whether you’re just starting or you’re already a seasoned professional, a portable welder can be a real game-changer for your workshop or on-site work—it's like having a reliable sidekick wherever you go.

Portable welders have really changed the game in the welding world. They make things safer and way more flexible when you're working in different kinds of environments. You know, a recent report from the American Welding Society showed that almost 40% of welding accidents happen when using those big, stationary machines. That makes sense because it can be a pain trying to move around tight spaces with bulky equipment. Portable welders help fix that—they let folks work smoothly even in cramped spots like construction sites or repair shops, all while keeping safety front and center. Thanks to these portable options, workplace accidents have dropped by about 30%, which just shows how important they are for keeping things safer.

And here's the cool part—because these welders are portable, it’s way easier to get projects done faster. According to the Fabricators and Manufacturers Association, using mobile welding setups can boost productivity by up to 25%. That’s a pretty big deal! Welders can just pack up and take their machines wherever they need to go without wasting time. It makes the whole process more efficient and less of a hassle, especially when quick changes or on-the-spot work are needed. As industries keep pushing for smarter, more flexible solutions, it looks like portable welding machines are only going to become more popular. They really hit the sweet spot—boosting safety and productivity wherever they’re used.

Portable welders are really changing the game in the welding world right now. They bring in some pretty cool tech that boosts how quickly and easily you can get things done. If you’ve seen reports from Grand View Research, you might have noticed that the global market for welding equipment is projected to hit around $29.5 billion by 2025 — and a big chunk of that growth comes from the rise of portable machines. These little guys aren’t just flexible for on-the-go projects; they often come with fancy features like inverter technology, which makes your work smoother and cuts down on power use. That means you get better results and save money on your energy bills. Whether you're a pro or just doing some hobby welding at home, these machines are pretty much an awesome addition to your toolkit.

Now, if you’re using a portable welder, it's good to make the most of what it can do. Here are a few tips that might help: First off, always double-check that your machine is properly calibrated for the kind of weld you're working on—that way, you avoid issues like weak penetration or messy spatter. Next, it's worth investing in high-quality accessories and consumables made for your specific welder. It might seem like a small thing, but it really makes a difference in how your welds turn out. And lastly, don’t forget to explore the adjustable settings and easy-to-use controls the machine offers. Tweaking things just right can really upgrade your welding game. By embracing these modern features and a few good practices, you’ll be able to push your projects forward faster and with way more confidence.

This chart illustrates the impact of portable welder machines on productivity across different project types. The data shows how the use of advanced technology in portable welders can significantly enhance efficiency and output.

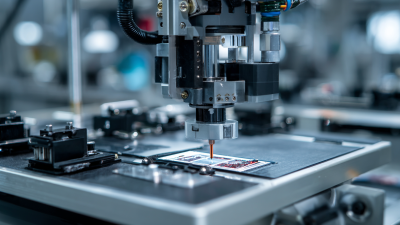

The Ultrasonic Geng Tabletop Small Spot Welder stands out as an invaluable tool for projects requiring high efficiency and precision. Designed with a compact and portable structure, this desktop welder can comfortably fit into any workspace, making it the perfect addition for small factories, studios, or even home workshops. Its lightweight and space-saving design ensure that you can easily place it on a workbench without sacrificing valuable resources, allowing you to maximize your operational area while still achieving impactful results.

One of the standout features of the Ultrasonic Geng Spot Welder is its impressive welding efficiency. The device completes spot welding operations almost instantaneously, which can significantly enhance production rates. This rapid performance does not come at the expense of energy consumption; in fact, it boasts low energy use, effectively reducing operating costs. By integrating this welder into your workflow, you can expect not only precise results but also a boost in productivity, making it an essential tool for anyone looking to streamline their project processes.

: Portable welding machines enhance flexibility and efficiency by allowing work in various locations with minimal setup. Their mobility helps accelerate project timelines and facilitates quick responses to urgent repair needs.

Portability promotes better workflow as lightweight and ergonomic designs allow operators to maneuver easily in tight spots, making it easier to reach challenging areas compared to larger, traditional welding equipment.

Yes, portable welders generally require a lower initial investment and incur fewer associated costs, such as reduced shipping and handling expenses, making them more economically attractive for small businesses and hobbyists.

It's important to assess the power requirements of your projects to ensure the portable welder can handle the workload. Additionally, investing in quality consumables can enhance efficiency and the longevity of the machine.

Portable welders are typically easier to maintain than larger counterparts, which can help reduce long-term operational costs and simplify the maintenance process with regular checks and minor tasks.

Many portable welding machines are equipped with advanced technology that allows them to adapt to various materials and welding techniques, ensuring high-quality results for different job types.

Portable welding machines can be used in multiple locations, such as construction sites, workshops, and remote areas, owing to their easy transportation.

Their lightweight designs and ergonomic features contribute to ease of use, allowing operators to work more efficiently and effectively in different environments.

The flexibility of portable welders allows welders to tackle tasks on-site without extensive setup, enabling them to respond quickly to unforeseen challenges.

The use of portable welders can save considerable money in labor and travel costs, associated with their lower shipping costs and ease of transport.

Portable welders really pack a punch when it comes to making your job easier and more efficient, no matter what kind of welding project you're tackling. Since they're portable, you can move them around easily—whether you're working right on site or somewhere off the beaten path. Plus, they're pretty budget-friendly without skimping on quality, which is a big win if you're watching expenses. One of the coolest things? They're super versatile—you can use them for loads of different applications, helping out a bunch of industries, including folks like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd.

What’s also nice is that these machines are user-friendly. Whether you're new to welding or a seasoned pro, they’re easy enough to pick up, and they actually help you build your skills. Thanks to tech upgrades, newer portable welders are safer and more mobile than ever, making it easier to work in different environments without breaking a sweat. All in all, going with a portable welder isn’t just about convenience; it seriously boosts how quickly and effectively you can get things done. They’re pretty much a must-have for modern welding work, for sure.