Ultrasonic Welding has really started to shake things up in how PSA cards are made. Honestly, it’s a pretty clever tech that makes bonding easier and boosts the overall quality of the cards. What’s cool is that using ultrasonic waves, manufacturers can put together the cards quickly — no messy adhesives needed — and the end product is usually more durable too. The process works by sending high-frequency vibrations to create a super-strong bond, which is pretty neat if you ask me.

One of the biggest perks is how precise it is. That means designers can go all out with intricate patterns or details, and everyone can be confident that the layers are lined up just right. Of course, it’s not all smooth sailing — dialing in the perfect settings for different materials takes some trial and error. Sometimes, operators might struggle to keep the energy consistent, and that can lead to little flaws in the final cards. It usually needs some tinkering to get it right.

Still, despite those growing pains, the advantages are pretty impressive. Being able to produce lightweight, flexible cards really opens up a lot of new possibilities. As more companies jump on the bandwagon and try this tech out, continuous tweaks and improvements are bound to happen. Overall, ultrasonic welding is becoming a key player in the card world, pushing innovation and helping make a better product — it’s definitely a game-changer.

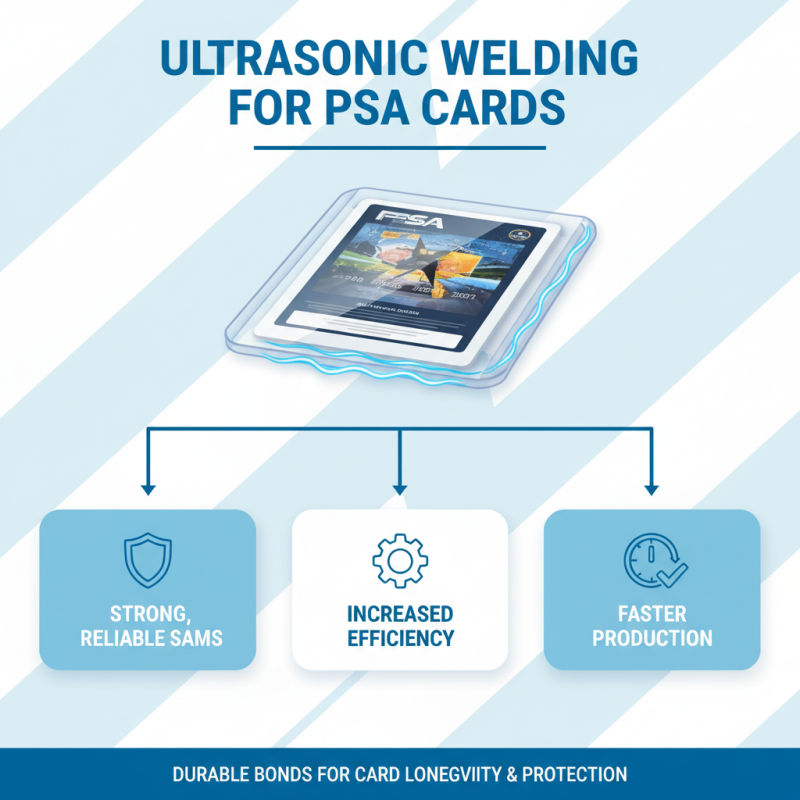

Ultrasonic welding has gained popularity for creating strong, reliable seams in PSA cards. This process uses high-frequency sound waves to generate heat, melting the materials at the joint. The result is a durable bond, crucial for card longevity and protection. This method can also increase production efficiency. Less time is needed compared to traditional adhesive methods.

Moreover, ultrasonic welding minimizes the risk of damage. Since it generates heat only at the intended points, surrounding areas remain unaffected. This precision is valuable, especially for delicate card materials. Yet, the process isn't without challenges. Operators must calibrate the equipment carefully. Inconsistencies in the material or improper setup could lead to weak bonds. Regular maintenance is essential to ensure optimal performance and longevity of the equipment.

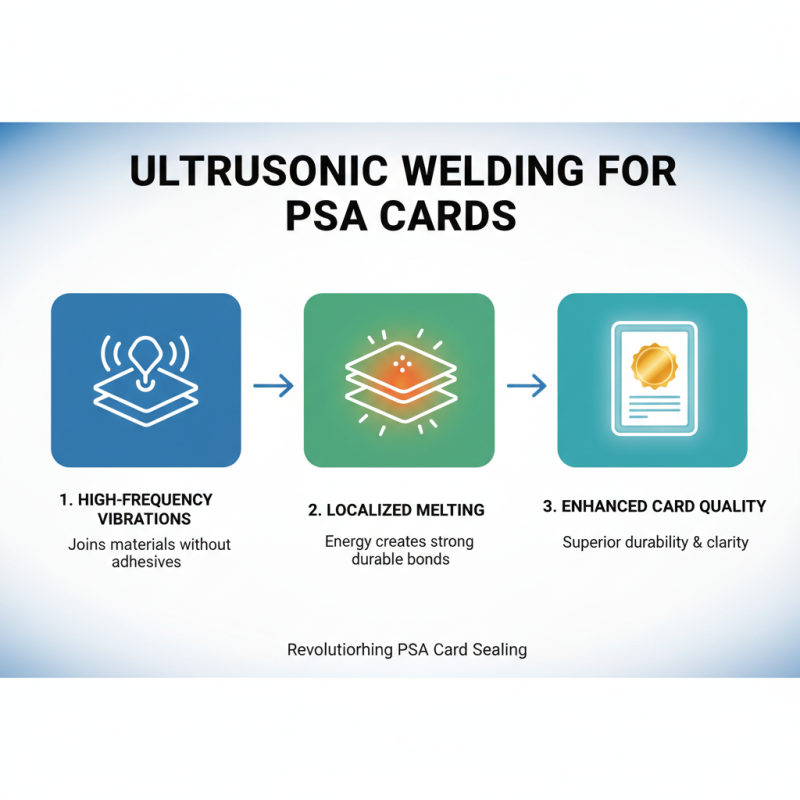

Ultrasonic welding is a fascinating process. It uses high-frequency sound waves to bond materials together. This method is particularly effective for PSA cards. The process is efficient yet simple.

To start, the components must align perfectly. An Ultrasonic Transducer generates vibrations. These vibrations travel through a sonotrode. The interface of the materials receives the vibrations, causing them to soften. As pressure is applied, the materials fuse together almost instantly. This is whereprecision is crucial; even slight misalignment can impact the bond quality.

After the welding, the components cool quickly. This speed is beneficial for production. However, it leaves little room for error. Operators must be trained to spot any defects. A proper setup is essential to achieve the desired results. Quality control becomes even more critical to ensure that the final product meets standards. Mistakes can happen, and reflecting on this process helps improve the technique.

Ultrasonic welding has revolutionized PSA card production. This process uses high-frequency sound waves to join materials seamlessly. Unlike traditional methods, it requires no adhesives or additional components. Industry reports indicate that ultrasonic welding can enhance production speeds by approximately 30%. This efficiency can significantly reduce lead times for manufacturers.

Another key advantage lies in material integrity. Ultrasonic welding minimizes the risk of thermal damage. Unlike heat-based methods, it keeps materials cool. This property is particularly beneficial for sensitive components. According to a recent market analysis, using ultrasonic welding can reduce defect rates by up to 25%. Reduced defects mean higher quality products with fewer returns.

Despite these benefits, challenges exist. For example, initial setup costs can be high. Not all manufacturing lines are equipped for this technology. Additionally, training staff to operate these systems requires investment and time. As manufacturers adapt, ongoing assessment of the process is crucial. Keeping track of production metrics helps identify areas for improvement.

Ultrasonic welding is a revolutionary technique that significantly enhances the quality of PSA cards. This method uses high-frequency vibrations to join materials without the need for adhesives. The energy generated creates localized melting, leading to strong, durable bonds. As a result, the overall quality of the cards improves.

One notable aspect is the precision of ultrasonic welding. Each weld is made with great accuracy. However, there can be inconsistencies if the parameters aren't well controlled. For example, variations in amplitude or pressure can affect weld strength. Maintaining these parameters requires careful monitoring and adjustment. This highlights the need for skilled operators who understand the process deeply.

Additionally, ultrasonic welding minimizes damage to sensitive materials. Traditional methods can often lead to wear and tear. Yet, ultrasonic welding protects the integrity of PSA cards. While the craftsmanship is remarkably effective, challenges remain. For instance, material compatibility is crucial. Not all materials react well to ultrasonic welding. Understanding these nuances is essential to maximize benefits and improve quality.

Ultrasonic welding offers notable cost-efficiency for PSA cards. This method eliminates the need for additional materials, such as adhesives. According to a report by Grand View Research, ultrasonic welding can reduce production costs by up to 30%. This efficiency allows manufacturers to allocate resources more effectively.

Moreover, ultrasonic welding minimizes production time. Traditional methods may require longer curing periods or manual assembly. In contrast, ultrasonic welding can join materials in seconds. A study from the Ultrasonic Technology Association indicates that this speed can increase overall productivity by 25%. Yet, some manufacturers hesitate to adopt this technology due to initial investment concerns.

Non-optimal setups can lead to inconsistent weld quality. With proper training and maintenance, manufacturers can ensure reliable results. However, the learning curve may deter some businesses. Balancing initial costs with long-term savings is essential. Every investment carries risk, but the potential rewards of ultrasonic welding in PSA card production are significant.

Ultrasonic welding is revolutionizing the manufacturing of PSA cards. This method offers a cleaner alternative to traditional bonding techniques. It uses high-frequency vibrations to fuse materials together. This process generates minimal waste and energy compared to methods like adhesive bonding, which often uses volatile organic compounds (VOCs).

According to recent studies, ultrasonic welding can reduce energy consumption by up to 60% during production. The Environmental Protection Agency reports that typical adhesive processes generate significant VOC emissions, contributing to air pollution. In contrast, ultrasonic welding creates a safer workspace with fewer harmful emissions. This lower environmental footprint is crucial for sustainable manufacturing practices.

However, not all aspects of this technology are perfect. The setup cost for ultrasonic welding equipment can be high. Manufacturers may face challenges in adapting their processes. Some materials might not weld as efficiently using this method. It highlights the need for research and development in optimizing ultrasonic welding techniques for various applications. Balancing efficiency and sustainability remains an ongoing conversation in the industry.

| Benefit | Description | Environmental Impact |

|---|---|---|

| Energy Efficiency | Ultrasonic welding requires less energy compared to traditional welding methods, making it more efficient. | Reduces overall carbon footprint due to lower energy consumption. |

| Minimal Waste | The process generates little to no waste as it bonds surfaces without the need for filler materials. | Decreases landfill waste and promotes sustainable manufacturing practices. |

| Durable Bonds | Creates strong and durable bonds that can withstand extreme conditions. | Less frequent replacements may lead to reduced resource consumption over time. |

| Noise Reduction | The ultrasonic process generates significantly less noise compared to mechanical methods. | Improves workplace safety and employee well-being. |

| Versatility | Can be used on a wide range of materials including plastics and metals. | Facilitates the recycling process by allowing for more material types to be joined efficiently. |

Ultrasonic welding is gaining traction in the production of PSA cards. This technique offers precision and speed. Manufacturers are drawn to its ability to create strong, durable bonds without the need for adhesives. As the technology evolves, new applications are emerging.

Future trends indicate a shift towards automation in ultrasonic welding systems. This will enhance efficiency and reduce manual errors. However, adapting to these changes may be challenging for some businesses. Investing in training and equipment is essential but costly.

Another trend is the focus on sustainability. Ultrasonic welding reduces material waste, benefiting the environment. Yet, the transition to more eco-friendly practices may require significant investment. Companies must balance innovation and cost-effectiveness. The road ahead is paved with opportunities and challenges.

The advancement of ultrasonic technology has significantly enhanced industrial processes, with the CG00 Series Ultrasonic Generator standing out for its ability to maximize efficiency and precision in various applications. Designed to produce a range of multi-frequency electrical signals—commonly at frequencies such as 15kHz, 20kHz, and up to 40kHz—this ultrasonic generator is adept at driving transducers to convert electrical energy into high-frequency mechanical vibrations. This conversion is essential for generating ultrasonic waves, which can be harnessed in a variety of industrial applications, from cleaning delicate components to aiding in material processing.

One of the key attributes of the CG00 Series is its core components, including an oscillator circuit, amplifier, and matching circuit, which are meticulously engineered to ensure optimal performance. The oscillator circuit generates stable frequencies, while the amplifier boosts the output power to meet the specific demands of various operations. The matching circuit plays a crucial role in optimizing the energy transfer between the transducer and the ultrasonic generator, thereby enhancing the precision and efficacy of the ultrasonic waves produced. By efficiently converting electrical energy into ultrasonic energy, industries can achieve improved results in tasks such as welding, cutting, and cleaning, ultimately leading to increased productivity and cost savings.

: Assess your needs. Think about your budget and available options. Compare features, and read reviews.

Gather more information. Consider different viewpoints. Reflect on past decisions and their outcomes.

It happens. Analyze what went wrong. Learn from your choices. Adjust your approach for the future.

Identify your priorities. List must-have features. Narrow down choices based on personal usage.

Most places allow returns. Check the policy. Keep the receipt and packaging intact for easier returns.

Set a clear spending limit. Track your expenses. Prioritize essentials over wants. It’s challenging but necessary.

Yes, user feedback provides insights. Look for patterns in reviews. But remember, opinions vary greatly.

Reach out for clarification. Ask experts or consult online resources. Don't hesitate to seek help.

Create a shopping list. Stick to it strictly. Allow time to think before making a purchase. It can be tough.

Research thoroughly. Compare options carefully. Consider long-term value rather than short-term appeal. Reflect on results.

Ultrasonic Welding PSA Card technology is revolutionizing the production process for collectible cards, offering numerous benefits that enhance both quality and efficiency. This innovative method involves the use of high-frequency ultrasonic vibrations to create strong, reliable bonds between materials without the need for adhesives or extensive heating. The step-by-step process ensures precision and consistency, which significantly improves the overall quality of PSA cards.

Moreover, Ultrasonic Welding for PSA Card production is cost-effective, leading to savings in both materials and time due to its rapid bonding capabilities. Environmentally, this technique reduces waste and energy consumption compared to traditional methods. As the industry evolves, future trends indicate an increased adoption of ultrasonic welding, further optimizing manufacturing practices for PSA cards and setting new standards for quality and sustainability.