In the fast-changing world of electronics, it’s pretty clear just how important Electronic Component Packaging really is. As we look into the top tips for effective packaging in 2023, it’s good to keep in mind what industry experts are saying. Take Dr. Emily Carter, for example — she’s a real authority when it comes to electronic engineering and packaging tech. She often stresses, “The way we package our electronic parts has a huge influence on how they perform, how long they last, and ultimately, whether the final product is a hit or a miss.”

Getting the packaging right isn’t just about protecting delicate components — it’s also a big deal for making manufacturing smoother and improving the overall reliability of products, especially with how competitive the market’s gotten. Thanks to new materials and smarter design approaches, figuring out the best packaging solutions has become quite the challenge for engineers and manufacturers alike.

As we dive into the top ten packaging tips for 2023, we’ll focus on fresh strategies that try to balance speed, cost, and sustainability — all while making sure products live up to customer expectations and stay friendly to the environment. The upcoming sections will lay out some crucial insights and practical recommendations to help you handle the tricky world of electronic packaging more effectively.

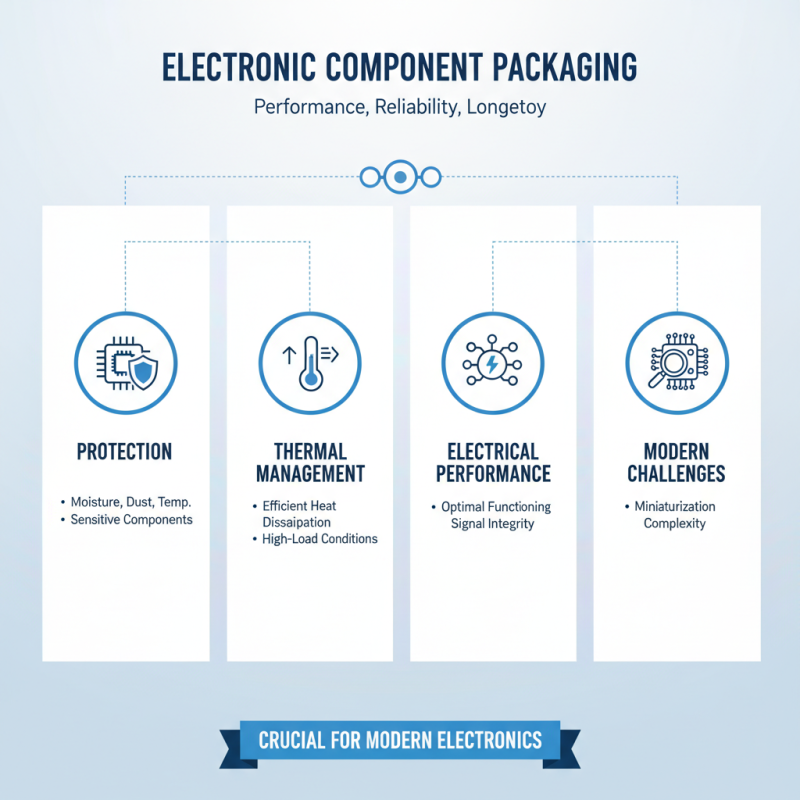

Electronic component packaging is a crucial aspect of electronics design that significantly influences the performance, reliability, and longevity of devices. In an era where miniaturization and complexity of electronics are at an all-time high, the importance of effective packaging cannot be overstated. It serves not only to protect sensitive components from environmental factors such as moisture, dust, and extreme temperatures, but also allows for improved thermal management and electrical performance. Proper packaging designs enable efficient heat dissipation, which is vital for maintaining optimal functioning of electronic devices, especially those that operate under high-load conditions.

Moreover, packaging plays a pivotal role in ensuring the integrity of the component during transport and assembly processes. Well-designed packaging provides adequate cushioning and support to minimize the risk of mechanical damage. It also facilitates ease of handling during manufacturing, reducing the chances of defects that could lead to failure in the final product. Ultimately, understanding the importance of electronic component packaging leads to better design decisions, enhancing not only the durability of electronic products but also their market viability. Ensuring that packaging meets industry standards and addresses specific application needs is key to promoting innovation and efficiency within the electronics sector.

Effective packaging design for electronic components is critical for ensuring product reliability, safety, and sustainability. A recent report from the Electronics Packaging Society highlights that up to 30% of electronic failures are attributed to inadequate packaging solutions. Therefore, prioritizing key factors in packaging design is essential for minimizing risks and enhancing performance.

One major aspect to consider is the choice of materials. With the growing emphasis on sustainability, biodegradable and recyclable materials are becoming increasingly popular. According to a 2022 market analysis, the eco-friendly packaging segment is expected to grow at a CAGR of 12% over the next five years. Additionally, factors such as temperature, humidity, and mechanical stress play a significant role in determining the longevity of the electronic components. Engineers should conduct thorough environmental assessments to select materials that not only protect against these threats but also comply with regulations like RoHS and REACH.

Another critical consideration is the integration of shock-absorbing features within packaging. The IPC standards indicate that improved cushioning can reduce damage during transit by up to 40%. Incorporating advanced cushioning materials can help absorb vibrations and shocks, ensuring that components remain intact throughout the supply chain. As the demand for miniaturization in electronics continues, packaging must adapt to increasingly compact designs while maintaining effective protection and functionality, ensuring that the components inside are preserved for their intended use.

When selecting materials for electronic component packaging in 2023, it is crucial to prioritize not only functionality but also sustainability and cost-effectiveness. Recent studies reveal that the global electronic packaging market is expected to reach USD 36.7 billion by 2028, with sustainability becoming a focal point for manufacturers. This shift is reflected in the increasing use of bio-based materials for packaging, which can reduce the environmental impact of electronic waste. For instance, adopting materials such as biodegradable polymers can significantly lower the carbon footprint of packaged components, aligning with global sustainability goals.

Moreover, the choice of materials should consider the specific environmental conditions the components will face. A report by the Institute of Packaging Professionals highlighted that packaging materials must provide adequate protection against moisture, temperature fluctuations, and mechanical stress. For example, using moisture barrier films can help extend the lifespan of sensitive electronic components by preventing corrosion and short circuits. Additionally, integrating shock-absorbing materials in the packaging design enhances the resilience of fragile components during transit, ensuring they arrive intact. In conclusion, the right material selection is essential for optimizing both the performance and sustainability of electronic component packaging in a rapidly evolving market.

In 2023, the integration of advanced technologies in electronic component packaging has transformed how manufacturers approach efficiency and reliability. The adoption of smart packaging solutions, such as embedded sensors and monitoring systems, has revolutionized the industry. According to a recent industry report by Research and Markets, the global smart packaging market is projected to grow from $30.2 billion in 2021 to over $46 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 8.5%. These innovative technologies enable real-time tracking of components, ensuring optimal conditions during transportation and storage, which is vital for maintaining product integrity.

Moreover, the use of automation and robotics in packaging processes has significantly reduced labor costs and improved consistency. A report from Statista highlights that automation in packaging is expected to boost productivity by up to 25% while minimizing human error. The implementation of advanced materials, such as biodegradable films and protective coatings, not only meets sustainability goals but also enhances durability against environmental factors. As electronic devices become smaller and more complex, the demand for intricate packaging designs that protect sensitive components continues to rise, driving the need for cutting-edge technology in packaging processes. This shift not only elevates operational efficiency but also aligns with evolving consumer expectations for sustainable and reliable electronic products.

In the realm of electronic component packaging, adhering to industry standards and regulations is paramount in 2023. Effective packaging is not just a measure of physical protection but also ensures the integrity and reliability of the components throughout their lifecycle. Compliance with established standards such as IPC-A-610 or IEC 60950-1 plays a critical role in mitigating risks associated with product failures, safety hazards, and environmental concerns. It is essential for manufacturers to familiarize themselves with these regulations, which dictate material selection, design considerations, and testing protocols.

Furthermore, staying updated with evolving industry regulations ensures that companies remain competitive in a rapidly changing market. This includes understanding international standards, such as RoHS and WEEE directives, which address the environmental impact of electronic waste. By integrating compliance checks at every step of the packaging process—from design to final distribution—companies can minimize legal liabilities and enhance their reputation as responsible manufacturers. Moreover, engaging in regular training and audits can help maintain compliance, ensuring that packaging practices not only meet but exceed the necessary requirements, thereby fostering consumer trust and satisfaction.

| Practice | Description | Compliance Standards | Benefits |

|---|---|---|---|

| Material Selection | Choosing appropriate materials for durability and performance. | RoHS, REACH | Increased longevity and reliability of components. |

| Eco-Friendly Packaging | Using recyclable and biodegradable materials for packaging. | ISO 14001 | Reduced environmental impact. |

| Proper Labeling | Ensuring all components are correctly labeled. | IEC 62047 | Facilitates identification and handling. |

| Shock and Vibration Testing | Testing packaging for durability against shocks and vibrations. | MIL-STD-810 | Prevention of damage during transport. |

| Humidity Control | Using desiccants and moisture barriers in packaging. | IPC/JEDEC J-STD-020 | Protection against corrosion and performance degradation. |

| Serialization and Traceability | Implementing unique identifiers for tracking. | ISO 9001 | Enhanced accountability and quality assurance. |

| Static Protection | Using ESD (Electrostatic Discharge) safe materials. | ANSI/ESD S20.20 | Mitigation of damage to sensitive components. |

| Supply Chain Collaboration | Working closely with suppliers for best practices. | SA8000 | Improved efficiency and reliability. |

| Continuous Improvement | Regularly updating packaging processes and materials. | ISO 9001 | Enhanced product quality and customer satisfaction. |

In the quest for sustainable and eco-friendly packaging solutions in the electronic component industry, companies are increasingly focusing on integrating environmentally responsible materials and practices. One of the most effective strategies is to utilize biodegradable and recyclable materials that minimize waste and reduce the carbon footprint. This includes using plants-based plastics, recycled cardboard, and other renewable resources that can be easily processed at the end of their lifecycle. By opting for materials that are not only functional but also environmentally friendly, manufacturers can ensure their products contribute positively to sustainability goals.

Another crucial practice is to optimize packaging design to reduce material usage without compromising protection. Streamlining packaging dimensions and eliminating unnecessary layers can significantly lessen material consumption. Moreover, implementing modular designs that allow for multiple components to be packaged together can further reduce waste. Additionally, educating suppliers and consumers about the importance of recycling and proper disposal methods is essential for maximizing the lifecycle of the packaging materials. By adopting these practices, companies can create a market presence that resonates with eco-conscious consumers, while contributing to a more sustainable future for the electronics industry.

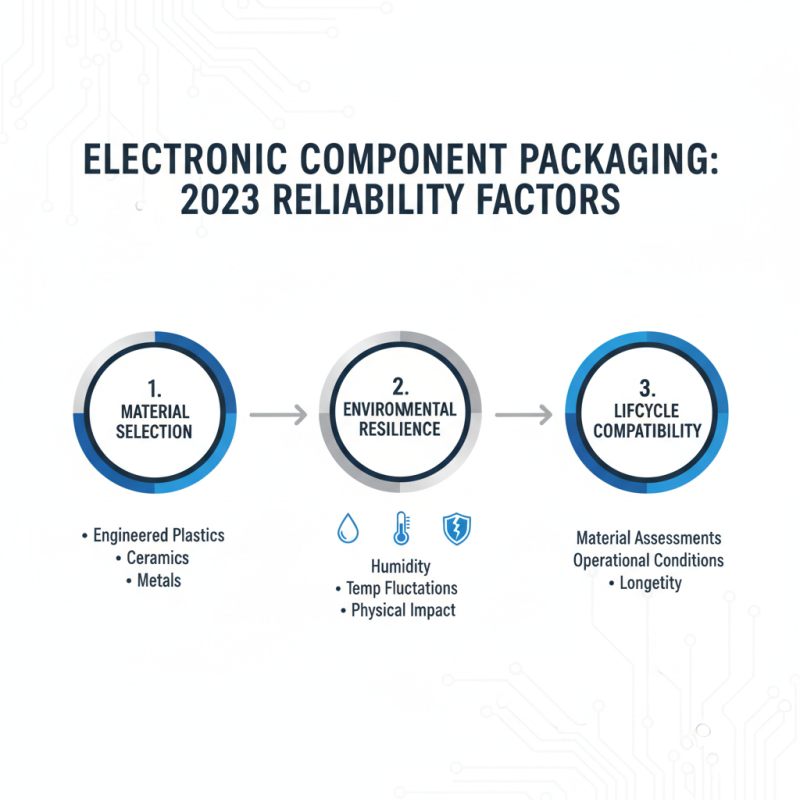

When evaluating packaging performance and reliability for electronic components in 2023, several key factors must be considered to ensure optimal functionality and longevity. One vital consideration is the choice of materials used in the packaging process. High-performance materials such as engineered plastics, ceramics, and metals can significantly enhance a component's resistance to environmental stressors, such as humidity, temperature fluctuations, and physical impact. It is essential to conduct detailed material compatibility assessments to ensure that the packaging can withstand the operational conditions it will face throughout its lifecycle.

In addition to material selection, the design of the packaging plays a crucial role in determining reliability. Effective thermal management is paramount; thus, packaging designs should facilitate heat dissipation to prevent overheating, which can lead to premature failure. Moreover, incorporating features such as moisture barriers can protect sensitive components from corrosion and electrical failures. Regular testing of packaging prototypes under simulated environmental conditions helps in identifying weaknesses and ensuring that the final product meets industry standards for reliability and performance. Ultimately, a comprehensive approach that combines material science and innovative design strategies will yield packaging solutions that support the increasing demands of electronic components in today's technology-driven landscape.

: When selecting materials, it is crucial to prioritize functionality, sustainability, and cost-effectiveness.

The global electronic packaging market is expected to reach USD 36.7 billion by 2028.

The increasing use of bio-based materials, such as biodegradable polymers, helps reduce the environmental impact of electronic waste and lowers the carbon footprint of packaged components.

Packaging materials should provide adequate protection against moisture, temperature fluctuations, and mechanical stress to ensure the longevity of electronic components.

Advanced technologies, such as smart packaging solutions and automation, enhance efficiency, reliability, and real-time tracking, significantly improving product integrity during transportation and storage.

Effective packaging design should facilitate heat dissipation and include moisture barriers to protect components from corrosion and electrical failures.

Conducting detailed material compatibility assessments ensures that the packaging materials can withstand the operational conditions throughout the product's lifecycle.

Regular testing under simulated environmental conditions helps identify weaknesses and ensures compliance with industry standards for reliability and performance.

Automation in packaging processes can boost productivity by up to 25% and minimize human error, resulting in improved consistency and reduced labor costs.

A comprehensive approach that combines material science with innovative design strategies is essential to meet the increasing demands of electronic components.

Effective Electronic Component Packaging is crucial in today's technology-driven landscape. The article emphasizes the importance of packaging in safeguarding components from environmental factors and ensuring optimal performance. Key factors for designing effective packaging solutions include understanding the specific requirements of the components and the application environment. Selecting the right materials is essential, as they contribute to durability and efficiency.

The implementation of advanced technologies in the packaging process enhances protection and performance while ensuring compliance with industry standards and regulations is paramount. The article also highlights best practices for sustainable and eco-friendly packaging solutions, which are increasingly important in modern manufacturing. Lastly, evaluating packaging performance and reliability factors helps ensure that the packaged components meet the necessary specifications and customer expectations.