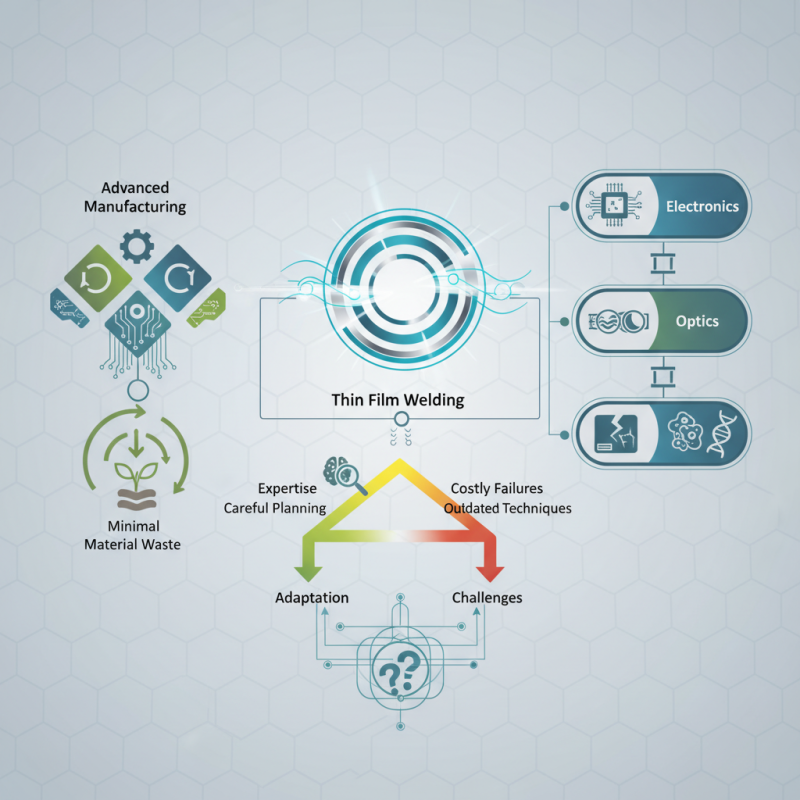

When you think about advanced manufacturing these days, Thin Film Welding really catches the eye—it's all about precision and efficiency. I read what Dr. Michael Anderson from Advanced Materials Solutions said recently, and he mentioned, “The future is really about how we make the most of thin film techniques.” These methods are pushing the limits in fields like electronics, optics, and even bioengineering, which is pretty exciting.

What’s cool about Thin Film Welding is how versatile it is. It helps reduce material waste, which is a big deal when we're talking about sustainability. More and more manufacturers are starting to question the old-school methods and look into this new approach. Switching over can really boost product performance and make things last longer. But honestly, it's not just plug-and-play—they need the right expertise and careful planning. A single misstep could turn into a costly headache.

It really makes you stop and think—are companies ready to embrace these changes? Getting the hang of Thin Film Welding isn’t just about adopting new tech; it’s about mastering it. Every improvement comes with its own set of risks, so weighing the pros and cons is super important. It’s an exciting time, but also one that needs thoughtful decision-making.

As the demand for thin film welding intensifies, industries are evolving their techniques. Manufacturing sectors are currently adopting advanced laser welding methods. These methods offer high precision and efficiency. They create robust joints suitable for delicate materials.

Another emerging trend is the integration of automation. Automated systems significantly reduce human error. They provide consistent quality in the welding process. Yet, this shift requires skilled operators to monitor machinery. Training needs to be ongoing, especially as technology advances.

Sustainability is becoming essential. Eco-friendly materials are now in focus. It prompts industries to rethink traditional welding approaches. However, adapting these practices is challenging. Many companies hesitate due to initial costs. Balancing innovation with budget constraints remains a critical area for reflection.

| Technique | Description | Applications | Industry | Advantages |

|---|---|---|---|---|

| Laser Welding | Utilizes a focused beam of light to join materials. | Semiconductors, Electronics | Electronics Manufacturing | High precision, minimal thermal distortion. |

| Electron Beam Welding | Uses a beam of electrons to fuse materials in a vacuum. | Aerospace, Nuclear | Aerospace Engineering | Deep penetration, low heat input. |

| Ultrasonic Welding | Applies high-frequency vibrations to fuse materials. | Plastic Components, Microelectronics | Consumer Electronics | Fast process, suitable for thermoplastics. |

| Friction Stir Welding | Join materials through mechanical friction and heat. | Automotive, Shipbuilding | Transportation Engineering | No filler materials, strong joints. |

| Spot Welding | Uses electric current to join metal sheets at points. | Automotive Panels | Automotive Industry | Fast and efficient for mass production. |

Thin film welding is an evolving technique in materials science. It involves joining materials at microscopic levels. This welding method requires precision and a thorough understanding of fundamental principles. It allows for the creation of strong bonds with minimal thermal impact. Various techniques, such as laser welding and electron beam welding, are often used. Each method has distinct advantages and limitations.

Understanding heat transfer is crucial in thin film welding. The focus is on controlling heat input to avoid damage. Often, achieving uniform temperature is challenging. For instance, local overheating can lead to defects in thin films. Choosing the right technique for specific applications is vital. The differences may impact the final product. Reflection on these choices is essential for successful outcomes. Additionally, process parameters must be carefully adjusted. Slight variations can result in significant differences in weld quality.

Implementation of these techniques often requires iterative testing. Trial and error may reveal unexpected challenges. Each project may present unique issues that require innovative solutions. This dynamic nature of thin film welding demands an open mindset. It is essential to remain adaptable in this field. Engaging deeply with the technical details can uncover new possibilities.

As industries progress, the choice between laser and electron beam welding techniques in thin films becomes critical. Laser welding is renowned for its precision. It excels in applications requiring high speed and minimal thermal impact. The ability to focus the laser beam allows for fine control over weld depth. Reports indicate that laser welding can achieve a weld speed of up to 60 inches per minute. However, achieving consistent results can be challenging. Factors such as material type and thickness can significantly influence outcomes.

On the other hand, electron beam welding offers unique advantages. It operates in a vacuum, minimizing contamination risks. This technique is effective for thicker materials. A comparative study found that electron beam welding has a higher penetration depth than laser welding. However, it also requires significant capital investment. Users need to consider their budget and project scale carefully.

**Tips:** When selecting a welding technique, evaluate your specific application requirements. Test both methods on sample materials before full-scale implementation. Remember, consistent training is vital for skilled operation. Delve into case studies to learn from past projects, as they can reveal pitfalls to avoid.

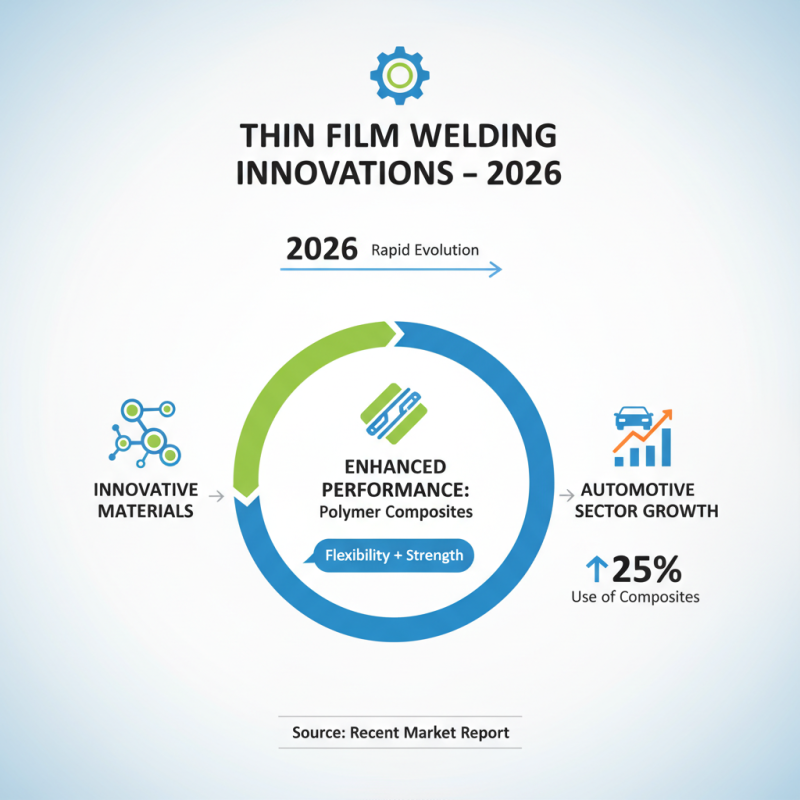

In 2026, the landscape of thin film welding applications is evolving rapidly. Innovative materials play a pivotal role in enhancing performance. For instance, polymer composites are gaining traction. These materials offer exceptional flexibility and strength. According to a recent market report, the use of these composites has increased by 25% in the automotive sector alone.

Metallic thin films are also making waves. Their high thermal and electrical conductivity sets them apart in applications like electronics. Recent studies suggest that integrating nanostructured metals can improve longevity and efficiency. Yet, challenges remain. The complexity of deposition processes can lead to inconsistencies in quality. Maintaining uniform thickness is often a concern.

Moreover, environmentally friendly materials are becoming a priority. Biodegradable films show promise for sustainable practices. However, their mechanical properties can sometimes fall short. There’s a real need for further research to bridge these gaps. As industries adopt these innovative materials, a balance between performance and sustainability must be achieved.

Thin film welding techniques have significantly advanced in aerospace and electronics. The aerospace industry relies on strong, lightweight materials. Engineers often use thin films to bond components while minimizing weight. This is crucial for improving fuel efficiency. One case study involved a new method where films were fused at lower temperatures. This improved the integrity of sensitive electronic parts.

In electronics, thin film welding is vital for manufacturing compact gadgets. A recent project highlighted the challenges of achieving consistent quality. Despite promising results, occasional defects were reported. These issues prompted teams to rethink their approach. They began to focus on enhancing process controls and quality assurance. This helped reduce the failure rate significantly.

Such success stories underline the importance of continuous improvement in welding techniques. While advancements are impressive, there is still work to be done. The journey involves learning from each project and refining methods step by step. The evolution of thin film welding illustrates a blend of innovation and real-world challenges.

Thin film welding techniques are reshaping the manufacturing landscape. By providing precision and strength, these methods enhance production efficiency. A recent industry report indicated that using advanced welding techniques can reduce material waste by up to 30%. This reduction not only saves costs but also lessens environmental impact.

Welding techniques like laser and electron beam welding contribute significantly. They offer improved heat control and minimize distortion. The high-speed capabilities of these methods can increase production rates by more than 50%. However, adopting these technologies may require significant upfront investments. Many companies struggle with the learning curve associated with new equipment and methods.

Manufacturing efficiency metrics depend on various factors, including turnaround time and defect rates. Recent studies show that implementing thin film welding can lower defects by up to 25%. Yet, the complexity of integrating these systems can be overwhelming for some manufacturers. Balancing innovation with practical limitations remains a challenge in this evolving field.

The future of thin film welding technologies presents exciting possibilities. By 2026, advancements could reshape industries, particularly in electronics and renewable energy. Thin film welding may enable lighter, more efficient devices. Applications could range from solar panels to flexible displays. However, the path is not without challenges.

Technical hurdles remain significant. Precise control over welding parameters is vital. Inconsistent results could lead to product failure. Material compatibility poses another concern. Some materials may struggle to bond effectively. Research continues to address these issues, but uncertainty lingers.

Moreover, the adoption of these technologies varies across sectors. Some industries embrace innovation faster than others. Resistance to change can slow progress. Businesses must weigh the risks and rewards. Investment in research and skilled labor is essential but costly. The balance between innovation and practicality remains delicate.

In the realm of plastic welding, maximizing efficiency and precision has become essential for manufacturers seeking to enhance operational performance. The introduction of CGSF Servo Ultrasonic Plastic Welding Machines embodies this pursuit, offering significant benefits through advanced technology. The servo system integrated within these machines provides high welding precision, ensuring accurate control of parameters such as welding position and depth. This level of precision guarantees product consistency across production runs, an essential factor in maintaining quality standards.

Moreover, the stable energy output of ultrasonic technology plays a pivotal role in achieving superior weld quality. By delivering consistent ultrasonic energy that adapts to various plastic materials and welding requirements, these machines minimize the risk of errors during the welding process. Additionally, the high intelligence of the system allows for preset welding parameters to be stored and easily recalled, facilitating an effortless operation while supporting automated production lines. The result is a significant reduction in cycle times and enhanced productivity, making these machines a valuable asset for businesses aiming to optimize their manufacturing processes.

: The product aims to improve daily productivity and organization. It helps users manage tasks effectively.

Begin by setting up your account and inputting your routines. User guides are available to assist you.

Regularly update your goals and review your progress. Small adjustments can lead to better results.

Check the troubleshooting guide first. If problems persist, consider reaching out for community support.

Yes, there’s a mobile version that allows you to access features on the go. It might not include everything.

Customization options are limited, but you can adjust some settings to make it feel more personal.

Feedback can be submitted via the online form. Your input is valuable, though it may not lead to immediate changes.

The product is designed for various users. However, some features might be complex for younger individuals.

It's common to miss deadlines. Reflect on why, and adjust your planning methods accordingly.

Updates are planned based on user feedback. However, the timeline can be unpredictable.

The article "2026 Best Thin Film Welding Techniques and Applications" explores the cutting-edge trends in thin film welding across various industries. It provides a comprehensive overview of the fundamental principles of thin film welding, highlighting the important techniques and innovations expected to shape the industry by 2026. A comparative analysis between laser and electron beam welding reveals the strengths and limitations of each method, while the introduction of innovative materials paves the way for enhanced applications.

Moreover, the article includes case studies demonstrating successful thin film welding in fields such as aerospace and electronics, emphasizing its impact on manufacturing efficiency metrics. Lastly, the discussion on future prospects and challenges outlines the ongoing developments and potential barriers that might affect the growth of thin film welding technologies in the coming years, making it a vital area of study for engineers and manufacturers alike.