You know, in the last few years, China has really stepped up its game in the global manufacturing scene, especially when it comes to Metal Weld technology. They’re becoming a real powerhouse in quality production. A recent report from Research and Markets even predicts that the global metal welding market could hit $31.22 billion by 2026! That's huge!

I mean, this growth is largely thanks to the rising demand in various sectors like automotive and construction. One company leading the charge is Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. With over 20 yearsunder their belt, they specialize in ultrasonic plastic Welding Systems and equipment. It’s pretty impressive! Their commitment totop-notch quality means industries all around the world are getting to use some of the best ultrasonic welding solutions out there, which really helps boost China's reputation for quality manufacturing and innovation in metal welding processes.

You know, in today’s cutthroat world of global metal weld manufacturing, after-sales service is really standing out as a key player in keeping customers happy and ensuring everything runs smoothly. It’s not just about cranking out top-notch welding machines; it’s equally about how well manufacturers can support their customers after they make a purchase. Honestly, that exceptional after-sales service can really set a company apart from the rest, offering customers not just help but also some peace of mind while they work with that complex machinery.

And let’s face it, having solid after-sales support can really strengthen the bond between manufacturers and their clients. You see, companies that put a lot of emphasis on things like training, maintenance, and quick responses to service requests tend to build this fantastic reputation for being reliable and just plain excellent. It’s like a win-win! Not only does this boost customer satisfaction, but it also increases the chances of getting return business and useful referrals. Plus, in China’s ever-changing metal weld manufacturing scene, getting a grip on how crucial after-sales service is can make a huge difference for growth and reputation. It really reinforces the pride that the nation has in its manufacturing prowess on the world stage.

When it comes to global metal weld manufacturing, maintenance costs are a big deal for keeping things running smoothly and staying profitable. A recent report from the International Institute of Welding (IIW) found that manufacturers often allocate a whopping 15-25% of their total maintenance budget just for welding equipment. This really highlights how important it is to stay on top of regular maintenance if you want to avoid those costly downtimes and keep producing high-quality work.

Plus, there’s this study from Deloitte that suggests if you adopt proactive maintenance strategies, you could cut down on unexpected failures by as much as 30%! In the cutthroat world of global manufacturing, especially with China being such a heavyweight, getting a grip on these maintenance costs is super important for staying ahead of the curve.

By using advanced predictive maintenance tech, not only can you make better use of your resources, but you can also extend the life of your welding gear. That means more productivity and lower operational costs. So, for any manufacturer wanting to stay on top in this increasingly competitive market, embracing these strategies is really essential.

You know, China’s metal weld manufacturing is really making waves on the global stage lately. A big part of that comes from their focus on not just cranking out high-quality products, but also providing top-notch after-sales support. In today’s fierce market competition, having solid after-sales services can really tip the scales for clients, and it’s impressive how Chinese manufacturers have woven this into their business strategies. By being there for their customers with timely support, maintenance, and repair help, they’re keeping downtime to a minimum. This really boosts customer satisfaction and keeps them coming back for more.

Plus, with all the buzz around new technologies like laser welding, the whole metal fabrication scene is changing fast! Experts predict that the global laser welding market is going to grow quite a bit, which shows that everyone’s on the lookout for more efficient and precise ways to manufacture things. And with cool innovations in additive manufacturing, companies are really taking advantage of new production avenues. We’re seeing some exciting successes in niche markets. These advancements really highlight how strategically positioned China is in the global landscape, showcasing not just their tech skills but also their all-around commitment to keeping clients happy with fabulous after-sales support.

| No. | Manufacturing Aspect | Description | After-Sales Support Factor | Rating (1-5) |

|---|---|---|---|---|

| 1 | Quality Control | Rigorous testing and inspection processes to ensure high standards. | Warranty Services | 5 |

| 2 | Technology Integration | Utilization of advanced manufacturing technologies like robots and AI. | Technical Support | 4 |

| 3 | Skill Development | Investments in workforce training and skill enhancement. | Training Programs | 5 |

| 4 | Customization | Ability to produce tailored solutions for specific client needs. | Personalized Service | 5 |

| 5 | Research and Development | Continuous innovation to improve products and processes. | Product Updates | 4 |

In today’s competitive world of global metal welding, keeping repair costs in check is super important. You know, having the right strategies can really boost how smoothly things run and, at the same time, make a big difference to the company's profits. There are quite a few approaches companies can take—like setting up predictive maintenance schedules, investing in top-notch welding gear, and using the latest monitoring tech. By catching potential problems before they turn into expensive repairs, businesses can really streamline their workflow and make the best use of their resources.

Take Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. for instance. They really shine when it comes to welding technologies, especially with ultrasonic plastic welding. With over two decades in the game, Chengguan offers cutting-edge ultrasonic welding systems and equipment tailored for all sorts of industrial needs. By jumping on these advanced tech solutions, manufacturers can cut down the chances of botched welds and the costly repairs that come with them. As the market keeps changing, businesses that think outside the box and revamp their welding processes will not only maintain China’s strong reputation in global manufacturing but also bring those costs down effectively.

You know, these days, keeping customers loyal is all about providing top-notch service, right? Well, in China, the metal weld manufacturing scene really stands out, especially because they put a big emphasis on after-sales support. A solid after-sales service doesn’t just tackle customer concerns – it actually builds that all-important trust in the brand. Companies that are quick to handle maintenance, solve problems effectively, and offer some training get to create strong, lasting connections with their clients. When manufacturers really take the time to understand what their customers need, they can tweak their services to make folks even happier.

Here’s a little tip: setting up a feedback loop can really boost that after-sales service. If companies regularly ask for customer input, they can catch any issues and fine-tune their service strategies.

And let’s not forget about education! If customers know how to use and maintain their products properly, it can seriously cut down on the number of issues they report. Providing detailed manuals, helpful online tutorials, or even having a team ready to support can really make customers feel appreciated and empowered.

Oh, and one more thing! How about launching a customer support app? It could be a game changer, giving users easy access to resources, letting them submit service requests, and keeping the line of communication open with support staff. It's all about creating a smooth experience that leaves everyone feeling satisfied.

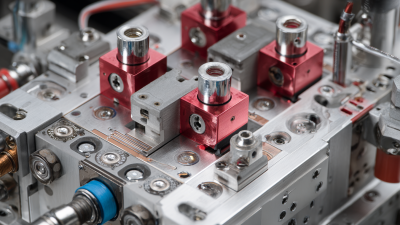

When selecting the right metal welding machine for copper wire welding and cutting, understanding the benefits of low-temperature welding is crucial. A significant advantage of this method is the elimination of high-temperature metal melting, which minimizes the risk of deformation and brittleness in the base material. According to a report by the International Institute of Welding, low-temperature welding can reduce thermal distortions by up to 60%, making it particularly effective for applications where material integrity is paramount.

Moreover, modern welding technologies are shifting towards eco-friendly practices. Machines that operate without flux or filler materials not only contribute to a cleaner working environment but also comply with stringent environmental regulations. The absence of harmful gases and slag aligns with the sustainability goals embraced by many industries today. A study from the Welding Technology Institute indicates that using these eco-friendly methods can decrease post-welding cleaning efforts by nearly 40%, thereby enhancing operational efficiency.

High welding quality is another critical factor to consider when choosing a welding machine. The joints created through advanced techniques display remarkable strength and excellent sealing properties, which are essential for applications in automotive and aerospace industries where quality standards are exceptionally high. Furthermore, these machines exhibit strong adaptability, capable of welding various metal combinations, including dissimilar metals like copper-aluminum and nickel-stainless steel. This versatility allows for broader applications, catering to industries that require precision and reliability in their welding processes.

: Effective strategies include implementing predictive maintenance schedules, investing in high-quality welding equipment, and utilizing advanced monitoring technologies to proactively identify potential issues.

Chengguan specializes in ultrasonic welding systems that minimize the risk of defective welds, thereby reducing the subsequent repair costs associated with rework.

Strong after-sales service addresses customer concerns, enhances brand trust, and fosters long-lasting relationships, ultimately leading to increased customer loyalty.

Companies can enhance after-sales service by offering timely maintenance, effective problem resolution, user training, and implementing feedback loops for continuous improvement.

Educating customers about product usage and maintenance can decrease the frequency of issues, as informed customers are better equipped to utilize products effectively.

Companies can provide comprehensive manuals, online tutorials, and dedicated customer support to empower users and improve their overall experience.

Companies can launch customer support apps that allow users to access resources, submit service requests, and communicate with support staff, enhancing overall satisfaction.

Proactively identifying potential issues before they escalate into costly repairs enables organizations to streamline operations and maximize resource allocation.

Investing in high-quality welding equipment reduces the likelihood of defects, leads to better performance, and ultimately lowers repair costs.

Regularly soliciting input from customers through feedback loops allows companies to identify areas for improvement and adjust service strategies, leading to enhanced customer satisfaction.