Picking the right manufacturer for your Acrylic Welding Machine isn’t exactly a walk in the park. The market’s flooded with options, each claiming to be the best, but let’s be honest — not every one of them actually lives up to those promises. The experience a company has and how well they control quality can seriously make or break the final product you get.

When you're weighing your choices, it’s a good idea to check out their reputation and what other customers are saying. If you can find companies that specialize in Acrylic Welding Machines — and have been around for a while — that’s generally a good sign. A long track record usually hints at reliability and steady quality. But hey, even the most established guys aren’t perfect or without their flaws.

Don’t forget to ask specific questions about what the machines can do and what kind of warranty they offer. Some companies are super transparent and give detailed specs — others might keep things a bit vague. That kind of openness or lack thereof can really impact whether you end up happy with your choice. The goal is to find a partner that actually makes your production smoother, not more complicated. So, take your time and choose wisely — you’ll thank yourself later.

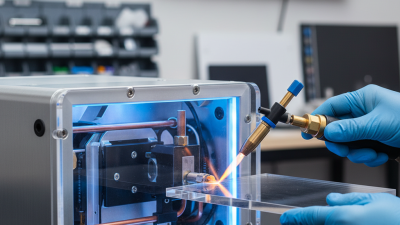

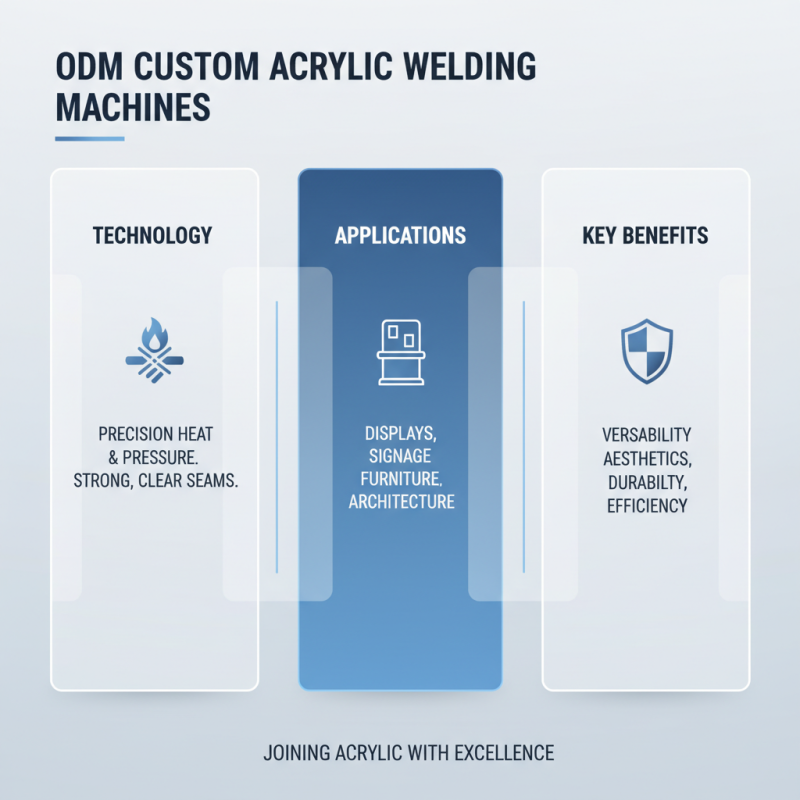

ODM custom acrylic welding machines play a crucial role in various industries. These machines are designed to join acrylic materials through precise heat and pressure. This technique ensures strong, clear seams that retain the material's aesthetic qualities. Users often utilize these machines for crafting displays, signage, and even furniture. The versatility of acrylic makes it a popular choice across different applications.

When considering an ODM custom acrylic welding machine, understanding its applications is vital. Many industries require specific welding techniques tailored to their needs. For example, the quality of seams can vary depending on the thickness of acrylic. Some users might encounter challenges with consistency. Ensuring that the machine can handle varying material types is essential.

Attention to detail cannot be overlooked. Machine specifications should match project requirements to prevent errors. It's also important to consider operator training. Without proper guidance, even the best machines can underperform. Testing and refining processes might be necessary to achieve desired results.

Choosing the right manufacturer for ODM custom acrylic welding machines requires careful consideration of their reputation. A company's reputation serves as a window into its quality and reliability. Businesses often rely on online reviews, industry ratings, and customer testimonials to gauge this. Positive feedback can signal strong performance, while negative reviews may indicate potential issues.

Reputation also reflects the manufacturer's experience and expertise. Companies with a long-standing presence in the market often have established efficient processes. They may use advanced technology and adhere to industry standards. However, not all reputable manufacturers guarantee the best results. It's essential to delve deeper into their past projects. Some may have impressive credentials but fail in delivering on time, which could disrupt your operations.

A solid reputation should accompany transparency. Look for manufacturers who openly discuss their methodology and offer clear pricing. Beware of those who hide vital information. Some companies may exaggerate their capabilities. It’s crucial to ask for case studies or examples of their work. Understanding their strengths and weaknesses can help you make a knowledgeable choice. This way, you avoid potential pitfalls and ensure a smoother production process.

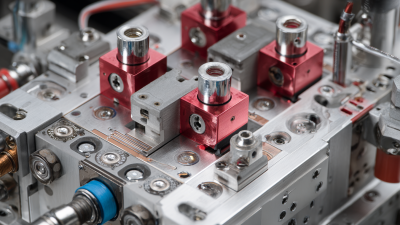

When selecting an ODM custom Acrylic Welding machine manufacturer, focus on key specifications. Acrylic welding involves precision and durability. The machine's power is critical. According to industry data, machines with 1000-2000 watts are ideal for standard acrylic projects. This range ensures strong welds without overheating the material.

Consider the machine's versatility. Some models are designed strictly for acrylic welding, while others can handle various plastics. A multifunctional machine might save costs in the long term. Also, evaluate the size and weight. A portable machine can be beneficial for on-site work. However, heavier machines often provide more stability during operation.

Another important specification is the warranty offered by the manufacturer. Some industry reports suggest that a warranty of at least two years is a good indicator of quality. Manufacturers who back their products tend to produce more reliable machines. It’s important to note that not all manufacturers meet these standards. Some tools fail to deliver, leading to rework and wasted materials. Careful consideration of these factors is essential for successful acrylic welding.

| Specification | Considerations |

|---|---|

| Welding Speed | Assess the machine's speed to ensure it meets production needs. |

| Wattage | Higher wattage typically results in more powerful and efficient welding. |

| Temperature Control | Look for adjustable temperature settings for different acrylic thicknesses. |

| Ease of Use | Ensure the machine is user-friendly and has clear controls. |

| Safety Features | Look for features such as emergency shut-off and protective covers. |

| Warranty and Support | Consider the length of the warranty and support options available. |

| Size and Portability | Evaluate the dimensions for your workspace and transport needs. |

| Material Compatibility | Ensure the machine is compatible with the types of acrylic you will use. |

| Customer Reviews | Research feedback from other users regarding their experiences. |

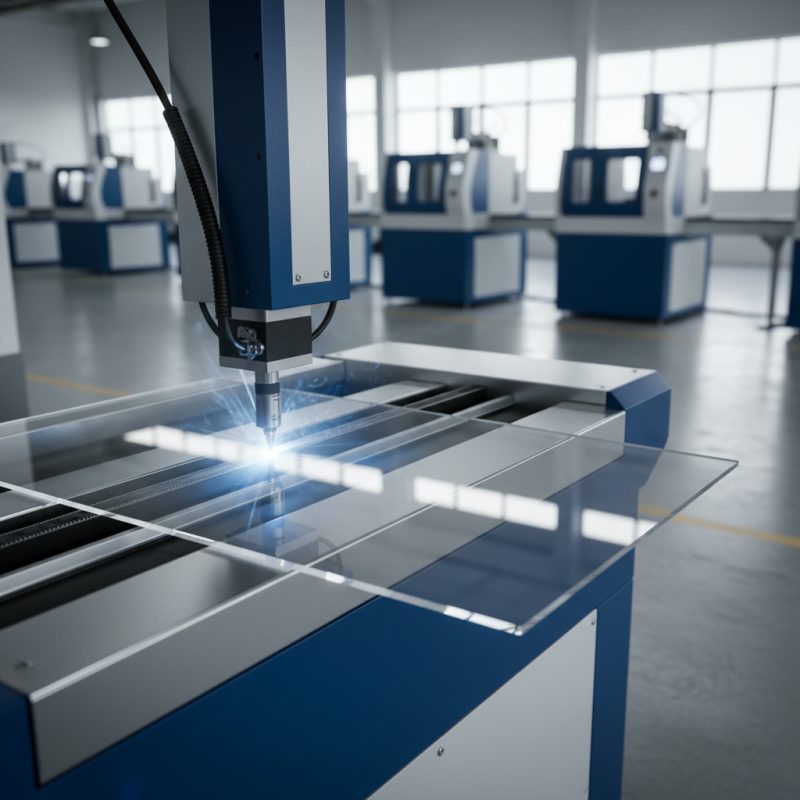

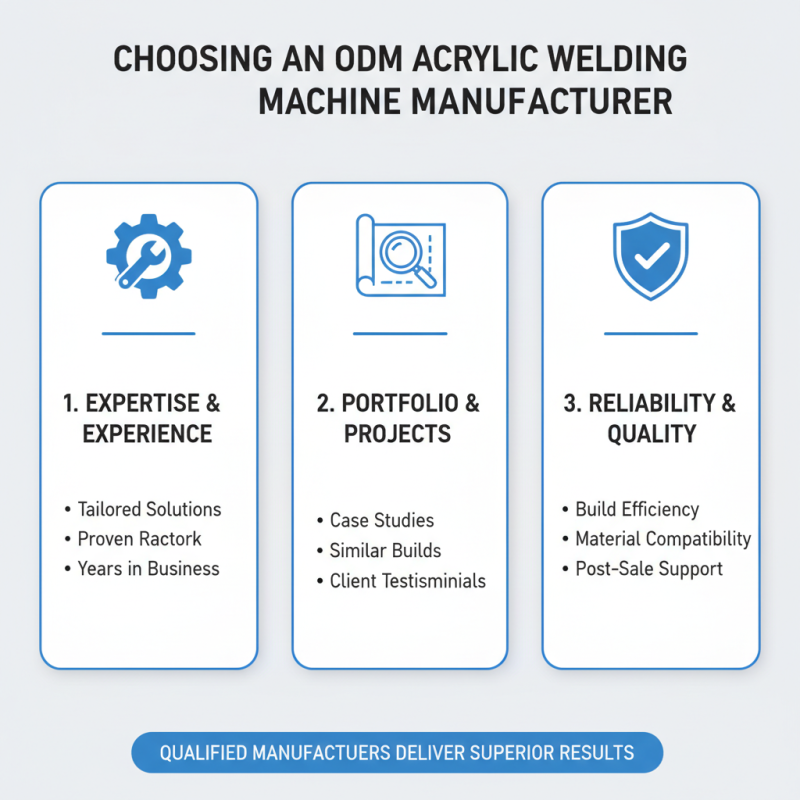

When searching for an ODM custom acrylic welding machine manufacturer, expertise is crucial. Look for manufacturers that have experience in creating tailored solutions. Evaluate their portfolio and past projects. A manufacturer who has completed similar projects successfully is often more reliable. Their expertise can lead to better quality and efficiency.

Understand the technology behind the Professional Welding Machine they produce. Ask about the materials used and their fabrication techniques. A knowledgeable manufacturer will provide clear answers. They should also engage in discussions about your specific needs. It's essential to determine if they can adapt their machines for your projects.

Consider their customer support as well. A strong manufacturer will offer comprehensive guidance. They should assist you from the initial inquiry to the final delivery. Review feedback from previous clients. This can provide insights into their reliability and commitment. Manufacturers should be receptive to suggestions, as this leads to better solutions. Remember, experience alone isn't enough; the willingness to innovate and improve is vital.

Choosing the right ODM custom acrylic welding machine manufacturer involves careful consideration of quality assurance and compliance standards. Quality assurance ensures that the machines meet specific performance criteria. Compliance standards relate to safety regulations and industry best practices. Both elements are crucial for the longevity and efficiency of the equipment.

Tips for evaluating manufacturers: Look for those with ISO certifications. This demonstrates a commitment to quality management. Check their history with compliance. A track record of meeting industry standards is a positive sign. Don’t hesitate to ask for references. Feedback from previous clients can reveal much about their experiences.

Quality issues can arise from poor manufacturing practices. A machine that fails to meet standards can lead to production delays. It’s important to reflect on these risks. Are you prioritizing compliance over cost? Remember, quality machines save money long-term. Investing in a reputable manufacturer leads to better outcomes and less stress over time.

When choosing an ODM custom acrylic welding machine manufacturer, analyzing cost structures is essential. The initial expense is only part of the equation. Consider ongoing costs, like maintenance and operation. A cheap machine may lead to high operational costs. Hidden fees can drain your budget quickly.

Return on investment (ROI) is another crucial factor. Look into the efficiency of the Polyethylene Welding Machine. A more efficient machine may have a higher upfront cost but can save money in the long run. Shorter production times lead to increased output. Assess how each option aligns with your production goals to avoid regrets.

Remember, the manufacturer's reputation matters. Research their history and client feedback. Products can vary, and not all manufacturers deliver quality. Consider visiting their facilities. Observing operations can provide insight into their commitment to quality. Balance your financial investment with the quality you expect for long-term success.

Choosing the right ODM custom acrylic welding machine manufacturer is essential, but customer support is critical. Effective communication ensures smooth operations. When manufacturers provide excellent after-sales service, you can handle any issues promptly.

Tips: Check response times. A manufacturer with fast replies shows commitment. Ask potential partners about their support channels. Support through chat, email, and phone is valuable.

Look for manufacturers who offer training with their machines, like the Portable Hand Welding Machine. This training can save time and reduce errors. Consider their warranty policy. A solid warranty reflects a manufacturer’s confidence in their product. All of these factors play a role in your decision.

Not every manufacturer prioritizes after-sales service, leading to frustration during production. Some might promise great support, but can’t deliver when it matters. Reflect on the experiences of others before making a choice. Learning from others' mistakes is key in this process.

: It is designed to enhance daily living and provide convenience. People often find it improves their routines.

Follow the included instructions carefully. Start with small amounts to avoid overwhelming effects.

Some users report mild discomfort. It's important to listen to your body and adjust usage accordingly.

Mixing with other items may not be recommended. It's best to consult a guide before trying combinations.

Keep it in a cool, dry place. Improper storage may affect its performance and quality over time.

Not everyone reacts the same way. Individual sensitivities can vary, so monitor your response closely.

The duration of effects can differ among users. Some notice changes quickly, while others may take more time.

Stop using it immediately and consult a healthcare professional if necessary. Reflecting on dosage is crucial.

Consistency is key. Also, maintaining a proper diet and lifestyle enhances effectiveness.

Policies vary; check the provider's guidelines. Ensure to keep receipts for possible refunds.

When selecting an ODM custom acrylic welding machine manufacturer, it's crucial to understand the specific applications of acrylic welding machines and the advantages they offer. Evaluating the reputation of the manufacturer can significantly influence your choice, as a reputable company often indicates reliability and quality. Additionally, potential buyers should consider key specifications that align with their production needs, along with the manufacturer's expertise in providing tailored solutions.

Quality assurance and compliance standards play a vital role in ensuring the safety and efficiency of the equipment. Moreover, analyzing cost structures and potential return on investment (ROI) is essential for making financially sound decisions. Lastly, effective customer support and after-sales service are critical components that enhance the overall experience of working with a manufacturer, ensuring that any challenges encountered post-purchase can be efficiently addressed.