In the fast-changing world of industrial manufacturing, picking the right Plastic Spot Welder isn’t just a small detail — it’s actually pretty crucial if you want things to run smoothly and get top-quality products. Market trends show that the ultrasonic Plastic Welding industry is on the rise, expected to hit around $1.65 billion by 2027. That just goes to show how much demand there’s been for more precise joining techniques, especially in sectors like automotive, electronics, and medical devices. I’ve got to say, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been a real leader in this space for over 20 years. They offer advanced ultrasonic welding systems designed to meet the unique needs of different manufacturers. As companies look to step up their welding game, it’s super important to really understand the specific application needs and tech capabilities of various Plastic Spot Welders. Making an informed choice here can make all the difference in hitting your project goals and getting the results you want.

In the fast-changing world of industrial manufacturing, picking the right Plastic Spot Welder isn’t just a small detail — it’s actually pretty crucial if you want things to run smoothly and get top-quality products. Market trends show that the ultrasonic Plastic Welding industry is on the rise, expected to hit around $1.65 billion by 2027. That just goes to show how much demand there’s been for more precise joining techniques, especially in sectors like automotive, electronics, and medical devices. I’ve got to say, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been a real leader in this space for over 20 years. They offer advanced ultrasonic welding systems designed to meet the unique needs of different manufacturers. As companies look to step up their welding game, it’s super important to really understand the specific application needs and tech capabilities of various Plastic Spot Welders. Making an informed choice here can make all the difference in hitting your project goals and getting the results you want.

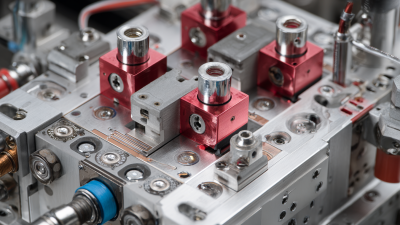

So, if you're trying to pick out the right plastic spot welder for your project, it’s pretty important to get a good grip on how plastic spot welding actually works. Basically, it’s a process where you join thermoplastics by pressing them together and applying heat through electrodes. Trust me, this method works really well for making strong, durable seams—whether you're working on cars, electronics, or everyday consumer stuff. Getting to know the different types of welders and what they can do can really help you improve your results and avoid headaches.

Now, here are some tips to keep in mind:

1. **Think About Your Project Needs** — Before you buy, take a moment to consider what types of plastics and how thick they are. Different welders have different power options, so finding one that matches your materials will ensure your seams are solid.

2. **Pay Attention to Features** — Look for welders with good temperature controls, adjustable timers, and safety features. These little things make a big difference when it comes to getting tidy, precise welds, and they also help keep your equipment in good shape.

3. **Do Your Homework** — Spend some time checking out online reviews and user feedback. Learning from folks who’ve already tried different models can really point you in the right direction and help you avoid costly mistakes.

Getting a handle on these basics and tips can make a huge difference in choosing the right tool for your project—and save you from a lot of frustration down the line.

| Feature | Importance | Considerations | Example Materials |

|---|---|---|---|

| Power Output | High | Ensure the welder can handle your material thickness | Polyethylene, Polypropylene |

| Control Features | Medium | Look for adjustable timers and voltage settings | Acrylonitrile Butadiene Styrene (ABS) |

| Portability | Variable | Consider if you need a stationary or portable option | PVC, CPVC |

| Heat Time | High | Shorter heat time may improve productivity | Polycarbonate, POM |

| Safety Features | Very High | Overheating protection and safety guards are essential | Nylon, PET |

When you're on the hunt for the right plastic spot welder for your project, it helps to understand a few key features—that way, your welding experience not only gets better but also the results speak for themselves. For starters, one of the most important things to look at is the machine's power controls. I’ve read in a report from the American Welding Society that a welder with adjustable power settings is a real game-changer because it allows you to work with different types of plastics, making sure you get a solid fusion without messing things up. Ideally, you want a welder that offers a range of power options—somewhere between 200 and 600 watts—so you can handle all sorts of tasks with ease.

Then there's the tip design and size. This might seem like a small detail, but it actually makes a huge difference in the quality of your weld. According to a study published in the Journal of Plastic Welding Technology, a conical tip tends to do a better job of penetrating and reducing thermal spread, which results in a cleaner, more efficient weld. Plus, if you go for a welder that has interchangeable tips, you’re kind of set—you're able to adapt to different materials, whether you're working with thin films or thicker pieces, without breaking a sweat. So, as you start comparing models, definitely keep an eye out for ones that come with a variety of tips—they'll give your project the versatility and precision it needs.

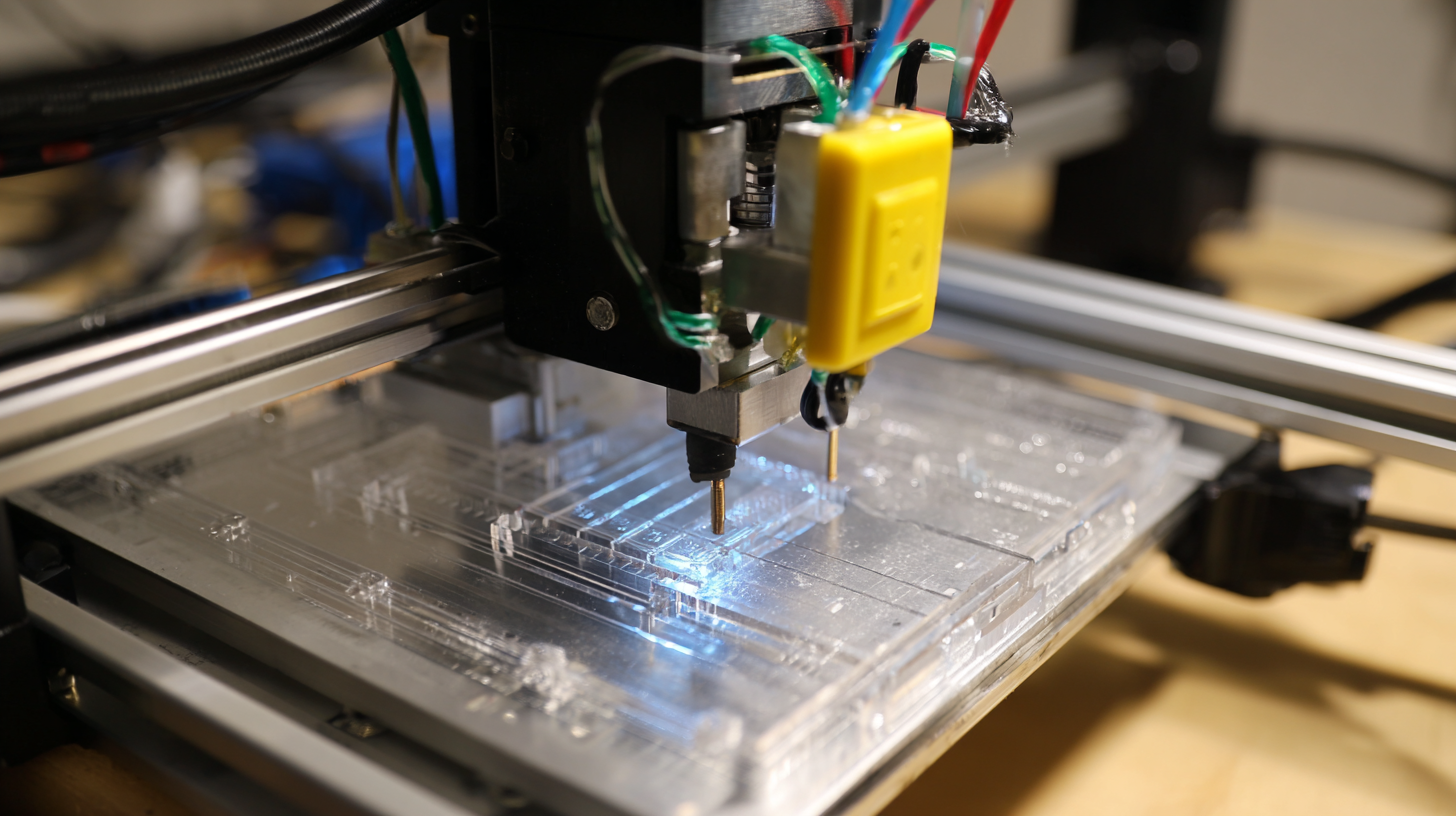

When you're picking out the right plastic spot welder for your project, it’s pretty important to consider the power and temperature controls—it really depends on the materials you're working with and how sturdy you need the finished product to be. Recent studies show that managing heat properly is super crucial in a bunch of different applications. For example, there was this big review of how heat pumps work in residential buildings, and it turns out that different electricity rate plans can really affect how flexible and efficient the heating system is. Basically, that means choosing a spot welder with adjustable power settings can really improve performance—kind of like how electric heating systems adjust based on energy costs at the moment.

When you're picking out the right plastic spot welder for your project, it’s pretty important to consider the power and temperature controls—it really depends on the materials you're working with and how sturdy you need the finished product to be. Recent studies show that managing heat properly is super crucial in a bunch of different applications. For example, there was this big review of how heat pumps work in residential buildings, and it turns out that different electricity rate plans can really affect how flexible and efficient the heating system is. Basically, that means choosing a spot welder with adjustable power settings can really improve performance—kind of like how electric heating systems adjust based on energy costs at the moment.

Also, getting a good grip on the thermal conditions of your workspace can help you make smarter choices. There’s been some research on combined heat and power systems that highlights how important it is to look at both plant and system-wide performance, especially when dealing with things like carbon capture tech. This kind of info points to the fact that a plastic spot welder which can keep a steady temperature might be a total lifesaver for projects that need complex designs and a strong bond—it helps make sure the materials stay solid and reliable, even under stress.

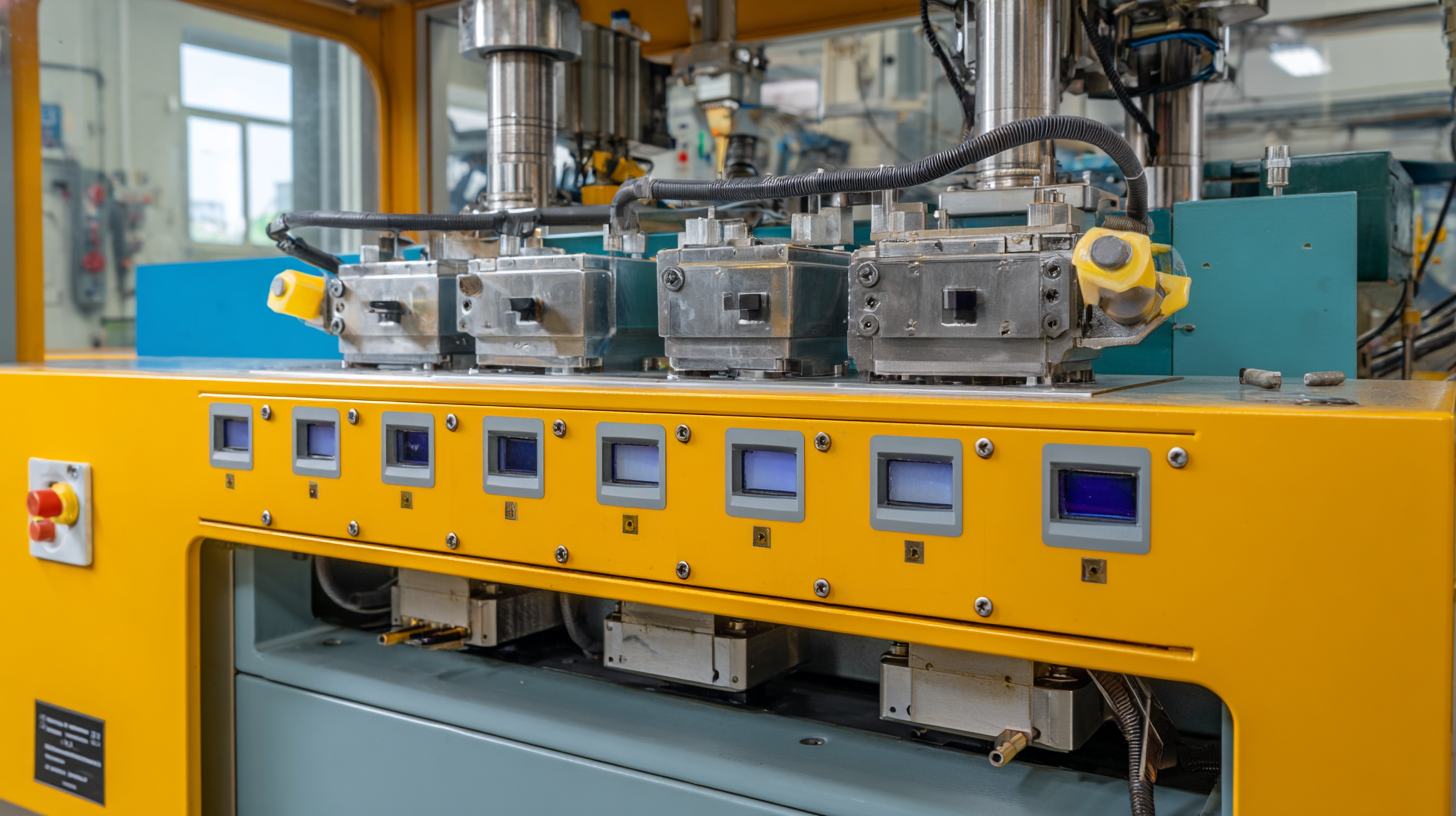

When you're picking out a plastic spot welder for your project, it’s pretty important to think about whether it’ll work well with different types of plastics. You see, plastics like polyethylene (PE), polypropylene (PP), and PVC all behave differently when heated and pressed, which can really influence how they weld together. So, having a good idea of their melting points and how well they conduct heat can make a big difference—it helps you pick a machine that's up to the task.

Also, it’s worth considering what kind of welding method works best for the plastics you're dealing with. For example, some materials might need more pressure or specific electrode shapes to get a solid bond. Checking out the welder’s features—like adjustable temperature controls and power settings—can make your life easier and help you get cleaner, stronger results across different plastics. All in all, making sure the welder matches your materials is key to getting durable, reliable joints. Plus, it just makes the whole process smoother and less frustrating!

When you're choosing a plastic spot welder for your project, it's pretty important to keep the budget in mind. Based on industry reports, good quality ultrasonic welding machines usually run somewhere between $5,000 and over $20,000, depending on the features, capabilities, and who makes them. It's a good idea for companies to really think about what they need and how much they can afford. Remember, investing in a dependable welding system might seem costly upfront, but it can pay off in the long run — saving you money through better efficiency and less material waste.

Plus, as industries like sheet metal fabrication get more advanced with things like fiber laser cutting, don’t overlook the cool stuff ultrasonic welding can do. In fact, recent tech upgrades have shown it can boost production speed and quality without breaking the bank, proving that choosing the right welder can seriously make a difference.

Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has over 20 years of experience in this space, offering custom ultrasonic solutions that fit various budgets but still get the job done right. So, doing some proper research and chatting with knowledgeable suppliers can really help you find that sweet spot between your budget and the perfect welding equipment for your project.

When you're choosing a plastic spot welder, it's really important to keep comfort and safety features in mind. I mean, according to the Industrial Safety and Health Report from 2022, good ergonomics can actually make a big difference in preventing workplace injuries. They found that tools that aren’t designed well can bump up the risk of repetitive strain injuries by about 30%. So, going for a welder with ergonomic handles or adjustable grips isn’t just a nice bonus — it makes your job a lot easier and lets you work longer without feeling uncomfortable.

Safety's just as crucial, especially because welding involves high temps and some pretty serious hazards. A survey by the American Welding Society in 2023 showed that nearly 40% of workers experienced safety incidents due to not enough protective measures. That’s a pretty eye-opening stat! When shopping around, look for features like thermal overload protection, safety interlocks, and automatic shut-offs. These safety extras don’t just keep you safer — they can also help you stay productive by reducing downtime caused by accidents. Picking a welder that focuses on both good ergonomics and safety isn’t just smart — it really creates a better, more comfortable workspace and can even lead to better results on your projects.

: It is crucial because different plastics like polyethylene, polypropylene, and PVC have distinct properties that affect their reaction to heat and pressure during the welding process, influencing the choice of welder necessary for optimal results.

Understanding the melting temperatures and thermal conductivity of the plastics you will be using is important as it helps in selecting a welder that can appropriately accommodate the specific requirements and prevent damage to the materials.

Different materials may require varying pressure levels and specific electrode shapes to achieve strong bonds, making it essential to consider the welding technique that matches the plastic material for effective welding.

Features like adjustable temperature settings and power settings are important as they enhance the ability to work efficiently with different types of plastics.

Ergonomics are important because they reduce the risk of repetitive strain injuries, allowing operators to work for longer periods without discomfort, which is crucial for overall productivity and safety.

Prioritize safety features such as thermal overload protection, safety interlocks, and automatic shut-off, as these not only protect users from hazards but also enhance productivity by reducing downtime due to accidents.

Ergonomic designs can significantly enhance ease of use and operator comfort, which helps to decrease the likelihood of workplace injuries associated with poorly designed tools.

Inadequate protective measures can lead to safety incidents, as nearly 40% of workers reported such occurrences, emphasizing the importance of choosing welders with proper safety features.

Choosing a welder that ensures compatibility with plastic materials and offers ergonomic and safety features can lead to improved efficiency, comfort, and overall project outcomes.

Improved user comfort through ergonomic designs can lead to increased efficiency and productivity, as operators are less likely to experience discomfort or injuries while using the equipment.

So, when you're trying to pick the right plastic spot welder for your project, it’s really important to get a good grasp of how plastic spot welding tech actually works. A few things you want to keep in mind? First, check out the power and temperature controls—make sure they match what you actually need. You also want to think about whether it can handle different types of plastics comfortably. Oh, and don’t forget about safety features and how easy the machine is to use—believe me, comfort matters, especially if you're doing long sessions. And of course, your budget is a big deal—you don’t want to overspend, but also don’t want to skimp on quality.

Now, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been around for 20 years, specializing in ultrasonic plastic welding. They've got a variety of products that can really help you get the best welds out of your equipment. By focusing on what your project actually needs, you can pick a plastic spot welder that fits your budget, while also boosting efficiency and keeping things safe and smooth on the shop floor.