When it comes to advanced manufacturing, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. really stands out as a leader in innovation and quality—especially in ultrasonic plastic welding. With over 20 years of experience under our belt, we've been pushing the boundaries with cutting-edge tech that’s used across a bunch of industries, from ultraSonic Welding systems to specialized equipment. Our latest project, the Bag Sewing Machines, really highlights our commitment to delivering top-notch solutions that meet the needs of customers worldwide. As we continue to lead the way in ultrasonic tech, this Bag Sewing Machine isn’t just another product—it's a real reflection of our core philosophy: '卓越制造,源自中国,服务全球,' which basically means exceptional manufacturing from China, serving the whole world.

Basically, in China's big manufacturing scene, bag making is going through some pretty exciting changes. Thanks to the latest Sewing Machines—those high-tech ones built for top-notch efficiency and quality—things are catching a real boost. As manufacturers keep adopting this new tech, the lessons learned from the biggest production hub are super valuable for any business wanting to step up their game. Automation and precision engineering are really making a difference by cutting down waste and making sure every bag meets the highest craftsmanship standards.

**Pro tip:** When you're choosing a bag sewing machine, think about how versatile it is. Machines that can handle different fabrics and styles not only save you time but also give you more flexibility to keep up with market trends on the fly.

And here's another thing—staying in the loop with the latest tech updates can really help you stay ahead of the competition. Features like programmable stitch patterns and easy-to-use interfaces can seriously boost your production line’s efficiency.

**Another tip:** Regular maintenance is key. Set up a routine to check on your machines so minor issues don’t turn into big problems later on. This way, you’ll keep things running smoothly and get the most out of your equipment—less downtime, more productivity.

| Machine Model | Stitches Per Minute | Power Consumption (W) | Weight (kg) | Price (USD) |

|---|---|---|---|---|

| Model A | 1200 | 300 | 45 | 1500 |

| Model B | 1500 | 350 | 50 | 1800 |

| Model C | 1000 | 250 | 40 | 1200 |

| Model D | 1600 | 400 | 55 | 2000 |

Come 2025, the world of bag sewing machines is really about to change in a big way — thanks to some groundbreaking tech innovations. China's top manufacturers are leading the charge, creating machines that aren’t just more efficient but also super precise and versatile. We're seeing a lot of fancy automation features and even AI integrated into these machines, which is totally shaking up how things are produced. It means businesses can move faster, adapt more easily to different demands, and still keep quality on point—all while cutting down on wait times.

And it’s not just about fancy tech. Sustainability is becoming a huge deal, too. More companies are now using eco-friendly materials and designing energy-efficient machines, really showing they care about reducing their environmental impact. As these manufacturers pour more resources into R&D, they’re not only improving their products but also helping push the industry toward a more sustainable future. This mix of innovation and eco-consciousness positions China as a real leader in making bag sewing machines, and it’s exciting to think about the kinds of new things that’ll come out of this in the years ahead.

So, the bag sewing machine market right now is going through quite a shake-up, and a lot of it has to do with current industry trends. Looking ahead to 2025, it’s clear that tech upgrades and new innovations are really changing how things get done—making processes smoother and more efficient. For example, lots of manufacturers are now bringing automation into their factories. Not only does this speed things up, but it also boosts precision and the overall quality of the products. Recent reports suggest that using automated textile equipment can bump up productivity by as much as 30%. That’s a huge deal if companies want to stay competitive out there, you know?

On top of all that, sustainability is becoming a huge deal in this industry. More and more companies are jumping on the eco-friendly bandwagon, using sustainable materials and greener production methods. Turns out, consumers are really paying attention—about 60% of folks are even willing to shell out a bit more cash for products made with sustainability in mind. That puts some serious pressure on manufacturers to keep innovating. Plus, studies show that investing in eco-friendly practices can actually save money in the long run, which is a win-win for both the environment and the bottom line.

And let’s not forget about the folks making all this happen—the skilled professionals in the bag manufacturing world. As recent research points out, giving workers advanced training and new technical skills is super important for keeping up with these rapid changes. When the industry is evolving so quickly, having a talented, well-trained team is key to making the most out of new tech and staying ahead of the game.

In the fast-moving world of bag manufacturing, having the right tools really can make all the difference. China's top factory specializes in making cutting-edge bag sewing machines that are built to fit the unique needs of different production lines. I recently came across a report from MarketWatch that predicts the global bag market will hit around $490 billion by 2027 — no joke! That just shows how much folks are craving efficient, flexible machinery to keep up with demand. These machines not only boost productivity but also allow manufacturers to adapt to various materials and styles, making sure they stay on top of market trends.

If you're serious about streamlining your production, investing in good quality sewing machines is a must. Here's a tip: look for machines that are versatile enough to handle different stitching styles—think eco-friendly totes or luxe leather bags. Features like programmable settings can really speed things up and cut down on downtime, which is a real game-changer.

As the market keeps changing, staying ahead means being proactive. My advice? Regularly review your production setup and keep an eye on the latest tech innovations—things like automated sewing solutions. Jumping on new tech can help make your operation smoother, improve the quality of your products, and leave your customers happy. At the end of the day, those sewing machines aren’t just tools—they're pretty much a strategic advantage in this competitive bag game.

Lately, the bag sewing world has really started focusing more on sustainability. You can see it in how leading factories in China are trying out new methods that cut down on waste and boost efficiency—all while still making top-notch quality products. They're using eco-friendly materials and greener processes, which not only help the environment but also set a pretty high standard for everyone else in the industry.

If you're looking to make your own bag sewing practices a bit greener, here are a few tips that might help. First off, go for eco-friendly fabrics—think recycled or biodegradable materials. It’s a simple way to lessen the environmental impact and also catch the eye of customers who care about sustainability. Next, try to use energy-efficient machines—this can really cut down on electricity bills and waste. And lastly, focus on making sturdy, long-lasting bags. When your products last longer, people don’t need to buy replacements as often, which means fewer resources consumed overall.

Honestly, caring about sustainability isn’t just some passing trend anymore; it’s becoming a key part of doing solid business. As more factories jump on board with these practices, the whole bag sewing industry is gradually moving towards being more responsible. It’s a step towards a greener, more mindful future.

In today’s fast-moving world of manufacturing, how smooth and efficient your operations are really depends a lot on the quality of your sewing machines. Upgrading to the latest sewing technology from top factories in China isn’t just a nice-to-have anymore — it’s pretty much a smart move to keep your business secure and ready for what's next. These modern machines are built to handle the changing demands of the market, offering incredible precision, speed, and durability that really stand out. As customers keep raising their expectations, bringing high-performance equipment into your production line can give you that extra edge you need to stay ahead of the game.

Plus, with all the recent advances in sewing tech, your shop can stay flexible and ready for new trends and hurdles that come up. Investing in these advanced machines isn’t just about boosting productivity — it also saves you money in the long run by cutting down on maintenance issues and reducing downtime. Thanks to their smart features and automation, modern sewing machines streamline what you do, cut waste, and help boost product quality overall. So, focusing on upgrading your gear isn’t just a good idea — it’s pretty much essential if you want to stay relevant, competitive, and quick to respond to what customers want next. Jumping on these new tech trends is honestly the best shot at building a strong, successful future in the fast-paced fashion and apparel world.

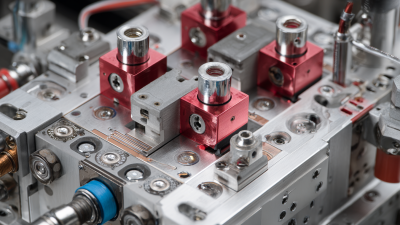

In today's fast-paced manufacturing environment, optimizing production lines is essential for maintaining competitiveness. Ultrasonic multi-station turntable automatic filling and sealing machines offer a revolutionary solution to enhance both efficiency and product quality. According to industry reports, automation in production can boost efficiency by over 30%, a significant gain that directly impacts the bottom line. These machines use advanced ultrasonic sealing technology, achieving speeds of 200 to 500 pieces per minute without the risk of contamination or leakage—features critical for sectors like cosmetics and pharmaceuticals.

The design of these machines is tailored for fully automatic, multi-station operations. A rotary multi-station system integrates automatic tube loading, precise quantitative filling, ultrasonic sealing, and material discharge detection in one seamless workflow. This collaborative approach not only minimizes human intervention but also ensures consistent performance and higher output. As manufacturers increasingly turn to automation, the adoption of ultrasonic filling and sealing machines stands out, positioning companies to meet growing demand while optimizing resource utilization and reducing operational costs. By transforming their production lines with this technology, businesses can ensure high-quality products and increased customer satisfaction, setting a new standard in the industry.

: By 2025, bag sewing machines are expected to undergo significant transformations driven by technological innovations, enhancing efficiency, precision, and versatility.

Chinese manufacturers are leading the development of advanced sewing machines that integrate automation features and artificial intelligence, streamlining production processes and maintaining high quality standards.

Sustainability is becoming crucial as manufacturers are adopting eco-friendly materials and energy-efficient designs, which reflects a commitment to reducing the environmental impact of production operations.

Advanced sewing machines offer unparalleled precision, speed, and durability, allowing manufacturers to meet evolving market demands and enhance productivity while reducing long-term maintenance costs.

Upgrading to modern sewing machinery can improve operational efficiency by streamlining workflows, minimizing waste, and improving overall product quality.

Automation in modern sewing machines helps to enhance productivity, reduce lead times, and adapt production processes to new consumer trends and challenges.

Investing in research and development is crucial as it fosters technological advancements and sustainable practices, positioning manufacturers for future growth in the textile industry.

By integrating high-performance sewing equipment and continuously upgrading their machinery, manufacturers can respond swiftly to consumer preferences and remain competitive in the fast-paced market.

Smart technologies in sewing machinery allow for streamlined operations, efficient workflows, and improved production quality, contributing to a reduction in downtime and operational costs.

The convergence of technology and sustainability in manufacturing creates a new standard, allowing companies to innovate while being mindful of their environmental impact and promoting a more sustainable future.