You know, in the fast-changing world of manufacturing these days, it’s clear that folks are really rethinking old-school methods like Wire Harness Welding. According to a recent report from Grand View Research, the global marketfor ultrasonic Welding Equipment is estimated to hit around$1.65 billion by 2027. That’s mostly because of new tech breakthroughs and how widely these processes are being adopted across different industries.

At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been in the game for over 20 years, focusing on ultrasonic plastic welding. We’re pretty excited about this trend and are dedicated to offering smarter, more innovative alternatives to traditional welding. Our range includes ultrasonic welding systems and equipment that put us right at the forefront of this industry shift. It’s all about helping businesses boost their efficiency and make their products more reliable.

As we compare some of these fresh, innovative methods to the old wire harness welding techniques, we want to highlight how ultrasonic tech can really make a difference across various fields and applications.

The world of wire harness connectivity is really changing these days, thanks to some pretty exciting new technologies. You know, industries are looking for faster, more reliable ways to get connections done, so alternative methods to traditional wire harness welding are starting to catch on. Things like advanced adhesive bonding and laser joining are really stepping into the spotlight now—offering better performance and durability, all while shaving down production times. Plus, these methods not only make the connections stronger, but also help save weight, which is a big deal in fields like automotive and aerospace where every little bit matters.

And that’s not all—innovations like smart materials and self-healing polymers are really shaking things up. These materials can adjust to different environmental conditions, making sure everything stays reliable over time. Oh, and adding IoT—yep, the Internet of Things—capabilities into wire harnesses is pretty amazing, too. It allows for real-time monitoring and diagnostics, so maintenance becomes more proactive rather than reactive. As these techs keep evolving, it looks like we’re heading toward much more efficient, reliable electrical systems — pretty exciting times, right?

When it comes to finding more efficient ways to connect things, taking a closer look at different connection methods really sheds some light on the options out there beyond just sticking with the traditional wire harness welding. Honestly, the old-school methods often just don’t cut it when you need flexibility and scalability—especially in industries that are constantly shifting gears to new tech and designs. For example, recent research has shown that newer solutions like multi-silicone bilateral soft physical twins actually offer way better adaptability for remote operations, and they seem to outshine the usual interfaces quite a bit.

On top of that, comparing digital tools with traditional methods across various fields is pretty revealing. In education, for instance, studies have pointed out that digital tools tend to lead to better learning outcomes compared to good old textbooks. It’s kind of the same story in other areas too, like in teleoperated medical tech—remote palpation techniques are starting to challenge and even improve upon the standard practices we’re used to. And with machine learning getting better at predicting waste generation than those traditional methods, it’s clear that industries really need to take these new innovations seriously. They’re not just about speed anymore—they also push us towards more sustainable solutions in a world that’s changing faster than ever.

Honestly, these advancements are pretty exciting—they’re shaking things up and opening up new possibilities we didn’t even consider before.

You know, adhesive bonding is really starting to shake things up as a cool alternative to traditional wire harness welding when it comes to electrical assemblies. It’s a pretty exciting development because it tends to make connections more reliable while also keeping the manufacturing process simpler. Using adhesives gives manufacturers a lot more flexibility — they can design for all sorts of shapes and sizes without worrying about losing strength or durability. Plus, it reduces the heat stress on delicate electronic parts, which is a big deal since welding can sometimes damage or weaken sensitive components.

At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we get how important it is to stay ahead with cutting-edge tech in this fast-changing industry. With over 20 years under our belt in ultrasonic plastic welding, we’ve gone beyond just the basics. Our ultrasonic systems are built to support effective adhesive bonding, helping boost production speed and dependability. As companies push for smarter, more sustainable solutions, adopting adhesive bonding in electrical assemblies can really take performance to the next level. It’s all about pushing boundaries and staying committed to innovation and high-quality ultrasonic applications.

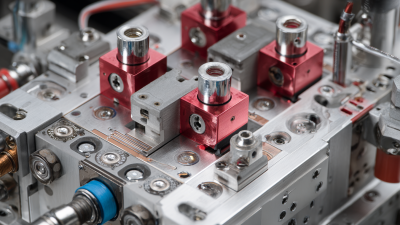

For ages, the automotive and electronics worlds have mostly relied on wire harness welding to connect everything inside their complex systems. But now, with 3D printing catching on, things are starting to change in a big way. It’s pretty exciting—this new tech lets manufacturers create custom wiring setups that are perfectly tailored to each specific job. Instead of mass-producing generic parts and wasting materials, companies can now print exactly what they need, which is a total game-changer for efficiency and waste reduction.

What's even cooler is that 3D printing makes it super easy to add extra features right into the wiring. Stuff like built-in connectors, protective covers, or even intricate shapes—no problem! This not only boosts overall performance but also makes the whole wiring system more flexible and adaptable to whatever tech advances come next. As more industries jump on the 3D printing bandwagon, we're likely to see a pretty big shift in how wiring is designed and made—moving us toward smarter, sleeker, and way more efficient connectivity options.

Hey, have you heard about how smart materials are really shaking up the wire harness world? It’s pretty exciting stuff — they’re not just making things smarter but also cutting down on costs big time. Industry folks say that by using lightweight, multifunctional materials, they can slash the weight of wire harnesses by up to 30%. That means better fuel economy for cars and snappier performance for electronics — who wouldn't be into that? These smart materials, like shape memory alloys and conductive polymers, are pretty amazing because they can adapt to their environment. They even have cool features like self-healing and better heat management, which are super important as tech keeps evolving so quickly.

Back in the game for over 20 years, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been leading the way with their ultrasonic plastic welding tech. Their equipment really helps boost production efficiency and keeps up with the rising quality standards in wire harness manufacturing. As automation and smart tech become the norm, using ultrasonic welding becomes more and more essential if companies want to stay competitive in this fast-changing industry. So yeah, it’s an exciting time for anyone involved in wire harness tech!

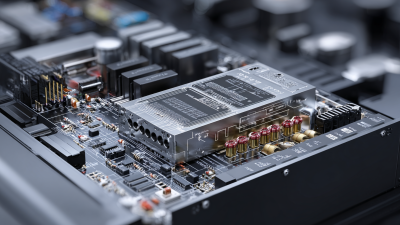

In the realm of advanced manufacturing, ultrasonic welding has emerged as a groundbreaking technique for plastic assembly, and the CGTC Series Ultrasonic Welding Machine stands at the forefront of this revolution. Featuring a robust thickened steel body and a concentric straight axis design, this machine ensures a stable structure and precise welding, which is critical for achieving consistent quality in production. Research indicates that more than 80% of manufacturers report enhanced structural integrity when utilizing advanced welding techniques, illustrating the necessity of reliability in assembly processes.

One of the notable advantages of the CGTC Series is its upgraded titanium alloy through-rod transducer, fully compatible with various materials such as steel, aluminum, and titanium molds. This versatility allows for diversified application scenarios, enabling manufacturers to adapt to different production needs without significant downtime. According to a recent market analysis, the demand for ultrasonic welding in plastic assembly is projected to grow by 25% over the next five years, driven by its ability to enhance operational efficiency and broaden application capabilities.

Moreover, the incorporation of a brand new operating system with support for 485 communication facilitates digital operation, making the machine user-friendly. The capacitance digital matching along with yellow and black ceramic tiles guarantees full compatibility and enhances the overall performance. Such innovations not only streamline processes but also reduce the learning curve for operators, further boosting productivity. As industries increasingly seek automation and precision, the CGTC Series Ultrasonic Welding Machine is poised to redefine standards in plastic assembly.

: Emerging technologies such as advanced adhesive bonding, laser joining, smart materials, and self-healing polymers are transforming wire harness connectivity, enhancing performance and durability while reducing production times.

These methods provide superior structural integrity and significant weight savings, which are essential for industries like automotive and aerospace, where minimizing weight is critical.

Smart materials enhance connectivity by making wire harnesses lighter and enabling functionalities like self-healing and improved thermal management, which contribute to better performance in vehicles and electronic devices.

The use of lightweight and multifunctional smart materials can reduce wire harness weight by up to 30%, leading to improved fuel efficiency and overall performance.

The integration of IoT capabilities enables real-time monitoring and diagnostics for wire harness assemblies, leading to proactive maintenance and increased reliability in electrical systems.

Chengguan has specialized in ultrasonic plastic welding solutions for over 20 years, enhancing the efficiency of wire harness production and supporting the innovative use of smart materials.

As the industry shifts towards smart technologies, incorporating automation helps manufacturers maintain a competitive edge and meet the rising demands for reliability and functionality.

Self-healing polymers can adapt to various environmental conditions, ensuring consistent performance over time, which is vital for the longevity and reliability of wire harnesses.

Laser joining techniques improve connectivity by providing quicker production times and enhanced durability, making them an appealing alternative to traditional welding methods.

The adoption of smart materials in wire harness design can lead to significantly reduced manufacturing costs due to their lightweight properties and multifunctional capabilities.

In the constantly changing world of electrical connections, wire harness welding has always been a key technique. But nowadays, new tech is really shaking things up and changing how we handle this important process. In this blog, we’re exploring some pretty exciting alternatives like adhesive bonding — which, honestly, can be a game-changer because it’s more durable and often makes assembly easier. We also compare these modern methods to the traditional ones, giving you a peek into how they can improve efficiency and even help manufacturers save money.

On top of that, the piece looks into how 3D printing is becoming a big deal for creating custom wiring solutions tailored to specific needs. Plus, there’s talk about smart materials that make wire harnesses more adaptable, responding to different conditions on the fly. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are really pushing boundaries with ultrasonic plastic welding tech, and all of this points to a future where old-school methods blend smoothly with cutting-edge innovations. It’s an exciting time for the industry, for sure.