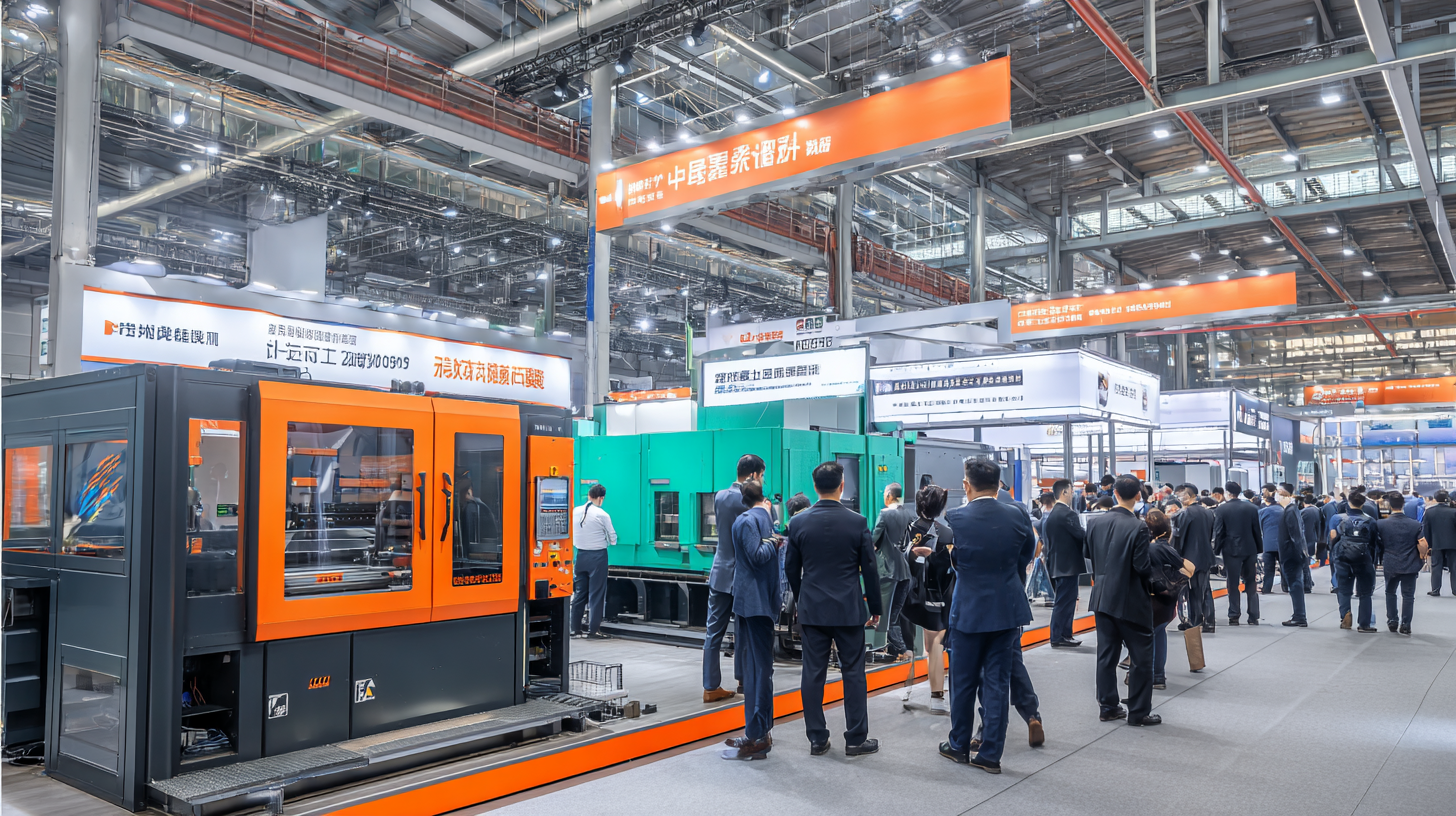

So, at the 138th Canton Fair in 2025, the spotlight’s really gonna be on some pretty cool, innovative techniques—especially Friction Welding. This method is totally changing the game in manufacturing across all kinds of industries. What’s so great about Friction Welding? Well, it’s known for being able to bond different materials really well without causing a ton of heat distortion, which is a big deal for precision. It’s actually catching on fast, and experts expect the global welding equipment market to hit around $20 billion by 2025. Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been riding this wave for a while now, leveraging over 20 years of experience in ultrasonic plastic welding. They’ve got a pretty wide selection of ultrasonic tools—everything from plastic welding systems to ultrasonic lace and cutting equipment—that help manufacturers work more efficiently. As industries keep shifting toward more advanced welding tech, what’s showcased at the Canton Fair will give a pretty good idea of where things are headed. It really highlights how Friction Welding is shaping the future of industry trends and innovation.

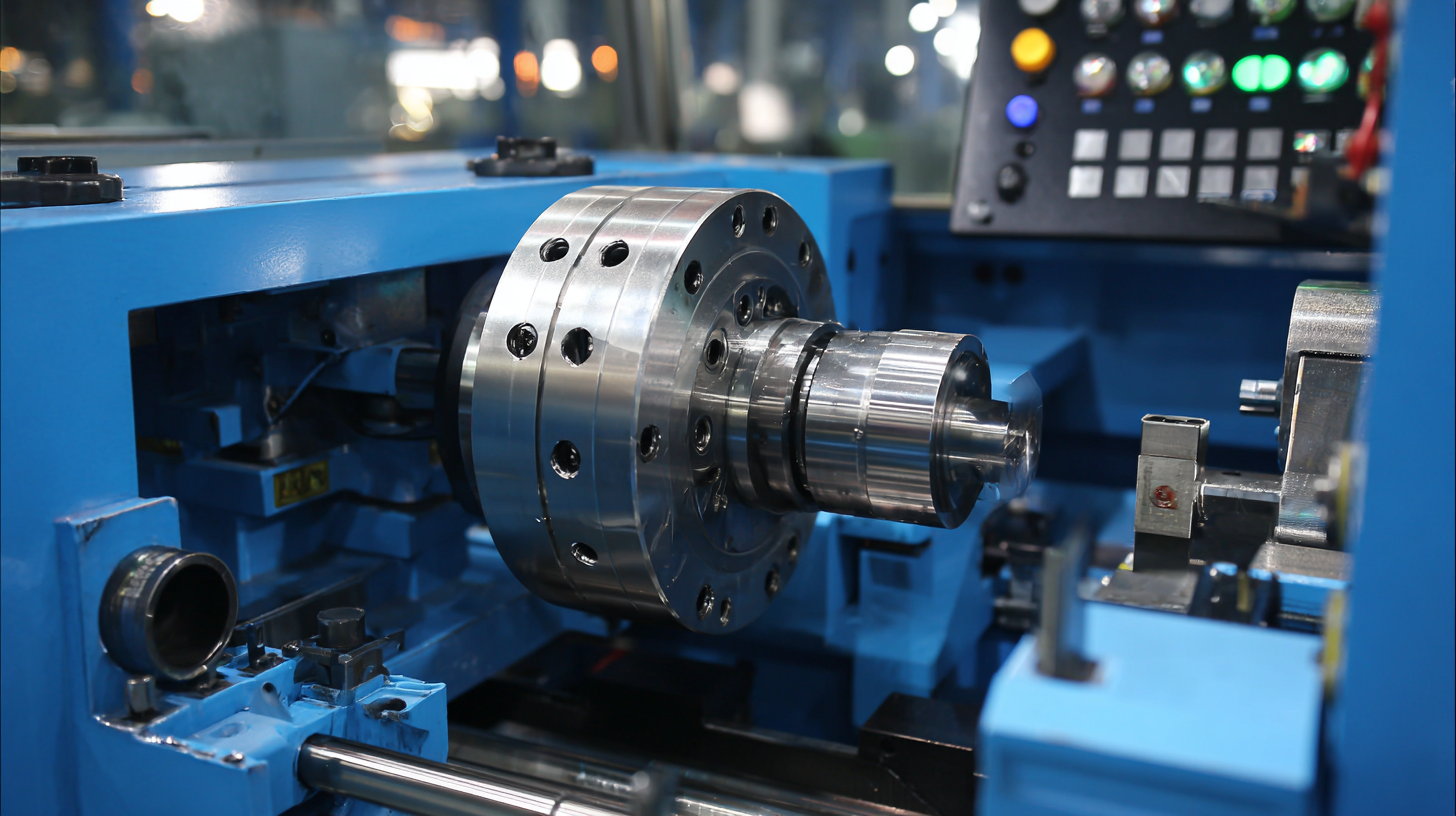

Hey, have you heard about Friction Welding? It's really shaking up the manufacturing world, and they showcased some amazing stuff at the 138th Canton Fair in 2025. Basically, this method uses heat from friction itself to bond materials together. It’s pretty clever because it makes super strong, durable joints — kind of a game changer for all sorts of industries. What’s cool is that, unlike traditional welding, it uses way less energy and doesn’t need a bunch of extra materials, so it’s more eco-friendly and sustainable overall.

At the fair, industry folks were pretty excited about how new advancements are making production faster and products better quality. They’re now turning to automated systems and real-time monitoring, which means things are more precise and consistent. That helps streamline the whole process and cut down on production time. As more companies jump on board with these techniques, not only are they seeing some serious improvements in their products, but they’re also moving towards greener, more sustainable manufacturing. The innovations shown at Canton really signal a big shift towards more efficient and environmentally-conscious industry practices.

This chart represents the adoption rates of different friction welding techniques over the past five years, showcasing the revolution in manufacturing processes.

So, at the 138th Canton Fair, everyone was buzzing about the latest in friction welding tech—things that could really shake up industry standards. From what I’ve read, the global market for friction welding is expected to hit around $1.2 billion by 2027. That’s pretty impressive, huh? It’s growing at roughly 6.5% every year from 2020 onward. A big reason for this rapid growth? Industries like automotive and aerospace are constantly on the lookout for lighter yet super strong materials. Basically, they need to cut down weight without sacrificing the strength of their structures.

Some of the coolest innovations they showed off included new friction stir welding techniques. These allow different kinds of materials to be joined together without needing extra filler stuff—sounds simple, but it’s actually pretty revolutionary. Plus, these methods boost the mechanical qualities of the welds and make the whole manufacturing process more energy-efficient. According to a report by MarketsandMarkets, friction welding can cut energy use by around 30% compared to the old-school methods. As makers and manufacturers are really pushing towards more eco-friendly practices, these new techs are definitely going to play a big part in that transition to greener, cleaner production methods.

Friction welding is really making waves in the industrial world right now, especially highlighted at the 138th Canton Fair in 2025. It’s such an innovative technique — not only does it boost the performance and lifespan of materials, but it also ticks the box for those of us who care about sustainability. By cutting down on waste and energy use, friction welding offers a practical solution for companies wanting to leave a smaller environmental footprint. Plus, it produces less heat and works more efficiently than traditional welding methods, making it a pretty appealing choice.

If your company is thinking about jumping into friction welding, here’s a little tip: really dig into understanding your materials first. Knowing which are most compatible can save you a ton of time and headaches down the line. Also, investing in proper training for your team on the latest equipment can make a big difference — it keeps things running smoothly and sustainably. And hey, partnering up with eco-focused organizations isn’t a bad idea either — it can help ramp up your green initiatives.

Getting on board with friction welding isn’t just about following industry standards; it shows you’re serious about being eco-friendly. As more industries look for greener options, adopting this kind of tech is becoming essential if you want to stay competitive and do right by the planet. This shift toward sustainability is a major step forward in responsible manufacturing, and honestly, it’s an exciting one.

| Innovation | Description | Impact on Sustainability | Eco-Friendly Practices |

|---|---|---|---|

| Advanced Friction Stir Welding | Utilizes rotational friction to join materials without melting. | Reduces energy consumption compared to traditional welding. | Minimizes waste and promotes recycling of materials. |

| Hybrid Welding Techniques | Combines friction welding with laser welding for enhanced precision. | Lowers carbon footprint through efficient processing. | Encourages the use of thinner materials to reduce resource consumption. |

| Eco-Friendly Automation | Integrates smart technology for optimizing welding processes. | Enhances efficiency and reduces emissions during production. | Encourages the use of sustainable energy sources. |

| Innovative Tooling | Development of tools that extend the life of equipment. | Reduces material waste and operational costs. | Supports a circular economy by enhancing tool reusability. |

So, have you heard? At the upcoming 138th Canton Fair in 2025, friction welding tech is definitely going to steal the spotlight. It’s pretty exciting because we’re seeing some fresh trends popping up in how it’s used across different industries. The global market for friction welding is actually expected to grow about 6.8% annually from 2023 to 2030 — that’s thanks to cool advancements in manufacturing techniques and a rising need for super precise parts, especially in cars and aerospace. Basically, it points to a shift toward smarter, more sustainable ways of making things. Friction welding's pretty great because it can join different kinds of materials without needing extra fixtures or materials — it’s more efficient that way.

One thing that’s really catching attention is how AI is being integrated into these welding processes. According to the International Journal of Advanced Manufacturing Technology, AI-powered systems can tweak welding settings in real time, which means better quality welds and faster cycle times. Plus, with industries like auto manufacturing pushing for lighter materials, friction welding is becoming a go-to solution — especially when it comes to making lightweight composites, which are huge for electric vehicle parts. And honestly, I think the Canton Fair will be packed with showcases of these breakthroughs, giving us a glimpse into what’s coming next in friction welding tech.

Hey there! So, the 138th Canton Fair in 2025 is really shaping up to be an incredible opportunity for folks in the industry. It’s not just about checking out the latest in friction welding tech, but also about meeting new people and expanding your network. Honestly, it’s a perfect place to see some cutting-edge innovations and have some good, real conversations with others in manufacturing. You’ll get the chance to chat, share stories, and maybe even find some collaboration ideas that could really push your projects forward.

What’s cool about the Canton Fair is that networking isn't just about handing out business cards. They’ve got a bunch of organized events, panel talks, and workshops where you can actually connect with experts and innovators from all over the world. These sessions are packed with insights on emerging trends—not just in friction welding but in related tech too. Plus, it’s a great way to get inspired and gather ideas that could make a real difference for your business. At the end of the day, it’s all about building genuine relationships — those connections are what often lead to exciting collaborations and help raise industry standards. So, honestly, it’s a can't-miss event if you’re serious about staying ahead in the game!

These days, as the global car industry shifts gears toward electrification and lightweight designs, magnesium alloys are really gaining popularity. People are seeing just how awesome they are—thanks to their high strength combined with low weight, which is a game-changer for boosting fuel efficiency and giving electric vehicles a longer range. According to the 'Global Rotary Friction Welding Machine Market Growth 2025-2031' report, the adoption of advanced welding methods, like friction welding, is a big part of making magnesium alloys work smoothly in manufacturing. This ties in perfectly with the industry’s push for more sustainable and efficient car production.

Friction welding, especially rotary friction welding, looks set to keep growing steadily. It’s a pretty clever way to join different metals without much hassle, and it supports the bigger goal of eco-friendly manufacturing practices. Recent reviews of the latest trends show how important it is to use methods that not only meet today’s production needs but also protect the environment for the future. This aligns well with recent investments in flexible manufacturing systems, which can handle making internal combustion engine cars, hybrids, and electric vehicles all on the same line. It just shows how adaptable the industry is becoming to meet changing market demands.

: Friction welding techniques utilize heat generated from friction to create strong, durable bonds between materials, making them a revolutionary joining method in manufacturing.

Friction welding reduces energy consumption and minimizes the need for additional materials compared to traditional welding methods, leading to a more sustainable approach in manufacturing.

The fair showcased advancements in friction welding technologies, including automated systems and real-time monitoring that enhance precision, consistency, and production efficiency.

The global friction welding market is projected to reach $1.2 billion by 2027, with a compound annual growth rate (CAGR) of about 6.5% from 2020 to 2027.

The demand is mainly driven by industries such as automotive and aerospace, where lightweight and high-strength materials are essential for reducing weight while maintaining structural integrity.

Key innovations include advanced friction stir welding techniques that can join dissimilar materials without additional filler materials, thus enhancing mechanical properties and energy efficiency.

Friction welding technologies contribute to energy savings, reducing energy consumption by approximately 30% compared to traditional welding methods.

Magnesium alloys have a high strength-to-weight ratio, which is crucial for enhancing fuel efficiency and extending the range of electric vehicles.

Friction welding is expected to thrive in the market, particularly due to its efficiency in joining dissimilar metals and supporting sustainable manufacturing practices.

The industry is investing in flexible manufacturing systems that can accommodate different vehicle models on the same assembly line, supporting the transition towards sustainable and efficient production.

So, the 138th Canton Fair in 2025 was pretty exciting, especially with all the new stuff happening around Friction Welding. They really showed off how much this technology is changing the game in manufacturing. Some demos highlighted the latest tricks of the trade that help speed things up and improve quality in industrial work—it's like watching innovation in action. Plus, there was a real focus on sustainability too; it’s great to see how Friction Welding helps cut down on waste and energy use, making manufacturing a bit greener.

What’s cool is that more industries are jumping on these advanced joining tech. The fair was a great place for folks to swap ideas and think about where Friction Welding might go next in high-tech manufacturing. And with over 20 years of experience in ultrasonic welding, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. gets how important these breakthroughs are. They’re still dedicated to providing top-notch ultrasonic solutions to support all kinds of industries as the technology evolves.