The cosmetics industry is changing so fast these days! Can you believe the global cosmetics packaging market is expected to hit a whopping $60 billion by 2025? It's all thanks to consumers looking for more innovative and sustainable products. One of the coolest innovations making waves is the Cosmetics Tube Sealing Machine. This little wonder not only keeps products safe and sound but also makes using them a better experience overall. Now, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been in the game for 20 years, specializing in ultrasonic Plastic Welding, and they’re leading the pack in this space. As brands scramble to keep up with the rising standards of our industry, picking the right sealing technology is super important. The ultrasonic sealing process really kicks things up a notch by boosting production efficiency and cutting down on material waste. This is totally in line with the push for greener packaging solutions nowadays. By keeping an eye on upcoming trends in cosmetics tube sealing tech, companies can make smart decisions that not only optimize their operations but also match what today’s consumers really want.

You know, emerging technologies are really shaking things up in the world of cosmetics tube sealing. It's all about being efficient, eco-friendly, and giving customers what they want. I read in a recent market report that the global cosmetics packaging scene is expected to hit a whopping $45.5 billion by 2025, and guess what? Tube packaging is taking a big slice of that pie. One cool innovation that’s gaining traction is Ultrasonic Sealing. This uses high-frequency vibrations to create super airtight seals—pretty neat, huh? It can boost production by up to 30%, which is a game-changer for places running large operations.

Then there’s this trend where smart technology is being worked into sealing machines. Machines with IoT capabilities can monitor everything in real-time, along with all kinds of data analytics, which really helps manufacturers fine-tune their processes. Some reports even say that companies who embrace this advanced automation can cut their operating costs by roughly 20%. That’s a pretty solid reason to invest! Plus, as people are leaning more towards eco-friendly packaging, manufacturers are getting creative with machines that can handle recyclable and biodegradable materials. It's exciting to see how these tech advancements are pushing the envelope in tube sealing!

So, if you’re on the hunt for a sealing machine for cosmetic tubes in 2025, there are a few important things to think about. First off, check out the sealing methods—there's quite a handful to choose from! You’ve got heat sealing, which is super reliable and pretty much a classic in the game. Then there’s ultrasonic sealing, which is all about getting those seals extra clean and precise. Weigh your production needs and pick a machine that fits your vibe and requirements.

Another biggie is whether the machine can handle different tube materials. With a lot of brands switching to more eco-friendly packaging nowadays, it’s key to go for a machine that’s versatile enough to work with recyclable plastics and even biodegradable ones. And, hey, don’t forget to make sure it can handle various tube sizes and shapes. That flexibility will be handy down the line as your product lineup evolves.

**Quick Tips:**

- Always go for machines that are easy to use—trust me, it’ll make training your staff a breeze and keep everything running smoothly.

- And think about how often the machine needs maintenance. Keeping it in good shape with regular check-ups helps reduce downtime and can really stretch out the lifespan of your equipment, keeping your production on point!

You know, the cosmetics industry is really changing fast, and one big thing that's coming up is sustainability. It's becoming super important for companies, especially when you look ahead to 2025 and beyond. A recent report from Allied Market Research even says that the global sustainable cosmetics market could hit a whopping $22 billion by 2025. It’s no surprise, right? People are really starting to care about eco-friendly packaging these days. This trend isn't just about companies keeping up with consumer demand; it’s about them making some serious changes in how they do things, especially when it comes to sealing those tubes.

So, what are companies doing about it? Well, they’re pouring money into new sealing technologies that cut down on waste and make recycling way easier. Techniques like cold sealing and ultrasonic sealing are really taking off because they help use less energy and ditch the nasty solvents. It's pretty neat! Plus, there’s a growing buzz around using biodegradable and recyclable materials for making those tubes. Did you know that more than 50% of consumers are likely to buy products in sustainable packaging? It's like a wake-up call for brands. As they shift towards being more eco-conscious, choosing the right sealing machine is going to be really important. It's all about balancing efficiency with what consumers care about these days.

So, when you're picking out a tube sealing machine for your cosmetics production line, you've really gotta think about cost-effectiveness. It's all about finding that sweet spot between quality and what's in your budget, you know? The industry is moving fast, and manufacturers are feeling the heat to churn out top-notch products without breaking the bank. It’s super important to look beyond just the initial price tag. You also want to factor in the long-term costs, like maintenance, energy bills, and any potential downtime. Sure, a rock-solid machine might cost more upfront, but in the long run, it could save you a pile of money by cutting down waste and boosting how efficiently you produce.

Oh, and don’t forget to think about what your specific production line actually needs. Different machines handle different speeds, sealing techniques, and tube materials, so it’s worth doing a bit of homework. Get a few quotes and see what options are out there that fit both your production goals and budget. It’s also a good idea to look at stuff like automation features, how easy the machine is to use, and the support you get afterward. All these little things can really amp up the value and help you get a sealing solution that not only meets quality standards but also ticks your financial boxes as you plan for 2025.

You know, the cosmetics industry is really changing fast, and one of the big things making waves right now is how important automation and efficiency are in tube sealing operations. A new report from Market Research Future is predicting that the global cosmetic packaging market is set to grow by a whopping 5.7% annually from 2020 to 2025! And guess what? This growth is all about the rising consumer demand for cool and innovative packaging solutions. So, it seems like having top-notch sealing technology is becoming super important to keep products fresh and reduce waste.

When brands invest in automated sealing machines, it does more than just speed up production—it also helps them stick to high quality standards. A study by Smithers Pira found that these automated systems can actually boost production efficiency by as much as 30%! That’s a serious reduction in labor costs and errors. Plus, these systems provide way better precision when sealing, which is key for keeping products safe and stopping any leaks.

And let’s not forget about sustainability—it's on everyone’s mind these days. Brands really need to look for machines that are energy-efficient and help cut down on material waste if they want to resonate with consumers by 2025. Going forward, automation and smart technologies are going to transform the way we handle cosmetic tube sealing, leading to more intelligent operations and better profits. Exciting times ahead!

| Dimension | 2023 Trends | 2025 Predictions | Key Features |

|---|---|---|---|

| Automation Level | Semi-automated systems with manual adjustments | Fully automated, smart systems with AI integration | Predictive maintenance, reduced human error |

| Material Compatibility | Standard plastics and aluminum | Eco-friendly materials and biodegradable options | Sustainable sourcing and recyclability |

| Sealing Technology | Heat sealing and ultrasonic sealing | Advancements in laser and induction sealing | Enhanced leakage prevention and integrity |

| Production Speed | Up to 300 tubes per minute | Projected speeds of 600 tubes per minute | Optimized workflows and faster changeover times |

| Quality Control | Manual inspection and standard testing | AI-driven quality assurance and analytics | Real-time monitoring and feedback systems |

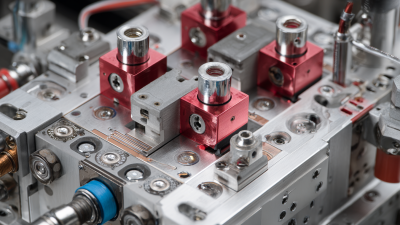

The ultrasonic multi-station turntable automatic filling and sealing machine is revolutionizing production efficiency in various industries by significantly enhancing both the speed and accuracy of the filling and sealing processes. Recent industry reports highlight that the incorporation of ultrasonic sealing technology allows for high-speed sealing of up to 500 pieces per minute, ensuring a non-contact and pollution-free operation. This technology not only guarantees a robust sealing strength but also eliminates the risk of leakage, making it particularly advantageous for sensitive products such as ointments and cosmetics.

Moreover, the fully automatic multi-station collaboration design of these machines dramatically streamlines the production workflow. By integrating essential functions such as automatic tube loading, precise filling, ultrasonic sealing, and material discharge detection, manufacturers can achieve unmanned continuous production. Industry data suggests that such automation can improve operational efficiency by more than 30%, proving that investing in advanced filling and sealing technology is not just a trend but a crucial step towards sustained competitive advantage in today’s fast-paced market. As businesses continue to seek ways to optimize their production lines, the ultrasonic multi-station turntable technology stands out as a powerful solution for enhancing efficiency and reliability.

: The cosmetics industry's evolution towards sustainability is primarily driven by growing consumer demand for eco-friendly packaging solutions, with the global sustainable cosmetics market projected to reach $22 billion by 2025.

Manufacturers are investing in advanced sealing technologies, such as cold sealing and ultrasonic sealing, which minimize waste, enhance recyclability, reduce energy consumption, and eliminate harmful solvents.

Biodegradable and recyclable materials are gaining popularity in tube manufacturing, as more than 50% of consumers prefer products with sustainable packaging.

Companies need to balance cost-effectiveness with quality by evaluating initial investment costs, long-term operational expenses, specific production line needs, and the machine's features, such as automation and ease of use.

Automation enhances production speed, increases efficiency up to 30%, reduces labor costs and errors, and ensures better precision in sealing, which is crucial for maintaining product integrity.

With sustainability becoming a priority, choosing machines designed for energy efficiency and minimal material waste is essential for brands to align with consumer values in 2025.

Investing in reliable and efficient machines may incur higher upfront costs but can lead to significant savings over time by reducing waste and increasing production efficiency.

The global cosmetic packaging market is predicted to grow at a CAGR of 5.7% during this period, driven by increasing consumer demand for innovative packaging solutions.

Selecting the right sealing machine is pivotal for meeting operational efficiency and eco-conscious consumer expectations, especially as leading brands prioritize sustainability.

Enhanced automation coupled with smart technologies will shape the future landscape of cosmetic tube sealing, leading to smarter operations and increased profitability.