As the 138th China Import and Export Fair in 2025 gets closer, it’s pretty clear that the High Frequency Welder market is on the verge of some serious growth. That’s mainly because industries like automotive, electronics, and medical devices are really stepping up their demand. I’ve seen reports suggesting that the global Ultrasonic Welding market could hit around USD 3.1 billion by 2026, with a healthy growth rate of about 8.2% from 2021 to 2026.

As the 138th China Import and Export Fair in 2025 gets closer, it’s pretty clear that the High Frequency Welder market is on the verge of some serious growth. That’s mainly because industries like automotive, electronics, and medical devices are really stepping up their demand. I’ve seen reports suggesting that the global Ultrasonic Welding market could hit around USD 3.1 billion by 2026, with a healthy growth rate of about 8.2% from 2021 to 2026.

Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been in this game for more than 20 years when it comes to ultrasonic plastic welding, and honestly, they’re right there at the forefront. Their focus on innovating ultrasonic tech — especially with their high-frequency welders — puts them in a great spot to meet what customers need as things keep evolving.

With companies trying to boost both production efficiency and product quality, having reliable high-frequency welding solutions isn’t just a bonus anymore — it’s pretty much a must if you want to stay competitive these days.

You know, the high-frequency welder market is really starting to catch more eyes lately, especially after all the buzz from the 138th Canton Fair. It’s such a huge event where companies from all over the world come together—I've even noticed some new players, like suppliers from Vietnam, trying to break into the global scene. Turns out, industry reports are predicting that this sector will grow about 6.5% annually over the next five years. That’s mainly because sectors like automotive, construction, and electronics are demanding more of these welders.

What’s pretty exciting is how industries worldwide are all about finding smarter ways to manufacture stuff. Incorporating high frequency welding tech can really up the game, making production faster and more efficient. And here's the kicker—these machines are energy-efficient too! Some data suggests they can cut down production costs by nearly 20%, which is a big deal for companies looking to boost their profits. So, when events like the Canton Fair showcase opportunities for collaboration and tech sharing, it’s clear that companies jumping on these advancements are much more likely to stay ahead in today’s super competitive market.

The High Frequency Welder market is really shaping up to grow quite a bit. Especially with all the latest innovations in welding tech being showcased at the China Import and Export Fair 2025, things are getting exciting. Industry experts are predicting a compound annual growth rate of around 6.3% from 2023 to 2028 — pretty impressive! That’s mainly thanks to new advancements in making the process more efficient and automation getting smarter. Some of the coolest stuff this year includes energy-saving systems that cut down waste and boost precision. Companies are pouring more money into these new tools because there's more and more demand for stronger, longer-lasting welds across industries like auto manufacturing, textiles, and electronics.

If you're thinking about investing in high-frequency welding equipment, I’d suggest looking closely at companies that are all about sustainability and saving energy. According to research reports, these features not only help cut down operating costs but also attract customers who really care about eco-friendly practices.

Plus, there's this game-changing trend: smart welding machines with AI that can monitor everything in real-time. They're making a huge difference by reducing human error and ensuring top-quality welds, which helps companies stay competitive and meet strict industry standards. As the market heats up and more players jump in, making use of these cutting-edge innovations might just give your business the edge it needs to stand out and succeed.

| Innovations | Impact | Market Trend | Projected Growth (%) | Year |

|---|---|---|---|---|

| Advanced Pulse Control | Improved weld quality and consistency | Increasing demand for precision welding | 8 | 2025 |

| Wireless Control Systems | Enhanced operational flexibility | Rise in automated welding solutions | 12 | 2025 |

| Smart Welding Machines | Real-time monitoring and adjustments | Growth in smart manufacturing | 15 | 2025 |

| Energy-Efficient Technologies | Reduction in operational costs | Increased environmental regulations | 10 | 2025 |

| CNC Integration | Automated and precise welding processes | Increased demand in diverse applications | 20 | 2025 |

You know, the demand for high frequency welders in China is really picking up steam. It’s all thanks to the country’s booming industrial scene and some pretty impressive tech upgrades. As more money goes into manufacturing—think auto stuff and electronics—the need for welding solutions that are both precise and super efficient is more important than ever. High frequency welding has been catching on because it’s fast, reliable, and makes top-notch quality joints. Manufacturers are really interested in it now, especially as they look to boost productivity without sacrificing durability.

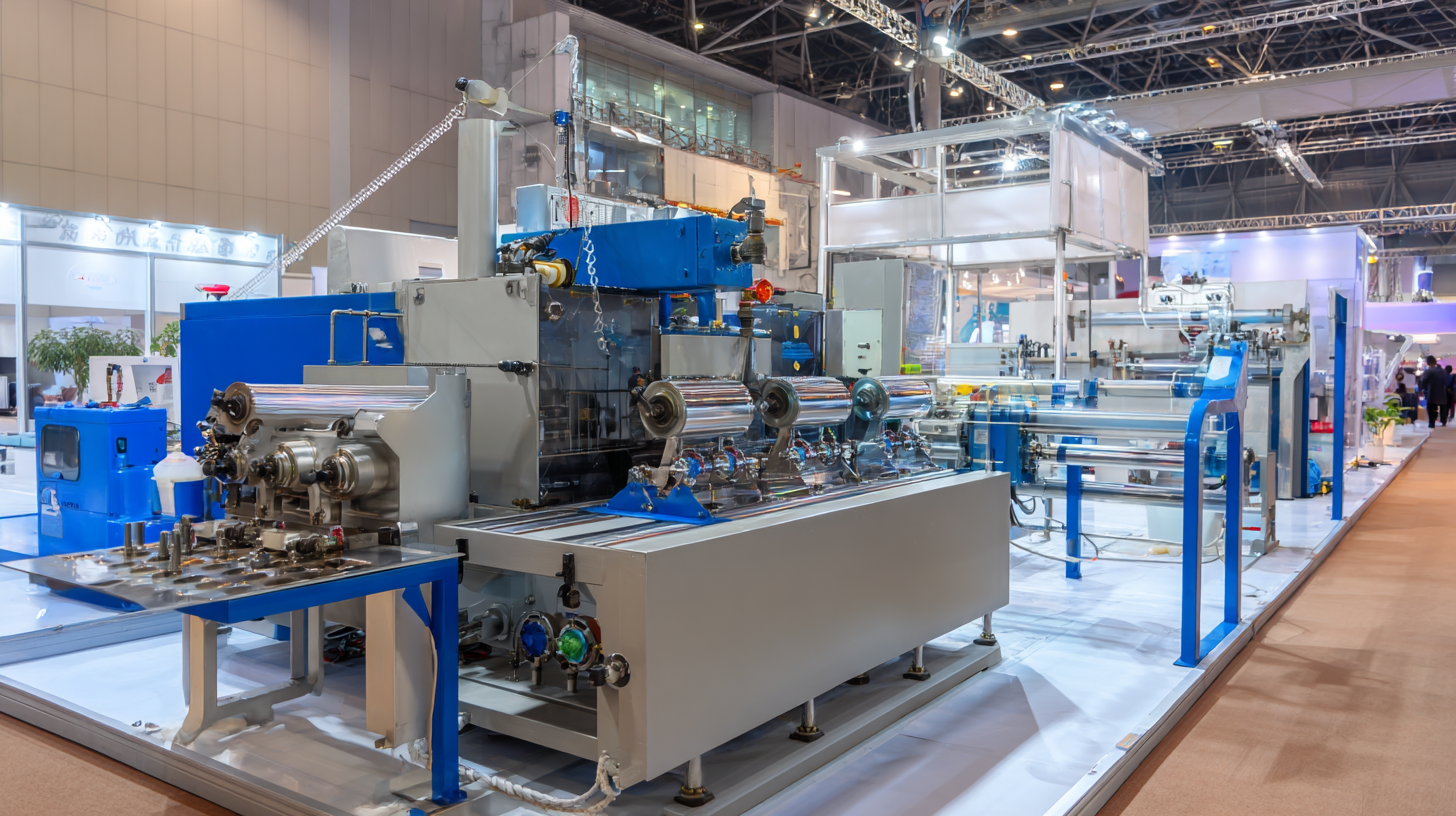

At the China Import and Export Fair 2025, we’re probably going to see a lot of these trends in action. Exhibitors will maybe show off some cool new features like better energy efficiency and automation — stuff that ties into the whole sustainability vibe. Plus, with the shift towards smart manufacturing, there’s definitely going to be a lot of buzz around welders that can easily plug into modern, high-tech production lines. It really shows how customer expectations and operational needs are changing pretty fast in this industry.

Wow, it looks like the high frequency welder market is really booming lately. I mean, especially with all the buzz around the China Import and Export Fair 2025, there's definitely a lot of opportunity out there. I came across a recent industry report that predicts the global need for these welders could grow by over 12% every year—that's pretty impressive. This surge is largely thanks to advances in manufacturing tech and the fact that industries like automotive and construction are really ramping up their use of these welders. If you're thinking about exporting high frequency welders, it's a pretty sweet chance, especially for manufacturers aiming at emerging markets where industries are booming.

The Canton Fair, officially known as the China Import and Export Fair, is really one of those must-visit events for manufacturers and buyers looking to connect and uncover new opportunities. As the high-frequency welder market keeps growing, this year's event feels like it’s gearing up to be more exciting than ever. You’ll get the chance to chat directly with suppliers, check out the latest innovative products, and even build partnerships that could benefit both sides. It’s especially important if you're trying to boost your production game or bring in some new tech to your business.

A tip from me—try to prep a quick elevator pitch before you go. Just a few lines that highlight what your business is all about and what you're looking for in the high-frequency welder scene. It’ll help you stand out and make more meaningful conversations.

Also, don’t miss out on the seminars and panel discussions. Those sessions are packed with industry insights, current trends, and some pretty good advice. Plus, they’re a great chance to meet industry veterans and potential partners in a more relaxed setting.

And don’t forget—bring plenty of business cards! Be ready to swap contact info, and make sure to follow up with anyone you meet. Keeping those connections alive can open up all kinds of doors down the line.

You know, the high-frequency welder market is really set to go through some big changes after the 2025 China Import and Export Fair. One of the main drivers? Well, there's this growing demand for energy-efficient and top-notch welding solutions across a bunch of different industries. As companies push for sustainability and look to boost how efficiently they operate, we're probably going to see a big jump in the use of advanced tech in high-frequency welding—think automotive, electronics, construction, and more. It’s exciting to imagine the new, innovative applications that could come out of this!

And it’s not just that. The market’s also being shaped by bigger shifts like automation and digitalization. Businesses are definitely investing a lot more in automation tools that incorporate high-frequency welding tech—mainly to speed things up and cut down on labor costs. Because of all this, I think we’ll see more collaborations between tech providers and welding gear makers, leading to smarter, more efficient welding systems that hit the specific needs of various industries once we hit 2025. It’s a pretty fascinating time for this field!

: The consumer demand for high frequency welders in China is driven by rapid industrial growth, technological advancements, and increasing investment in manufacturing sectors like automotive and electronics.

The fair is expected to unveil trends such as energy efficiency, automation features, and welders that can integrate with advanced production lines, reflecting shifts towards sustainability and smart manufacturing.

The Canton Fair provides a platform for manufacturers and buyers to connect, explore innovative products, and establish partnerships, which is crucial for enhancing production capabilities and technological integration.

Attendees should prepare a concise elevator pitch highlighting their business strengths, bring plenty of business cards, and follow up with new contacts to foster relationships and potential opportunities.

Key factors include the rising demand for energy-efficient and high-performance welding solutions, advancements in automation and digitalization, and a shift towards sustainable manufacturing practices.

Technology integration will improve production efficiency, reduce labor costs, and lead to the development of smarter welding systems, as businesses invest in automation solutions.

The demand is expected to increase in sectors such as automotive, electronics, and construction.

Advanced technologies are likely to enable innovative applications that enhance productivity and energy efficiency across diverse manufacturing sectors.

Seminars and panel discussions offer insights into industry trends and challenges, along with opportunities to meet industry leaders and potential collaborators.

Collaboration is expected to lead to the development of more efficient welding systems tailored to the specific needs of various industries, driving further innovation in the market.

So, at the 138th Canton Fair, they focused a lot on the