In today’s ever-changing world of manufacturing, you really can't ignore how important advanced welding technologies have become — especially the rise of High Frequency Welders. As companies chase after better efficiency and fresh innovation, these machines have completely changed the game when it comes to precision and speed. For over 20 years, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been right there leading the charge, focusing on ultrasonic plastic Welding Systems and a whole bunch of related tools. By using High Frequency Welders, Chengguan helps businesses in different industries improve their manufacturing, cut down on costs, and boost product quality. In this article, I’ll take a look at how High Frequency Welders are transforming the industry, highlighting some of the key innovations and strategies that boost efficiency in fabrication. Basically, it’s about how Chengguan’s know-how can help us build a more productive, future-proof way of making things.

You know, high-frequency welding technology is really starting to shake things up in modern manufacturing. It's a pretty big deal because it helps cut down on both time and costs — making the whole process way more efficient. As industries are moving towards smarter, more eco-friendly ways of doing things, high-frequency welding stands out for being super precise and reliable. Plus, it doesn't just make the finished parts stronger; it also speeds up production cycles big time. That means manufacturers can get more products out the door without sacrificing quality — pretty awesome, right?

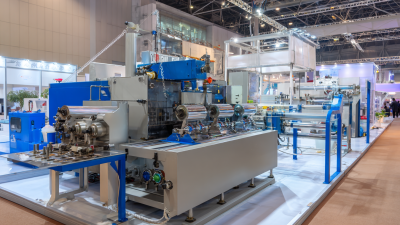

And the latest gear for high-frequency welding? It’s evolving fast and really lining up with what automation needs today. With smart tech built in, these machines can monitor themselves and tweak things on the fly to keep everything running perfect. On top of that, there’s a real push for greener manufacturing practices, so this tech tends to produce less waste and use less energy compared to old-school welding methods. All in all, if companies want to stay competitive, boost efficiency, and keep up with market trends, jumping on the high-frequency welding bandwagon has definitely become more important than ever.

| Dimension | Value |

|---|---|

| Welding Speed (m/min) | 8.5 |

| Power Consumption (kW) | 5.2 |

| Material Thickness (mm) | 2.0 |

| Production Efficiency (%) | 92 |

| Cost per Unit ($) | 1.75 |

| Setup Time (min) | 15 |

| Operator Training (hours) | 10 |

| Maintenance Frequency (weeks) | 4 |

You know, the world of modern fabrication has been changing pretty fast lately, especially with more folks starting to use High Frequency Welders. When you compare traditional welding methods to these newer high frequency ones, it’s clear they’re way ahead — they’re more efficient and often give you much better precision. Market reports from recent times suggest that the inverter welding machine scene is about to see some serious growth. We’re talking about different types of welding like MMA, MIG/MAG, and TIG, and these are being used across all kinds of industries — from cutting-edge tech projects to heavy manufacturing plants.

By 2023, it’s pretty obvious that high frequency welders help get stuff done faster. They cut down the time needed for each weld and still give you top-notch quality. One thing folks really like is how quickly these welders can switch between different materials, making the whole manufacturing process smoother and more adaptable. All this cool tech being packed into inverter welders makes them the go-to choice for fabricators wanting to boost efficiency. Plus, the market for welding equipment, especially high frequency ones, is expected to grow a lot — it’s pretty much becoming the standard, especially in metal processing industries right now.

High frequency welding has really changed the game in the fabrication world. It’s brought in some pretty cool tech that boosts both efficiency and the quality of the output. For example, advanced inverter tech and automation — those are real game-changers, giving manufacturers the ability to control the welding process with much more precision. That means stronger welds and fewer defects, which helps boost industry standards across the board. Plus, smart sensors are now a part of the picture, providing real-time feedback and monitoring. It’s kind of like having an extra pair of eyes that helps you tweak things on the fly for better results.

If you’re thinking about using high frequency welding for your projects, definitely check that you’re working with the latest gear that incorporates these new technologies. Regular maintenance? Absolutely essential. It keeps your machines running smoothly and makes sure your results stay consistent — plus, it can help extend their lifespan.

And the future? It’s looking bright, especially with new materials and eco-friendly practices coming into play. Lighter, stronger composites are making their way into industries from cars to space ships. As everyone aims for sustainability, switching to high frequency welding methods that cut down on energy use and waste isn’t just good for the planet — it makes your operation more efficient, too.

A tip: try to stay up-to-date on the latest materials and techniques in high frequency welding. Working with suppliers who care about innovation can really give you an edge and help you make the most out of your manufacturing processes.

High frequency welding, or HFW, has really shaken up the fabrication world. It’s all about making welded joints stronger and improving the overall properties of materials. The cool thing? It heats things up using electromagnetic induction, which means parts—like metals and plastics—can fuse together super quickly. Because of that, HFW helps cut down on thermal stresses and warping, especially compared to the old-school welding methods.

This is a game-changer when you need precision and a solid, reliable weld—because, let’s be honest, the final product’s performance totally depends on how good that weld is.

And honestly, the impact on material properties is pretty impressive too. Not only can HFW join different kinds of materials together, but it also boosts the mechanical strength of the final product. The fast heating and cooling cycles help refine the grain structure, which translates to more durability and toughness. Plus, it preserves the natural characteristics of the materials, unlike traditional welding that sometimes messes things up. That’s why industries like automotive and aerospace are jumping on board—HFW offers a way to get stronger, more reliable structures. It’s honestly becoming a must-have in modern manufacturing.

High-frequency welders have really changed the game in modern manufacturing. They offer efficiency and precision that you just don’t get with traditional methods. Since adopting high-frequency welding tech, companies have seen a huge boost in how fast they can produce stuff—some reports say up to 50% more output compared to older welding methods. That kind of jump? It means big savings and healthier profits, especially in industries like auto manufacturing and packaging, where producing tons of stuff quickly is key.

If you look at real-world examples, you'll see just how practical these benefits are. For example, in the auto world, ultrasonic welding has helped put together lightweight parts more efficiently—cutting energy use by about 30%. And in packaging, firms have noticed that using high-frequency welders not only makes seals stronger and last longer but also helps reduce waste during production. Plus, companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. have been leading the charge for over 20 years, pushing out innovative ultrasonic welding solutions that fit all sorts of industry needs. All of this adds up to more streamlined, cost-effective operations for their clients.

You know, the high frequency welding industry is really on the brink of some exciting changes, especially with all these new smart tech and predictive maintenance tools coming into play. As the market for induction heating systems keeps growing—it's expected to jump from around $687 million in 2024 to about $728 million in 2025—people are craving more efficient and dependable welding solutions. This surge is largely due to the push towards automation and the use of data-driven methods that boost production efficiency.

Looking ahead, it seems like predictive maintenance, powered by these clever new technologies, will make a huge difference. We’re talking about shaving down downtime and cutting maintenance costs, which basically means things run smoother overall. Thanks to data analytics and IoT (that’s internet of things stuff), manufacturers can keep an eye on equipment performance in real time, catching issues before they even become a problem. It’s a more proactive approach that not only streamlines the whole process but also improves the quality of the finished products. Honestly, high frequency welding is becoming a key player in modern fabrication. As the industry keeps evolving, adopting these innovations will totally shake up industry standards, opening up a new chapter of productivity and precision in manufacturing.

: High frequency welding technology optimizes production time and costs, enhances structural integrity of welded components, reduces cycle time, and increases throughput without compromising quality.

High frequency welding often results in less waste and lower energy consumption compared to traditional welding methods, aligning it with the push for green manufacturing.

The integration of smart technologies allows for real-time monitoring and adjustments during the welding process, ensuring optimal performance and efficiency.

High frequency welding methods are more efficient and precise than traditional welding techniques, significantly reducing the time needed for welds while ensuring high quality.

The anticipated rapid growth of the inverter welding machine market is driven by the increasing adoption of high frequency welders and the demand for diverse welding types catering to various industrial applications.

High frequency welders are favored for their flexibility, ability to adapt quickly to different material types, and the technological advancements that improve operational effectiveness.

High frequency welding technology is being increasingly adopted in high-tech sectors and heavy industries, where its efficiency and adaptability are crucial for production.

The welding equipment market is expected to grow significantly, with high frequency welding becoming a mainstream option, particularly in metal processing industries.

Reduced cycle times enable manufacturers to increase their throughput, ultimately improving productivity and potentially reducing overall production costs.

As companies strive to improve operational efficiency and respond to changing market conditions, the demand for high frequency welding technology has surged, making it more critical than ever.

High Frequency Welders have really changed the game in modern fabrication. They've drastically cut down production times and helped companies save big on costs. This tech basically outshines traditional welding methods, thanks to advanced techniques that boost efficiency while still hitting that sweet spot of precision. You know, with innovations like smart tech and predictive maintenance, high frequency welding is setting new standards in the industry—and giving businesses a serious edge.

And it’s not just about speed; these welders actually improve the material properties, making structures way more solid and reliable. That’s why so many companies, including those in ultrasonic plastic welding like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., are seeing real results from using high frequency welders. As things keep evolving, it's safe to say we’re heading into an exciting new era of fabrication excellence—pretty cool, right?