In the fast-changing world of energy storage, the way we do Battery Tab Welding is actually making a big difference when it comes to boosting how long batteries last and how well they perform. As more people and industries move towards renewable energy and electric cars, the need for powerful, reliable batteries has skyrocketed. That's where new and smarter methods of Battery Tab Welding come in—they help make batteries stronger and more efficient. Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been around for about 20 years, specializing in ultrasonic plastic welding, and they're really leading the charge in this space. They offer high-tech ultraSonic Welding tools and systems customized for different industries, which not only streamlines the manufacturing process but also helps ensure that the next wave of energy storage solutions actually live up to high standards for durability and performance. This article is all about how these advanced welding techniques are changing the way batteries are made—and what that means for the future of energy storage technology.

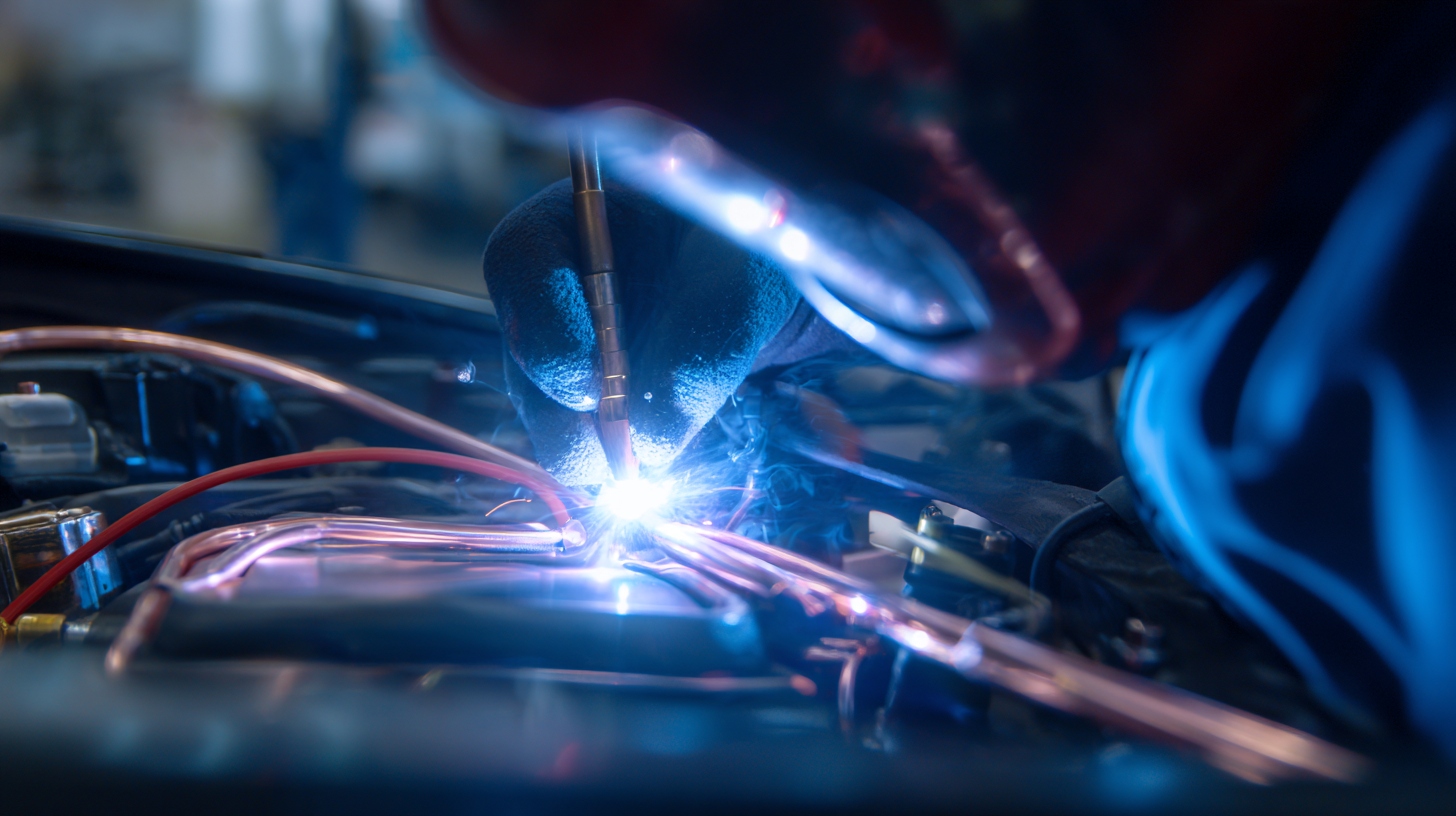

When it comes to making energy storage systems better and last longer, advanced battery tab welding techniques really make a difference. You see, traditional welding methods often end up creating weaker connections, which can cause more resistive losses and drag down the efficiency — it’s kind of like having a loose connection in your electronics. But newer methods like laser welding and Ultrasonic Welding are a game-changer. They offer much more precision and control, so the bonds between the battery cells and tabs are stronger and more reliable. Plus, these techniques help reduce heat stress during the process, which helps keep all the battery parts intact and makes sure the energy flows smoothly without hiccups.

And there's more to it — using these advanced welding methods actually helps extend the battery’s lifespan. When the connections are solid and free of defects, the chances of failure or performance dips over time drop a lot. For example, better tab welding means the current gets distributed more evenly inside the battery. That means improved charging and discharging cycles, which ultimately makes the battery last longer. As demand for more efficient energy storage keeps growing, it’s pretty clear that understanding and adopting these cutting-edge welding techniques is going to be a must for manufacturers wanting to produce higher quality, longer-lasting batteries.

| Welding Technique | Impact on Lifespan (Years) | Charge Efficiency (%) | Heat Generation (°C) | Cost (per unit) |

|---|---|---|---|---|

| Ultrasonic Welding | 7-10 | 95 | 30 | $0.50 |

| Laser Welding | 10-12 | 98 | 25 | $1.00 |

| Resistance Spot Welding | 5-7 | 92 | 40 | $0.30 |

| TIG Welding | 6-9 | 90 | 35 | $0.80 |

| Friction Stir Welding | 8-11 | 96 | 28 | $1.20 |

Advanced techniques for welding battery tabs really make a difference when it comes to making batteries last longer and work more efficiently, especially since the need for better energy storage keeps growing. So, what really counts for battery performance? Well, the quality of the welding process, the materials used, and the overall design of the battery cells all play big roles. For instance, ultrasonic welding is quite popular because it offers precision and really strong joints, which can help prevent early failures in battery systems.

Advanced techniques for welding battery tabs really make a difference when it comes to making batteries last longer and work more efficiently, especially since the need for better energy storage keeps growing. So, what really counts for battery performance? Well, the quality of the welding process, the materials used, and the overall design of the battery cells all play big roles. For instance, ultrasonic welding is quite popular because it offers precision and really strong joints, which can help prevent early failures in battery systems.

A quick tip: When you're choosing ultrasonic welding equipment for your battery production line, it's a good idea to look at factors like the frequency, power output, and whether it's compatible with your battery materials. Getting these right ensures you get the best results.

By the way, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been around for over 20 years, building up serious expertise in ultrasonic plastic welding. They provide top-notch systems that meet the tricky demands of battery manufacturing. Their equipment doesn’t just improve the quality of the welds on the tabs but also helps make batteries that last longer and work better.

And here's a little extra tip: Regular maintenance of your ultrasonic welding gear is key—freezing performance issues and extending the lifespan of both the equipment and your batteries. Plus, investing in good-quality components is totally worth it if you're aiming for reliable, top-notch welding results.

When it comes to boosting the performance and lifespan of energy storage systems, advanced battery tab welding techniques are a big deal. Using innovative materials in the welding process really makes a difference—helping us get better conductivity and lower resistance, which are key for making batteries work more efficiently. These tech improvements mean we can create tighter, more reliable connections in battery packs, which not only cuts down on failures but also extends the life of batteries used in electric vehicles and renewable energy setups.

Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we've been at the forefront of the ultrasonic plastic welding scene for over 20 years. Our deep experience in developing ultrasonic welding systems allows us to craft solutions that are perfectly tailored to the unique needs of battery tab welding. By blending cutting-edge welding techniques with the latest materials, we help our clients push their energy storage systems to higher levels of performance and reliability. Basically, we’re contributing to the exciting shift happening in energy tech—or, as I like to think of it, helping power the future.

When it comes to batteries, how the tabs are welded really makes a big difference in both how long the battery lasts and how well it performs. You see, traditional methods like ultrasonic or resistance welding do a decent job, but they often can’t quite hit the mark when it comes to making a solid, consistent connection. That can lead to some issues—like hotspots or increased resistance—which, over time, can drain your battery faster and reduce its overall lifespan.

On the flip side, newer, more advanced welding techniques like laser beam welding and friction stir welding are changing the game. Laser welding, for example, gives you super precise control over heat input, so the welds end up tighter and there’s less thermal distortion. Basically, it makes the joint stronger and less prone to failure, which means your battery stays in top shape longer. Friction stir welding is another cool option—it keeps the material properties intact because it’s a solid-state process. That results in really durable, solid connections that can stand up to wear and tear.

All in all, these newer methods don’t just extend the battery’s lifespan; they also boost energy density and efficiency. It’s exciting because they pave the way for better energy storage solutions in the future—meaning longer-lasting, more reliable batteries for everyone.

Lately, there's been a real buzz around how advanced battery tab welding techniques are changing the game for energy storage systems. They're helping make batteries last longer and work more efficiently, which is pretty exciting. If you're a manufacturer or engineer thinking about jumping into these techs, one thing to keep in mind is how important precision and consistency are during the welding process—that stuff really matters.

A good tip? Invest in top-notch welding machines that give you solid control over things like temperature and pressure. When the power delivery is steady, each weld turns out pretty consistent, and that’s key to getting the most out of your batteries. Also, don’t overlook the prep work: keep the surfaces clean and free of any contaminants before welding—that tiny step makes a big difference in the quality of the joint, leading to better conductivity and overall performance.

And here’s another thing—consider switching over to automated welding systems. They can cut down on human errors, speed things up, and make your process way more repeatable. Plus, making sure your team keeps up with regular training and tech updates will help you get the most out of these advanced methods. All in all, staying on top of these techniques means your production stays innovative and ahead of the curve when it comes to energy storage solutions.

The energy storage system (ESS) market is really on the rise these days. By 2024, it’s expected to be worth around $14.7 billion, and if things keep going as forecasted, it could jump up to over $55 billion by 2032 — that’s a compound annual growth rate (CAGR) of about 15.2%. A big reason for this explosion? Well, it’s primarily because we're seeing more and more renewable energy sources being integrated, plus breakthroughs in battery tech, and of course, the growing need for stable and efficient grids. One tech that’s catching a lot of attention right now is Vanadium Redox Batteries (VRBs). They’re pretty exciting because of their unique way of storing energy, and they really point to a shift toward more innovative solutions in this space.

As the market continues to evolve, solid-state batteries are starting to get more traction. People are really hopeful about their potential to significantly improve the performance of lithium batteries. They’re still in the development stage, but efforts to find new electrode materials are promising — aiming to pack even more energy into smaller packages. Industry experts are even talking about the whole global energy storage market hitting a massive $6.7 trillion by 2024, and possibly reaching $51.2 trillion by 2034. That just shows how urgent it is to improve things like battery tab welding—because making batteries last longer and work more efficiently is a big deal.

My tip? Keep an eye on the latest in battery tech — it’s super important for anyone involved in the industry. And if you’re thinking about investing, flexible energy storage options like VRBs might be a smart move, especially since they’re reliable enough to support more renewable energy projects. It’s an exciting time, no doubt!

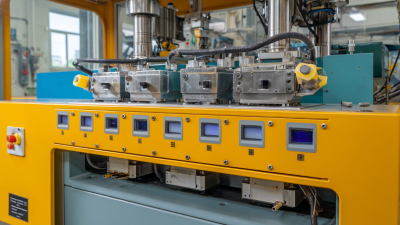

The global manufacturing sector is experiencing a transformational shift with the adoption of advanced technologies, particularly in welding processes. CGSF Servo Ultrasonic Plastic Welding Machines are leading this change, offering remarkable efficiency that stands out in an increasingly competitive market. According to a recent report by Markets and Markets, the ultrasonic welding equipment market is projected to reach $1.2 billion by 2025, driven by innovations in technology and rising demand for high-precision manufacturing. The integration of servo systems in these machines ensures exceptional welding precision, which is essential for industries that require stringent quality standards.

One of the key advantages of CGSF Servo Ultrasonic Plastic Welding Machines is their ability to deliver stable energy output. This technology allows for consistent ultrasonic energy delivery, which can adapt seamlessly to various plastic materials and specific welding requirements, ultimately enhancing product quality. As highlighted in a study published by Grand View Research, advances in ultrasonic welding technology have significantly minimized defects during production, thereby reducing material waste and operational costs.

Moreover, the high intelligence embedded in these machines simplifies the welding process with preset parameters that can be stored and recalled. This feature not only makes operation intuitive but also facilitates automated production processes, which is critical as manufacturers seek to optimize efficiencies. Fast welding speeds ensure shorter cycle times, contributing to increased productivity across manufacturing lines. With efficiency as a focal point, CGSF Servo Ultrasonic Plastic Welding Machines are positioned to redefine standards in the global manufacturing landscape.

: Advanced battery tab welding techniques include methods like laser welding and ultrasonic welding that enhance the performance and longevity of energy storage systems by providing stronger and more reliable bonds between battery cells and tabs.

Traditional welding methods may offer reliability but often result in weak connections, increased resistive losses, and inconsistent weld quality, while advanced techniques optimize connection integrity and reduce thermal stress, promoting better performance.

Precise control over heat input, as seen in laser welding, allows for tighter tolerances and reduces thermal distortion, minimizing the risk of joint failure and enhancing overall battery performance.

Advanced welding technologies help ensure robust connections, which significantly reduce the risk of failures and performance degradation over time, ultimately extending a battery's operational life.

Improved tab welding can lead to better current distribution within the battery, enhancing charge and discharge cycles and increasing the overall lifespan and efficiency of the battery.

Friction stir welding is a solid-state processing method that preserves material properties, resulting in stronger and more durable battery tab connections that contribute to improved energy density and efficiency.

Strong battery connections are crucial for minimizing resistive losses and optimizing energy transfer, which enhances the efficiency and lifespan of energy storage systems.

By enhancing battery lifespan and efficiency, advanced welding techniques pave the way for next-generation energy storage solutions, meeting the rising demand for more efficient systems.

Weak connections can lead to increased resistive losses, inconsistent performance, potential hotspots, and ultimately shorten the battery's life and efficiency.

The integration of advanced welding technologies is essential for manufacturers aiming to deliver higher quality and longer-lasting battery systems in response to growing demands for efficient energy storage solutions.

Hey, have you ever thought about how much battery technology is changing right now? The article titled "Revolutionizing Energy Storage: The Impact of Advanced Battery Tab Welding Techniques on Lifespan and Efficiency" really dives into how new welding methods are actually making batteries last longer and work better. It kicks off by exploring some pretty sophisticated welding techniques and shows how these can seriously boost battery life and efficiency. Plus, it talks about some cool new materials being used in tab welding that help with energy storage performance — kind of like upgrading the core of the whole process.

Then, it compares the old-school welding methods with these new, advanced ones, highlighting why switching to newer tech is a game changer. The article also throws in some practical tips for manufacturers who want to jump on board and start using these methods — no need to reinvent the wheel, right? And toward the end, it gets pretty exciting by predicting where energy storage and battery tech are heading, stressing how crucial efficient battery tab welding is for a sustainable future. Oh, and with over 20 years under their belt, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is out there supporting these innovations with top-notch ultrasonic welding gear—helping push battery production to the next level.

So yeah, it's quite the look into where things are headed in battery tech and why adopting smarter welding techniques really matters!