Alright, let’s dive into the world of global manufacturing—it's quite the competitive space out there! Nowadays, everyone's talking about the growing need for top-notch Plastic Welding solutions. Why? Well, thanks to some pretty cool advancements in technology, and, of course, the increasing use of these solutions across a bunch of industries. Have you heard about the Plastic Spot Welder? It’s become a must-have tool for creating strong and lasting plastic joints.

Manufacturers are really on the lookout for reliable options to boost both productivity and quality. In fact, I came across this recent market research report that predicts the global ultrasonic plastic welding market is set to explode, potentially hitting a whopping USD 1.5 billion by 2025! That's a solid compound annual growth rate (CAGR) of 6.7%.

One company that’s making waves is Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. With 20 years of experience under their belt, they've earned a reputation as a go-to provider, offering innovative ultrasonic plastic welding systems and gear that meet the diverse needs of different industries. As we take a closer look at the best ways to choose a plastic spot welder, we’ll definitely highlight the importance of quality and reliability, which have become synonymous with what folks often refer to as "Globally Trusted Chinese Manufacturing."

Alright, so when you're on the hunt for the best plastic spot welder out there for global markets, you've gotta really pay attention to the key technical specs. You know, ultrasonic welding is like the cool new kid on the block. It’s got this super fast joining speed and the joints it creates are just incredibly strong. Seriously, it leaves the old-school mechanical and adhesive bonding techniques in the dust, especially when you’re working in super precise fields like medical device assembly. And let me tell you, when you’re dealing with components that need to stick to some pretty strict regulatory standards, having those consistent, strong bonds is absolutely crucial.

Now, as the demand for efficient welding solutions keeps picking up, you can totally see that reflected in the welding electrodes market. Back in 2019, it was already a hefty USD 3 billion, and it's expected to jump to about USD 4.46 billion by 2032, which means it's growing at a rate of around 2.8% a year. That just goes to show how much different sectors, especially healthcare, are leaning on these advanced welding technologies.

So, if you’re a manufacturer picking out a plastic spot welder, make sure you keep an eye on important specs like welding speed, energy use, and whether it works well with different types of plastic. Trust me, it’ll make a world of difference in how reliable and efficient your production process turns out to be.

| Feature | Specification | Importance |

|---|---|---|

| Power Output | 3-10 kW | High power for thicker materials |

| Welding Time | 0.1 - 3 seconds | Faster cycle times improve efficiency |

| Cooling System | Air or water cooling | Prevents overheating during continuous use |

| Electrode Material | Copper alloys | Enhances conductivity and lifespan |

| Control System | Digital or analog | Ensures precise welding settings |

| Weight | 20 - 100 kg | Portability considerations |

| Power Supply Requirements | Single phase or three-phase | Compatibility with local grid |

So, when you're trying to pick out a plastic spot welder, it’s super important to get a grip on the welding current and how it affects the performance. You see, research shows that if you optimize that welding current just right, it can have a huge impact on how strong and durable those welded joints turn out. For example, some recent studies have indicated that tweaking the welding current can really change how well materials hold up, especially in extreme temperatures. This is where things get pretty interesting—manufacturers are starting to use advanced techniques like artificial neural networks to get a better handle on welding performance, particularly for complex materials like CF/PEEK. This not only boosts reliability but also opens up options for high-stress applications.

And there’s more! Innovations in welding methods are showing us that using auxiliary heating techniques—like those pulse current applications—can actually improve the mechanical properties of the welding joints. These tweaks ensure that the joint integrity and load capacity are just right, which is super important in industries that need strong and durable welds. As welding technology keeps evolving, especially in the realm of plastics, knowing the ins and outs of welding current will really help you make smart choices. You'll end up picking the best plastic spot welder that fits your specific needs perfectly. With all the ongoing research and improvements, it’s exciting to see how technology and material science are coming together to create more efficient and effective welding solutions across the globe.

When you're in the market for a plastic spot welder, one of the big things to think about is the duty cycle. So, what's the duty cycle all about? Basically, it tells you how long the welder can keep running before it needs to take a chill pill and cool off. If you get a welder with a high duty cycle, you're in for a treat—this means it can handle longer sessions without breaking a sweat. This is super handy for all those tough jobs or if you’re working in a more professional setting. Knowing about the duty cycle can really help you dodge any overheating headaches and keep things running smoothly during those marathon cooking sessions.

There are lots of cool models out there with great duty cycles that fit different welding styles. Take, for example, machines made just for precision work—they often come with nifty features that let you tweak the heat and voltage, which boosts performance. Picking a welder with the right duty cycle means you can tackle all sorts of projects without having to stop every five minutes, whether you’re working on a personal project or a big professional gig. Just remember to think about how much you'll be using it and what materials you'll be dealing with; this way, you’ll pick a welder that fits your specific needs like a glove.

When it comes to plastic spot welding, picking the right electrode material is super important for how well everything holds together. Different materials have different levels of electrical and thermal conductivity, which really affects the quality of the weld.  Take copper, for instance—it’s a go-to choice for a lot of folks because it conducts electricity like a champ. But here’s the thing: it can wear out pretty quickly when the heat’s on, which isn’t ideal. On the other hand, aluminum electrodes are lighter and do a pretty decent job in certain situations, but you might need to crank up the current, which can lead to longer weld times.

Take copper, for instance—it’s a go-to choice for a lot of folks because it conducts electricity like a champ. But here’s the thing: it can wear out pretty quickly when the heat’s on, which isn’t ideal. On the other hand, aluminum electrodes are lighter and do a pretty decent job in certain situations, but you might need to crank up the current, which can lead to longer weld times.

You’ve also got to consider how compatible the electrode material is with the types of plastics you’re working with. Thermoplastics, thermosets, and elastomers all react differently when heat and pressure come into play, so you really need to choose your electrodes wisely for each one. And let’s not forget about surface treatment—using coatings that boost durability or cut down on oxidation can really help to extend the life of your electrodes, ensuring weld quality stays consistent.

By carefully picking the right electrode material and design, manufacturers can really fine-tune their plastic spot welding processes, leading to stronger bonds and overall better product performance. It’s all in the details!

So, when you're picking out a plastic spot welder, one of the biggest things you need to think about is temperature control. Seriously, having good temperature management can really make or break your welding results. Lately, we’ve seen some fantastic tech advancements that really highlight how important heat input is for welding quality. It turns out, if you can keep the temperature just right, it can really help maintain the strength of your welds. For example, recent studies show that keeping the temperature consistently distributed during welding can cut down on defects, which is super important in fields like shipbuilding, where they have to stick to really strict quality standards.

One interesting study even pointed out that if you focus on optimizing temperature uniformity in multi-functional oven systems, it can seriously boost welding quality. This suggests to me (and others, too) that manufacturers and users should definitely pay attention to innovative temperature management techniques. Plus, with the rise of machine learning and deep learning, folks are now using these techy methods to analyze welding parameters. It’s clear that there’s a growing trend towards using data-driven solutions to keep quality in check, which is pretty cool!

Here are a few tips for you:

Choosing a plastic spot welder? Well, let’s talk about a couple of things that really matter: ergonomics and portability! These two factors can seriously make or break your work experience. You know, a welder designed with your comfort in mind can really help reduce the strain on your body. This means you can work longer without feeling totally wiped out. Look for ones that have adjustable handles – it’s a game changer! When the grip fits the shape of your hand, you’ll notice a big difference when you’re using it for a while.

And hey, if you’re like many professionals who are constantly on the move, portability is key! A lightweight welder that’s also compact is super easy to transport, and you won’t lose any power in the process. Really, it’s best to go for models that include carrying cases or that have built-in storage options to keep everything nice and tidy. Oh, and don’t forget to check the battery life and the charging options if you’re going to be in places without an easy power source.

Quick Tips:

1. Look for welders that have anti-slip features. They really help with grip and control when you're in the thick of it.

2. It’s smart to consider models that let you customize settings for different types of plastic. This gives you versatility while still keeping that ergonomic edge.

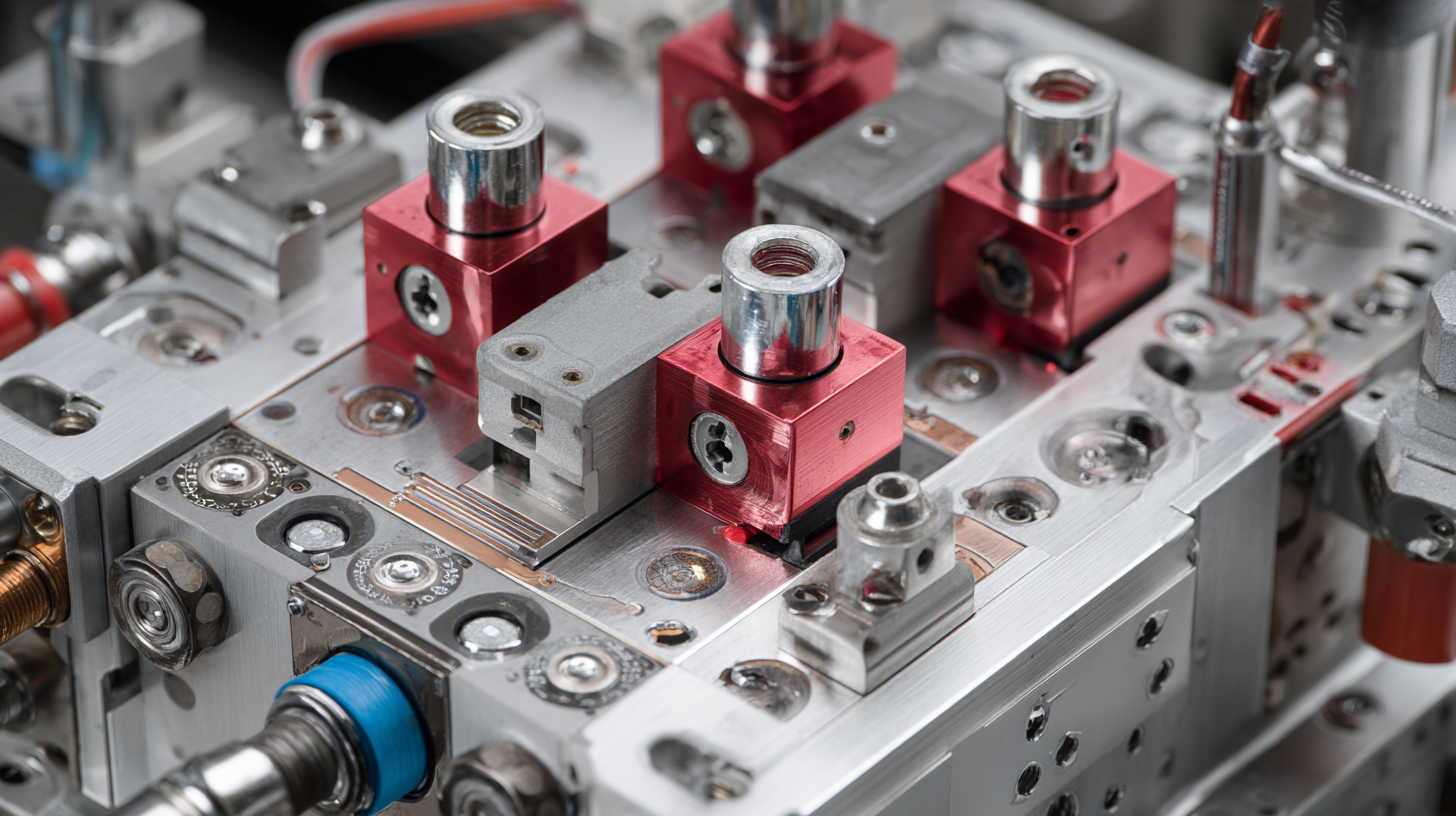

In the ever-evolving landscape of manufacturing, efficiency is paramount. The CGTC Series Ultrasonic Plastic Welding Machine stands out as a crucial innovation that enhances productivity while ensuring precision in the welding process. With its thickened steel body and concentric straight axis design, this machine offers a more stable structure that translates to more accurate welding. According to a recent industry report, a 20% increase in welding accuracy can significantly reduce material waste and increase product quality, thereby maximizing overall operational efficiency.

One of the key features of the CGTC Series is its upgraded titanium alloy through-rod transducer, which is fully compatible with a range of materials including steel, aluminum, and titanium molds. This compatibility is critical in diverse manufacturing scenarios, allowing companies to switch between projects seamlessly without the need for equipment overhaul. Furthermore, the horizontal four-point adjustment mechanism simplifies mold adjustments, reducing setup times and minimizing downtime. Industry data indicates that optimized tooling setups can enhance productivity by up to 30%.

Additionally, the machine is equipped with a brand new operating system that supports 485 communication and offers digital operation capabilities. This advancement enables real-time monitoring and adjustments, further streamlining the welding process. The integration of capacitance digital matching and fully compatible yellow and black ceramic tiles ensures that the machine maintains consistent performance across various applications. Given the current trends in automated manufacturing, leveraging such advanced technology can position companies ahead in the competitive market landscape.

: Understanding welding current is crucial because it significantly influences the mechanical properties and durability of welded joints, affecting the strength and resilience of materials under extreme service temperatures.

Manufacturers can utilize advanced techniques like artificial neural networks to better predict and enhance welding performance, especially for complex materials, leading to more reliable applications in high-stress environments.

Auxiliary heating methods, such as pulse current applications, refine the mechanical properties of welding joints, ensuring optimal joint integrity and load capacity, which is critical for robust welds in various industries.

The duty cycle indicates how long a welder can operate continuously before needing a cooldown period, which is essential for preventing overheating and ensuring efficiency during prolonged use.

A welder with a high duty cycle is suitable for demanding tasks or professional applications, allowing for extended use without interruptions, which is essential based on workload and materials involved.

Look for welders designed with adjustable handles and grips that conform to the hand's shape, as these features can reduce body strain and enhance comfort during extended use.

Portability is vital for professionals who need to transport equipment between job sites. A lightweight design with compact features allows for easy movement without sacrificing power.

Choose models with anti-slip features for better grip and control, and consider welders that offer customizable settings for different types of plastic to enhance versatility while maintaining ergonomic benefits.

Choosing a welder that matches your duty cycle and ergonomic needs ensures you can handle various projects efficiently, preventing interruptions and improving productivity during both personal and professional tasks.

It's essential to check battery life and charging options for welders, especially if working in areas without immediate access to power sources, to ensure continuous operation.