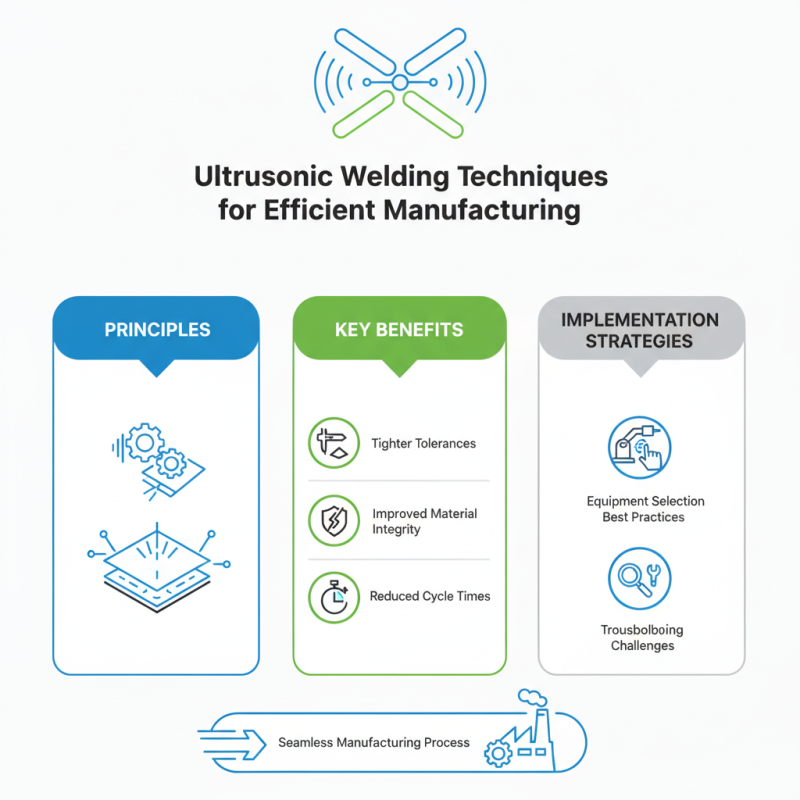

Hey, in today’s fast-changing world of manufacturing, Ultrasonic Welding has really become a game-changer. It’s a pretty clever technology that’s all about getting super precise and efficient joins. Basically, it uses these high-frequency ultrasonic vibrations to bond materials together—no glue, no screws needed. As companies are all about ramping up productivity while cutting costs, getting the hang of Ultrasonic Welding isn’t just useful; it’s kind of essential if you want to stay ahead in the global market.

Now, understanding how Ultrasonic Welding works isn’t just important for the folks on the shop floor. Engineers and design teams also need to be in the know. When you master this technique, you can punch out parts with tighter tolerances, make sure materials stay strong, and speed up the overall cycle time. So, really, diving deep into how to do this right can seriously boost what a company can produce—and make the whole manufacturing process smoother and more reliable.

In the sections ahead, we’ll walk through some practical tips on how to get the most out of Ultrasonic Welding—like choosing the right equipment, best practices for operation, and troubleshooting hiccups along the way. By picking up these skills, manufacturers can unlock the full potential of this tech and be better prepared to handle what modern production throws at them.

Ultrasonic welding is a critical technique that leverages high-frequency sound waves to join materials, primarily plastics and metals, without the need for additional adhesives or fixtures. The core principle lies in the conversion of electrical energy into mechanical vibration, which produces localized heat at the interface of components being welded. This process not only minimizes thermal degradation but also enhances the precision of the weld, making it an ideal choice for high-volume manufacturing applications.

Understanding the key elements of ultrasonic welding is essential for optimizing the manufacturing process. Factors such as amplitude, frequency, and duration of the ultrasonic energy significantly influence the effectiveness of the weld. Moreover, the material properties, including their thickness and composition, dictate the specific settings required to achieve optimal results. As manufacturers increasingly adopt this technology, the ability to manipulate these variables plays a vital role in achieving consistent quality and efficiency in production lines.

Mastering these principles allows businesses to streamline their operations and reduce waste while ensuring strong, durable joins.

Ultrasonic welding has emerged as a preferred technique in modern manufacturing due to its numerous advantages over traditional joining methods. One of the key benefits is the ability to achieve strong, reliable welds without the need for additional adhesives or fasteners. This not only leads to reduced material costs but also minimizes the complexity of assembly processes. Since ultrasonic welding allows for the joining of dissimilar materials, manufacturers can explore innovative designs and tailored solutions that enhance product performance.

Another significant advantage is the speed and efficiency of the ultrasonic welding process. Unlike methods that require prolonged heating or cooling periods, ultrasonic welding operates in seconds, which translates into higher throughput rates and increased production efficiency. The process generates minimal thermal damage to the materials being joined, maintaining their integrity and durability. This combination of speed and precision makes ultrasonic welding an attractive choice for industries looking to streamline operations while ensuring product quality.

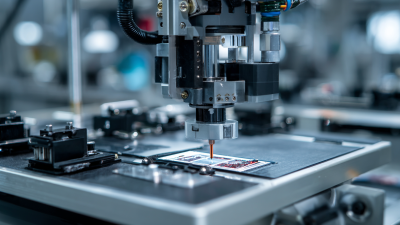

Ultrasonic welding has emerged as a crucial process in modern manufacturing, offering precision and efficiency across various industries. Essential equipment plays a pivotal role in ensuring successful ultrasonic welding outcomes. Key components include ultrasonic generators, transducers, and sonotrodes, each contributing to the creation of high-frequency vibrations that enable materials to bond effectively. According to a report from Grand View Research, the global ultrasonic welding machine market is projected to reach $6.78 billion by 2025, reflecting its widespread adoption in sectors such as automotive, electronics, and medical device manufacturing.

To optimize ultrasonic welding processes, investing in advanced equipment tailored to specific applications is crucial. For instance, high-performance generators capable of adjusting frequency output can enhance weld consistency and quality. Additionally, choosing the right transducer ensures optimal energy transfer, which is critical for materials that vary in thickness and composition.

Tips:

Ultrasonic welding is becoming increasingly vital in manufacturing due to its ability to produce strong, consistent welds rapidly. However, the quality and efficiency of the ultrasonic welding process are significantly influenced by various parameters. Key factors such as frequency, amplitude, pressure, and weld time play crucial roles in determining the outcome of the welding process. Industry reports indicate that optimizing these parameters can enhance joint strength by up to 30%, making it essential for manufacturers to understand and control these variables.

Recent studies have shown that frequency, typically ranging from 20 kHz to 70 kHz, directly impacts the energy transfer during welding. As the frequency increases, the ability to weld thinner materials improves, yet it also requires precise control to prevent defects. Additionally, amplitude adjustments affect the displacement of the ultrasonic waves; industry insights suggest that an optimal amplitude can lead to a reduction in cycle time by 20%, significantly bolstering production efficiency. Furthermore, the application of the correct pressure is imperative, as it influences the molten flow of the materials being welded. Reports confirm that inappropriate pressure settings can result in weak joints and increase the likelihood of failure by as much as 15%.

In conclusion, mastering these parameters is vital for manufacturers aiming to improve their ultrasonic welding processes. Continuous monitoring and adjustment of frequency, amplitude, pressure, and weld time are not just recommendations; they are key practices supported by industry data that fundamentally enhance manufacturing efficiency and product quality.

This bar chart illustrates the impact of various ultrasonic welding parameters on the quality score of the welding process. Parameters such as amplitude, welding time, pressure, and fixture alignment are critical for achieving optimal welding quality and efficiency.

Ultrasonic welding, a widely utilized technique in various industries, offers numerous applications that enhance manufacturing efficiency. This joining method employs high-frequency ultrasonic vibrations to create heat through friction, allowing materials to fuse together with remarkable strength and precision. The automotive industry, for example, frequently utilizes ultrasonic welding for assembling components such as dashboards and electrical connectors, ensuring reliable, durable assemblies while minimizing production time.

Ultrasonic welding, a widely utilized technique in various industries, offers numerous applications that enhance manufacturing efficiency. This joining method employs high-frequency ultrasonic vibrations to create heat through friction, allowing materials to fuse together with remarkable strength and precision. The automotive industry, for example, frequently utilizes ultrasonic welding for assembling components such as dashboards and electrical connectors, ensuring reliable, durable assemblies while minimizing production time.

In the medical device sector, ultrasonic welding is invaluable for assembling items like disposable syringes and IV bags. The precision of this technique guarantees that these products maintain sterility and integrity while remaining lightweight and cost-effective. Electronics manufacturers also benefit from ultrasonic welding for soldering delicate components without the risk of thermal damage, leading to improved reliability and performance in consumer electronics.

Tips for mastering ultrasonic welding techniques include ensuring that the materials to be welded are clean and free from contaminants, as this can significantly impact bonding quality. Additionally, it's crucial to optimize the welding parameters such as time, amplitude, and pressure to achieve the best results. Regular maintenance of ultrasonic welding machinery is also essential to prevent downtimes and ensure consistent quality across production runs. By focusing on these factors, manufacturers can achieve outstanding results in their ultrasonic welding applications.

Ultrasonic welding is a widely adopted method in manufacturing, known for its efficiency and precision in joining materials, particularly thermoplastics and metals. However, while mastering this technique, it is paramount to prioritize safety considerations to protect both operators and equipment. According to a report by the International Institute of Welding, nearly 15% of welding-related injuries stem from improper safety practices, highlighting the urgent need for establishing robust guidelines in ultrasonic welding operations.

One key safety measure involves the use of personal protective equipment (PPE). Operators should wear gloves, safety goggles, and hearing protection to mitigate risks associated with high-frequency sound waves and potential splatter during the welding process. Furthermore, maintaining a hazard-free work environment is crucial. The Occupational Safety and Health Administration (OSHA) states that over 50% of workplace accidents can be attributed to environmental factors such as cluttered spaces and poorly maintained equipment. Regular inspections and housekeeping protocols can significantly reduce these risks, ensuring a safer working atmosphere for all employees involved in ultrasonic welding.

Training programs tailored to ultrasonic welding safety can further enhance awareness and preparedness among workers. Industry standards recommend that companies conduct regular safety seminars and provide hands-on training to keep personnel informed about proper operating procedures, equipment handling, and emergency response strategies. By integrating these safety practices, organizations not only comply with regulatory requirements but also cultivate a culture of safety that contributes to overall operational efficiency and worker well-being.

| Technique | Application | Materials Used | Safety Considerations |

|---|---|---|---|

| Energy Director Welding | Joining thermoplastics | Polypropylene, ABS | Protective goggles required |

| Spot Welding | Metal components | Aluminum, Steel | High temperature caution |

| Transmission Welding | Complex geometries | Polyethylene, PVC | Noise protection recommended |

| Vibrational Welding | Large surface area items | Thermosetting plastics | Gloves must be worn |

| Ultrasonic Staking | Assembly of components | Nylon, Polypropylene | Ensure area is clear of obstructions |

The future of ultrasonic welding technology is poised for significant advancements, driven by innovations that cater to increasing industrial demands for efficiency and precision. According to a recent industry report by Markets and Markets, the ultrasonic welding market is projected to reach USD 1.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1% from 2021. This growth is fueled by the technology's growing applications across various sectors, including automotive, aerospace, and electronics, where the need for strong, reliable, and thermoplastic joints is paramount.

One of the most promising trends in ultrasonic welding is the integration of smart technologies and automation. Systems equipped with real-time monitoring and data analytics can significantly enhance the quality control process, allowing manufacturers to gather detailed insights into their production lines. The adoption of Industry 4.0 principles will further streamline operations, making ultrasonic welding not only faster but also more adaptable to changing manufacturing requirements. These innovations are expected to reduce production costs and time while improving product quality, thus making ultrasonic welding an increasingly vital component of modern manufacturing strategies.

When selecting metal welding machines for copper wire welding and cutting, it is crucial to consider specific features that enhance efficiency while ensuring high-quality results. One of the standout advantages of low-temperature welding technology is that it does not require high-temperature metal melting. This approach minimizes the negative impact on the base material's properties, reducing the risks of deformation and brittleness that often accompany traditional high-heat methods. By maintaining a lower heat application, these machines preserve the integrity of the metals, making them an excellent choice for precision work.

Moreover, eco-friendly practices are integral to modern welding techniques. The use of machines that operate without flux or filler materials greatly reduces the emission of harmful gases and minimizes the production of slag. This adherence to stringent environmental standards means less post-welding cleanup, enhancing workplace safety and reducing production downtime. Additionally, the quality of welded joints achieved with these machines is exceptional, showcasing strong bonding and excellent sealing capabilities. This is particularly important for applications that demand high levels of reliability and strength.

Furthermore, the adaptability of modern welding machines allows for effective welding across a range of metal types, including both similar and dissimilar metals like copper-aluminum and nickel-stainless steel. This versatility ensures that users can achieve desired outcomes, regardless of the materials they are working with. The combination of low-temperature techniques, eco-friendliness, and strong adaptability makes these welding machines a comprehensive solution for anyone involved in metal welding and cutting tasks.

: Ultrasonic welding is a technique that uses high-frequency sound waves to join materials like plastics and metals without adhesives or fixtures, creating localized heat at the welding interface.

The effectiveness of ultrasonic welding is influenced by factors such as amplitude, frequency, duration of ultrasonic energy, and the properties of the materials being welded, including their thickness and composition.

Essential equipment for ultrasonic welding includes ultrasonic generators, transducers, and sonotrodes, which work together to create high-frequency vibrations that allow materials to bond effectively.

Manufacturers can optimize their ultrasonic welding processes by investing in advanced equipment tailored to their specific applications, maintaining and calibrating equipment regularly, and experimenting with different sonotrode designs.

Regular maintenance and calibration of ultrasonic welding equipment are crucial to prevent performance degradation, ensure accuracy, and maintain the quality of the welding process.

Ultrasonic welding minimizes thermal degradation and enhances weld precision, making it ideal for high-volume manufacturing applications where consistency and efficiency are essential.

The choice of transducer is critical for optimal energy transfer, especially when working with materials of varying thickness and composition, which directly impacts weld quality.

Staying informed about advancements in ultrasonic welding technology can lead to the adoption of innovative solutions that enhance efficiency and reduce costs in manufacturing processes.

Ultrasonic Welding is a highly efficient manufacturing technique that leverages high-frequency ultrasonic vibrations to join materials, primarily thermoplastics. This method offers significant advantages over traditional joining processes, including faster production times, reduced energy consumption, and a cleaner finish. Understanding the fundamental principles of Ultrasonic Welding is crucial, as it directly impacts the quality and efficiency of the final product.

Essential equipment, such as ultrasonic generators and transducers, plays a vital role in the welding process. Various parameters, including pressure, time, and amplitude, must be carefully controlled to achieve optimal results. Industries ranging from automotive to electronics are increasingly adopting Ultrasonic Welding techniques due to their versatility and effectiveness. As safety considerations are paramount in any manufacturing operation, proper training and adherence to guidelines are essential. Additionally, advancements in technology promise to enhance the capabilities and applications of Ultrasonic Welding, leading to further innovations in the manufacturing sector.