In the ever-changing world of manufacturing, getting a good grip on Wire Harness Welding is pretty much essential if you want top-notch quality and efficiency. Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has really made a name for itself over the past twenty years in ultrasonic Plastic Welding — they’re always pushing the envelope with the latest tech. Their expertise means businesses can really boost their wire harness assemblies, making them more durable and better performing. This guide will walk you through the key techniques and best practices for Wire Harness Welding, so manufacturers can make the most of advanced welding tech for great results. We’re all about quality and innovation, and our goal is to help industries produce with confidence—sticking to top standards of reliability and efficiency every step of the way.

Wire Harness Welding might not be the most glamorous topic, but it’s totally essential when it comes to building reliable electrical systems—especially in cars and airplanes. If you get the hang of the basic techniques, it can really up the quality of your connections and help avoid future headaches. Funny thing is, studies show that if you don’t weld properly, failure rates can shoot up to around 20%. That’s a big deal because it often leads to expensive recalls and repairs—nobody wants that. So, mastering these welding skills is pretty much non-negotiable for manufacturers who want to hit high-quality standards.

One of the main methods folks rely on is resistance welding. It’s super popular because it’s quick and effective at joining lots of wires at once. According to the International Journal of Advanced Manufacturing Technology, when you do resistance welding right, the joints can actually be as strong as the wires themselves. The trick is in tweaking things like the current and how long you apply the heat—get those just right, and you can cut down defects by over 30%. Ultrasonic welding is also on the rise. It’s a pretty cool process—less heat means it’s gentler on sensitive parts and keeps everything cleaner.

And here’s a little tip: adding advanced quality control tools, like real-time monitoring and feedback systems, makes a huge difference. A study from the Welding Institute showed that companies using automated systems saw defects drop by about 25%. That’s huge. Bottom line? If you focus on these key practices and keep improving the process, you’ll end up with better welds, better products, and happier customers in the long run.

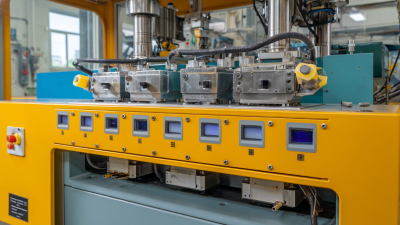

When it comes to wire harness welding, having the right tools and equipment really makes all the difference. Take ultrasonic welding systems, for example — companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are actually leading the way with some pretty advanced tech. They've been honing their ultrasonic welding solutions for over 20 years, serving all kinds of industries that need precise and durable wire harnesses. I saw in a recent industry report that the ultrasonic welding market is expected to grow at about a 5.2% compound annual rate. That just goes to show how much people are relying on this tech for getting things done efficiently.

Choosing the right equipment isn’t just about picking something off the shelf; you want to think about factors like the frequency, power, and how well it plays nice with different materials. Ultrasonic welders use high-frequency sound waves to join things really quickly and strongly — especially handy for thermoplastics in wire harnesses. According to data from the International Ultrasonic Technology Association, this method can cut down processing times by as much as 30% compared to the old-school methods. That’s a huge boost in productivity, plus it often means better quality and less waste. It’s why so many manufacturers, especially in the automotive and electronics industries, swear by ultrasonic welding these days.

Getting ready for wire harness welding is super important — it can really make or break the final quality of your work. Before you dive in, make sure all the parts are squeaky clean and free of any gunk. That means the wires, connectors, and anything else you're planning to join. Taking the time to clean everything properly isn't just about making better welds; it also helps the harness last longer. Trust me, a little extra effort here pays off down the line.

A quick tip: use a good solvent for cleaning, and pick lint-free cloths — you don’t want any leftover fibers messing things up. Also, keep your workspace organized so all your tools and materials are within arm’s reach. It really helps the workflow and saves you from scrambling around midway.

Another key step is to measure and cut your wires carefully. Getting the lengths just right means less waste and a nicer fit overall. Make sure you’re paying attention to how everything lines up — you want enough slack for connections but no excess hanging around.

Tip: use quality wire cutters and double-check your measurements. It’s also handy to label different wires — that way, you won’t get mixed up when you’re actually welding. Focusing on these little prep details makes a big difference and sets you up for a smooth, successful wire harness weld project.

Wire harness welding is a pretty essential part of lots of industries, especially in things like cars and electronics. But, honestly, it’s not always smooth sailing — common issues pop up, like inconsistent weld strength, misaligned parts, or even overheating. I read somewhere from the International Ultrasonics Association that up to 30% of weld failures can be traced back to settings being off or equipment not being properly calibrated. That just goes to show, you really gotta pay close attention during the setup to get things right.

Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been in the ultrasonic plastic welding game for over 20 years. We totally get these challenges, and that’s why we’ve developed top-of-the-line ultrasonic welding systems. They’re designed to give you better precision and make your wire harness welding more reliable. Our machines come with cool features like adjustable energy output and real-time monitoring, so you can fine-tune things on the fly and get consistent results. A study from the Welding Institute even says using ultrasonic tech can boost efficiency by up to 50%, which is a pretty big deal if you ask me — especially if you're aiming for higher quality and faster production.

Getting strong, reliable welds in wire harness assembly isn't just about following some steps—it's about really paying attention to the details. First off, you gotta make sure you're using the right welding equipment and settings, tuned specifically for the wires and insulation you're working with. Knowing the specs of your wires helps you pick the right voltage, current, and travel speed, which really makes a difference in how consistent your welds turn out. Also, don’t forget to keep your machines in top shape—regular maintenance and calibration are key to avoiding those pesky defects that come from faulty equipment.

Preparation is where it all begins, honestly. Make sure you strip those wires to the right length and double-check that there’s no dirt, oil, or anything that could mess up the weld. Using fixtures or clamps to hold everything steady can save you from headaches later on—keeps things aligned and secure during welding. Once you’re done, take the time to inspect your welds closely, whether that’s just visual checks or more advanced tests, to make sure everything’s up to standard.

Follow these simple tips, and you’ll see a real improvement in the quality and reliability of your wire harness projects—they make all the difference!

Safety really has to be a top priority when it comes to wire harness welding. The process is pretty complex, and let’s be honest, it can expose workers to all kinds of hazards—sparks flying, heat, fumes—you name it. Did you know that OSHA reports around 42,000 workplace injuries related to welding each year? That’s a lot, and it just goes to show how important it is to have solid safety measures in place. Things like wearing proper gear—helmets, gloves, flame-resistant clothes—they’re not just fancy accessories; they actually protect you from burns and burns from sparks and heat. Plus, making sure there's good ventilation is super important, too, because bad air quality can lead to serious respiratory problems—over 40% of welders have reported breathing issues linked to fumes, which is pretty concerning.

On top of that, ongoing safety training is a game-changer. The American Welding Society mentions that regular refreshers on safety practices can cut down accidents by nearly a third. And let’s not forget to keep equipment in check—routine inspections and safety checklists can really make a difference. Technology can be a lifesaver here too; automated welding systems aren’t just cool gadgets—they help reduce mistakes and boost precision, making the whole process safer and producing better results. Looking out for your team by sticking to these safety tips isn’t just about avoiding accidents. It helps improve overall efficiency and quality, making everyone’s job easier and safer in the long run.

| Safety Protocol | Description | Importance Level | Compliance Measures |

|---|---|---|---|

| Personal Protective Equipment (PPE) | Ensure welder wears gloves, mask, and protective clothing. | High | Regular training and audits on PPE usage. |

| Ventilation | Ensure adequate ventilation to avoid inhaling fumes. | High | Use exhaust fans and check air quality regularly. |

| Proper Equipment Setup | Check and calibrate welding equipment before use. | Medium | Implement a pre-welding checklist. |

| Fire Safety Measures | Have fire extinguishers and first aid kits accessible. | High | Regular drills and checks on equipment functionality. |

| Training and Certification | Ensure all staff are trained and certified for welding tasks. | High | Maintain records of training and skills assessments. |

: Cleaning components such as wires and connectors is crucial because it enhances weld quality and increases the durability of the harness. Contaminants can weaken the weld, so it's essential to ensure that all surfaces are clean and free from dirt or oil.

Wires should be accurately measured and cut to the desired lengths to minimize waste and ensure a proper fit within the harness assembly. It's also important to pay attention to the wiring configuration and allow enough length for connections without excess slack.

Using a quality wire cutter, measuring tools to ensure precision, and labeling tools to keep track of different wire types and lengths can enhance the preparation process, making the welding workflow more efficient.

Common issues include inconsistent weld strength, poor alignment, and overheating. Many of these problems can stem from improper settings or equipment calibration.

Ultrasonic welding technology can significantly reduce the risks of common issues by offering adjustable energy output and real-time monitoring. This technology can enhance precision and reliability, potentially increasing the welding process's efficiency by up to 50%.

Best practices include using the correct welding equipment and settings, properly stripping wires to the right length, ensuring cleanliness of surfaces, using fixtures or clamps for alignment, and conducting post-weld inspections to verify the strength and reliability of the welds.

Regular maintenance and calibration of welding machines are vital because they help prevent defects caused by equipment failure and ensure consistent quality in the welding process.

Techniques such as visual inspection and non-destructive testing can be employed to ensure that the welds meet the required strength and reliability standards.

Organizing the workspace to have all necessary tools and materials within reach can lead to a more efficient workflow, reducing the likelihood of mistakes and improving overall productivity.

Proper preparation, which includes cleaning, measuring, and cutting wires accurately, is critical for the quality of welds as it lays a solid foundation for successful and reliable welding operations.

Getting the hang of wire harness welding isn't just about knowing a few techniques — it’s about really understanding the ins and outs of the right tools and methods to get those perfect, strong welds. It all kicks off with mastering the basics of different welding techniques, and honestly, familiarizing yourself with the essential equipment makes a huge difference. Having a clear, step-by-step prep guide can be a lifesaver, especially when it points out common problems you might run into and how to tackle them. Following best practices is key to making sure your welds are solid and dependable, and of course, safety shouldn’t be overlooked — working safely keeps everyone out of trouble.

Here at Shenzhen Chengguan, we’re all about ultrasonic welding systems — these guys are game-changers for boosting both the efficiency and quality of wire harness welding. With more than 20 years under our belt in ultrasonic plastic welding, we’re dedicated to delivering top-notch equipment that fits the needs of different industries. Our goal? To help you get reliable, high-performance results every time you work on wire harnesses.