You know, as everyone freaks out over electric vehicles (EVs) and renewable energy, making these things efficiently is more important than ever—especially when it comes to Battery Tab Welding. I read somewhere that, by 2025, the global battery market could hit around $120 billion, and a big chunk of that growth is thanks to advancements in EV tech. Getting the hang of Battery Tab Welding isn’t just about making sure the batteries hold together; it’s also about speeding up production and keeping everything running smoothly.

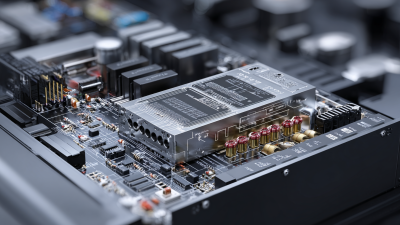

At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been in the ultrasonic game for 20 years. We use that experience to create innovative solutions that keep up with what the battery industry needs today. Our ultrasonic Welding Systems help boost both the speed and precision ofBattery Tab Welding, so manufacturers can hit those demanding standards for modern batteries without breaking a sweat.

Battery tab welding might sound like a small part of making lithium-ion batteries, but honestly, it’s a pretty big deal. It’s all about creating solid, reliable connections—stuff that really determines how well your battery performs and how long it lasts. If you follow some basic principles during this process, it can seriously boost your production speed and make sure the end product is top-notch. Key tricks include keeping the right settings—like temperature and pressure—so you get those strong, lasting bonds between the battery cells and their tabs. And using fancy equipment that’s designed to reduce human error? That’s a game-changer for keeping the quality consistent.

Lately, we’ve seen a big shift with the launch of fully automatic production lines in the lithium-ion battery world. This really highlights how much demand there is for cleaner energy solutions. These high-tech factories are built to handle super precise battery tab welding, making sure every single connection is up to the toughest standards. Not only does this automation speed things up quite a bit, but it also helps manufacturers keep up with the climbing global need for sustainable energy. When companies get a good grip on these welding techniques, they’re not just making batteries—they’re helping change the energy game, all while delivering high-quality products consumers can trust.

In the fast-changing world of battery manufacturing, choosing the right welding method is actually pretty crucial for ensuring both quality and efficiency in the final product. In this blog, I want to compare two major techniques: resistance welding and laser welding — both pretty common approaches you’ll see in the industry.  Resistance welding has been around forever, mainly because it’s simple and cost-effective, which makes it perfect for mass production. Basically, it heats up through electrical resistance and fuses the battery tabs to the cells. That said, it’s not perfect — it can cause thermal stress or uneven welds, especially with more complex battery designs.

Resistance welding has been around forever, mainly because it’s simple and cost-effective, which makes it perfect for mass production. Basically, it heats up through electrical resistance and fuses the battery tabs to the cells. That said, it’s not perfect — it can cause thermal stress or uneven welds, especially with more complex battery designs.

On the flip side, laser welding is kind of the modern alternative. It’s great because it causes less thermal damage, allowing for super precise and strong joints — especially when accuracy really matters. At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’re all about pushing the boundaries of welding tech. While our main specialty is ultrasonic welding systems, we totally get that developing reliable battery joining methods—whether ultrasonic, resistance, or laser—is key to meeting the rising needs of the battery industry. Ultimately, focusing on innovative welding techniques will help us make batteries that are safer, with higher capacities—really crucial for the future of energy storage and electric vehicles.

When it comes to making batteries more efficiently, I’ve found that really understanding what affects weld quality is super important. One of the first things you gotta get right is choosing the right materials for the battery tabs and the welding electrodes. If those don’t play nicely together, the weld might not be as strong or consistent as you want. For example, using aluminum tabs with copper electrodes can cause adhesion issues because their thermal properties don’t match up well. So, taking the time to pick the right materials really pays off in making sure the connections are solid and reliable.

Another big deal is dialing in the welding parameters just right. Things like the welding current, how long you hold the weld, and the pressure you apply need to be carefully adjusted. If the current's too high, it can heat things up too much, messing with the materials and leading to weak welds. On the flip side, if it’s too low, the weld might be pretty flimsy. Plus, keeping the surfaces clean is a must because dirt or oils can really mess up the weld quality. By paying attention to these details, manufacturers can improve weld strength, which in turn helps make the batteries last longer and perform better overall.

When it comes to making batteries, having efficient welding processes is a total game-changer. They really help boost production speeds and make sure the batteries last longer. As battery tech keeps evolving, bringing in cutting-edge equipment is more important than ever. Lately, industry buzz around ultrasonic welding—especially for attaching battery tabs—has been growing a lot. Why? Because it offers laser-precision and a super-strong bond without messing up the delicate materials. In fact, the global market for ultrasonic welding gear is expected to hit about USD 1.98 billion by 2026, showing just how much demand there is for reliable, efficient batteries, especially with electric vehicles taking off.

Now, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is really stepping up in this space. With over 20 years of experience in ultrasonic plastic welding, they’ve built a solid reputation. Their equipment is designed specifically for the battery industry—think simultaneous tab welding that keeps heat input low, so the batteries stay in top shape. This doesn’t just improve weld quality; it also speeds things up—making it a must-have for manufacturers trying to stay ahead in the rapidly growing EV market. As the world moves toward greener energy, getting a grip on these welding techniques isn’t just a good idea, it’s pretty much essential for success in battery production.

In the fast-paced world of battery tab welding these days, staying on top of the latest techniques is super important if you wanna keep defects at bay and improve how efficiently your production runs. Lately, industry folks have been saying that using high-speed inspection systems can really make a difference — catching those sneaky welding flaws before they cause big problems or lead to customer complaints. For example, automated inspection tools have shown they can boost quality control accuracy by up to 30%, especially in electronics manufacturing where tiny defects can seriously mess up the final product's integrity.

On top of that, the fiber laser market is booming — it’s expected to grow from around $4.63 billion in 2025 to a whopping $10.75 billion by 2032. This just shows how much there's a push for more precision and dependability in manufacturing, including in battery production. Adding these cutting-edge techs into battery tab welding doesn’t just make things more efficient — it also helps us hit sustainability targets by reducing waste and saving resources. That's a huge deal these days, with companies aiming for smarter, greener manufacturing. As manufacturers jump on these new techniques, they’re really focused on boosting weld quality and smoothing out production processes at the same time.

When it comes to making batteries, staying ahead in the game means paying close attention to how we weld those tabs. Sharpening our welding techniques isn't just about getting it done—it's about doing it smarter, faster, and more reliably. One of the coolest tricks? Using data to actually tell us what's working and what's not. I came across a recent report by Smith & Associates, and it turns out that companies who started tracking their welding metrics saw about a 20% drop in defects and a big boost in their overall yields. So, really, focusing on things like how long each cycle takes, how much energy we're using, and how strong the joints are can help spot weak spots and guide us in fixing them.

And here's the fun part: with some of those fancy analytics tools, like machine learning, we can monitor everything in real time! A study from the Battery Technologies Journal showed that companies using predictive analytics saw their efficiency jump by around 15%. Tracking stuff like the heat input and how the weld nugget forms can really tell us if our process is consistent — which is key for hitting those tight tolerances. Honestly, jumping on this data-driven train not only helps us make better quality batteries but also cuts costs and makes the whole process more sustainable. Pretty exciting, right?

The ultrasonic welding market is experiencing a transformative phase, driven by advancements in technology and the increasing demand for efficient manufacturing processes. Recent reports indicate that the global ultrasonic welding equipment market is projected to grow significantly, with an anticipated CAGR of over 5% through the next five years. This growth is largely attributed to innovations in machine design and material compatibility, as seen in products like the CGTC Series Ultrasonic Plastic Welding Machine.

One of the standout features of the CGTC Series is its thickened steel body and concentric straight axis design, which offers a more stable structure and ensures precise welding outcomes. The upgraded titanium alloy through-rod transducer enhances compatibility with a range of molds—whether steel, aluminum, or titanium—thereby expanding its applicability across diverse manufacturing scenarios. Notably, the horizontal four-point adjustment feature facilitates more convenient mold adjustments, streamlining operation for manufacturers and enhancing overall efficiency.

Moreover, the machine incorporates capacitance digital matching, allowing full compatibility with yellow and black ceramic tiles, a benefit noted in recent industry reports emphasizing the need for adaptable welding solutions. With a brand new operating system that supports 485 communication and digital operation, users can expect a modernized interface for improved operation control. The continued evolution of ultrasonic welding technology, exemplified by these advancements, is crucial for manufacturers looking to boost productivity and maintain competitive advantage in the market.

: Battery tab welding is the process of creating connections between battery cells and tabs in lithium-ion batteries. It is crucial for ensuring high-quality connections that contribute to optimal performance and longevity of the batteries.

Key techniques include maintaining appropriate welding parameters like temperature and pressure, and utilizing advanced equipment to minimize human error, which leads to more consistent quality.

Automation streamlines the production process and maximizes output, ensuring that each connection meets stringent industry standards. This helps manufacturers meet the growing global demand for sustainable energy.

Resistance welding is cost-effective and suitable for high-volume production but may lead to thermal stress and inconsistent weld quality. Laser welding minimizes thermal damage and offers precise control over the weld quality, making it ideal for delicate applications.

Key factors include the selection of appropriate materials for battery tabs and electrodes, optimization of welding parameters (such as current, duration, and pressure), and maintaining cleanliness of the weld surfaces to avoid contamination.

Material selection is crucial because incompatible materials, like aluminum tabs with copper electrodes, can lead to poor adhesion and affect the strength and consistency of the weld.

Welding parameters such as current, duration, and pressure need to be carefully calibrated. Excessive heat from high current can distort materials, while low current may yield weak joints, impacting overall weld quality.

Cleanliness is vital for ensuring weld integrity, as any contaminants on the weld surfaces can severely compromise the strength and reliability of the connection between battery cells and tabs.

In the fast-changing world of battery manufacturing, getting a good handle on Battery Tab Welding techniques is pretty much a must. It’s key to keeping the production smooth and making sure those connections are solid. In this post, I’ll walk you through the basics of battery tab welding—kind of like the essentials you need to know—and compare resistance welding with laser welding to see which one might be better for your needs. We’ll also look at what factors really affect weld quality, so you can improve your process by choosing the right equipment and trying out some new techniques. This way, you can cut down on defects and boost overall efficiency.

On top of that, I’ll highlight why data matters—digging into how tracking performance metrics can really help optimize your welding process. With over 20 years under our belt, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is a leader when it comes to ultrasonic welding tech. We offer top-notch systems designed to meet all sorts of industrial needs. By bringing in these advanced ultrasonic solutions, manufacturers can really level up their battery tab welding game—leading to faster production runs and more reliable products. Trust me, the right tools and know-how can make a huge difference.”