In today’s world of modern manufacturing, Metal Foil Welding is really starting to make waves as a top-notch way to create strong, reliable joints across a variety of applications. As industries look for ways to boost efficiency and get more done, the flexibility and precision that Metal Foil Welding offers are quick to prove just how valuable they can be. Our company, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., has been leading the way in ultrasonic tech for over 20 years. We’re passionate about providing the latest solutions in ultrasonic plastic Welding Systems and equipment. Our dedication helps clients from different industries tap into advanced welding methods like Metal Foil Welding, so they can achieve better results and keep up with market demands.

So, in a nutshell, this sets the stage for understanding how Metal Foil Welding is really transforming manufacturing, and it shows just how important innovative tech is for pushing our industry forward.

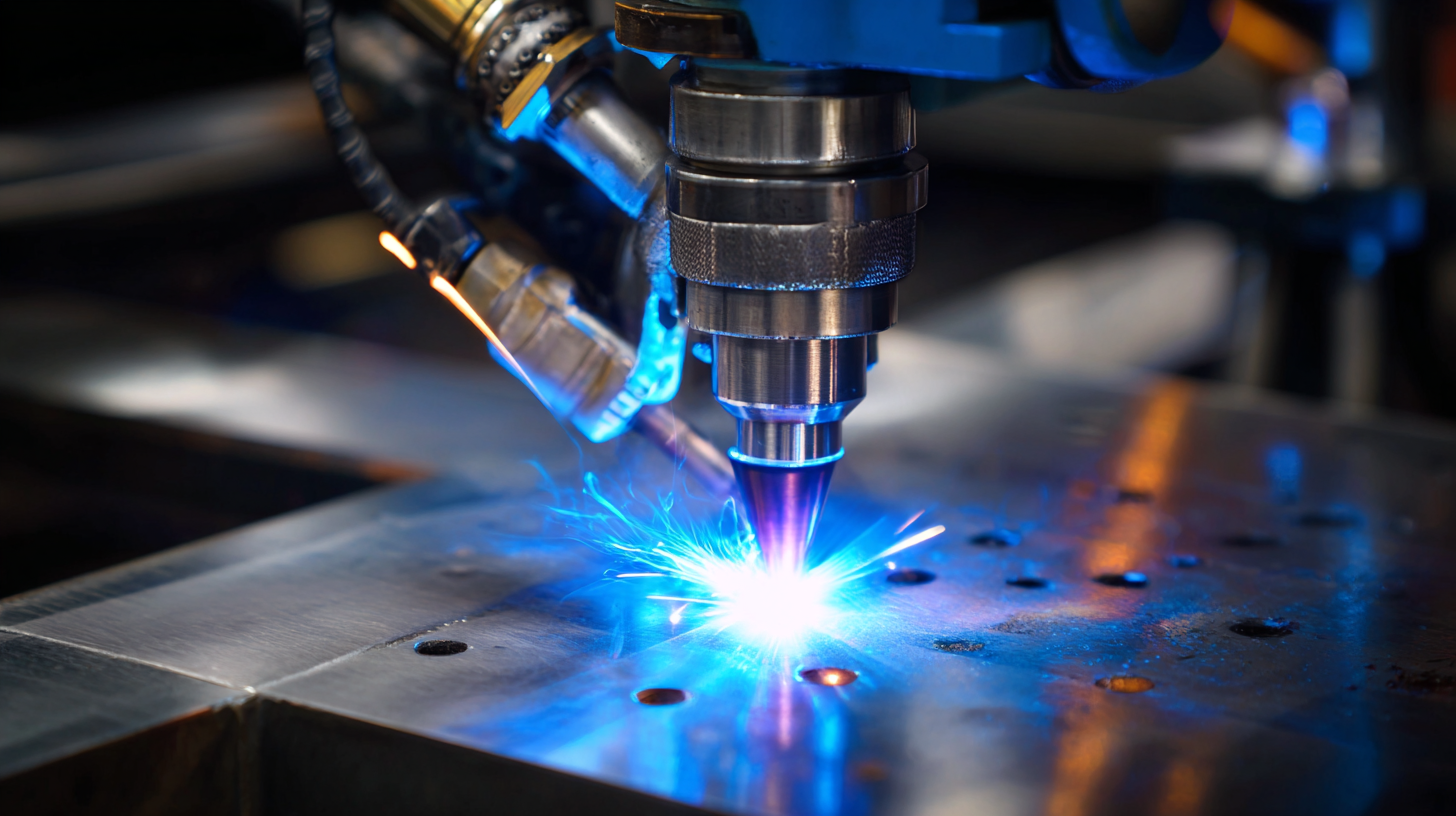

You know, metal foil welding techniques are really catching on these days in manufacturing—and for good reason. They let you create strong, precise bonds without messing up the material too much, which is pretty impressive. Basically, they use heat and pressure to fuse these super-thin metal sheets, called foils. What’s cool is how accurate these methods are, letting folks build really intricate parts with tight tolerances. That’s why industries like aerospace, electronics, and automotive are so into it—they need to cut down on weight but still keep things running smoothly.

Getting the hang of metal foil welding involves knowing a few different methods, like laser welding, ultrasonic welding, and resistance welding. Each one has its own perks depending on what you’re working with and what you need. For instance, laser welding is great if you want speed and precision, making it perfect for tiny electronics. On the other hand, ultrasonic welding works well with thermoplastics. If you really get a grasp on these techniques, you can deliver top-notch results, save some money in production, and boost the overall quality of your products. It’s pretty exciting stuff!

When it comes to manufacturing, getting the heat input just right during metal foil welding is a big deal — it really makes a difference in both quality and efficiency. Lately, I’ve come across some studies showing that having precise control over heat can actually improve the whole welding process a ton. It helps cut down on defects and makes sure those joints stay strong. For example, using the correct thermal settings with techniques like TIG welding can really boost the quality of the weld, especially when you're working with different metals like AA5083 and AA7075. The nice thing is, doing this kind of precise control not only makes the joints tougher but also reduces the risk of brittleness that you often get with more traditional welding methods.

A little tip: When you're adjusting heat input parameters, it’s a good idea to start with a baseline based on some experiments — kind of like a starting point. Playing around with the path of the heat source can also help manage how heat spreads during welding, which is something recent research in electro-gas welding has pointed out. And if you’re trying out other techniques like ultrasonic or magnetic pulse welding, it’s super important to think about what materials you're working with, making sure the method fits the specific needs for durability and performance. It’s all about tailoring the process to get the best results.

Metal foil welding actually gives you a pretty significant edge over the traditional methods folks have been using for ages. I mean, sure, traditional welding has been the go-to for a long time, but honestly, it can come with some headaches—like heat distortion or even weakening the materials you're working with. The cool thing about metal foil welding is that it uses lower temps, which means less thermal stress and better preservation of the original materials. Not only does this improve the overall quality of the final product, but it also opens up more options for different metals that can be joined successfully.

Metal foil welding actually gives you a pretty significant edge over the traditional methods folks have been using for ages. I mean, sure, traditional welding has been the go-to for a long time, but honestly, it can come with some headaches—like heat distortion or even weakening the materials you're working with. The cool thing about metal foil welding is that it uses lower temps, which means less thermal stress and better preservation of the original materials. Not only does this improve the overall quality of the final product, but it also opens up more options for different metals that can be joined successfully.

A quick tip: When you’re switching over to metal foil welding, make sure you’re choosing the right kind of foil for what you need. Different metal alloys have their own quirks, and those can affect how well the welding goes and how the finished product holds up.

On top of that, this technique is pretty efficient—speeding up the process and eating up less energy compared to some traditional methods. That’s a win for saving money and getting your projects done quicker. Plus, since everyone’s pushing for more sustainable practices these days, the lower energy use of metal foil welding is definitely a big plus.

Another tip: It’s worth investing some time in training your team on this technique. The more familiar everyone is with the equipment and process, the better your welds will turn out, and your whole manufacturing workflow will get smoother.

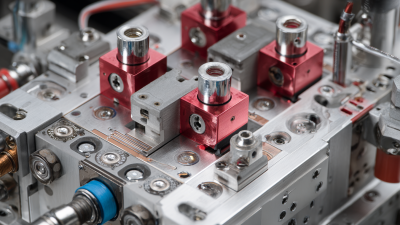

You know, advanced equipment really makes a big difference when it comes to getting precise, high-quality welds on metal foils. These days, as industries push for better performance and more reliable products, using the latest welding machines can totally upgrade the strength and integrity of the welds. They help with better temperature control and keep pressure more consistent, which means fewer defects and joints that last longer — pretty cool, right?

On another note, did you see how the global market for precision resistors is skyrocketing? From about $4.35 billion in 2022, it’s expected to hit around $6.40 billion by 2029. That just shows how much manufacturers are investing in top-tier tech, like advanced welding methods, to make resistors that are tighter in tolerances and perform even better. The crazy thing is, this pattern isn’t just about making cooler stuff; it’s also about helping companies stay ahead of the game in a pretty competitive field. Basically, leveling up manufacturing techniques through cutting-edge tech isn’t just a trend — it’s a must if you wanna keep up and deliver top-quality products.

All in all, it’s clear that upgrading to these advanced methods isn’t just a luxury anymore. It’s the key to making stronger, better products and staying competitive. Pretty fascinating, huh?

You know, metal foil welding techniques have really become a game-changer in the high-tech world. If you look at some recent case studies, it’s clear just how many benefits they bring. For example, the global market for these welding techs is projected to hit around $22 billion by 2025 — pretty impressive, right? This boom is mainly fueled by advances in areas like electronics and aerospace. One thing that stands out is how the precise welding of ultra-thin metal foils can seriously boost the performance of products and even cut down manufacturing costs. It’s like hitting two birds with one stone.

Here’s where Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. comes in. They’ve been leading the charge for years — with two decades of know-how in ultrasonic plastic welding, they’re now helping their clients get comfortable with metal foil welding techniques. Recent projects show that their ultrasonic welding systems can create joints that are stronger than 90% of the original material’s strength. That’s a huge win for making high-tech gear more reliable and durable. Plus, with features like cutting and extraction, their ultrasonic equipment makes the whole process smoother, helps reduce waste, and keeps productivity high. Pretty cool, huh?

| Industry | Application | Technique Used | Benefits Realized | Outcome |

|---|---|---|---|---|

| Electronics | Battery Components | Ultrasonic Welding | Reduced cycle times, enhanced joint strength | Increased production efficiency by 30% |

| Aerospace | Fuel System Components | Laser Welding | Improved precision, minimized material waste | Cost savings of 15% on materials |

| Medical Devices | Implantable Devices | Resistance Welding | Enhanced biocompatibility, superior joint integrity | Achieved compliance with stringent health standards |

| Automotive | Electronic Control Units | Orbital Welding | Increased durability, greater thermal stability | Enhanced product lifespan by 20% |

| Telecommunications | Signal Components | TIG Welding | Improved electrical conductivity, reduced defect rates | Defect rates decreased by 40% |

The future of metal foil welding tech is looking pretty exciting and could totally shake up how we make things. With all these new innovations, it’s like everything’s moving towards faster, more precise ways of working. As industries keep pushing for lighter yet stronger materials, we’re seeing some cool advancements in welding methods to keep up. Techniques like laser welding and ultrasonic welding are really catching on — they’re super accurate and help minimize things like thermal distortion. Not only do they make the joints stronger and more reliable, but they also open up new possibilities for connecting different types of metals, which is a game-changer for sectors like aerospace, cars, and electronics.

On top of the tech side of things, automation and smart manufacturing are really transforming the game. By bringing artificial intelligence and machine learning into the mix, manufacturers can now keep an eye on things in real-time and tweak processes on the fly. This means fewer mistakes, better quality, and faster production. Plus, modular systems are making it easier for factories to adapt quickly as needs change — which is great for keeping costs down and staying sustainable. As all these trends develop, the metal foil welding industry is just getting started on unlocking its full potential, leading to better results and a whole new future for manufacturing.

The CGZP Ultrasonic Rotary Plastic Welding Machine represents a significant leap forward in modern manufacturing, particularly as industries increasingly prioritize efficiency and precision. With its innovative turntable design, this machine facilitates continuous operation for batch production, a feature that can substantially boost productivity. According to a report from the International Journal of Advanced Manufacturing Technology, manufacturers utilizing continuous processing methods can improve output by as much as 30%, making CGZP an invaluable asset in high-demand environments.

Moreover, precision positioning technology is a cornerstone of the CGZP machine's design, ensuring that workpieces are consistently aligned to exact specifications. This high-accuracy positioning mitigates the risks of misalignment and production errors, leading to enhanced product quality. The industry standards for alignment precision are often below 0.1mm, and the CGZP meets and exceeds these expectations, driving quality assurance processes in manufacturing settings.

In addition to efficiency and precision, the CGZP Ultrasonic Rotary Plastic Welding Machine offers superior welding capabilities. The technology does not require filler materials, which results in high-strength welds with excellent sealing properties and minimal heat damage to the workpieces. A report from the Welding Research Council underscores that ultrasonic welding can reduce thermal distortion and preserve the integrity of sensitive components, making the CGZP an ideal choice for delicate manufacturing applications where precision and quality are paramount.

: Metal foil welding offers lower temperatures, minimizing thermal stress and preserving material integrity, leading to enhanced product quality and an expanded range of weldable materials.

Metal foil welding provides faster processing times and reduced energy consumption, which can result in significant cost savings and quicker project completion.

Teams should invest in training to master the metal foil welding technique, as familiarity with the equipment and process can greatly enhance weld quality and overall manufacturing efficiency.

Advanced equipment enhances the precision and quality of metal foil welds by providing better temperature control and consistent pressure application, which reduces defects and increases joint durability.

The growth of the precision resistor market underscores the demand for superior manufacturing techniques, including metal foil welding, to produce components with tighter tolerances and enhanced performance characteristics.

Expected trends include the adoption of technologies such as laser and ultrasonic welding for improved accuracy, automation for real-time monitoring, and the integration of AI and modular systems to enhance adaptability and efficiency.

The lower energy requirements of metal foil welding align with industries' goals for sustainability, making it an attractive option for manufacturers striving to reduce their environmental impact.

Automation and smart manufacturing lead to real-time monitoring and optimization of welding processes, resulting in reduced defects and increased production rates.

Metal foil welding is gaining traction in sectors such as aerospace, automotive, and electronics, where the joining of lightweight and high-strength materials is increasingly demanded.

Innovations in metal foil welding technology are expected to drive superior manufacturing outcomes, improving efficiency, precision, and the ability to join dissimilar metals, thus expanding application possibilities.

Lately, Metal Foil Welding has really started to stand out as a key technique in today's manufacturing world. It offers some pretty impressive advantages over the traditional ways of welding. When folks dig into the basics and get a good grasp of how heat input plays into the process, they can really fine-tune things for better efficiency. Comparing different methods shows that Metal Foil Welding not only boosts precision but also leads to higher-quality welds, making it a go-to option, especially for high-tech industries.

And if you look at various case studies, it’s clear that having the right advanced equipment makes all the difference in getting top-notch results with Metal Foil Welding. This really pushes innovation forward and helps manufacturers deliver better results overall. With Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. putting a big focus on ultrasonic tech, it seems like the industry is heading toward some exciting new trends, which should lead to even more productivity down the line.