You know, Thermoplastic Welding is really becoming a big deal across lots of different industries these days. It's all about meeting the growing demand for smarter manufacturing techniques—stuff that makes assembly seamless and cuts down on waste. From what I've read, the global market for ultraSonic Welding is expected to hit over a billion dollars by 2025, growing at around 7% each year. That honestly highlights how important it is for manufacturers to fine-tune their welding processes to get better at both efficiency and quality. And speaking of expertise, Shenzhen Chengguan Intelligent Ultrasonic Equipment has been a leader in this space for two decades. They’ve been really pushing the envelope with innovative solutions like ultrasonic cutting and homogenizing tech, aiming to help businesses in various sectors maximize their weld quality and productivity. Pretty impressive, right?

Thermoplastic welding is pretty important in manufacturing, and you’ll find it being used in all sorts of industries — from automotive and construction to textiles. If you want to get a handle on how it works, it’s good to understand how heat and pressure come into play to create strong, reliable bonds between thermoplastic materials. These materials, like polyethylene, polypropylene, and PVC, soften up when they’re heated enough, making it possible to join them smoothly using methods like hot air welding, extrusion welding, or Ultrasonic Welding. Each of these techniques has its own perks and is better suited for certain types of materials or specific jobs.

In real-world applications, the trick is often optimizing things like temperature, speed, and pressure to get the best results. For example, getting the temperature just right is super important — too hot, and you risk damaging the material; not hot enough, and the joint might be weak. Also, knowing the particular needs of each type of thermoplastic can really make a difference in the final outcome. When you fine-tune these basics, manufacturers can not only hit their quality goals but also work more efficiently, saving time and cutting costs along the way.

When you're working on thermoplastic welding projects, keeping an eye on efficiency really matters if you want to tighten up the whole process. KPIs, or Key Performance Indicators, are super handy tools that help project managers see how well their welding efforts are actually going. For example, tracking things like how long each cycle takes, how much energy is used, or how many defects pop up can really highlight where improvements are needed. Like, if cycle times are taking longer than they should, that’s a clear sign you might want to look into your workflow. And watching energy consumption not only helps cut costs but also aligns with industry standards for being energy-efficient — a win-win!

On top of that, using the latest tech in welding can totally change the game. Modern equipment with multiprocess capabilities gives you the freedom to switch things up as needed. This flexibility can make your work smoother, cut down on downtime, and help you get more done in less time. As companies aim to make their operations leaner and more efficient, understanding these KPIs and leveraging good tech are key to keeping improvements rolling and staying ahead of the game.

Choosing the right welding equipment really matters if you want top-notch results in thermoplastic welding. I mean, especially in industries like shipbuilding, where welding makes up around 70% of the work, having the best tools can make all the difference in how smoothly things go and the quality you end up with. For example, picking equipment that matches the materials and techniques you're using can help cut down on mistakes and avoid redoing stuff, saving you a lot of time and resources.

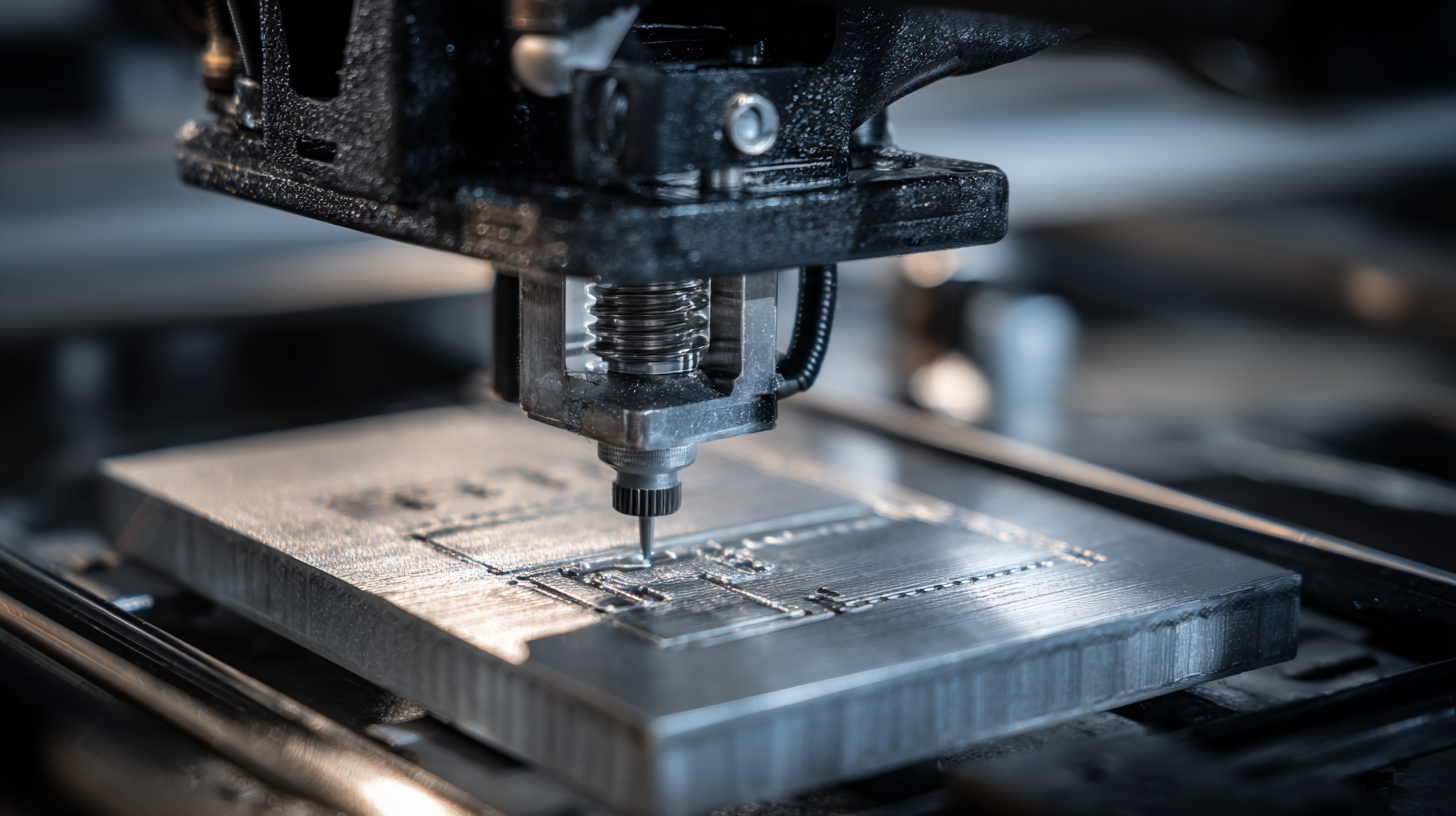

When you're shopping for welding gear, it's worth considering some of the newer tech out there. Stuff like heat input controls and automation can boost your precision and help tackle issues like shrinkage or deformation. And if you're into cutting-edge solutions, machine learning tools, like Random Forest algorithms, can actually give you predictions about welding quality, so you can make adjustments on the fly. Using these kinds of technologies can seriously improve your overall process.

Plus, if you're looking to really level up your team’s skills, VR training is a pretty cool option. It allows welders to practice in a safe, controlled environment before working on real projects. This kind of hands-on practice helps them get comfortable with the latest tools and techniques. All in all, pairing the right equipment with smart training choices can help maximize efficiency and deliver outstanding results in your thermoplastic welding projects.

Lately, there's been a real buzz around how advancements in thermoplastic composite welding are shaking things up in the aerospace world. I mean, these tech leaps are opening up some pretty exciting possibilities, especially when it comes to making aircraft more sustainable. One standout example is the MFFD project under the EU’s Clean Aviation initiative — they managed to build one of the biggest thermoplastic composite airplane structures out there. We're talking about an 8-meter-long piece with a 4-meter diameter. That’s no small feat! It really shows just how crucial good heat control is during welding, because nailing that can make a huge difference in how strong and long-lasting the final parts are.

To get better heat management during the welding process, many companies are trying out a bunch of techniques—think precise temperature checks, carefully regulating energy input, and adjusting welding schedules on the fly. These tricks help ensure the welds come out solid every time and also make the whole process more eco-friendly by cutting down on wasted materials and lowering energy use. Chengguan, with over two decades of experience, offers advanced ultrasonic plastic welding systems that fit right into these optimization strategies. Using ultrasonic tech, manufacturers can spread heat more evenly and achieve a much higher level of precision. It’s all about paving the way for more efficient thermoplastic welding—not just in aerospace, but across many industries.

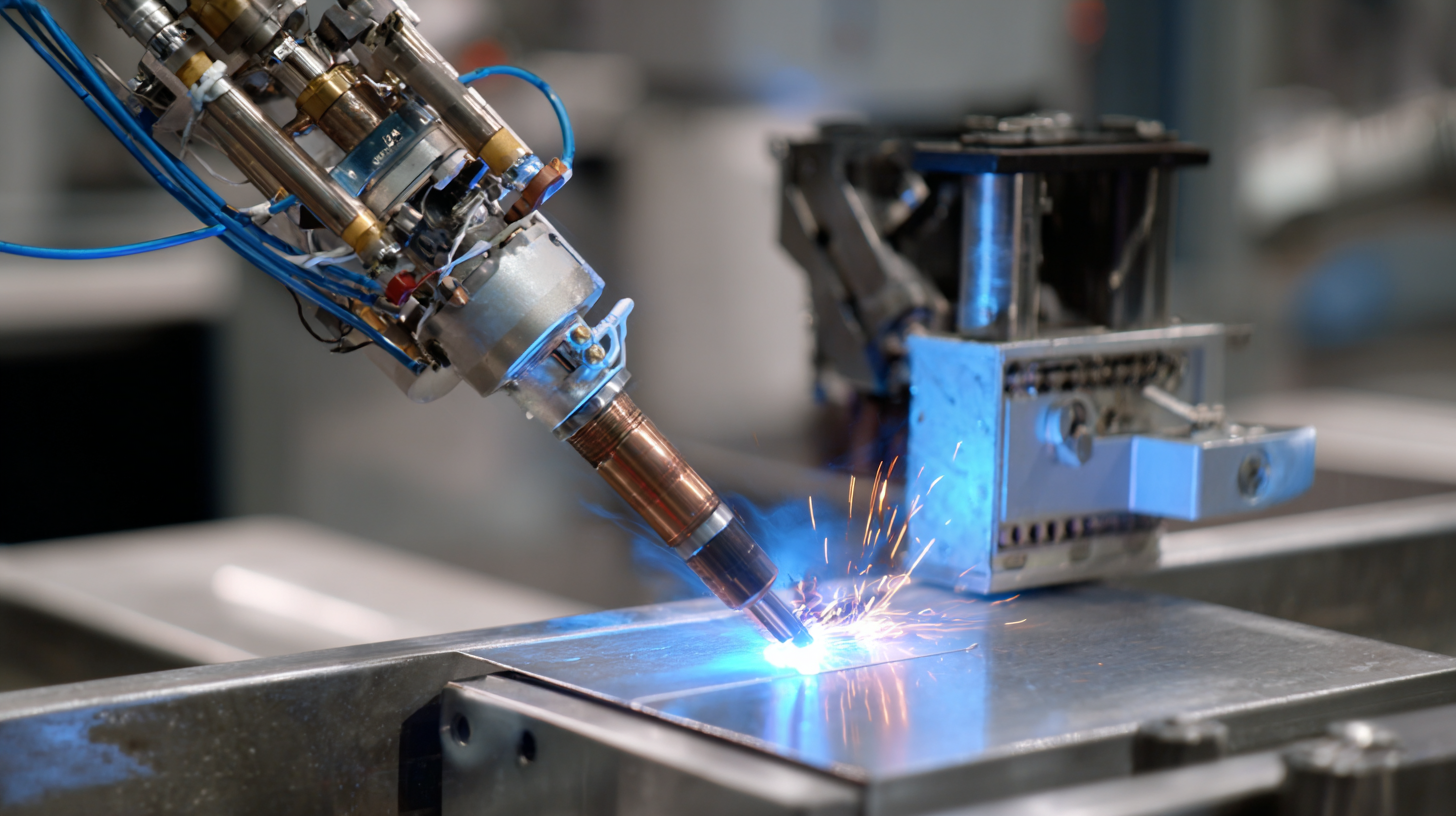

Thermoplastic welding definitely comes with its own set of challenges that can make things a bit tricky. One common hiccup is inconsistent heating, which can result in weak joints—frustrating, right? To get around that, you might want to think about investing in some really advanced welding robots. These machines can keep the temperature and pace just right, making sure every weld is solid as a rock. Plus, automating the process doesn’t just boost weld quality; it also ramps up productivity because you're cutting down on manual work.

Another issue that pops up is the changing environment—things like temperature and humidity that fluctuate and can throw off your welds. A smart move here is to set up sensors connected to IoT systems. These can monitor conditions in real-time and tweak the welding parameters on the fly, making sure everything stays just right throughout the job.

And let’s not forget the labor shortages that a lot of places are dealing with. The solution? Embracing technology, like training your team to work alongside robots. It’s a bit of a win-win—keeping skilled folks around while making your welding process way more efficient. Basically, by adopting these smarter solutions, you can tackle pretty much every common challenge in thermoplastic welding head-on and come out ahead.

You know, in the fast-moving world of thermoplastic welding, there’s always something new happening. Innovations keep coming in hot, really changing how things are done—making everything more efficient and effective. One of the biggest trends lately is the rise of advanced ultrasonic tech. Honestly, it’s a game-changer when it comes to precision and speed. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. have been leading the charge here, offering specialized ultrasonic welding systems that cater to all kinds of industries. These new tools don’t just speed up the welding process — they also improve the quality of the welds, cut down on waste, and boost overall production. Pretty cool, right?

And here’s another exciting bit: more and more companies are jumping on the automation and smart tech bandwagon. They’re using ultrasonic welders that come with real-time monitoring and smart control features. The result? Consistent, reliable results, every single time. Plus, automation helps cut labor costs while ramping up how much you can produce. Oh, and by digging into data analytics, businesses are continually tweaking and optimizing their processes, helping them stay ahead in this super competitive market. It’s all about working smarter, not harder, you know?

| Parameter | Current Value | Target Value | Improvement Strategy |

|---|---|---|---|

| Cycle Time | 12 seconds | 8 seconds | Implement advanced heating techniques |

| Energy Consumption | 15 kWh | 10 kWh | Utilize energy-efficient welding equipment |

| Weld Quality Rating | 85% | 95% | Conduct regular calibration of equipment |

| Material Waste | 5% | 2% | Optimize material feed and cutting processes |

| Operator Training Level | 70% | 100% | Implement comprehensive training programs |

The advent of ultrasonic handheld spot welding systems marks a significant turning point in modern manufacturing, unlocking numerous benefits that are crucial for staying competitive in today's fast-paced market. According to a report from MarketsandMarkets, the global ultrasonic welding market is expected to grow from USD 1.2 billion in 2020 to USD 1.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.7%. This growth is attributed to the increasing demand for high welding quality and efficiency, both of which are delivered by these innovative systems. Welded joints produced via ultrasonic methods demonstrate exceptional strength and durability, outperforming traditional welding techniques, with weld strengths nearing that of the raw materials used.

In addition to their superior welding capabilities, ultrasonic handheld systems offer substantial operational efficiency. The welding process is remarkably expedited, often completing in under one second, which significantly enhances production throughput. This is critical in an era where time-to-market can determine the success of a product. Furthermore, energy consumption is minimized since the welding process does not require external heat sources or chemical adhesives, thus promoting both energy savings and environmental sustainability. This innovative technology aligns with recent trends in green manufacturing, where reducing the ecological footprint is a primary objective for many companies.

The versatility of these handheld systems extends beyond welding thermoplastics; they are capable of riveting, inlaying, and edge pressing between various materials, from metals to fabrics. Compatibility with a wide range of materials—including polyethylene, polypropylene, and polyvinyl chloride—makes these systems indispensable tools for manufacturers looking to innovate their production processes. A report from Technavio highlights that manufacturers adopting advanced welding technologies like ultrasonic systems can expect to achieve operational efficiencies of up to 30%, further solidifying the role of this cutting-edge solution in contemporary manufacturing.

: Thermoplastic welding is a manufacturing process that uses heat and pressure to create strong bonds between thermoplastic materials, which become pliable at elevated temperatures.

Common thermoplastic materials include polyethylene, polypropylene, and PVC.

The different methods of thermoplastic welding include hot air welding, extrusion welding, and ultrasonic welding.

Maintaining the correct temperature is crucial because overheating can lead to material degradation, while insufficient heating can result in weak joints.

Manufacturers can enhance efficiency by optimizing parameters such as temperature, speed, and pressure, and by understanding the specific requirements of each thermoplastic material.

Selecting the right welding equipment is essential for achieving optimal results, minimizing errors, and reducing rework, which can save time and resources.

Consider investing in advanced technologies that feature heat input management and automation capabilities to improve precision and address common challenges.

Machine learning algorithms, like Random Forest, can provide insights into welding quality predictions, allowing for proactive adjustments during the welding process.

VR training provides hands-on practice in a controlled environment, enabling welders to refine their skills on the latest tools before they begin production, leading to better outcomes.

The right combination of high-quality equipment and comprehensive training directly contributes to maximizing efficiency and achieving superior results in thermoplastic welding endeavors.

You know, thermoplastic welding is pretty much a key process in a lot of industries these days. It’s all about joining plastic parts together using heat and pressure—kind of like melting and sticking them! If you really want to get the most out of this method, it’s super important to understand the basics. That way, you can make your welding more efficient and reliable. And let’s not forget about KPIs—those are the metrics that tell you how well the project is going. They help spot what’s working and what’s not, so you can tweak things accordingly. Picking the right equipment makes a big difference too—companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. offer some solid options that can really boost your welding game.

On top of that, messing around with better heat control techniques and addressing common hiccups can make the whole process run a lot smoother. As technology and industry standards keep moving forward, it’s a good idea to stay in the loop about new trends and innovations. Being up-to-date means your team can stay ahead of the curve in thermoplastic welding. All in all, focusing on these little things can really help businesses ramp up efficiency and deliver top-notch results on their projects.