You know, in today's world, when it comes to kids' toys, safety and quality are pretty much at the top of everyone's list, right? One piece of the puzzle that often doesn't get as much spotlight but is super important is 'Plastic Toy Sealing.' This process is all about making sure toys are sealed up tight—so no nasty surprises happen during manufacturing, shipping, or even when they sit on shelves. I remember talking with Dr. Emily Carter, a real expert in toy safety, and she told me, 'Effective Plastic Toy Sealing isn't just about following rules—it's about earning trust from parents and caregivers, showing them their little ones are playing with safe, high-quality toys.' It really hits home, doesn't it? Because this sealing step isn't just a small detail; it helps keep toys sturdy and safe from contamination or damage all through their lifespan. There are different ways to do it—like heat sealing or ultrasonic sealing—and choosing the right method can be a bit tricky, depending on the toy's materials and how kids will use it. And as folks become more aware of safety standards, knowing the best practices for sealing toys becomes even more essential. When manufacturers stick to proper sealing techniques and safety tips, they’re not just following the rules—they’re helping create a safer, more enjoyable playtime experience for kids everywhere. That way, parents can breathe easier knowing their little ones are safe, and everyone stays confident in the toys they buy.

Plastic toy sealing refers to the process of securely packaging toys made from plastic materials, ensuring they remain safe and intact during storage, transport, and display. This procedure typically involves wrapping the toys in protective films or placing them in rigid or flexible containers. The primary purpose of sealing plastic toys is to prevent contamination from dust, dirt, and moisture, which can compromise the integrity of the product and affect its usability. Furthermore, effective sealing plays a crucial role in ensuring that the toys meet safety standards, as it minimizes the risk of exposure to harmful substances.

In addition to protection, sealing plastic toys also serves an important marketing function. The packaging often includes attractive designs, colorful graphics, and essential information about the toy, such as age recommendations and safety guidelines. This not only enhances the product's visual appeal but also helps inform consumers, making it easier for them to make informed decisions. It is essential for manufacturers to consider both the aesthetic and functional aspects of toy sealing, as it directly impacts customer satisfaction and overall product safety.

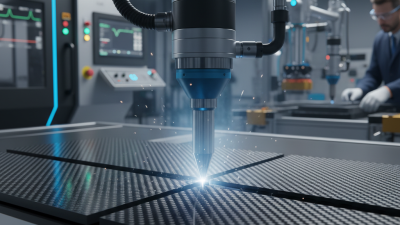

Plastic toy sealing is a crucial aspect of toy manufacturing that ensures safety, durability, and product integrity. Various methods are employed in the sealing process, each with distinct advantages tailored to specific manufacturing needs. Ultrasonic sealing is one method where high-frequency sound waves generate heat to bond plastic components seamlessly. This method is particularly favored for its efficiency and ability to create robust seals without the need for additional adhesives.

Another common technique is heat sealing, where heat is applied to the edges of plastic parts, effectively melting them together. This method is highly effective for creating airtight seals, which are essential in toys that require secure packaging or contain small parts. Additionally, adhesive sealing involves applying specially formulated adhesives to the surfaces of the toy parts, providing a strong bond that can withstand regular use.

Lastly, mechanical sealing methods, such as snap-fit designs, leverage the inherent properties of plastic to create interlocking components that hold together securely without external bonding agents. Each of these methods not only enhances the longevity of plastic toys but also plays a significant role in ensuring that they meet safety standards for children’s products. By understanding these sealing methods, manufacturers can better optimize production processes while prioritizing consumer safety.

| Sealing Method | Description | Importance | Safety Tips |

|---|---|---|---|

| Heat Sealing | Using heat to fuse two plastic parts together. | Provides strong and durable joints, making toys safer for children. | Ensure proper temperature settings to avoid damaging materials. |

| Ultrasonic Sealing | Using high-frequency ultrasonic waves to melt the plastic at the interface. | Achieves consistent seals without additional adhesives. | Regularly maintain machinery to ensure optimal performance. |

| Adhesive Bonding | Using adhesives to join plastic parts. | Allows for flexibility in materials and designs. | Use non-toxic adhesives that are safe for children. |

| Snap Fit | Mechanical interlocking of parts that snap together. | Easy assembly and disassembly, promoting user engagement. | Ensure edges are smooth to prevent injuries during usage. |

| Welding | Joining plastic through melting and cooling the materials together. | Creates robust bonds, enhancing toy longevity. | Monitor temperature closely to avoid overheating. |

Proper sealing of plastic toys plays a crucial role in ensuring both safety and durability. When toys are sealed correctly, it prevents the potential release of small parts that could pose choking hazards to young children. Sealing also helps in protecting the internal components of the toy from exposure to water, dust, or other environmental factors that could compromise its integrity. This reduces the risk of the toy breaking apart during play, which is essential for maintaining a safe environment for children.

Moreover, effective sealing contributes to the longevity of toys by preventing degradation over time. Toys that are not adequately sealed may deteriorate quickly, leading to potential safety risks as sharp edges or broken pieces can emerge. By employing proper sealing methods, manufacturers can enhance the overall quality of the toys, ensuring that they withstand vigorous play and retain their intended form. In addition, well-sealed toys are often easier to clean and maintain, further extending their usability. Thus, the importance of adequate sealing cannot be overstated, as it directly impacts the safety and durability of plastic toys, ultimately safeguarding children's play experiences.

This chart illustrates the importance of proper sealing in plastic toys across various dimensions, emphasizing child safety, durability, environmental impact, and production cost. With scores ranging from 1 to 10, we can see that child safety ranks highest in importance, reinforcing the need for rigorous sealing standards in toy manufacturing.

Plastic toy sealing involves the process of securely packaging toys to ensure their safety, hygiene, and quality during transportation and storage. The choice of materials used for sealing plays a crucial role in maintaining the integrity of the toys. Common materials include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), each offering distinct advantages. For instance, polyethylene is favored for its durability and moisture resistance, which prevents damage from environmental factors and ensures the toys remain in optimal condition.

According to a report by Grand View Research, the global plastic packaging market, which encompasses toy sealing, is projected to reach USD 640 billion by 2025, highlighting the significant demand for effective sealing solutions. Additionally, a study published in the Journal of Packaging Technology and Research indicated that the choice of sealing material can influence consumer perception of toy safety. For example, materials labeled as BPA-free are increasingly preferred due to growing health concerns, further pushing manufacturers to adopt safer, more consumer-favorable sealing options.

In the production of plastic toys, manufacturers often prioritize sustainable materials such as biodegradable plastics or recyclable options. Industry trends indicate that over 45% of consumers prefer environmentally friendly packaging, prompting companies to innovate in sealing technologies. This shift not only enhances the appeal of the products but also aligns with global sustainability initiatives, ensuring that both toy makers and consumers contribute to a healthier planet.

When selecting sealed plastic toys for children, safety should be a primary concern for consumers. Many parents are unaware of the different seals and certifications that can indicate the safety and quality of a toy. Always look for toys that have been tested for safety standards, including those ensuring they are free from harmful chemicals. Choosing toys from reputable manufacturers that adhere to strict safety regulations can provide peace of mind.

**Tips: Always check for age recommendations on the packaging to ensure the toy is suitable for your child's developmental stage. Pay attention to small parts that could pose choking hazards for younger children.**

Additionally, it's prudent to inspect the sealing of the toys. A well-sealed toy should have no visible gaps, which can trap dirt and bacteria. Opt for toys that are vacuum-sealed or come in tamper-resistant packaging to reduce the risk of contamination and ensure a longer lifespan of the product.

**Tips: Look for toys that are easy to clean and maintain, as hygiene is vital in protecting children’s health. Don’t hesitate to reach out to manufacturers for information about the materials used and their safety testing processes.**

The environmental impact of plastic toy sealing practices is an increasingly important issue in today's manufacturing landscape. As the demand for plastic toys continues to rise, it is essential to critically assess the sealing methods used to ensure both safety and sustainability. Traditional plastic sealing methods, often reliant on adhesives and synthetic materials, can contribute to environmental degradation over time, as many of these materials are not biodegradable. Therefore, manufacturers are encouraged to explore eco-friendly alternatives that minimize waste and reduce their reliance on harmful chemicals.

One effective approach involves the use of recyclable materials in the sealing process. By implementing biodegradable or recyclable plastics, manufacturers can help mitigate the negative environmental impact associated with toy production. Additionally, improving the efficiency of production methods can lead to less waste generation and reduced energy consumption. Continuous innovation in sealing technologies not only contributes to a healthier planet but also aligns with the growing consumer preference for sustainable products. Manufacturers that prioritize these practices not only enhance their corporate responsibility but also position themselves favorably in a competitive market that increasingly values environmental stewardship.

The future of plastic toy sealing technologies is poised for significant advancement, driven by increasing consumer awareness regarding safety and sustainability. With a growing emphasis on eco-friendly materials, many companies are exploring bio-based plastics and recyclable options for toy manufacturing and sealing. According to a recent report by the Toy Association, nearly 82% of parents express concern over the safety of toys regarding chemical exposures. This rising apprehension is prompting regulatory bodies to introduce stricter guidelines for toy sealing processes, ensuring that they meet rigorous safety standards.

Moreover, innovation in sealing methods is crucial as manufacturers seek to enhance product durability without sacrificing safety. Emerging technologies such as ultrasonic sealing and heat sealing are gaining traction due to their efficiency and ability to minimize the reliance on adhesives that can contain harmful chemicals. According to industry insights from Grand View Research, the global market for toy safety is expected to grow by over 5% annually, reflecting not only the increasing regulations but also a broader commitment to environmental responsibility. As technology evolves, companies are likely to adopt more automated sealing processes, ensuring both precision and compliance with international safety regulations.

: Plastic toy sealing is the process of securely packaging toys made from plastic materials to keep them safe and intact during storage, transport, and display.

The primary purpose is to prevent contamination from dust, dirt, and moisture, ensuring product integrity and compliance with safety standards.

Proper sealing prevents the release of small parts that could be choking hazards and protects internal components from environmental factors that may compromise the toy.

Effective sealing helps reduce wear and tear over time, preventing degradation that could lead to sharp edges or broken pieces emerging, thus enhancing the toy's longevity.

Packaging often features attractive designs and essential information, which enhances visual appeal and helps consumers make informed decisions about the product.

Yes, well-sealed toys are often easier to clean and maintain, which extends their usability and keeps them in better condition longer.

Toys are generally wrapped in protective films or placed in rigid or flexible containers as part of the sealing process.

By considering both aesthetic and functional aspects in sealing, manufacturers can enhance customer satisfaction through improved safety and product appeal.

Inadequate sealing can lead to safety risks, such as broken pieces that can harm children and a higher likelihood of toy deterioration.

Effective sealing minimizes the risk of exposure to harmful substances, thereby helping toys meet safety standards and ensuring child safety during play.

Plastic Toy Sealing refers to the techniques used to hermetically Seal Plastic toys to ensure their safety and durability. This process is essential in manufacturing, as it prevents the ingress of harmful substances and maintains the integrity of the toy. Various methods are utilized for sealing, including ultrasonic welding, heat sealing, and adhesive bonding, each tailored to enhance the toy's longevity and ensure compliance with safety standards.

The significance of proper sealing cannot be overstated, as it directly impacts consumer safety and the environmental footprint of plastic toys. Common materials for sealing include polymers and non-toxic adhesives, which are crucial for safe play. As consumers, it is important to be informed about safety tips when selecting sealed toys. Additionally, the industry is moving towards more sustainable sealing practices and innovative technologies, emphasizing eco-friendly materials and regulations to promote safer products for future generations.