In today’s manufacturing world, staying efficient and precise is more important than ever if you want to stay competitive. One cool innovation that’s been turning heads is the Seal Weld Machine. This high-tech machine not only boosts the strength and reliability of welds but also helps cut down on production time. By automating the welding process, it reduces human mistakes and makes sure every single weld is consistently high-quality.

Using a Seal Weld Machine can really give your manufacturing output a boost. It can perform top-notch, accurate welds much faster, so companies can keep up with the growing market demands without sacrificing quality. Plus, adding this tech to your production line means you can streamline your workflow and use your resources smarter. In the end, the Seal Weld Machine is changing the game for traditional welding, and honestly, it’s become a must-have for manufacturers who want to stay ahead in this constantly changing industry.

A seal weld machine is an advanced piece of equipment designed to create watertight and airtight seals during the welding process. This specialized machine uses a combination of heat and pressure to join materials together, ensuring that the seal is strong and durable. Seal welds are critical in various industries, especially where leakage can compromise the integrity of products or safety. By automating the welding process, seal weld machines streamline production, enhance consistency in quality, and reduce manual labor.

When integrating a seal weld machine into a manufacturing setup, it's essential to consider the materials and thicknesses being used. Adjusting parameters such as temperature and pressure can significantly impact the quality of the weld. Additionally, operators should regularly maintain the equipment to prevent downtime, ensuring it operates efficiently and safely.

Tips: Always conduct trial runs with different settings to identify the optimal parameters for your specific materials. Regular training and upskilling of the workforce can also enhance efficiency and output quality when operating a seal weld machine. Keeping safety protocols in mind during operation is crucial to minimizing risks and ensuring a smooth workflow.

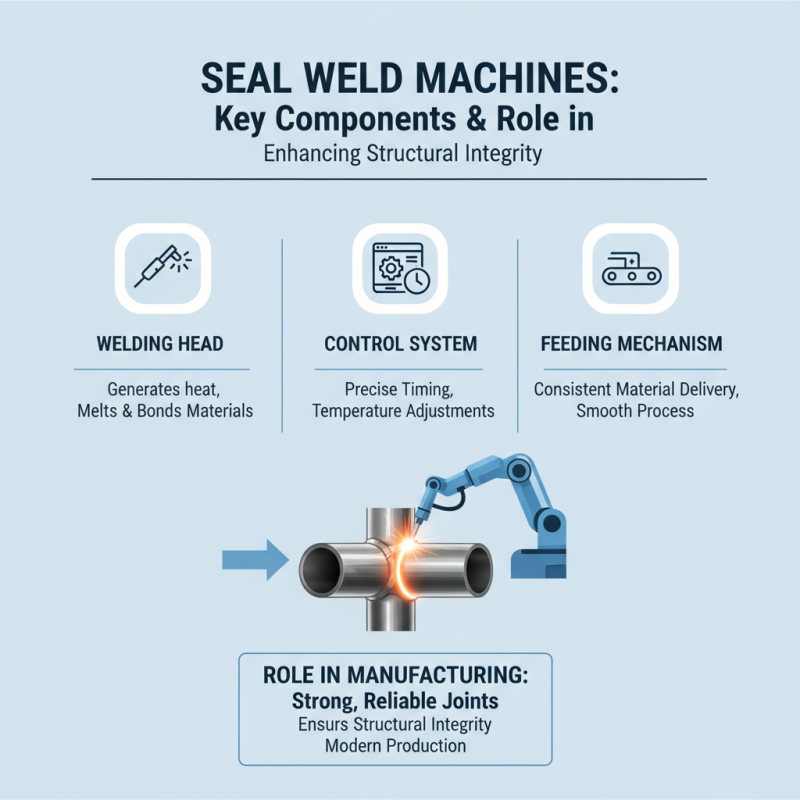

Seal weld machines play a critical role in modern manufacturing processes, ensuring strong, reliable joints that enhance structural integrity. The key components of these machines include the Welding Head, control system, and feeding mechanism. The welding head is responsible for generating the heat required to melt and bond materials, while the control system allows for precision in timing and temperature adjustments. The feeding mechanism ensures that materials are delivered consistently, facilitating a smooth and efficient welding process.

Tips: When selecting a seal weld machine, consider the materials you will be working with, as different setups may be needed for metals versus plastics. Regular maintenance of the welding head and feed mechanism is crucial to prevent downtime and ensure optimal performance.

Additionally, the automation features of seal weld machines can significantly cut down on labor costs and reduce human error. The integration of sensors and feedback systems not only streamlines production but also enhances the quality of the welds. Monitoring the machine's performance and making adjustments based on real-time data can lead to impressive improvements in manufacturing efficiency.

Seal welding plays a crucial role in various manufacturing processes by ensuring the integrity and longevity of products. This technique involves creating a strong, hermetic seal between two materials, often using advanced welding technologies to deliver precise and controlled results. Its primary function is to protect components from environmental factors such as moisture, dust, and chemicals, which could compromise their functionality over time. By employing seal welding, manufacturers can enhance the durability of their products, minimizing the risk of defects and the need for repairs or replacements.

Moreover, seal welding contributes significantly to manufacturing efficiency. The ability to join materials quickly and securely reduces assembly times, allowing for faster production cycles. This efficiency is particularly beneficial in industries where timing is critical, such as automotive and aerospace manufacturing. Additionally, the use of seal welding can lead to cost savings by reducing material waste and lowering labor expenses associated with assembly tasks. As manufacturers continue to prioritize efficiency and product quality, seal welding remains an essential technique that supports these goals.

Seal weld machines play a pivotal role across various industries, enhancing manufacturing processes through their unique capabilities. In the automotive sector, these machines are utilized to create strong, enduring seals that are critical for the integrity and safety of vehicles. By applying precision welding techniques, manufacturers can ensure that components such as fuel tanks and exhaust systems are leak-proof, ultimately improving overall product reliability and longevity.

Seal weld machines play a pivotal role across various industries, enhancing manufacturing processes through their unique capabilities. In the automotive sector, these machines are utilized to create strong, enduring seals that are critical for the integrity and safety of vehicles. By applying precision welding techniques, manufacturers can ensure that components such as fuel tanks and exhaust systems are leak-proof, ultimately improving overall product reliability and longevity.

In the aerospace industry, the application of seal weld machines is equally significant. They are employed to join materials that require both strength and lightweight characteristics, essential for aircraft performance. These machines facilitate the sealing of various parts, including fuel lines and structural components, thereby contributing to fuel efficiency and safety in flight operations. Additionally, in the construction and piping sectors, seal weld machines are used to create robust connections that withstand high-pressure environments, such as in oil and gas pipelines, enhancing the durability of infrastructure projects and minimizing maintenance costs associated with leaks and failures.

Seal weld machines are revolutionizing the manufacturing landscape by enhancing efficiency and precision in the welding process. According to a recent report from the American Welding Society, companies that implement seal weld technology can experience a reduction in labor costs by up to 30%. This improvement is largely attributed to the automation of repetitive welding tasks, allowing skilled workers to focus on more complex operations that require human oversight and expertise.

Moreover, the integration of seal weld machines can lead to a notable decrease in production time. A study by the National Institute of Standards and Technology found that factories utilizing advanced welding machinery saw a 25% increase in throughput. The consistency and quality achieved by seal weld processes reduce the likelihood of defects, thereby minimizing rework and waste. With precise control over weld parameters, manufacturers are also able to enhance the integrity of their products, further contributing to customer satisfaction and retention.

Quantifying these efficiency gains reveals that investing in seal weld technology not only improves the bottom line but also positions manufacturers to stay competitive in an increasingly demanding market. Companies that adopt these advancements are likely to see a significant return on investment, making seal weld machines a critical component in the quest for operational excellence.

Seal welding is an innovative technique that has shown significant advantages over traditional welding methods in various manufacturing sectors. Unlike conventional methods that typically focus on joining materials through surface melting, seal welding creates a continuous, impervious bond without altering the base material’s structural integrity. According to a report from the American Welding Society, seal welding can achieve up to a 50% reduction in the time required for assembly tasks, thus streamlining the manufacturing process and enhancing overall productivity.

A comparative analysis reveals that while traditional welding methods often require extensive post-weld treatments such as grinding or sealing to eliminate leaks and ensure durability, seal welding minimizes these additional steps. This not only cuts down on labor costs but also reduces the consumption of materials, contributing to a more sustainable manufacturing environment. Furthermore, a study published in the Journal of Manufacturing Science and Engineering indicates that seal welding can provide tensile strength improvements of over 20%, making it an attractive option for industries that demand high-performance and resilient joints.

By adopting seal welding, manufacturers can thus achieve better quality while also expediting production timelines, ultimately contributing to increased efficiency and profitability.

As technology continues to advance, the future of seal weld machines is poised for significant transformation through automation and smart technologies. These machines, essential for producing strong and airtight joints in manufacturing processes, are increasingly integrating artificial intelligence (AI) and machine learning. This integration allows for real-time monitoring and adjustment, enhancing precision and reducing waste. Manufacturers can expect more efficient workflows, as automated seal Welding Systems can operate continuously with minimal human intervention, leading to increased production rates and lower operational costs.

Tips for manufacturers looking to upgrade their seal weld machines include investing in systems that incorporate predictive maintenance technologies. By utilizing sensors and data analytics, potential issues can be identified before they lead to downtime, thereby maintaining efficiency. Additionally, consider training your workforce on the latest automation tools to ensure they are equipped to operate advanced machinery effectively, further optimizing the manufacturing process.

Furthermore, embracing collaborations between software and hardware developers can pave the way for innovations in seal welding technology. Future trends are likely to see the rise of modular systems that can easily adapt to changing production needs. By remaining flexible and open to incorporating new technologies, manufacturers can position themselves to capitalize on the evolving landscape of seal welding and boost overall manufacturing efficiency.

| Feature | Benefit | Impact on Manufacturing Efficiency | Future Trend |

|---|---|---|---|

| Automated Controls | Reduced human error | Increased consistency and quality | Advanced automation technology |

| Real-time Monitoring | Immediate feedback on quality | Faster adjustments lead to less waste | Integration with IoT |

| High Precision Welding | Improved joint strength | Reduces rework and improves durability | Continued development in laser technology |

| Energy Efficiency | Lower operating costs | Reduced carbon footprint | Sustainable manufacturing practices |

| Modular Design | Easier scalability | Flexibility in production lines | Adoption of Industry 4.0 |

: A seal weld machine is a specialized piece of equipment designed to create watertight and airtight seals by using heat and pressure to join materials together during the welding process.

It enhances efficiency and precision in the welding process, reduces labor costs, and decreases production time by automating repetitive tasks, allowing skilled workers to focus on more complex operations.

Various industries benefit, particularly those where leakage could compromise product integrity or safety, such as manufacturing and construction.

Operators should adjust parameters such as temperature and pressure based on the materials and thicknesses used to ensure optimal weld quality.

Companies can measure labor cost reductions, increased throughput, and improved product quality, all of which contribute to a significant return on investment.

Regular maintenance and conducting trial runs to identify optimal settings are crucial for preventing downtime and ensuring efficient, safe operations.

Regular training and upskilling of the workforce enhance efficiency and output quality, ensuring that operators are adept at managing the machinery.

Seal weld machines improve consistency and quality in welding, reducing defects and minimizing the need for rework and waste.

Automation allows skilled workers to concentrate on more complex tasks, improving overall job satisfaction and operational efficiencies in the workplace.

Adhering to safety protocols during operation is essential to minimize risks and ensure a smooth workflow while using seal weld machinery.

Seal Weld Machines are innovative devices designed to enhance manufacturing efficiency by creating airtight and watertight seals through welding. These machines consist of key components that work together to deliver precise and reliable welds, making them crucial in various industries such as automotive, aerospace, and construction. By integrating seal welding into production processes, manufacturers can achieve better quality control and reduce the risk of leaks, thus improving overall product durability.

The advantages of Seal Weld Machines over traditional welding methods are significant, including time savings, less material waste, and improved safety for operators. As industries continue to evolve, the future of seal welding technology points towards increased automation and advancements that will further streamline operations. Quantifying the efficiency gains from using Seal Weld Machines highlights not just their cost-effectiveness, but also their vital role in modern manufacturing practices.