Hey, if you’re into plastic manufacturing, you’ve probably noticed just how quickly things are changing. One pretty exciting tech right now is UltraSonic Welding for PSA cards — it’s a game-changer when it comes to making seamless joins and speeding up production. Recent market reports say that the worldwide market for ultrasonic welding equipment is expected to hit around 4.2 billion dollars by 2026. That huge jump is mainly thanks to all the new innovations and rising demand across different industries. A company like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd.—with over 20 years of experience in ultrasonic plastic welding—is really leading the charge here. They offer a variety of top-notch ultrasonic welding systems that help manufacturers get better at their craft, making sure that PSA cards are bonded reliably and precisely. Basically, this sets the scene for an in-depth look at how ultrasonic welding can totally change the game in card manufacturing and boost product quality overall.

You know, Ultrasonic Welding is pretty awesome tech that's really changed the game when it comes to making Pressure Sensitive Adhesive (PSA) cards. Instead of fussing with glues or heat, it uses these super high-frequency ultrasonic waves to bond materials together—fast, strong, and reliable. Honestly, the biggest perks? Faster manufacturing, less waste, and cards that just last longer. Plus, it makes sure those delicate components inside the PSA cards stay safe and intact, without any seams that look or feel off.

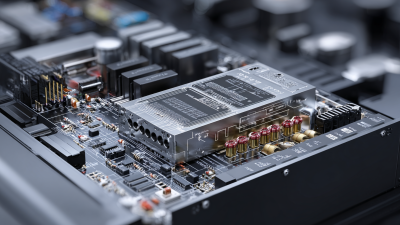

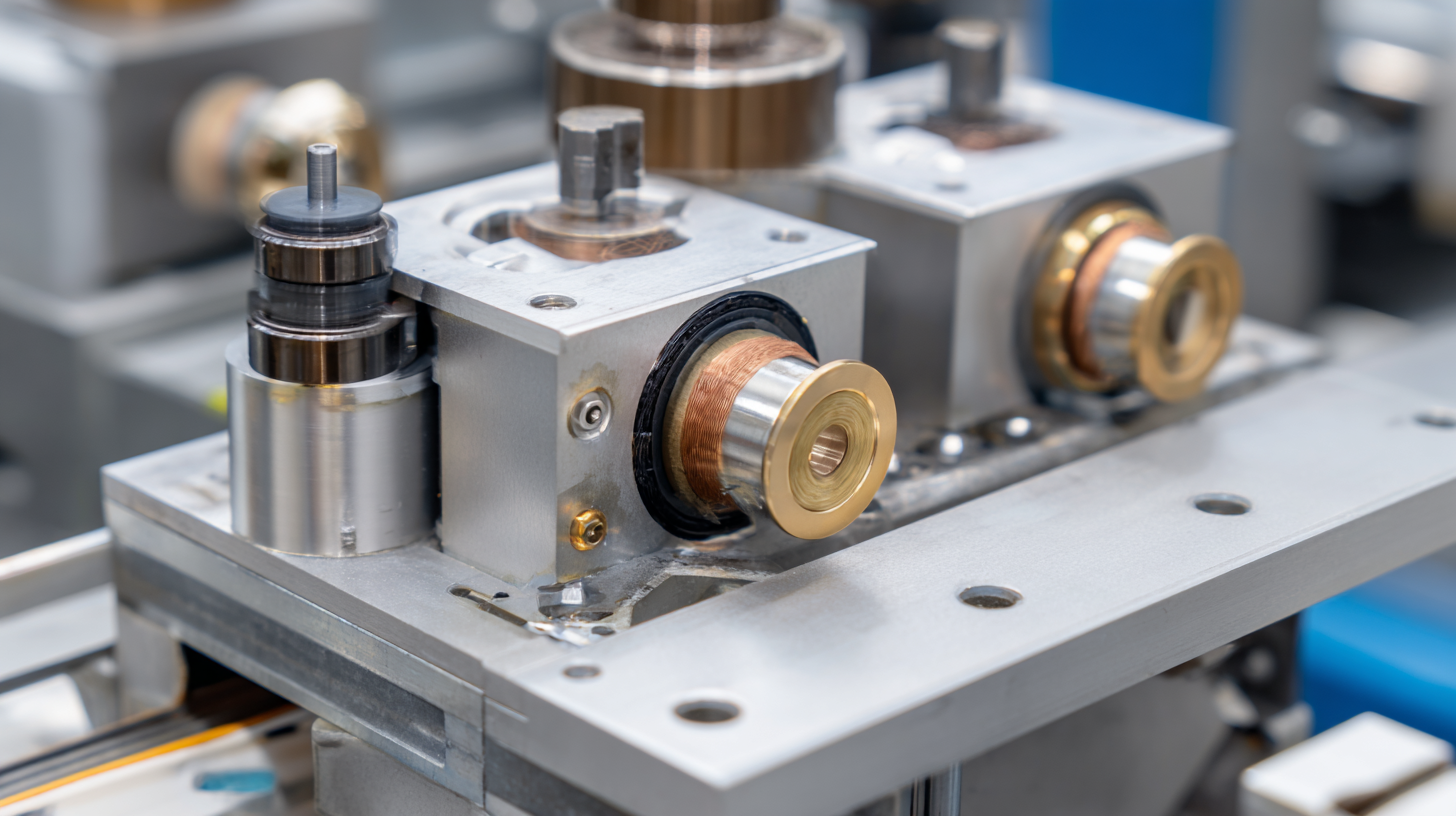

When it comes to making sure PSA cards connect seamlessly, understanding the main parts and gear involved in ultrasonic welding is super important. Basically, ultrasonic welding uses really high-frequency vibrations to instantly create a strong, lasting bond between materials. The key parts you need to know about are the ultrasonic generator, the stack, and the welding horn—each one’s job is to turn electrical energy into mechanical movement. Picking the right components is crucial because it helps get the best energy transfer and a high-quality weld.

If you want to improve your ultrasonic welding process, here are a few tips. First off, always make sure the surfaces you're welding are clean and free from dirt or grease—that’s how you get a good, solid bond and avoid failures. Next, get familiar with the recommended settings for your specific materials, since they can vary a lot. And finally, invest in good quality equipment; cheap tools might save you a buck upfront, but they can cause inconsistent results and mean more headaches down the road.

By paying attention to these main parts and sticking to best practices, manufacturers can achieve reliable, strong ultrasonic welds for PSA cards. That way, you’re sure they meet the quality and performance standards needed in real-world applications.

| Component | Description | Importance | Typical Specifications |

|---|---|---|---|

| Ultrasonic Generator | Converts electrical energy to ultrasonic frequency. | Essential for initiating the welding process. | Frequency range: 20kHz - 40kHz |

| Sonotrode | The tool that transmits ultrasonic energy to the workpiece. | Crucial for effective material joining. | Length: 100mm - 300mm |

| Fixture | Holds the components in place during welding. | Ensures parts align for consistent connections. | Material: Aluminum or steel |

| Power Supply | Provides the necessary electrical input for welding. | Critical for maintaining correct energy levels. | Voltage: 220V - 240V |

| Cooling System | Regulates temperature of ultrasonic equipment. | Prevents overheating during operation. | Type: Water-cooled or air-cooled |

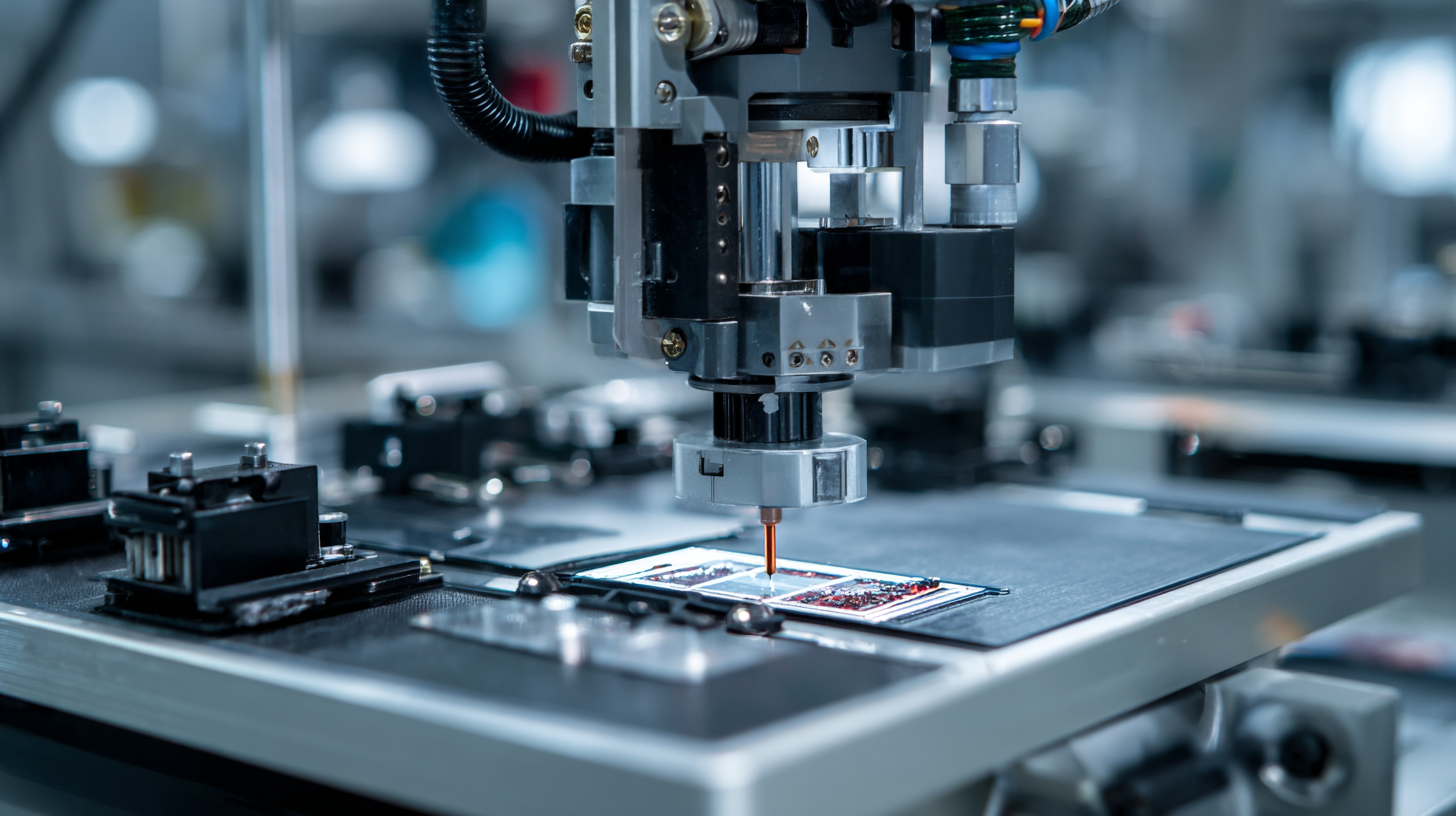

Ultrasonic welding has really become a game-changer when it comes to making seamless connections in the production of PSA cards, you know, those pressure-sensitive adhesive ones. The process isn’t too complicated—basically, it involves generating high-frequency ultrasonic vibrations that melt the materials together without needing any extra glue or adhesives. I saw in this recent report by MarketsandMarkets that the ultrasonic welding market might hit around $2.7 billion by 2026. That’s mainly because there's increasing demand for quick, precise bonding solutions across industries like electronics and packaging—pretty impressive, right?

So, it all starts with prepping the surfaces to make sure they’re clean and compatible. Once that’s done, you load the materials into the welding machine, where they’re held tightly under pressure. When the ultrasonic energy kicks in, it heats up the interface super fast, softening the materials just enough to bond securely—in just milliseconds. According to the International Journal of Advanced Manufacturing Technology, ultrasonic welding can produce bonds stronger than 50 MPa—that’s pretty sturdy, especially for PSA cards that need to hold up over time and under various conditions. What I love about this method is not just how quick it is, but also how it boosts the overall quality of the final product, making the whole process way more efficient.

Ultrasonic welding has really become a key player when it comes to making Pressure Sensitive Adhesive (PSA) cards. It’s great because it creates strong, long-lasting bonds without putting too much heat on the materials. That said, getting perfect results isn't always straightforward—there are some common hurdles manufacturers run into during the process. For instance, as highlighted in the International Journal of Adhesion and Adhesives, things like setting the right frequency or controlling the energy output can make a huge difference in the quality of the weld. Just a tiny 5 kHz shift in the frequency can cut bond strength by nearly a third, which shows how crucial precise calibration of the equipment really is.

Ultrasonic welding has really become a key player when it comes to making Pressure Sensitive Adhesive (PSA) cards. It’s great because it creates strong, long-lasting bonds without putting too much heat on the materials. That said, getting perfect results isn't always straightforward—there are some common hurdles manufacturers run into during the process. For instance, as highlighted in the International Journal of Adhesion and Adhesives, things like setting the right frequency or controlling the energy output can make a huge difference in the quality of the weld. Just a tiny 5 kHz shift in the frequency can cut bond strength by nearly a third, which shows how crucial precise calibration of the equipment really is.

Another thing to keep in mind is the material itself. If the properties—like thickness or surface texture—are inconsistent, it can lead to weak spots or even total failures in the welds. A study in the Journal of Manufacturing Science and Engineering pointed out that if the substrate varies by more than 0.1 mm in thickness, the chances of defects shoot up by about 40%. To tackle these issues, manufacturers really need to focus on strict quality control and do thorough testing of their materials for PSA cards. Making sure every element meets the tight standards for ultrasonic welding is key to getting good, reliable results.

Keeping your ultrasonic welding machines in top shape is super important if you want those perfect, seamless connections when making PSA cards. Regular maintenance isn’t just a buzzword—it's essential for making sure your machines run at the right frequencies and amplitudes, which really matter for solid welds. Funny enough, industry reports show that neglecting maintenance can bump up defects by about 20%, which can seriously mess with product quality and slow things down.

One tip I’ve picked up? Try to do routine checks every 1 to 3 months, depending on how often those machines are running. During these visits, it’s good to look for any wear on parts like converters and boosters, and to double-check that the ultrasonic settings are spot-on. Studies from the International Ultrasonic Technology Association found that just by calibrating things properly, you could boost weld strength by around 15%. That’s a huge difference—fewer defects and less hassle overall.

And don’t forget about keeping good records! Jot down all maintenance and calibration activities. Not only does this help you stay compliant with quality standards, but it’s also a handy way to spot patterns in how your machines perform. By analyzing these logs, you can catch big issues early on, keep things running smoothly, and avoid costly downtime. Trust me, staying on top of these little details really pays off in the long run.

: Ultrasonic welding is a technology that uses high-frequency ultrasonic waves to create strong bonds between materials without the need for additional adhesives or heat.

The main advantages include improved manufacturing speed, reduced waste, enhanced product durability, and the ability to maintain the integrity of sensitive components.

Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been in the ultrasonic welding industry for over 20 years.

Industries that require precision and reliability, especially in the production of PSA cards, benefit from Chengguan's ultrasonic welding equipment.

Common issues include improper frequency settings and energy output, as well as inconsistent material properties like thickness and surface texture.

A deviation of just 5 kHz in frequency can lead to a 30% reduction in bond strength, highlighting the importance of precise calibration.

Inconsistent material properties, such as variations in thickness greater than 0.1 mm, can lead to weak welds or complete failures.

Manufacturers should invest in rigorous quality control measures and thorough testing of materials to ensure they meet the stringent requirements for ultrasonic welding.

Quality control is crucial in identifying and resolving potential issues with material consistency and welding parameters, thus ensuring optimal bonding quality.

Ultrasound welding technology enhances production capabilities by providing greater efficiency and superior bonding quality in an increasingly competitive market.

You know, ultrasonic welding has really become a go-to method for making seamless connections on PSA cards. It’s pretty impressive because it offers a bunch of benefits—like creating super strong bonds and cutting down on production time. Basically, the process relies on understanding some key tools and equipment—you gotta get those right to get the best results. Going through the steps carefully really helps ensure everything turns out smoothly. And yeah, it's normal to run into some issues along the way when welding PSA cards, but with a bit of troubleshooting, you can usually fix things pretty quickly and keep things running efficiently.

Besides that, taking good care of your ultrasonic welding machines—like regular maintenance and proper calibration—is super important if you want them to keep performing well over the long haul. Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been working with ultrasonic tech for over 20 years. We’re proud to offer high-quality ultrasonic welding systems made for a variety of industries, especially where precision in PSA card production really matters.