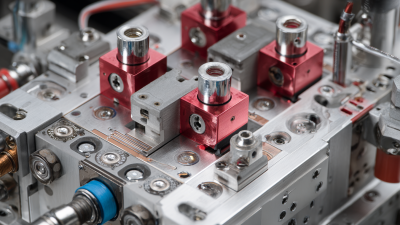

In today’s super fast-moving tech world, how well electronic components are packaged is becoming more and more important. I recently came across a market report from Grand View Research, and it says the global electronic packaging market is expected to hit around USD 36 billion by 2025, growing at about 4.8% annually. That’s a pretty clear sign that we really need those advanced packaging techniques — the ones that make sure devices work flawlessly and stay reliable. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. have been in the game for over 20 years, especially with ultrasonic plastic welding. They’re actually key players here, offering innovative solutions like ultraSonic Welding systems that fit all kinds of industries. As electronic parts get smaller and more complex, the demand for better, more efficient packaging just keeps climbing. This means companies like Chengguan are always pushing the envelope, developing new tech to streamline production and raise the overall quality of the final products.

Getting packaging right for electronic components is more important than you might think. With folks constantly demanding smaller, lighter, and more efficient gadgets, manufacturers really need to focus on optimizing how they package things. Not only does this cut down on costs—like saving money on materials—it also means less waste, which is pretty great for the environment, especially since our industry often gets a bad rap for its carbon footprint. When packaging is done efficiently, it helps protect the parts during shipping and storage, which means fewer returns and happier customers overall.

On top of that, making packaging more efficient can shake up the entire supply chain. If companies streamline how they package things, they can get products out faster and respond more quickly to market shifts or what consumers want. That kind of agility really sets a business apart in a crowded market, where being innovative and quick is everything. Things like automation, just-in-time packing, and using smarter, high-tech materials can make a big difference here. By adopting these methods, companies don’t just run smoother—they also boost their standing in a fast-changing tech world, staying ahead of the game and outpacing competitors.

You know, when it comes to Electronic Component Packaging, a lot of factors come into play—things really keep evolving as the industry tries to keep up with rising demand. Turns out, the global market for integrated packaging is expected to hit around $54.6 billion by 2025, and it’s projected to grow even more, reaching roughly $83.4 billion by 2032. That’s about a solid 6.25% CAGR! This boom is mainly fueled by new manufacturing tech and a bigger focus on eco-friendly packaging solutions. As companies look to get more efficient, innovations in materials and processes are pretty much essential in reaching those goals.

Now, in the booming world of e-commerce, packaging isn’t slowing down either—it's expected to be worth around $76.3 billion in 2024, with a crazy growth rate of about 13.2% from 2025 through 2034. And it’s not just about growth; stricter environmental rules and customers wanting greener options are really pushing this industry to change. On top of that, automation in packing lines is also gaining ground. The global market for packaging automation is forecasted to grow from about $78.3 billion in 2025 to nearly $134.7 billion by 2032—an impressive annual growth of over 8%. All these trends clearly point out that manufacturers really need to embrace new tech and sustainability to stay competitive, especially in the electronic components space.

You know, in the fast-paced world of electronic component packaging, staying ahead really means adopting some clever, new ways to streamline things. Using automation—like those high-tech machines for filling, sealing, and labeling—can make a huge difference, especially when dealing with high-demand industries like food, pharma, and consumer goods. These machines not only speed things up but also help keep things running smoothly and accurately. And as the market for packaging equipment keeps expanding—going from around $40 billion in 2023 to over $60 billion by 2032—it’s pretty clear that investing in the latest tech is more than just a good idea; it’s pretty much a must if you want to stay competitive.

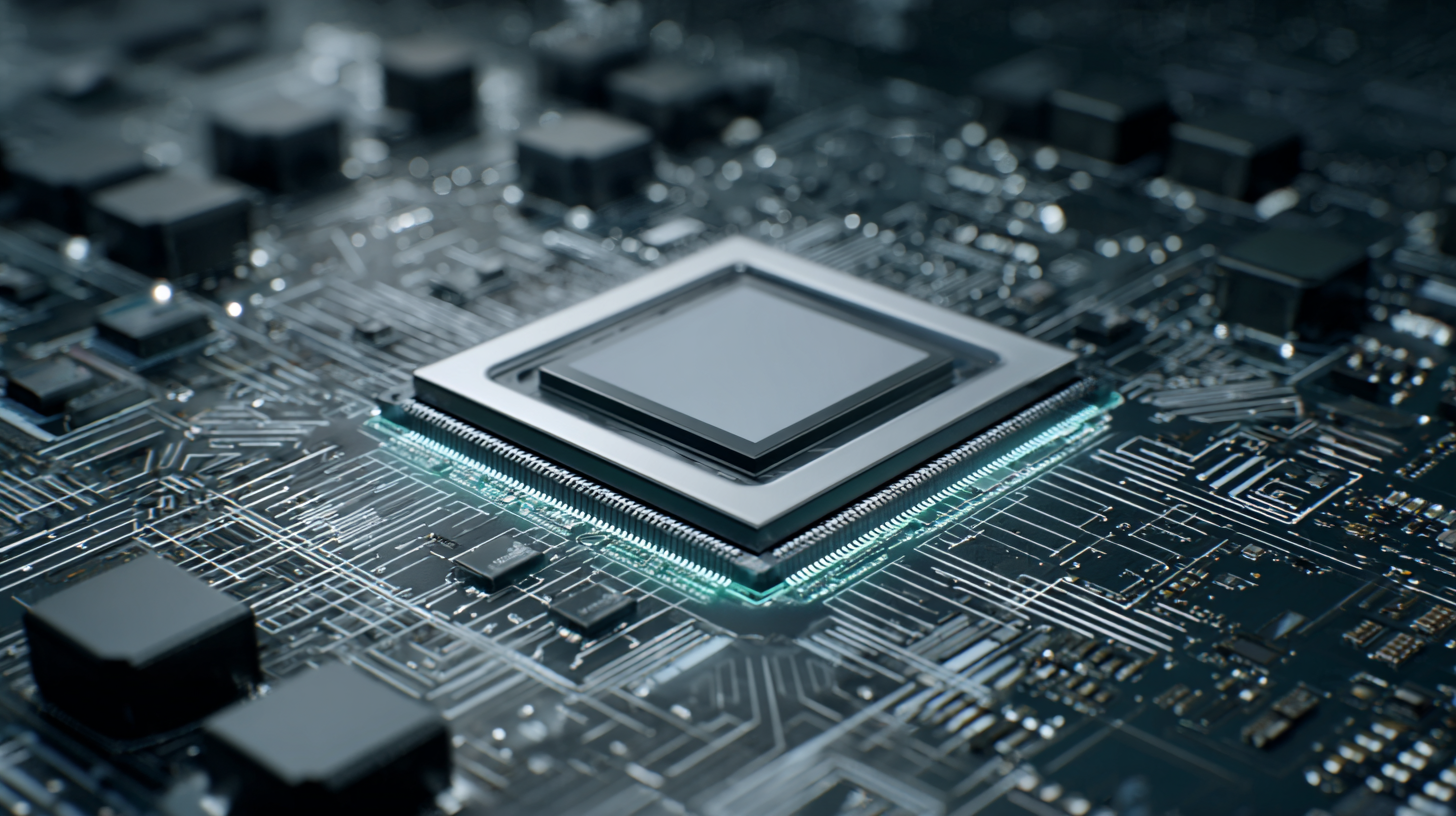

On top of that, new trends like AI and IoT are really shaking things up. For instance, the AI-driven packaging market is expected to grow from about $2.4 billion in 2024 to a whopping $6.2 billion by 2034, with a healthy annual growth rate of over 10%. These technologies do more than just boost efficiency—they help optimize resources, cut down on waste, and give companies access to real-time data that makes supply chains more transparent. As new regulations roll out, like those upcoming EU packaging standards, embracing these innovative tools will be key to staying compliant and offering more sustainable, smarter packaging solutions. It’s an exciting time, for sure, and those who jump on these trends early are probably the ones who’ll come out on top.

You know, the pace at which technology has been evolving in the world of electronic component packaging is pretty incredible. Automation has really become a game-changer for boosting efficiency. According to a report by the International Society of Automation, using automated packaging systems can bump up production rates by as much as 30%, all while cutting down on human errors. It’s not just about making things faster — it’s about doing it with better quality and consistency in the final product too. Interestingly, around 60% of manufacturers have already jumped on the automation bandwagon, which pretty much shows it’s shifting from being a nice-to-have to an industry standard rather than something optional anymore.

And honestly, the savings are nothing to sneeze at either. A study from Smith & Associates points out that companies that have adopted robotic automation in their packaging lines are seeing their labor costs drop by about 20-25%. Plus, with smart packaging tech on the rise, more businesses are taking advantage of IoT devices to keep an eye on packaging conditions in real-time—making sure everything runs smoothly, reducing waste, and upping efficiency overall. These tech advances really highlight how automation isn’t just a passing trend anymore — it’s revolutionizing the way we approach packaging in this industry.

You know, in today’s fast-changing world of electronics, sustainability really has become a huge deal, especially when it comes to packaging stuff. It’s not just about being eco-friendly for the sake of it — it actually makes things more efficient, cuts down on waste, and helps our planet out a bit. One cool thing companies are trying now is switching over to biodegradable materials instead of the old-school plastics. Stuff like recycled paper or bioplastics can do the job just as well, but with a much smaller carbon footprint, all while keeping your gadgets safe during shipping.

When you're looking to boost efficiency in electronic component packaging, keeping track of performance is a must. These performance metrics are like your go-to tools—they help you see how well your packaging strategies are working, so you can spot areas that need a little tweak and fine-tune your processes. Some of the key numbers to keep an eye on include cycle time, cost per package, and defect rates. Each one gives you a peek into how smooth your packaging runs, forming a solid base for making smarter, data-driven decisions.

One good way to see how efficient your packaging really is is to look at cycle time—the clock that starts ticking when you begin packaging and stops when the product’s ready to go. Generally, a shorter cycle time means the process is running pretty smoothly, helping you meet demands faster and cut down on costs. Then there's the cost per package—tracking this helps you see if the money you're shelling out aligns with what you're aiming for, which can guide how you plan your future budgets. And of course, keeping tabs on defect rates is super important because you want your packages to be reliable and perfect—happy customers depend on it, and it also means less waste for you. Focus on these metrics, and you'll be able to come up with targeted strategies that boost your overall efficiency and give you that competitive edge in the electronic components world.

| Packaging Method | Efficiency Metric | Performance Value | Notes |

|---|---|---|---|

| Surface Mount Technology (SMT) | Placement Accuracy (%) | 98.5% | High precision assembly method. |

| Through-Hole Technology (THT) | Defect Rate (%) | 1.2% | Lower defect rate due to manual assembly. |

| Automated Packaging | Cycle Time (seconds) | 15 seconds | Fast production line benefits. |

| Shrink Wrap Packaging | Material Usage (%) | 90% | Efficient material usage for packaging. |

| Bulk Packaging | Cost Reduction (%) | 20% | Significant cost savings in logistics. |

: Efficiency in packaging is crucial as it helps reduce production costs, minimizes material waste, and ensures components are well-protected during transportation and storage, leading to lower return rates and increased customer satisfaction.

Enhancing packaging efficiency shortens lead times, allowing manufacturers to respond quickly to market fluctuations and consumer demands, which is vital for maintaining a competitive edge.

The global integrated packaging market is expected to grow from $54.59 billion in 2025 to $83.44 billion by 2032, driven by advancements in manufacturing technologies and a focus on sustainable packaging solutions.

Sustainability practices enhance packaging efficiency by reducing waste and environmental impact, such as using biodegradable materials and optimizing packaging design to minimize material usage.

Effective strategies include using biodegradable materials, adopting minimalist packaging principles, utilizing advanced design simulation tools, and investing in reusable packaging systems.

The adoption of automation in packaging processes is projected to expand the global packaging automation market from $78.27 billion in 2025 to $134.65 billion by 2032, enhancing efficiency and reducing costs.

Biodegradable materials such as recycled paper and bioplastics can be used to replace traditional plastics, significantly lowering the carbon footprint while ensuring product protection.

Companies can adopt minimalist packaging principles and utilize simulation tools to create efficient designs that protect products while reducing waste.

The e-commerce packaging market is projected to be valued at $76.3 billion in 2024, reflecting a significant growth trend in the industry.

Embracing technological advancements is critical for improving operational performance and strengthening market position, especially in a rapidly evolving technological landscape.

Improving efficiency when it comes to packaging electronic components is a big deal for keeping production running smoothly in the electronics industry. There are a few key things that really make a difference—like choosing the right materials, designing the packaging thoughtfully, and bringing in new, innovative techniques. By adopting more advanced methods and embracing automation, manufacturers can really speed things up, cut down on waste, and boost overall productivity.

Plus, sustainability isn’t just a buzzword anymore; it’s actually crucial. Developing eco-friendly packaging solutions helps companies meet environmental standards without blowing their budgets. It’s also super important to have clear performance metrics in place—these help identify where things can improve and make the whole process more efficient. And if you look at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., with its impressive 20 years of experience in ultrasonic tech, you can see how investing in top-notch equipment can seriously level up packaging efficiency in the electronics world.