ThermoPlastic Welding is a pretty important technique that a lot of industries use to join thermoplastic materials smoothly and reliably. Honestly, this method isn’t just about creating strong bonds — it also helps speed things up and cut down on costs. As manufacturers keep pushing for better quality and more efficiency, getting a handle on thermoplastic welding really becomes a game-changer. When you understand the best practices around it, you can see a real difference in how well your products turn out, plus it supports more sustainable production processes.

In this article, I’m going to share the top 10 tips for thermoplastic welding that can help you improve your weld quality while making your operations run more smoothly. These aren’t just random tips — they cover essential techniques, the right tools, and things to watch out for, so no matter what kind of projects you’re working on, you can get better results. Whether you're just starting out or looking to sharpen your skills, trying out these tips will help you get more reliable, durable welds. That means better products and happier clients all around.

Thermoplastic welding is a vital process in various industries, characterized by its ability to create strong and durable joints. Understanding the key principles behind this technique can significantly enhance the quality of the final product. One fundamental aspect is temperature control; maintaining the appropriate heating temperature ensures that the thermoplastic material reaches its melting point without degradation. This is crucial for achieving consistent fusion between the parts being welded. Additionally, proper alignment during the welding process plays a vital role in preventing defects, as even slight misalignments can lead to weak joints.

Another important technique in thermoplastic welding is the selection of the right welding method, which can vary depending on the material type and application requirements. Methods such as hot gas welding, ultraSonic Welding, and laser welding each have distinct advantages and specific best practices. Mastering the nuances of these methods allows welders to select the most efficient approach for their projects. Furthermore, understanding the cooling time is critical; allowing adequate time for the welded joint to solidify ensures maximum strength and longevity. By focusing on these key principles and techniques, professionals can significantly improve both the quality and efficiency of thermoplastic welding.

Selecting the right thermoplastic materials is crucial for achieving optimal results in welding applications. According to the Plastics Industry Association, thermoplastics account for approximately 70% of the global plastics market, and their versatility allows for a wide range of applications, from automotive to biomedical products. When choosing materials, it is essential to consider factors such as melting temperature, tensile strength, and chemical resistance. For example, materials like polypropylene (PP) and polyvinyl chloride (PVC) are well-regarded for their balance of strength and flexibility, making them ideal for various welding projects.

In addition, industry reports indicate that improper material selection can lead to costly errors in production, with estimates suggesting that up to 30% of manufacturing inefficiencies stem from incompatible material choices. By utilizing material data sheets and understanding the properties of different thermoplastics, manufacturers can significantly enhance the quality and efficiency of their welding processes. Selecting materials that match the specific requirements of the application not only improves the performance and durability of the final product but also reduces waste and enhances cost-efficiency, ultimately boosting operational productivity.

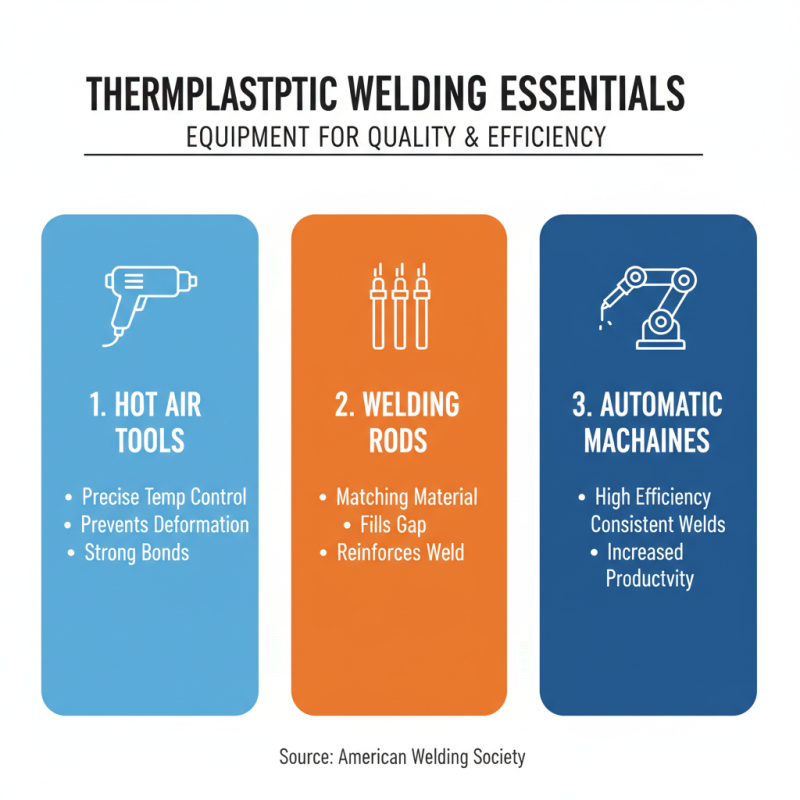

When it comes to thermoplastic welding, having the right equipment and tools is crucial for ensuring high quality and efficiency. Essential tools typically include hot air tools, welding rods, and automatic welding machines. According to the American Welding Society, the choice of equipment can significantly influence the integrity of the weld, as well as the overall productivity of the welding process. For instance, hot air tools are favored for their ability to achieve precise temperature control, which is critical when working with various types of thermoplastics. This control helps prevent thermal deformation and ensures a strong bond.

Moreover, sophisticated welding machines equipped with digital displays and programmable settings are increasingly becoming standard in the industry. A recent market analysis by Research and Markets projected that the global thermoplastic welding equipment market is expected to reach USD 1.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.2%. This growth is driven by advancements in technology that allow for enhanced performance and efficiency in thermoplastic welding operations. Investing in high-quality tools not only improves the quality of the final product but also enhances operational efficiency, reducing waste and rework costs in the long term.

Preparation is crucial for achieving high-quality thermoplastic welding. Proper surface preparation can significantly influence the strength and durability of the welded joint. According to a report by the American Welding Society, up to 70% of welding defects can be traced back to inadequate preparation processes. Cleaning the surfaces to be welded is essential; contaminants such as dirt, grease, and moisture can compromise the integrity of the weld. It is recommended to use appropriate solvents or detergents to ensure that surfaces are free from pollutants, and this step should never be overlooked.

Furthermore, achieving the correct alignment of the thermoplastic materials is critical. Misalignment can lead to weak joints and inconsistent seam quality. Industry standards indicate that maintaining a tolerance of +/- 0.5 mm can enhance the overall weld strength. Using jigs or fixtures during the welding process can assist in maintaining proper alignment and spacing. Additionally, pre-heating the materials, if applicable, can improve the fusion of the thermoplastic materials, especially in thicker sections, by reducing internal stresses and enhancing thermal conductivity. This thoughtful approach to preparation sets the foundation for successful thermoplastic welding, ultimately leading to improved efficiency and product longevity.

In thermoplastic welding, maintaining optimal temperature control is essential for achieving high-quality welds. One of the best practices is to regularly calibrate your welding equipment. Ensuring that your machinery is accurately set to the desired temperature can significantly reduce the risk of material degradation or improper fusion. This consistency not only enhances the quality of the bond but also contributes to the overall efficiency of the production process.

Additionally, monitoring the temperature during the welding process is crucial. Utilize infrared thermometers or thermal imaging cameras to assess real-time temperature data. This allows you to make immediate adjustments if the heat fluctuates, ensuring that the materials are welded at the ideal temperature. Implementing this practice promotes a better understanding of how different materials react to heat, allowing for more precise control over the welding parameters.

Finally, consider the use of pre-heating techniques as a way to enhance bonding quality. Pre-heating the thermoplastic materials before welding can help reduce the chances of thermal shock and improve fusion. This technique is particularly useful for thicker materials, where uniform heat distribution is vital. By integrating these temperature control strategies into your welding practices, you can achieve superior results in both quality and efficiency.

Achieving strong and durable welds in thermoplastic materials is critical for ensuring the longevity and performance of final products. The fundamental techniques center around optimal temperature control, ideal welding speed, and precise pressure application. According to a 2022 industry report from the Welding Society, maintaining a consistent temperature within ±5°C of the ideal welding range can significantly enhance joint strength, reducing the risk of defects by up to 30%.

One effective tip for maximizing weld quality is to properly prepare the surfaces to be joined—cleaning and possibly roughening the materials before welding can greatly improve adhesion. Additionally, using a suitable welding process, such as hot air or ultrasonic welding, depending on the materials involved, can create a stronger bond. A study published in the Journal of Polymer Engineering highlighted that the ultrasonic welding of polyolefins achieved a tensile strength increase of 15% compared to conventional methods.

Incorporating controlled cooling practices after welding is another vital technique. Rapid cooling can lead to stress concentrations and potential cracks. Employing a gradual cooling cycle not only enhances the durability of the welded joints but also minimizes warping and distortion. Following these practices aligns with findings from a 2023 Technical Review that emphasized the importance of controlled thermal management in improving the mechanical properties of welded joints.

Thermoplastic welding presents several common challenges that can hinder the quality and efficiency of the process. One frequent issue is improper surface preparation, which can lead to poor fusion and weak joints. To overcome this, it is crucial to thoroughly clean and dry the surfaces before welding. Using the right cleaning agents ensures that contaminants like oils and dust are eliminated, fostering better adhesion between the materials.

Another challenge is maintaining the correct temperature during welding. If the thermoplastic material is either overheated or not heated enough, it can result in defects. Implementing precise temperature control techniques will help maintain optimal conditions for welding. Monitoring the temperature of both the welding gun and the material can vastly improve adherence and overall joint strength.

Additionally, inconsistency in welding speed can lead to quality issues. A steady and controlled speed is vital to achieving a strong bond. Practicing uniform movement while welding not only enhances the quality of the weld but also boosts production efficiency. By addressing these challenges with strategic solutions, welders can significantly improve their outcomes in thermoplastic welding applications.

The CGZP Ultrasonic Rotary Plastic Welding Machine represents a significant advancement in manufacturing technology, primarily due to its high efficiency and precision positioning capabilities. Recent industry reports indicate that manufacturers utilizing ultrasonic welding technology can achieve production efficiency increases of up to 50%. The turntable's continuous operation allows for seamless batch production, which drastically reduces cycle times and elevates overall productivity. This is particularly beneficial in high-demand sectors such as automotive and consumer electronics, where rapid production rates are essential.

Moreover, the machine's precision positioning feature ensures high-accuracy alignment of workpieces, minimizing the risk of defects during the welding process. A study from the American Society of Mechanical Engineers (ASME) highlights that proper alignment can improve weld quality by up to 30%, further demonstrating the importance of precision in modern manufacturing. The CGZP's innovative design allows for consistent and reliable results, making it a vital asset for manufacturers seeking to enhance product quality and operational efficiency.

In addition to its efficiency and precision, the CGZP Ultrasonic Rotary Plastic Welding Machine stands out for its superior welding capabilities. This machine does not require any filler materials, ensuring high-strength welds with excellent sealing properties. Industry analyses reveal that such advantages can lead to a 20% reduction in material waste and a decrease in post-weld finishing costs. This combination of high-strength, minimal damage to the workpieces, and effective sealing positions the CGZP as a transformative tool in the quest for sustainable and economical manufacturing solutions.

: Essential tools for thermoplastic welding typically include hot air tools, welding rods, and automatic welding machines.

Temperature control is crucial because it prevents thermal deformation and ensures a strong bond when working with different types of thermoplastics.

Common challenges include improper surface preparation, maintaining the correct temperature, and inconsistency in welding speed.

Improper surface preparation can lead to poor fusion and weak joints, making thorough cleaning and drying of surfaces essential before welding.

Incorrect temperature can cause defects in the weld, as overheating or insufficient heating can compromise the integrity of the joint.

Practicing uniform movement while welding is vital, as steady and controlled speed enhances the quality of the weld and boosts production efficiency.

Advances in technology, including digital displays and programmable settings, enhance performance and efficiency in thermoplastic welding operations.

Using the right cleaning agents to eliminate contaminants like oils and dust before welding fosters better adhesion between materials.

Investing in high-quality tools improves the final product's quality and enhances operational efficiency, reducing waste and rework costs over time.

The global thermoplastic welding equipment market is projected to reach USD 1.5 billion by 2027, growing at a CAGR of 5.2%.

Thermoplastic Welding is a crucial process for achieving high-quality and efficient joins in various applications. Understanding the fundamental principles and techniques of thermoplastic welding is essential for selecting the appropriate materials, which significantly affects the outcome of the welds. Utilizing the right equipment and tools lays a foundation for successful welding, while thorough preparation steps ensure optimal results.

Temperature control is a critical factor in the welding process, as it directly impacts the strength and durability of the welds. By implementing best practices, welders can effectively navigate common challenges that arise during thermoplastic welding. Techniques for generating robust welds further enhance the overall reliability of the finished product. By focusing on these aspects, one can achieve superior results in thermoplastic welding and improve overall production efficiency.