In today's fast-changing manufacturing world, bringing in new tech is pretty much essential if you want to boost efficiency and performance. One standout innovation is Thin Film Welding — a technique that uses ultrasonic waves to create super strong bonds across a variety of materials, and with hardly any heat involved. I recently read a market report from Research and Markets, and it says that the global ultraSonic Welding market is expected to hit around $4.53 billion by 2027. That growth’s mainly driven by the increasing need for advanced joining methods in many industries. Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been a leader in ultrasonic plastic welding for over two decades, and they’re really driving this shift forward. They offer all sorts of products, like ultrasonic welding machines and cutting equipment, which help manufacturers adopt Thin Film Welding more easily. This not only makes production smoother and more efficient but also keeps quality and precision right on point.

So, Thin Film Welding is this pretty cool, cutting-edge technique that's becoming a big deal in modern manufacturing. Basically, it’s all about joining materials with exact precision—using just heat and pressure at really tiny, almost microscopic, levels. That means manufacturers can create super strong bonds without relying too much on adhesives, which is especially useful in industries like electronics, cars, and aerospace. By working with super thin layers of materials, they can make products that are not only stronger but also avoid wasting a bunch of extra stuff, helping keep things lean and mean.

One of the best parts about thin film welding? It’s fast and efficient. Traditional welding methods often need a lot of prep, longer heating times, and more material, which can slow things way down and jack up costs. But this technique? It’s quick, uses less energy, and generates less waste. Plus, working at such a tiny scale means the quality of the final product is generally way better. It even unlocks design possibilities that used to be impossible—making way for more complex, innovative stuff. Honestly, this is changing the game for manufacturing, making things more sustainable and cutting-edge all at the same time.

So, thin film welding is really making waves in the manufacturing world these days. It’s becoming a total game-changer, mainly because it bumps up efficiency and helps cut down costs. Honestly, this cool new technique is especially great when it comes to making those ultra-thin semiconductor films — you know, the ones that are super important in optoelectronics and photonics. By taking advantage of the special properties of these films, manufacturers aren’t just getting better performance; they’re also wasting less material, which means saving some serious bucks in the long run. That kind of efficiency is a huge deal right now, as industries try to make the most of their resources while still keeping up with what consumers want.

So, thin film welding is really making waves in the manufacturing world these days. It’s becoming a total game-changer, mainly because it bumps up efficiency and helps cut down costs. Honestly, this cool new technique is especially great when it comes to making those ultra-thin semiconductor films — you know, the ones that are super important in optoelectronics and photonics. By taking advantage of the special properties of these films, manufacturers aren’t just getting better performance; they’re also wasting less material, which means saving some serious bucks in the long run. That kind of efficiency is a huge deal right now, as industries try to make the most of their resources while still keeping up with what consumers want.

And it’s not just for one or two sectors either — thin film welding is proving useful across all sorts of fields like automotive manufacturing and renewable energy. Think about the U.S., where there are over 70 car plants churning out millions of vehicles each year. If those factories start using thin film tech, it could lead to serious savings and make energy use way more efficient. Plus, the move toward more flexible and smarter manufacturing methods — like new dry electrode tech and cutting-edge solar panels — really shows just how much potential this process has. As industries keep innovating, thin film welding is right there at the front, pushing us toward more sustainable and cost-effective ways to produce stuff. Honestly, it’s pretty exciting to see where this could all go.

Have you heard about thin film welding? It's gaining a lot of attention as a game-changer in manufacturing, and honestly, it’s pretty exciting. According to a report from Allied Market Research, the global market for this tech is projected to hit around $6.5 billion by 2027—that's a solid growth rate of about 10.2% annually since 2020. The big drivers? More and more industries, like electronics, automotive, and renewable energy, are dying for lighter, more energy-efficient parts, and thin film welding fits the bill perfectly. One of the coolest things about this method is how much it can cut down on energy use during production. Traditional welding can get pretty hot, which not only risks damaging your materials but also ramps up energy costs. Thin film welding, on the other hand, works at much lower temperatures. That means less thermal distortion and the ability to work with complex materials that might’ve been off-limits before. This is especially important in fields where precision and material quality really matter.

One of the coolest things about this method is how much it can cut down on energy use during production. Traditional welding can get pretty hot, which not only risks damaging your materials but also ramps up energy costs. Thin film welding, on the other hand, works at much lower temperatures. That means less thermal distortion and the ability to work with complex materials that might’ve been off-limits before. This is especially important in fields where precision and material quality really matter.

Thinking about trying it out? Here are a few tips:

Lately, thin film welding has really started to shake things up across various manufacturing industries. I mean, we've seen some pretty impressive examples where companies, especially in aerospace and automotive sectors, have adopted these techniques to boost their production speed without sacrificing the quality of their key parts. It's pretty cool because this new approach lets manufacturers get super clean joins with less heat distortion—huge win, especially when working with tricky shapes or high-performance materials.

On top of that, it helps solve some of the headaches that come with traditional welding methods. For example, controlling heat input and dealing with residual stresses? Much easier now. Stories from different companies show they're not just reducing shrinkage and warping, but also delivering parts that are more accurate and better quality overall. It’s really exciting to see how advanced welding tech like this is meeting the tough demands of today’s manufacturing world, making processes smoother and more efficient across the board.

Thin film welding is really picking up speed these days, mostly because everyone's so focused on making manufacturing more efficient than ever. I read somewhere that, according to MarketsandMarkets, the global market for this technology could hit around $15.5 billion by 2026, growing at an annual rate of about 8.2%. It’s a pretty exciting time—there are a lot of new innovations popping up, especially around the materials we use and how we do things. One of the cool trends I’ve seen is the move toward automation and even AI, which is helping to make the process more precise and cutting down cycle times. Basically, these tech advances mean manufacturers can keep up with faster production speeds without sacrificing quality.

And it’s not just limited to one area; applications of thin film welding are expanding into sectors like aerospace, electronics, and renewable energy. For instance, ResearchAndMarkets mentioned that demand for thin film solar panels is expected to grow a lot, with the market reaching about $10 billion by 2025. This shows how the technology isn’t just making traditional manufacturing better—it’s also driving sustainability efforts. Plus, companies are getting creative by exploring things like biocompatible materials for medical devices, which really opens up new possibilities at the crossroads of tech and eco-friendly solutions.

| Dimension | Description | Current Trends | Future Applications |

|---|---|---|---|

| Manufacturing Speed | Improved welding speed compared to traditional methods | Automation integration to increase throughput | High-volume production in electronics |

| Material Efficiency | Reduction in material waste during the welding process | Use of advanced materials for thinner films | Eco-friendly manufacturing processes |

| Heat Input | Lower heat input minimizes thermal distortion | Development of laser and electron beam welding techniques | High-precision applications in aerospace |

| Quality Control | Enhanced monitoring techniques for better quality assurance | Real-time data collection for quality tracking | Smart manufacturing with AI capabilities |

| Industry Applications | Widely applied in electronics, optics, and biomedical sectors | Expanding into renewable energy sectors | Integration in sustainable energy devices |

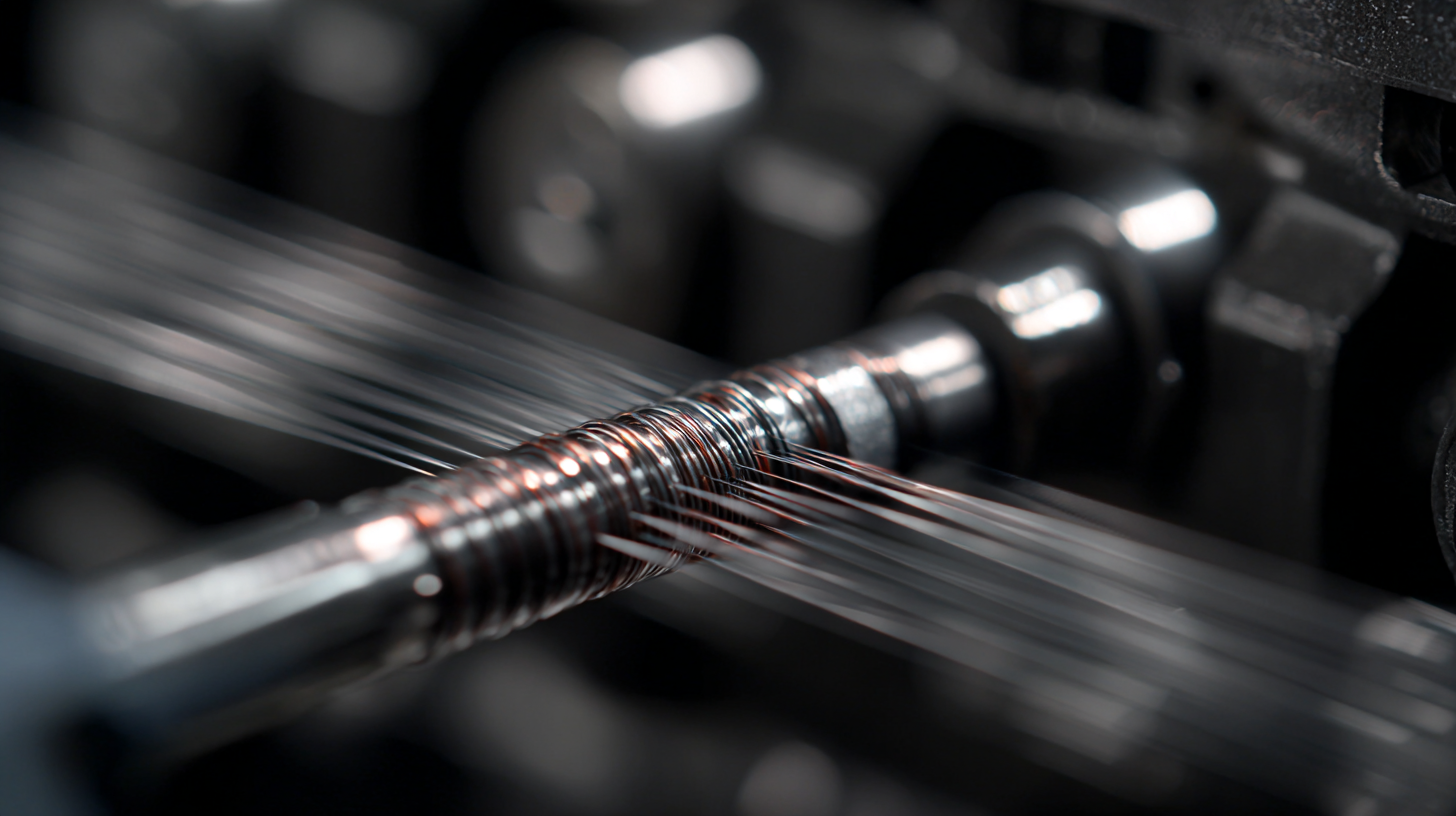

Revolutionizing Metal Fabrication: Insights from Industry Reports on the Efficacy of Metal Welding Machines for Copper Wire Applications

The landscape of metal fabrication is evolving, particularly in the domain of welding technologies. Recent industry reports emphasize the transformative impact of low-temperature welding techniques, which prioritize the integrity of the base materials. By eliminating the need for high-temperature melting, these advanced welding machines minimize the risk of deformation and brittleness typically associated with excessive heat. This is particularly beneficial for applications involving delicate metals like copper, ensuring that the material properties remain intact while achieving robust and reliable welds.

Moreover, the eco-friendly approach of modern welding machines cannot be overlooked. By operating without flux or filler materials, these machines not only comply with environmental standards but also significantly reduce the emission of harmful gases and the generation of slag. This clean welding process translates to lower maintenance efforts post-welding, streamlining operations in metal fabrication facilities. High welding quality is another hallmark of these innovative machines; the resulting joints exhibit exceptional strength and sealing capabilities, making them ideal for stringent quality demands in various industrial applications.

Finally, adaptability stands out as a crucial feature of today’s welding technology. The ability to efficiently weld a range of metal materials—whether similar or dissimilar, such as copper-aluminum or nickel-stainless steel—opens new avenues for multi-material construction and repair. As industry professionals seek to enhance productivity and versatility in metal fabrication, the efficacy of modern metal welding machines positions them as indispensable tools in the evolving landscape of metalworking.

: Thin film welding is a transformative technology that enhances manufacturing efficiency and sustainability by reducing energy consumption and minimizing thermal distortion during the welding process. It allows for the use of complex materials and is particularly beneficial for industries requiring precision and material integrity.

The global thin film technology market is projected to reach $6.5 billion by 2027, with a compound annual growth rate (CAGR) of 10.2% from 2020, driven by the demand for lightweight and energy-efficient components.

Thin film welding operates at lower temperatures than traditional welding, which reduces the risk of material degradation, minimizes thermal distortion, and allows for the joining of materials previously unsuitable for conventional methods.

Industries such as aerospace and automotive have successfully integrated thin film welding techniques, enhancing production efficiency while maintaining the integrity of critical components.

Manufacturers should assess material selection for compatibility with thin film welding, invest in workforce training, and monitor performance regularly to maximize the benefits of the technology.

Thin film welding helps manage heat input and control residual stresses, significantly reducing issues like shrinkage and deformation, and improving overall quality and accuracy in manufactured parts.

Precision is crucial in thin film welding as it allows manufacturers to deal with complex geometries and high-performance materials, ensuring superior join quality and material integrity.

Training is essential as it equips the workforce with the necessary skills and knowledge to effectively implement thin film welding technology, ensuring optimal results and efficient processes.

Thin film welding significantly reduces energy consumption during manufacturing by operating at lower temperatures, which leads to lower energy costs and less environmental impact.

You know, Thin Film Welding is really shaking things up in the manufacturing world. It's this pretty cool technique that’s all about getting things done faster and more cost-effectively. Basically, it lets you weld thin materials with a good amount of precision and speed—super handy in industries where every second counts. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are really leading the charge, offering innovative stuff like ultrasonic plastic welding systems that boost productivity without sacrificing quality.

What’s really impressive is how much impact Thin Film Welding has had across various manufacturing processes. We've seen tons of case studies showing how this tech has helped companies streamline their operations and ramp up their production. Looking ahead, it seems like more and more players are jumping on the bandwagon, adopting this technology and opening up new possibilities for even better, more versatile manufacturing. Honestly, it’s exciting to think about how this will shape the future—making lines more efficient and helping companies stay ahead in the game of innovation and competition.