Hey, have you heard about Thin Film Welding? It’s really shaking up the manufacturing world. I mean, this tech has opened up so many new possibilities for innovation and better performance across different industries. I was reading a report from MarketsandMarkets, and it said that the global market for Welding Equipment is expected to jump from around$18.7 billion in 2020 to about $25.8 billion by 2025. A big part of this growth is thanks to advances like Thin Film Welding. Not only does it deliver increased precision and strength, but it also helps cut down on waste—so it’s pretty much in line with the whole sustainability trend we’re seeing now.

What’s really cool about Thin Film Welding is how it uses super thin layers, which helps manage heat better and reduces the risk of distortion. This makes it especially awesome for high-performance stuff in fields like aerospace, cars, and electronics. Companies like Lincoln Electric and Miller Electric are putting a lot of resources into R&D to make these techniques even better. They’re betting that Thin Film Welding is going to be a game-changer for their products in the next few years. As manufacturers keep looking for ways to boost efficiency and make more reliable products, this technique really stands out as something that could push manufacturing into a whole new level of performance and creativity.

Thin film welding has emerged as a groundbreaking technology that is transforming various manufacturing industries. This advanced technique allows for the creation of exceptionally strong and durable bonds at a microscopic level, which results in improved product performance and longevity. By utilizing precision processes, manufacturers can achieve better thermal and electrical conductivity, making thin film welding particularly valuable in electronics, automotive, and aerospace sectors. The shift towards this innovative method signifies a move away from traditional welding techniques, offering solutions that are not only efficient but also environmentally friendly.

Tips for Implementing Thin Film Welding Techniques:

1. Start with Comprehensive Training: Ensure that your team is well-trained in the latest thin film welding technologies to maximize their potential benefits.

2. Invest in Quality Equipment: High-quality welding tools and materials can significantly improve the consistency and reliability of the welding process.

3. Monitor and Test Regularly: Implement regular testing and quality checks to identify any issues early in the production process, ensuring that the end products meet industry standards.

By focusing on these advancements, manufacturing industries can harness the power of thin film welding to enhance their production methods, leading to superior product performance and reduced waste.

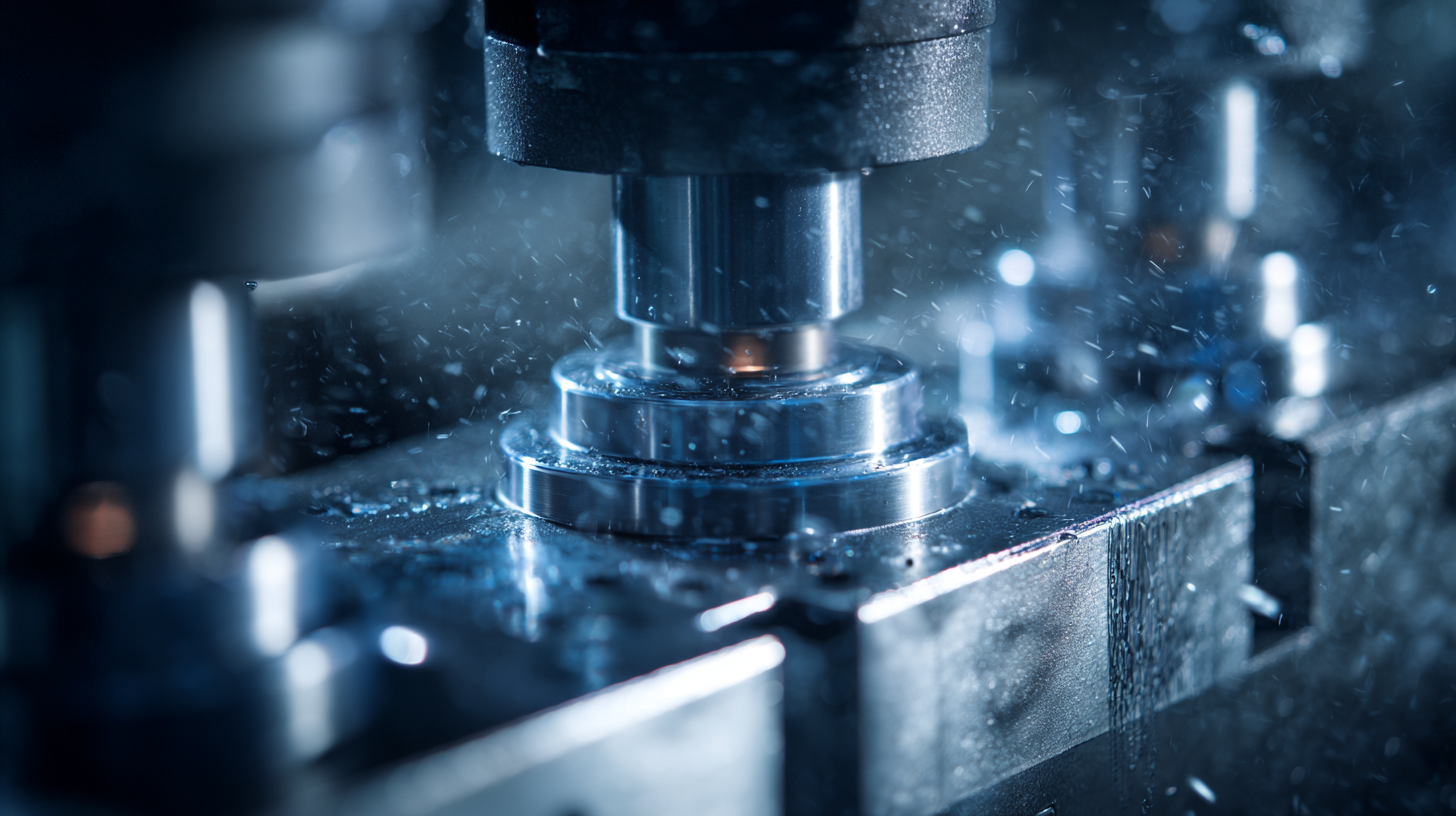

Thin film welding has emerged as a transformative manufacturing technique, significantly enhancing the performance and efficiency of various industrial applications. This innovative process relies on specific materials that optimize bonding strength and durability. Key materials such as polymers and advanced composites are increasingly utilized in thin film welding, allowing for the production of lightweight yet robust components. The choice of materials directly impacts the thermal and mechanical properties of the weld, resulting in superior performance and reliability in end products.

Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. stands at the forefront of this evolution, leveraging two decades of expertise in ultrasonic Plastic Welding technologies. The company's comprehensive range ofultrasonic plastic welding systems and equipment ensures that industries benefit from the latest advancements in thin film welding techniques. By utilizing high-quality ultrasonic lace, cutting, and extraction equipment, Chengguan enables clients to achieve precise and efficient manufacturing processes. The integration of cutting-edge materials with advanced ultrasonic technology not only enhances the quality of welds but also paves the way for innovations across diverse sectors, ensuring that manufacturers meet the growing demand for high-performance products.

Thin film welding is rapidly transforming modern manufacturing, particularly in enhancing product durability and efficiency. This innovative technique allows for the creation of strong, reliable bonds between materials while minimizing heat distortion, which is crucial for sensitive components. The recent launch of advanced products utilizing high-pressure embedded PCB technology exemplifies how thin film welding can lead to improved performance in the automotive sector, particularly for electric vehicles. By integrating low-loss and high-density features, manufacturers can produce more efficient and durable components tailored for next-generation applications.

One key advantage of thin film welding is its capability to enhance the longevity and efficiency of products. In the competitive landscape of automated devices like robotic lawn mowers, manufacturers are leveraging this technology to meet growing consumer demands for reliability and performance. As products become increasingly sophisticated, the ability to withstand various operational stresses while maintaining efficiency becomes a distinct market differentiator.

Tips: When considering materials for manufacturing, look for those that offer compatibility with thin film welding techniques. It’s also beneficial to explore how integration of advanced technologies, like embedded systems, can maximize product functionality. Staying updated on innovations in this field can provide a competitive edge in the market.

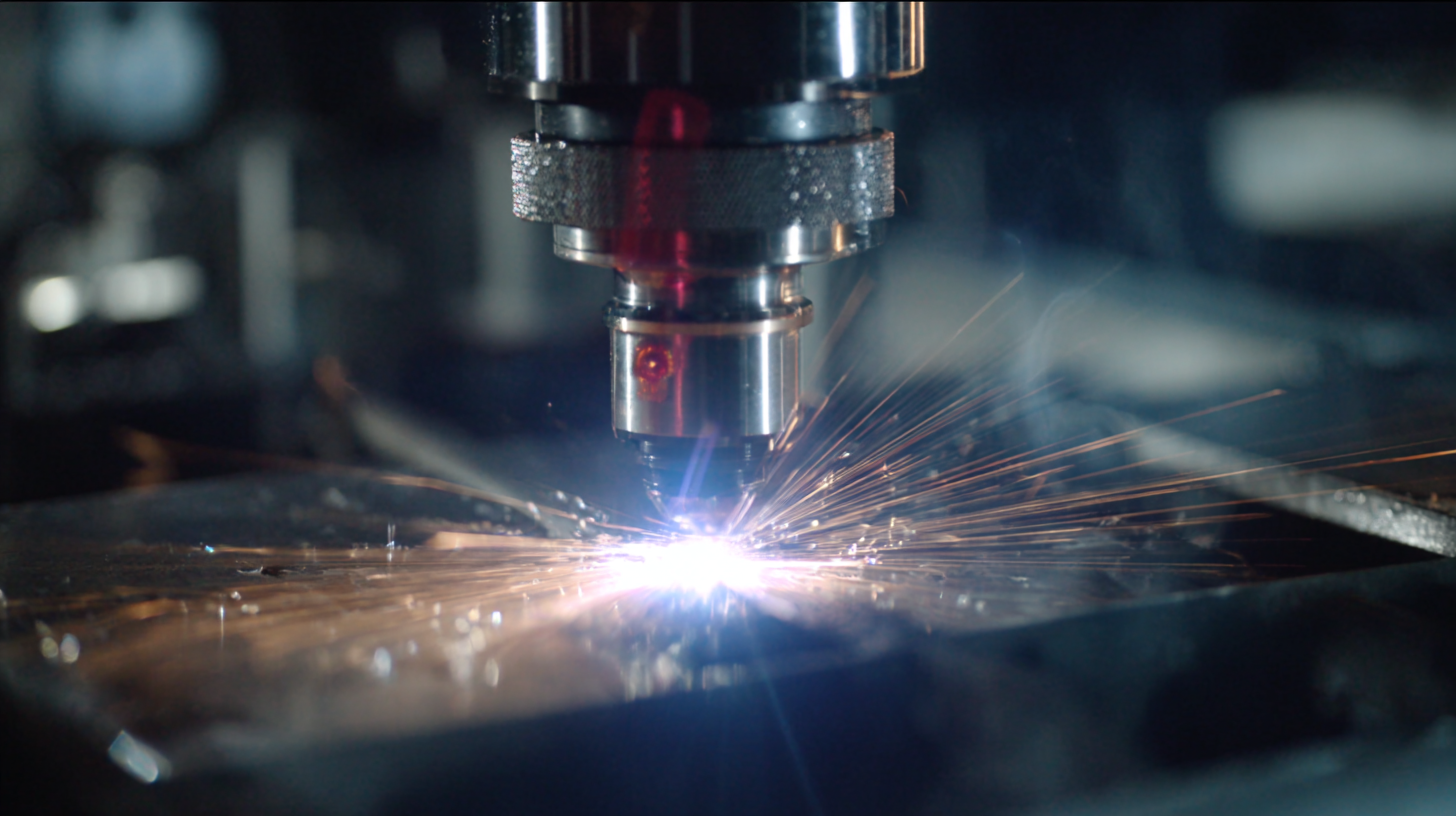

Thin film welding is increasingly being recognized as a transformative technique in modern manufacturing, particularly when juxtaposed with traditional welding methods. Unlike conventional welding, which often generates significant thermal damage and distortions, thin film welding utilizes advanced technologies such as high-speed laser cladding to achieve precise and efficient results. Recent studies indicate that this innovative approach not only enhances the integrity of welds, particularly in thin steel sheets, but also reduces overall emissions and waste, aligning with sustainable manufacturing practices.

Comparative analyses reveal that methods like thin film welding and ultrasonics, as championed by companies specializing in ultrasonic equipment, provide superior performance in terms of material preservation and structural integrity. For instance, high-energy ultrasonic techniques have shown promise in improving the welding characteristics of aluminum alloys, minimizing deformation while optimizing joint performance. As industries continue to move toward more eco-friendly solutions, adopting advanced welding technologies over traditional methods can lead to substantial advancements in manufacturing efficiency and product quality.

| Criteria | Thin Film Welding | Traditional Welding |

|---|---|---|

| Heat Input | Low | High |

| Material Distortion | Minimal | Significant |

| Welding Speed | High | Moderate |

| Surface Finish Quality | Superior | Good |

| Energy Efficiency | High | Low |

| Types of Materials | Various | Limited |

| Cost | Higher Initial Investment | Lower Initial Investment |

| Skill Requirement | Specialized | General |

Thin film welding is set to transform modern manufacturing practices, introducing innovative techniques that promise enhanced performance and efficiency. As industries increasingly seek lighter and stronger materials, the application of thin film welding becomes more relevant. This method allows for precise joins without the bulkiness of traditional welding techniques, enabling manufacturers to create products that are not only durable but also optimized for weight and functionality. Such advancements are particularly significant in sectors like aerospace and automotive, where performance and resource efficiency are paramount.

Looking ahead, the future of thin film welding is influenced by developments in materials science and automation. Emerging trends point towards the integration of smart technologies and real-time monitoring systems that will ensure optimal welding conditions and quality control. Additionally, the expansion of additive manufacturing combined with thin film processes could lead to unprecedented customization in product design, allowing for complex geometries and improved material properties. As these techniques evolve, manufacturers must adapt and rethink their strategies to fully harness the potential of thin film welding, paving the way for a new era of advanced manufacturing solutions.

: Thin film welding is an innovative technique that enhances product durability and efficiency by creating strong bonds between materials while minimizing heat distortion. It's particularly crucial for sensitive components and is transforming sectors like automotive, especially for electric vehicles.

Unlike traditional welding, which can cause significant thermal damage and distortions, thin film welding utilizes advanced technologies like high-speed laser cladding for precise results. It enhances weld integrity, reduces waste and emissions, and supports sustainable manufacturing practices.

The main advantages include improved longevity and efficiency of products, ability to withstand operational stresses, reduced material deformation, and overall enhancement in performance, making it a distinguishing factor in competitive markets like robotics.

Thin film welding is particularly significant in industries such as aerospace and automotive, where lightweight and strong materials are essential for performance and resource efficiency.

Emerging trends include the integration of smart technologies and real-time monitoring systems for optimal welding conditions, as well as combining additive manufacturing with thin film processes for advanced customization and improved material properties.

Manufacturers need to rethink their strategies by staying updated on innovations in thin film welding, exploring compatibility with advanced materials, and adopting new technologies to enhance functionality and product design.

Advances in materials science will play a crucial role in the evolution of thin film welding, allowing manufacturers to utilize lighter and stronger materials designed specifically for precise joining without the bulkiness of traditional methods.

Thin film welding reduces overall emissions and waste compared to traditional methods, contributing to sustainable practices while enhancing manufacturing efficiency and product quality.

Manufacturers might face challenges such as the need for updated equipment, the necessity to train staff on new techniques, and the integration of thin film welding with existing manufacturing processes.

Staying informed allows manufacturers to gain a competitive edge by efficiently integrating advanced technologies into their processes and leveraging thin film welding to meet growing consumer demands for high-performance, reliable products.

Thin Film Welding is revolutionizing modern manufacturing techniques by introducing advanced methods that significantly enhance product performance and efficiency. As outlined in our exploration of this innovative approach, advancements in Thin Film Welding techniques are transforming various manufacturing industries. Key materials used in this process play a crucial role in improving durability and efficiency, setting it apart from traditional welding methods. A comparative analysis highlights the superior benefits of Thin Film Welding, making it an essential choice for manufacturers seeking to elevate their production standards.

Looking ahead, the future trends in Thin Film Welding promise to further innovate manufacturing processes, offering implications that could reshape the industry landscape. As a company with two decades of experience in ultrasonic plastic welding, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is well-positioned to contribute to this evolution, providing cutting-edge ultrasonic solutions that complement the advancements in Thin Film Welding.