You know, as more and more industries are pushing for super accurate and efficient manufacturing processes, choosing the right equipment has become super important. One big player in this field is the Acrylic Welding Machine, which is now a must-have in sectors like automotive, electronics, and consumer goods. There’s even this recent analysis from MarketsandMarketsthat predicts the ultraSonic Welding equipment market is set to hit a whoppingUSD 2.5 billion by 2025! This growth is mainly fueled by tech advancements and the increasing shift towards automation.

For over 20 years now, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has been leading the charge in this innovation. They’ve got a real knack for crafting top-notch ultrasonic plastic welding systems and equipment. Their dedication to high-quality manufacturing solutions really helps clients adapt to the changing production landscape, keeping them competitive in this fast-moving world.

You know, when we're talking about acrylic welding, industry certifications really matter. They help keep manufacturers on their toes, making sure they stick to those high standards and deliver quality stuff. There was this recent report from the International Association of Plastics Engineers (IAPE) that said over 65% of businesses noticed a big boost in production efficiency and a cut in waste when they used certified welding machines. Pretty compelling stuff, right? It really highlights why companies should think about investing in machines that meet those established industry standards.

One certification that's a big deal is ISO 9001, which focuses on quality management systems. Companies that hold that ISO certification actually see about a 20% boost in customer satisfaction compared to those that don’t. That's a pretty impressive difference! Plus, the American Welding Society (AWS) puts out some guidelines that are critical for keeping things safe and efficient when it comes to acrylic welding. Machines that meet these standards ensure not just strong joints and great clarity in the acrylic, but they also help build a company’s reputation as a reliable player in a competitive market. So, investing in industry certifications is really not just a nice-to-have anymore; it’s pretty much a must for anyone wanting to succeed in the acrylic fabrication game.

So, when you're on the hunt for top-notch acrylic welding machines, there are a bunch of key features you really gotta think about if you want to boost your production efficiency and get some great output quality. First up, let's talk power settings – these are super important! I mean, a report from the International Society of Plastics Engineers shows that machines with adjustable power settings can handle everything from those super thin sheets to the thicker ones. This kind of flexibility not only makes the welding process smoother but also helps to avoid that dreaded overheating or any damage to your materials.

Now, another biggie is precision during the welding process. If you're looking at high-end acrylic welding machines, you’ll find they often come with some pretty cool tech, like laser or ultrasonic welding capabilities. In fact, there's this study by the American Welding Society that points out ultrasonic welding results in stronger joints and puts less stress on the substrate, which means a more durable final product. Plus, features like digital displays for temperature and speed control really help nail down the accuracy, leading to top-quality welds and less material waste. As the acrylic fabrication world keeps on expanding, it’s super important to invest in machines that have these features to stay ahead in the game and meet production demands!

Alright, so when you're looking at the best acrylic welding machines out there, it’s pretty clear that you need to dig into some key industry standards to really nail down what fits your production needs. You’ve got to consider things like precision, efficiency, and how user-friendly these machines are. They really make a difference in how quickly and effectively you can produce your products. Top manufacturers are constantly updating their gear with the latest tech, so it’s super important for businesses to keep tabs on what’s new in the acrylic welding world.

Plus, if you're deciding on the right machine, you should definitely think about how well it meshes with other parts of your manufacturing process. This means checking if it can work with different materials and how easy it is for your team to operate. With the acrylic market booming—thanks to its growing use in industries like automotive and consumer goods—picking a welding machine that checks all these boxes is a must if you want to stay ahead of the game and streamline your production workflows.

So, when you’re on the hunt for the perfect acrylic welding machine for your production line, it’s really important to keep a few industry standards in mind — they can make a big difference in how efficient you are and the quality of what you’re producing. First off, take a good look at the machine's power and frequency options. These factors can really influence how quickly you can weld and how strong those joints end up being. Having a machine that lets you tweak the power settings is a great way to get better control over the welding process. This way, you’ll achieve the best results no matter how thick your acrylic is.

And let's not overlook the fact that compatibility with ultrasonic technology is super important too. With over 20 years in the game, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. really knows their stuff when it comes to ultrasonic plastic welding systems. They’ve tailored their machines to fit a variety of production needs, so you can bet you’ll be getting equipment that’s all about precision and reliability – which, let’s be honest, boosts productivity. Oh, and keep an eye out for features like automatic settings and safety features. These can really help smooth out operations and cut down on risks on the production floor. In the end, you’ll not only have a more efficient process but a safer one too!

Taking care of your acrylic welding equipment is super important if you want it to run smoothly and give you great results over time. You know, a report from the Industrial Welding Institute found that if you do regular maintenance, you could actually bump the lifespan of your machines by as much as 40%! Can you believe that? It’s all about checking and calibrating things frequently—stuff like the nozzle and power supply—to make sure they're all in tip-top shape. Plus, having a little cleaning routine after each use really helps keep those pesky residues from piling up and causing problems down the line.

On top of that, what materials you use really matters too. A recent study by the American Welding Society highlighted that if you go for high-quality acrylic sheets that can handle heat and bending, you're not just improving your weld quality; you're also giving your machines a break by reducing wear and tear. And let’s not forget about storage! Keeping equipment in a climate-controlled space is key to avoiding damage from humidity and temperature changes. These little habits can really make a difference, extending your gear’s life while also keeping your production quality and efficiency on point.

You know, investing in some top-notch welding machines, especially for working with acrylics, can really boost both your production efficiency and the quality of your products. But it's not just about the initial cost; you have to think about the long-term benefits too, like better output and lower labor costs. Those fancy advanced welding machines often come with automation and precision features, which definitely makes them must-haves for companies wanting to streamline their operations and keep up with growing demand. If you take a look at some industry reports, you’ll notice how new tech is shaping manufacturing—especially in areas like electric vehicle production and container manufacturing.

Now, take Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., for example. They’ve been rocking the ultrasonic welding scene for 20 years, offering creative solutions that work across a bunch of different industries. With ultrasonic welding, businesses can get cleaner, stronger joints while using way less energy compared to the old-school methods. As companies look to up their production game, it's super important to grasp just how valuable investing in high-quality welding machines can be. The return on investment isn't just about making products better; it also comes from slashing operational costs and having the capability to meet those increasing production demands efficiently.

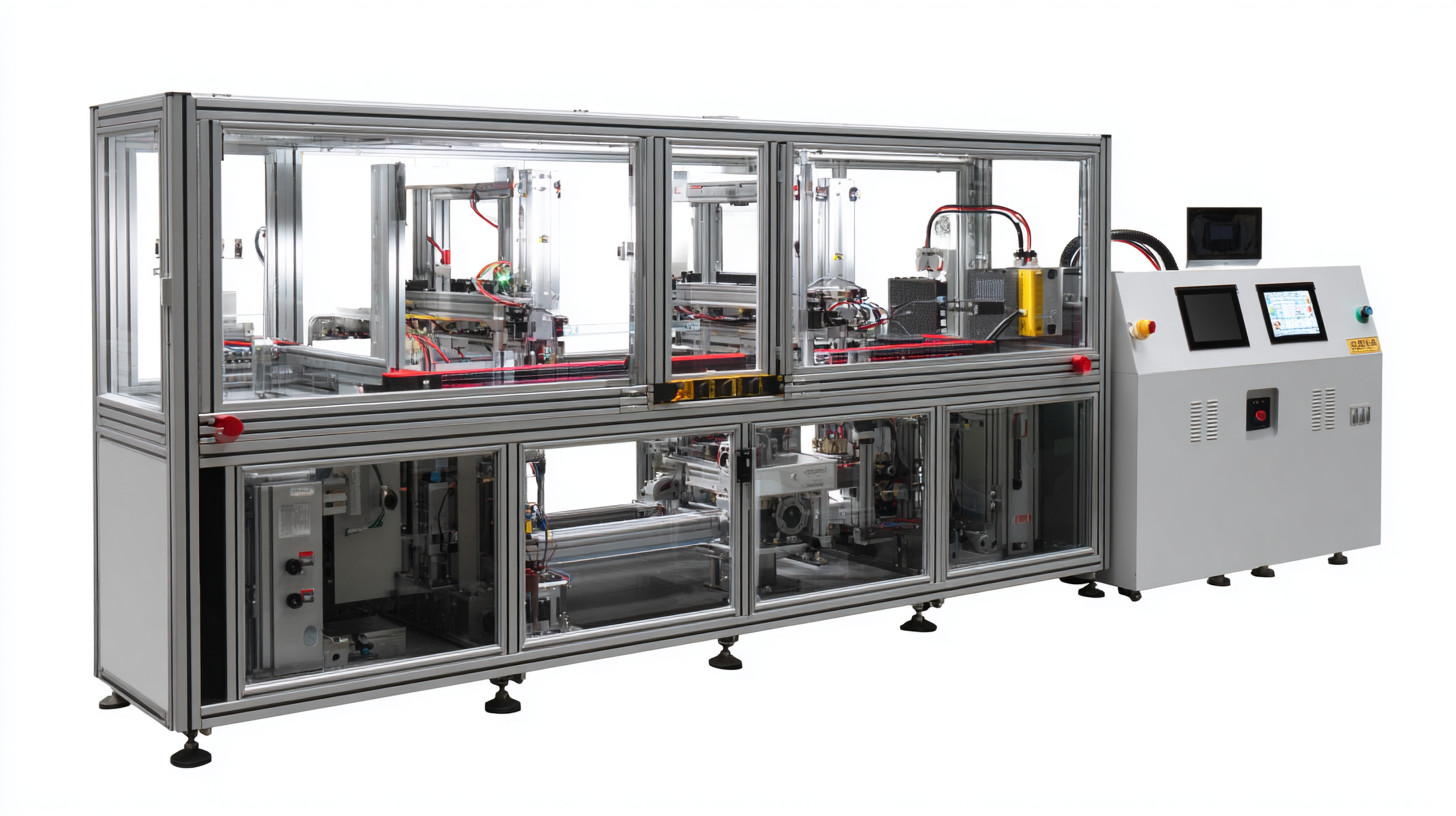

The CGZP Ultrasonic Rotary Plastic Welding Machine is poised to transform the manufacturing landscape with its cutting-edge technology and exceptional performance. At the core of its revolutionary impact is its high efficiency, thanks to the turntable's continuous operation designed for batch production. This feature not only streamlines the manufacturing process but also significantly boosts productivity, allowing businesses to meet growing demands with ease.

Furthermore, the machine's precision positioning capabilities ensure that workpieces are consistently aligned with high accuracy. This level of precision is crucial in eliminating discrepancies and ensuring quality in every weld. The superiority of the CGZP machine comes into play with its unique welding process that requires no filler materials. This not only enhances the strength of the finished products but also maintains excellent sealing while minimizing material damage. As industries evolve, the CGZP Ultrasonic Rotary Plastic Welding Machine stands out as a beacon of innovation, setting new standards in manufacturing efficiency and product quality.

: The key performance metrics include precision, efficiency, and user-friendliness, which impact production timelines and outcomes.

Compatibility with various materials and ease of operation are crucial for seamless integration into existing workflows, enhancing overall efficiency.

Assessing the machine's adjustable power settings is essential, as these options significantly affect welding speed and joint strength for different acrylic thicknesses.

Ultrasonic technology is critical for achieving precision and reliability in welding processes, and selecting machines that incorporate this technology can enhance productivity.

Regular maintenance, including frequent checks and calibrations, and implementing a cleaning protocol after each use are essential for optimal performance and longevity.

Using high-quality acrylic sheets that are heat and bending-resistant not only improves weld quality but also reduces wear and tear on the machinery.

Keeping the equipment in a climate-controlled environment is vital to preventing damage from humidity and temperature fluctuations.

According to a report from the Industrial Welding Institute, regular maintenance can increase the lifespan of welding machines by up to 40%.

Safety mechanisms and automatic settings are important features that streamline operations and minimize risks on the production floor.

Leading manufacturers continually enhance their offerings through innovative technologies, which is essential for maintaining a competitive advantage in the growing acrylic market.