Hey there! So, in today's super fast-moving world of manufacturing, picking the right equipment is absolutely key if you want to boost productivity and keep quality high. This really stands out when we're talking about something like a Plastic Spot Welder—it’s such an essential tool in lots of industries, from automotive to consumer goods and beyond. Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been doing this for over 20 years, and believe me, we know how varied our customers' needs can be. Our passion for innovation means we’ve thrown together a range of specialized ultrasonic Welding Systems, including some pretty nifty ultrasonic cutting and lace equipment. So, in this ultimate guide, we’ll dive into the important stuff to think about when you’re on the hunt for the best Plastic Spot Welder for your unique applications. The goal? To help you make a smart choice that not only fits your operational needs but also really amps up your production capabilities!

Hey there! So, in today's super fast-moving world of manufacturing, picking the right equipment is absolutely key if you want to boost productivity and keep quality high. This really stands out when we're talking about something like a Plastic Spot Welder—it’s such an essential tool in lots of industries, from automotive to consumer goods and beyond. Here at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we’ve been doing this for over 20 years, and believe me, we know how varied our customers' needs can be. Our passion for innovation means we’ve thrown together a range of specialized ultrasonic Welding Systems, including some pretty nifty ultrasonic cutting and lace equipment. So, in this ultimate guide, we’ll dive into the important stuff to think about when you’re on the hunt for the best Plastic Spot Welder for your unique applications. The goal? To help you make a smart choice that not only fits your operational needs but also really amps up your production capabilities!

Okay, so when you’re on the hunt for the perfect plastic spot welder, it’s super important to get a grip on the different types out there—whether you’re a DIY fan or a seasoned pro. You know, with all the cool advancements in plastic repair tech these days, modern welders are pretty versatile; they can handle a bunch of different plastic materials, which makes nailing those strong, long-lasting repairs way easier. I mean, just think about how we've come a long way from the old-school hot irons to these fancy welders that even come with nitrogen generators! It really shows how the industry is all about upping their game in terms of performance and user-friendliness.

And get this! A recent report said that the global plastic welding market is about to blow up. It’s expected to jump from around 3 billion bucks in 2019 to nearly 4.46 billion by 2032—talk about a significant growth spurt, right? That’s a CAGR of 2.8%. This rising demand just underscores how essential it is to pick high-quality equipment for both metal and plastic jobs. Honestly, investing in a reliable spot welder means you’re not just getting better repair outcomes, but you’re also boosting your efficiency across various fields, especially in automotive work.

Plus, having the ability to repair plastics is becoming a must-have for businesses that want to stay ahead in the ever-changing auto industry. With new materials popping up in vehicle manufacturing, having the right tools to fix plastic damage is going to really help you stay competitive. Thanks to the latest welding tech advancements, craftsmen can now tackle even the trickiest repairs, which is pretty awesome in adapting to the modern market demands.

This chart illustrates the performance ratings of various plastic spot welders available in the market, providing a clear comparison that can help you choose the best option based on your needs.

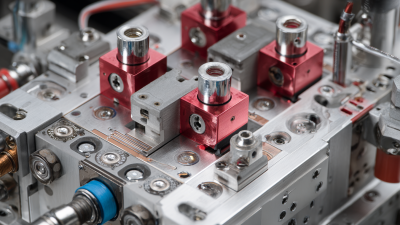

Choosing the right plastic spot welder can be a bit of a task, but it’s totally worth the effort if you want something that really works for you. First off, think about the welding capacity. This basically tells you how thick the plastics are that your welder can handle. If you find a model that can do a wider range, that’s a win – it means you can tackle all sorts of projects without a hitch. And hey, don't forget about power output! A welder with higher wattage usually means quicker weld times and smoother operations, which is especially great if you're in a professional setting.

Now, let’s chat about the temperature control system. Having precise temperature control is super important because it helps you get those consistent welding results. You definitely don’t want to mess up your materials, right? Plus, if the controls are user-friendly and adjustable, it really streamlines your workflow and gives you better control over the whole welding process.

And yeah, think about portability too! If you’re planning to use the welder in different spots, a lightweight design with comfy handles makes a world of difference. All in all, by weighing these features, you’ll be in a great position to pick out a plastic spot welder that suits your specific needs perfectly.

So, when you're trying to pick out the right plastic spot welder for what you need, it's super important to get a handle on price ranges. You want to make sure you're getting the best bang for your buck, right? I came across this industry report from Allied Market Research that says the plastic welding equipment market is set to grow about 4.1% a year from 2021 to 2027. This tells us it's a pretty competitive market where you often get what you pay for in terms of quality and features. You’ll notice budget models usually go for anywhere between $100 to $600, while some of those high-end ones can cost up to $2,500. Figuring out exactly what you need—like what materials you'll be working with or how big your projects will be—can really help you narrow things down.

Here’s a little tip: Before you hit that buy button, dive into user reviews and check out some case studies for the specific models you’re eyeing. It gives you a good sense of how they perform and hold up over time. Plus, think about the long-term value of spending a bit more on a better unit. It might have some nice features and last longer than those cheaper options.

Oh, and don’t forget to keep an eye out for extra costs that might sneak in, like replacement parts or maintenance down the line. Getting a solid grasp of all these factors will really help you make a decision that fits your needs without breaking the bank.

If you’re on the hunt for the best plastic spot welder, you really can’t skip checking out the top brands. It’s all about finding ones that you can count on for reliability and quality when you’re deep in your projects. One standout in the field is Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. They've built up quite the reputation over the last 20 years for their expertise in ultrasonic plastic welding. This company is all about offering a variety of ultrasonic welding solutions that work across different industries, making sure their gear is both precise and efficient.

What’s cool about Chengguan is that their ultrasonic plastic welding systems are not only innovative in tech but also super user-friendly. They don’t just stop at plastic spot welders; they have a whole lineup of ultrasonic lace equipment, cutting tools, and homogenizers, which makes them a go-to for professionals looking for that high-quality edge. So, when you’re picking a plastic spot welder, it’s worth considering how long a brand has been around and what they offer. It can really make a difference in how successful your welding projects turn out, giving you the right tools to nail those flawless results.

Alright, let’s talk about keeping your plastic spot welder in tip-top shape. Regular maintenance is super important if you want it to last and perform well. First off, make it a habit to clean the electrodes and the welding surfaces after each use. Trust me, any gunk that builds up can really mess with your welds and wear the machine out faster than you'd like. Just grab a soft cloth or a brush—works like a charm—and don’t forget to check the electrode alignment to avoid any misfires while you’re using it.

Also, take a peek at the power supply and cables every now and then. You want to catch any issues before they sneak up on you. Make sure all the connections are tight and keep an eye out for any fraying or damage on the wires. If something looks off beyond the usual wear and tear, it’s best to take care of it right away. Oh, and if you can, store your welder in a dry place where the temperature is steady. Extreme weather conditions can really take a toll on the materials over time. By following these simple maintenance tips, you’ll not only get more life out of your plastic spot welder but also boost its performance for all your upcoming projects!

Hey there! When you’re using plastic spot welders, it’s super important to steer clear of some common blunders if you want the best results and stay safe. One big mistake folks often make is messing up the weld settings. Seriously, a study from the International Journal of Adhesion and Adhesives points out that if the temperature settings aren’t right, your welds could end up weak. This can totally compromise the joint integrity, which is obviously not what you want! So, make sure you check the manufacturer’s guidelines for the correct voltage and heating times to get that solid weld you’re aiming for.

Another common pitfall is skipping proper surface prep. A report from the American Welding Society really drives home how crucial this step is—if there’s grease, dust, or even a bit of moisture on your welding surfaces, it can really mess with your weld quality. Cleaning and prepping your surfaces might take a little extra time, but trust me, it pays off. If you don’t, you might see defect rates soar by as much as 30% in joints that weren’t prepped right. So, investing that bit of time into prep work can really boost the durability and performance of your welds!

: The main types of plastic spot welders include basic hot irons and advanced models equipped with features like nitrogen generators, designed to handle a variety of plastic materials for strong and durable repairs.

The global plastic welding market is expected to grow from USD 3 billion in 2019 to approximately USD 4.46 billion by 2032, reflecting a compound annual growth rate (CAGR) of 2.8%.

Key features to consider include welding capacity (thickness of plastics), power output (higher wattage for faster welds), temperature control systems for consistent results, user-friendly controls, and portability for ease of use in different locations.

Regular maintenance is crucial for extending the lifespan and reliability of a plastic spot welder, as it prevents issues such as inconsistent welds and premature wear.

You should clean the electrodes and welding surfaces after each use, inspect the power supply and cables regularly, and store the welder in a dry, temperature-controlled environment to prevent damage.

Investing in a high-quality plastic spot welder leads to superior repair results and enhances operational efficiency across various applications, particularly in sectors like automotive services.

Advancements in welding technology allow craftsmen to tackle complex repairs effectively, ensuring that businesses can meet the evolving demands of the automotive industry.

The ability to address plastic damages with the right tools is crucial for businesses to maintain a competitive edge as vehicle manufacturing materials continue to evolve.