You know, in today's super competitive world, companies are really scrambling to find the best manufacturing techniques out there. This has definitely pushed Ultrasonic Weldinginto the spotlight as one of the coolest advancements in the industry. A recent market report even suggests that by 2025, the global market for ultrasonic Welding Equipment could hit a whoppingUSD 2.3 billion. Pretty impressive, right? This growth is all thanks to its amazing efficiency and adaptability across different sectors.

For over 20 years, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has led the pack, providing top-notch ultrasonic plastic welding systems and equipment. As businesses look to ramp up their production while keeping an eye on costs, ultrasonic welding stands out as a fantastic solution, letting manufacturers join materials together with both precision and speed.

In this guide, we’ll dig into some of the best ultrasonic welding techniques available to buyers around the world in 2023, sharing tips on how to tap into this technology for the best results.

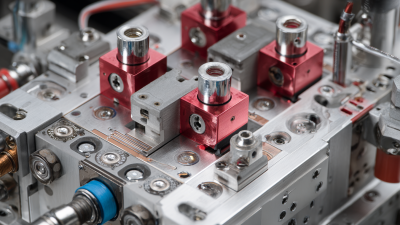

You know, ultrasonic welding (UW) has really taken off lately as a super efficient and versatile way to join materials, especially for industries that are working with different types of materials. Just this year, in 2023, folks have been using ultrasonic welding to combine 3003 aluminum alloy with some stainless steel foil, and the results are pretty impressive! They’ve found that welding setups using up to 2.4 kW have produced strong, reliable joints. In fact, there are studies out there that showcase the microstructure of the welds, and the interface regions show some serious quality in bonding.

When you’re diving into ultrasonic welding, it’s super important to grasp the different types of welding joints you can work with. Each design can really change how efficient and effective the weld ends up being. Plus, keeping an eye on things like pressure and amplitude? That’s key to getting top-notch welding strength, especially when you’re working with various materials.

A little tip: always run some preliminary tests to find the best settings for your particular materials. Also, don't overlook the mixing behavior you can spot at the interface—it can really impact the mechanical strength of the final product. And hey, if you stay updated with the latest advancements in ultrasonic welding tech, you’ll make sure your processes stay competitive and effective! It’s all about keeping that edge!

You know, ultrasonic welding has really become a game-changer in a bunch of industries, and it’s all thanks to its amazing efficiency and precision. The medical field, in particular, has really taken to this technique because it meets those super strict requirements for cleanliness and accuracy. What’s cool about ultrasonic welding is that it can bond materials without needing any adhesives or heat. This makes it perfect for crafting medical devices that have to strictly adhere to safety and performance standards. Plus, it ensures strong, reliable bonds while keeping contamination risks low, which is so critical in healthcare applications.

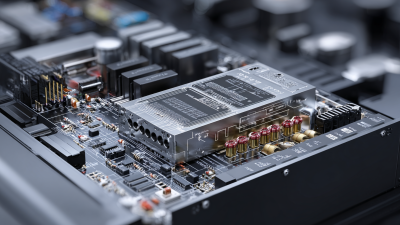

And it’s not just the medical industry that’s hopping on board. In automotive and electronics, they're using ultrasonic welding more and more for connecting components like wires and sensors. This technique lets manufacturers create lighter and more compact assemblies without sacrificing strength. As the hunt for smaller, more efficient devices heats up, ultrasonic welding really stands out as a key player in adapting to these new market demands.

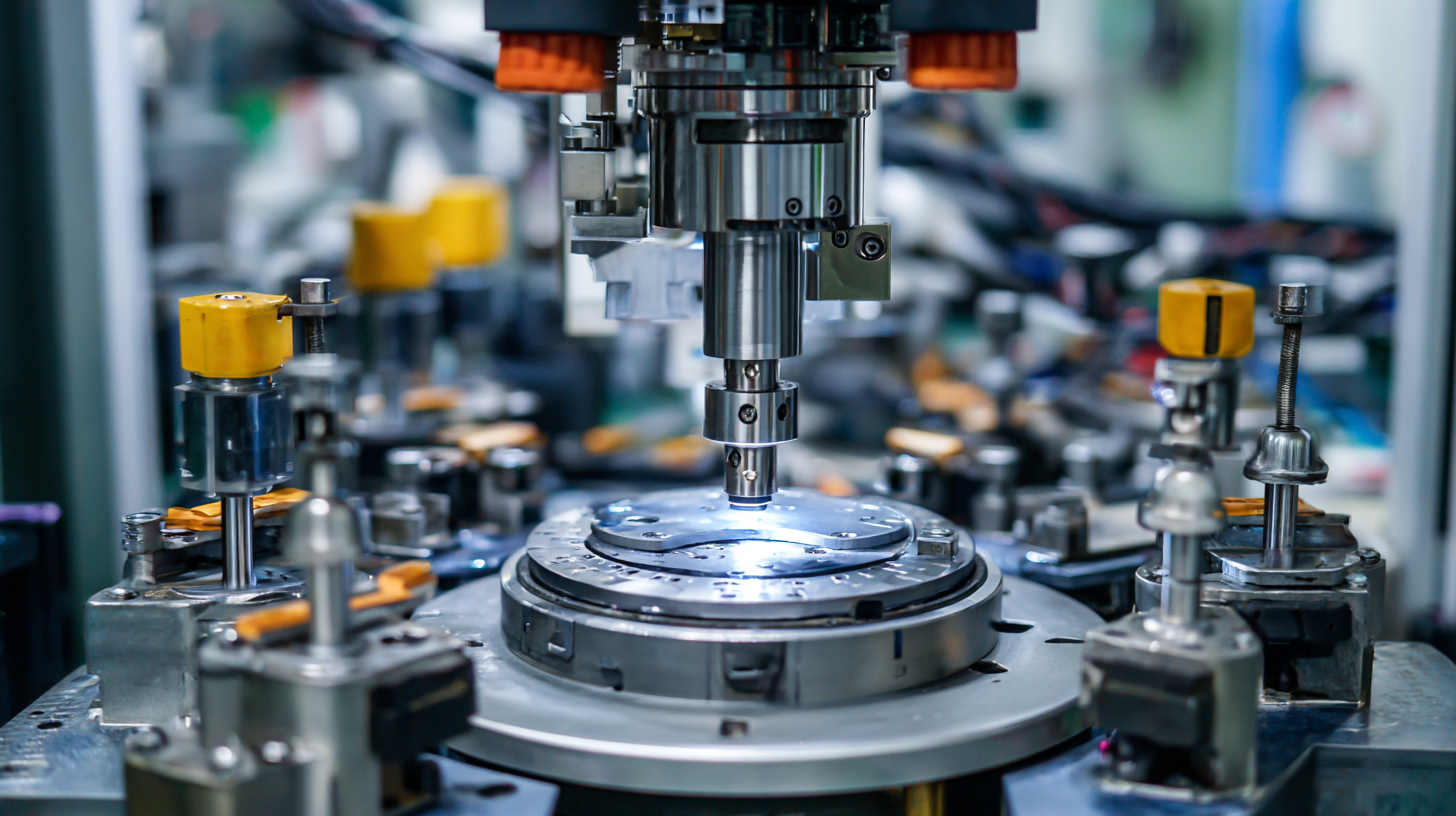

Now, if you’re diving into ultrasonic welding, there are a few tips that could really help you out. First off, make sure there’s proper acoustic coupling between the materials you’re joining, and keep an eye on that amplitude level during the process. Oh, and don’t forget to monitor tool wear! That can really boost reliability and extend the life of your equipment, which is super important for keeping production running smoothly in high-volume settings.

So, in 2023, when you look into ultrasonic welding techniques, it's pretty clear that there's been some serious progress in the tech world—it's really stepping up to meet the changing needs across different industries. Companies like Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are leading the charge here, bringing in about 20 years of know-how to boost the efficiency and performance of ultrasonic plastic welding systems. Their cool innovations, like ultrasonic lace and cutting equipment, really highlight how precision engineering can make a big difference in manufacturing.

With more and more people wanting high-quality and dependable welding methods, ultrasonic welding has become a go-to technique for joining materials while ensuring that structural integrity isn’t sacrificed. Chengguan's lineup of ultrasonic welding gear is specifically designed to handle all sorts of applications—from automotive stuff to electronics. When buyers compare things like continuous and pulse ultrasonic welding, they can really make smart choices that fit their production needs, which just goes to show how crucial ultrasonic tech has become in today’s manufacturing scene.

So, when you're looking for ultrasonic welding equipment, it's super important to think about what you really need for your specific application. You want to make sure you get the best quality and performance out of it. Ultrasonic welding is actually a pretty cool technology—it uses high-frequency vibrations to join plastic parts together really strong and consistently. If you're shopping around in 2023, keep an eye on things like frequency stability, weld quality, and how user-friendly the equipment is. You’ll want to go for equipment that gives you precise control over the welding process, because let’s be real, nobody wants defects messing up their production line, right? Plus, it can really help boost your overall efficiency.

Now, let's talk about Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. They've been leading the game in ultrasonic technology for about 20 years now, focusing on systems for ultrasonic plastic welding and a whole bunch of related gear. Their dedication to innovation and quality really means you can count on them to provide tough solutions for different industries. Whether you need ultrasonic lace equipment or cutting systems, their experience guarantees you'll find exactly what you need to meet your production goals. That way, you can improve your product quality and operational effectiveness, which is always a win.

So, here’s the deal: in 2023, keeping a close eye on quality control in ultrasonic welding has really stepped up in importance, especially in fields like medical, automotive, and electronics. With manufacturing getting more and more complex, businesses are on the hunt for solutions that not only make assembling products smoother but also keep them in line with global standards. Luckily, there have been some exciting innovations in ultrasonic welding platforms that tackle these tricky challenges head-on. They’ve got some pretty cool features that tweak welding parameters, which means better weld quality and greater reliability overall.

And let’s not forget about data integrity and security—it's becoming super crucial for ultrasonic welding tasks. As manufacturers are integrating more advanced tech, the possibility of data breaches during welding is definitely something to worry about. That's why we’re seeing a rise in solutions that beef up data security—they’re becoming a must-have in quality control. These new tools allow for real-time monitoring and checks on the welding processes, making sure everything meets industry standards and boosting confidence in product safety and longevity. By focusing on these quality control measures, companies around the globe are really upping their manufacturing game while staying compliant with tough regulations.

You know, the ultrasonic welding industry is really gearing up for some big changes in the next few years, especially with all the tech advancements and growing needs from manufacturing sectors. A recent report from MarketsandMarkets says that the ultrasonic welding market could hit around $4.5 billion by 2027, growing at a solid rate of 6.8% from 2022. It's pretty clear this shift is all about becoming more efficient and automated, which not only boosts production but also helps cut down on waste, which is a win-win!

One of the major trends driving this evolution is the cool integration of smart tech—like IoT and AI. These innovations are set to enable real-time monitoring and fine-tuning of welding parameters, leading to better precision and more consistent weld quality. A study from Research and Markets even notes that AI-driven systems in manufacturing could help companies save up to 20% in operational costs by 2025. As manufacturers jump on this tech bandwagon, they’re not just improving their efficiency but also stepping up their product quality, which is crucial for meeting those rising consumer expectations.

On top of that, the push for sustainability is really shaping how we’ll approach ultrasonic welding moving forward. More industries are on the lookout for eco-friendly solutions that can slash energy use and reduce their environmental footprint. The Ultrasonic Technology Group points out that advanced ultrasonic welding techniques can decrease energy consumption by up to 50% compared to the old-school methods. So, the mix of technology and a focus on sustainability is definitely leading us toward innovative manufacturing practices that cater to a more eco-conscious market.

In today’s manufacturing landscape, the demand for efficient and precise welding solutions has never been greater, particularly in the realm of copper wire applications. Ultrasonic welding machines have emerged as a game-changer, harnessing high-frequency vibrations to create strong and reliable bonds in a fraction of the time compared to traditional methods. The ability to complete bending-sealing-cutting operations in under one second not only accelerates production but also significantly enhances overall efficiency, allowing manufacturers to meet the fast-paced demands of modern industry.

These ultrasonic welding machines ensure exceptional quality with robust sealing strength that meets the rigorous requirements of contemporary welding processes. Their design minimizes the risk of air or liquid leakage, paving the way for tight and durable welds. Such reliability is crucial for industries where adherence to quality standards is non-negotiable. Furthermore, the impressive process control provided by these machines establishes a solid foundation for producing high-quality components.

Environmental conscientiousness is increasingly paramount in manufacturing, and ultrasonic welding aligns seamlessly with this trend. By eliminating the need for additional welding materials, these machines prevent the introduction of impurities, resulting in cleaner production processes. Coupled with low energy consumption, this makes ultrasonic welding machines a sustainable choice for businesses looking to embrace energy conservation and environmental protection while boosting their operational efficiency.

: Ultrasonic welding is a joining technique that uses high-frequency vibrations to create strong, consistent bonds between materials, particularly beneficial for bonding dissimilar materials.

Ultrasonic welding offers efficiency, precision, and the ability to bond without additional adhesives or heat, making it ideal for applications in the medical, automotive, and electronics industries.

Maintaining optimal parameters such as pressure and amplitude is crucial for achieving high welding strength across different materials, and conducting preliminary tests can help ascertain the best settings.

When selecting equipment, prioritize features like frequency stability, weld quality, and ease of use to ensure optimal quality and performance for your specific application.

It meets stringent safety and performance standards by ensuring strong, reliable bonds while minimizing contamination risks, making it ideal for producing medical devices.

It allows the joining of components like wires and sensors, enabling the production of lighter, more compact assemblies while maintaining structural integrity.

Proper acoustic coupling between the materials being joined is essential for successful ultrasonic welding, as it impacts the efficiency and quality of the weld.

Monitoring tool wear can enhance reliability and extend equipment lifespan, which is crucial for maintaining production efficiency in high-volume applications.

Regularly researching and keeping abreast of the latest advancements in ultrasonic welding technology can help ensure that your processes remain competitive and effective.

Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is a leading provider, specializing in ultrasonic plastic welding systems and related equipment, with over 20 years of experience in the industry.