You know, the manufacturing world is really changing these days, and it’s pretty exciting to see how advanced technologies are taking center stage in driving growth—especially in China. This country has built quite a reputation for its dedication to quality and innovation. Take Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., for instance. With nearly 20 yearsunder their belt in ultrasonic plastic welding, they're really leading the charge in this transformation. They're all about delivering top-notch ultrasonic plastic Welding Systems, including cool solutions like theUltraSonic Welding PSA Card, making sure they cater to the varying needs of different industries. Looking ahead to 2025, it's fascinating to think about how emerging trends in ultrasonic welding technology will team up with the perks of PSA (Pressure-Sensitive Adhesive) applications. This combo is bound to kick industry growth into high gear while boosting production efficiency and product reliability. So let’s dive in together and unpack these trends and the amazing changes they could bring for manufacturers around the globe!

Hey there! You know, as industries are really pushing to ramp up their manufacturing efficiency, ultrasonic welding is kind of stealing the spotlight in the world of joining tech. It's amazing how it can whip up strong, high-quality bonds way faster than the old-school welding methods. Seriously, it's shaking things up on production lines in all sorts of fields like automotive, electronics, and even medical devices. One of the coolest things about ultrasonic welding is that it can join different materials without needing extra adhesives or any thermal heat. That not only slashes production costs but also keeps everything super precise and clean—so it's perfect for those jobs where quality control is a big deal.

And get this, the latest advancements in ultrasonic tech are set to crank up productivity even more! We’re seeing trends like integrating smart automation systems that really smooth out the welding process, making the output and consistency of the welds much better. As manufacturers keep hopping on this train, the ultrasonic welding market is expected to grow a lot, especially with the challenges of rising material costs and changing market demands. So, it’s clear that ultrasonic welding isn't just a solid solution for manufacturing; it’s also a key player in achieving that operational excellence and gaining a competitive edge.

You know, ultrasonic welding technology is really making waves these days, especially with the rise of Pressure Sensitive Adhesives (PSAs). They're becoming a big deal because of how they simplify things. Imagine being able to bond materials without having to crank up the heat or apply extra pressure—that’s a game-changer for industries like automotive and electronics. It not only speeds up the welding process but also protects those sensitive components that just can’t handle high temperatures. So, as companies search for ways to make their operations smoother, incorporating PSAs into ultrasonic welding is really starting to look like a smart move.

But there's more! PSAs also play a huge role in bumping up the overall quality of the welds. They’re great at filling in those tiny gaps and surface imperfections, which means you get a more consistent bond. This is a really big deal when it's crucial to keep production standards on point. Plus, with PSAs in the mix, manufacturers can crank out products faster while cutting down on defects. That means less material waste and saves some bucks. Looking ahead to 2025, the combo of ultrasonic welding and PSAs is on track to shake up manufacturing practices, pushing innovation and efficiency in all sorts of industries.

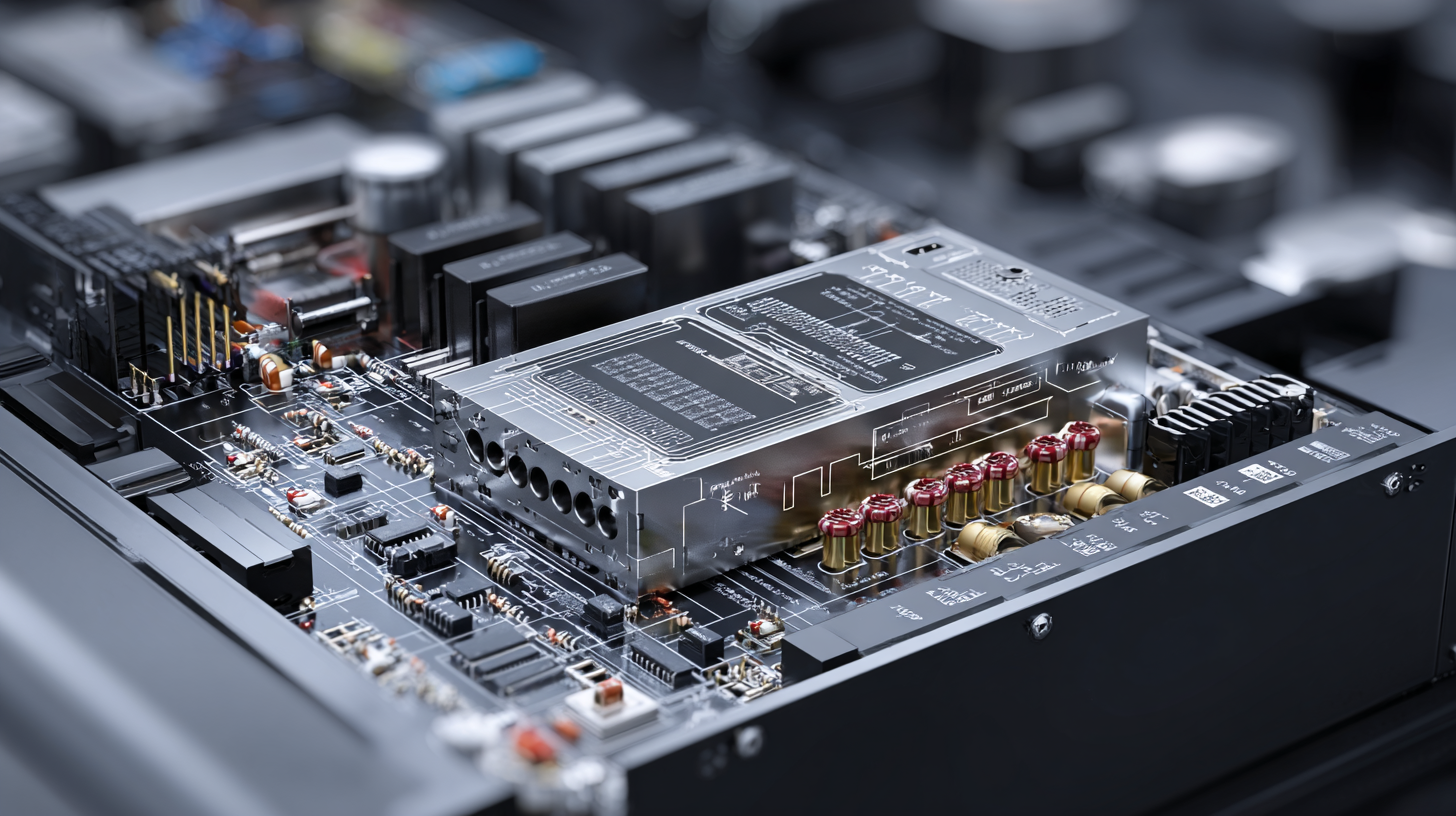

You know, as Industry 4.0 keeps shaking things up in the manufacturing world, ultrasonic welding tech is really on the verge of some exciting stuff! With smart technologies like the Internet of Things (IoT), artificial intelligence, and big data finding their way into ultrasonic welding, we’re seeing a boost in efficiency and precision like never before. Manufacturers can actually tap into real-time data to fine-tune their welding setups, cutting down on waste and ramping up product quality. Plus, with predictive maintenance becoming a thing, they can catch potential machine breakdowns before they throw a wrench in the works of production lines.

And that’s not all—another cool perk of bringing Industry 4.0 into ultrasonic welding is how it makes communication a breeze all across the supply chain. This connectedness means production schedules can be way more responsive, and resources can be aligned better too. Oh, and let’s not forget the smart robots! These machines come loaded with advanced ultrasonic welding features that allow them to handle complex patterns and tweaks in a heartbeat. So, not only does this speed things up, but it also opens up a whole new world of customization, letting manufacturers cater to all sorts of consumer demands. With all these advances, ultrasonic welding is really gearing up to be a key player in various industries as we march toward 2025. You’ve got to admit, it’s an exciting time for this important tech!

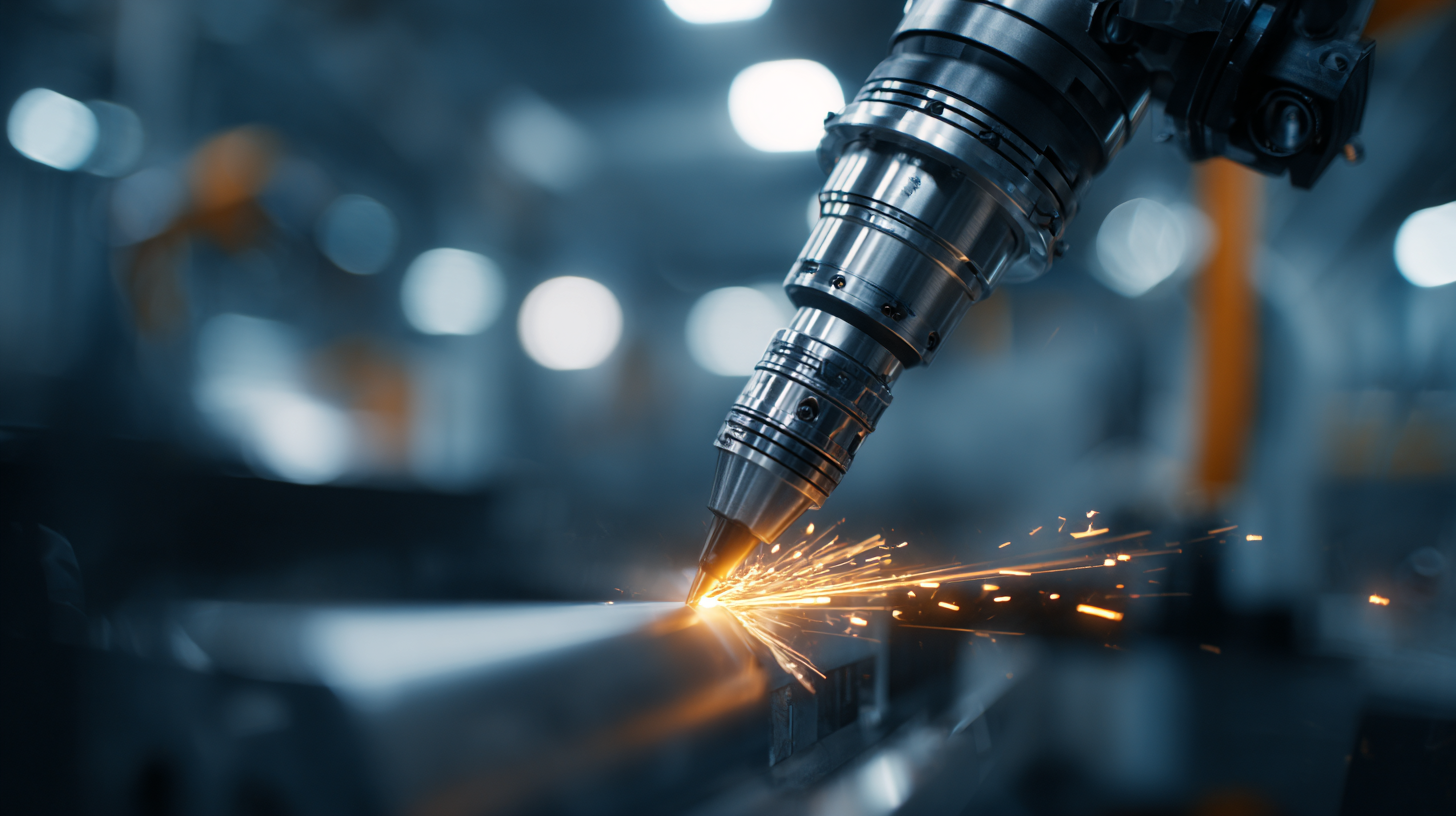

Looking ahead to 2025, it’s clear that ultrasonic welding tech is gearing up for some really exciting challenges and opportunities, especially when it comes to electric mobility. With the big shift towards electrification, there’s a growing need for dependable and efficient electrical connection systems, and that’s where ultrasonic welding really shines.

This tech can create strong bonds without needing any extra materials, which is super crucial for making advanced components—think electric vehicles (EVs) that demand high power density and durability.

Plus, we’re seeing the rise of advanced ultrasonic methods, like torsional welding, which are making it easier to tackle complex applications. This means bigger welds and access to those tricky spots that are usually a pain to reach.

As the market evolves, being able to innovate in ultrasonic welding is going to be a key factor for players in the industry. And you know what? Events that showcase the latest and greatest in ultrasonic welding will be a goldmine for gathering knowledge, boosting collaboration among experts, and paving the way for groundbreaking advancements in both the automotive and aerospace sectors, especially as industries adapt to the demands of space manufacturing and beyond.

Hey there! So, let’s talk about ultrasonic welding—it’s really changing the game these days. You know, the use of Process Safety Assurance (PSA) systems is making a big splash in this field. I came across this recent industry report, and it's pretty impressive: manufacturers who’ve started using PSAs in their ultrasonic welding processes have seen their weld quality consistency jump up by about 20%. That’s no small feat! A lot of this success seems to come from better monitoring and control that PSAs provide, keeping all those critical parameters in check during the welding cycle.

There are some cool case studies that show just how well PSAs can work. Take this big-name automotive manufacturer, for example—they put a PSA system on their production line and ended up cutting weld defects by 30%. Not only did this make their manufacturing run smoother, but they also saved a chunk of change in the process. Then there’s this well-known electronics company that saw a 25% drop in cycle times after they brought PSAs on board, which meant they could produce more without sacrificing quality. Pretty neat, right? These stories really highlight how PSAs are becoming essential tools for companies looking to boost their efficiency and product reliability in ultrasonic welding. I mean, it’s definitely paving the way for industry growth as we head toward 2025!

| Trend | Description | Advantages of PSAs | Case Study Result |

|---|---|---|---|

| Increased Automation | Adoption of automated ultrasonic welding systems for precision and speed. | Higher consistency and reduced labor costs. | 30% increase in production efficiency. |

| Advanced Material Compatibility | Improved ultrasonic welding methods for diverse materials. | Wider range of applications in various industries. | Successful welding of multi-layer composites. |

| Process Monitoring | Integration of sensors and data analytics in welding processes. | Real-time quality assurance and reduced waste. | Reduction in defects by 25%. |

| Compact Equipment Design | Shift towards smaller, more efficient ultrasonic welding machines. | Space-saving solutions for manufacturing floors. | Improved workflow with 15% space reduction. |

| Enhanced Energy Efficiency | Development of energy-efficient ultrasonic welding systems. | Lower energy costs and improved sustainability. | Energy savings of up to 40% documented. |

You know, ultrasonic welding technology is really taking off, especially in China. As the country modernizes its manufacturing game, there’s a big push for those high-precision and cost-effective joining methods. Ultrasonic welding is kinda leading the charge in industrial applications. What's cool is that it can weld complicated components without needing extra materials or heat, which makes things a lot more efficient and cuts down on waste. That definitely hits home with the growing focus on sustainable practices in manufacturing these days.

And there’s more! The rise of advanced automation tech is shaking things up in the ultrasonic welding scene. With robotics and smart sensors coming into play, manufacturers are getting a real boost in accuracy and safety. This means they have way better control over their processes. Plus, as these technologies become easier on the wallet, more and more industries across China are jumping on the ultrasonic welding bandwagon. This shift not only ramps up productivity but also gives businesses a leg up in the competition. So, it's super important for everyone involved to keep an eye on the latest developments and market changes that could affect their strategies down the line.

This chart illustrates the projected growth rates for ultrasonic welding technology from 2019 to 2025, highlighting the increasing adoption and technological advancements in the industry.

In modern manufacturing, the push for efficiency has led to a radical transformation in production processes, prominently fueled by ultrasonic automation systems. These advanced systems are designed to achieve comprehensive process automation, which significantly reduces the need for manual intervention. According to a report from McKinsey, manufacturing firms that adopt automation technology can increase their production efficiency by up to 30%, thereby cutting down labor costs and optimizing resource allocation.

The precision offered by ultrasonic automation systems is another significant advantage. Equipped with state-of-the-art control systems and sensors, these technologies allow for meticulous control over the frequency, amplitude, and duration of ultrasonic waves. This precise regulation ensures that the consistency and stability of product processing quality are maintained, which is crucial in industries such as automotive and electronics. A study published in the Journal of Manufacturing Science and Engineering highlights that enhanced control mechanisms can lead to a 25% reduction in product defects, underscoring the importance of precision in maintaining competitive advantage.

Moreover, the adaptability of ultrasonic systems stands out in diverse manufacturing environments. Customization options enable manufacturers to tailor the automation process according to specific production requirements, facilitating seamless integration with existing automated production lines. For instance, a survey by Industry Week found that 45% of manufacturers plan to upgrade their equipment with versatile automation solutions to improve overall production effectiveness. This trend reveals a growing recognition of ultrasonic automation systems as essential for achieving operational excellence in the fast-evolving landscape of modern manufacturing.

: Industry 4.0 enhances ultrasonic welding technology by integrating smart technologies such as IoT, artificial intelligence, and big data analytics, which improve efficiency, precision, and reduce waste.

Real-time data monitoring allows manufacturers to optimize welding parameters, thereby improving product quality and reducing waste during production.

Predictive maintenance enables manufacturers to anticipate and address potential equipment failures before they disrupt production lines, thereby maintaining operational continuity.

The interconnectedness fostered by Industry 4.0 enables seamless communication across the supply chain, leading to responsive production schedules and better resource alignment.

Smart robots equipped with advanced ultrasonic welding capabilities can perform complex patterns and adjustments instantaneously, accelerating production and enabling customization.

PSA systems are tools implemented in ultrasonic welding processes that enhance monitoring and control mechanisms, helping to maintain critical parameters and improve weld quality.

Manufacturers that have adopted PSAs have reported significant improvements, including a 20% increase in weld quality consistency and reductions in weld defects and cycle times.

An automotive manufacturer achieved a 30% reduction in weld defects with PSA integration, while an electronics firm experienced a 25% decrease in cycle times, enhancing overall throughput.

PSAs are becoming indispensable due to their ability to enhance operational efficiency and product reliability, supporting industry growth as manufacturers seek to improve their processes.

As Industry 4.0 continues to evolve, ultrasonic welding is expected to play a crucial role in various industries, indicating a promising future as advancements lead to better efficiency and flexibility in manufacturing.