- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

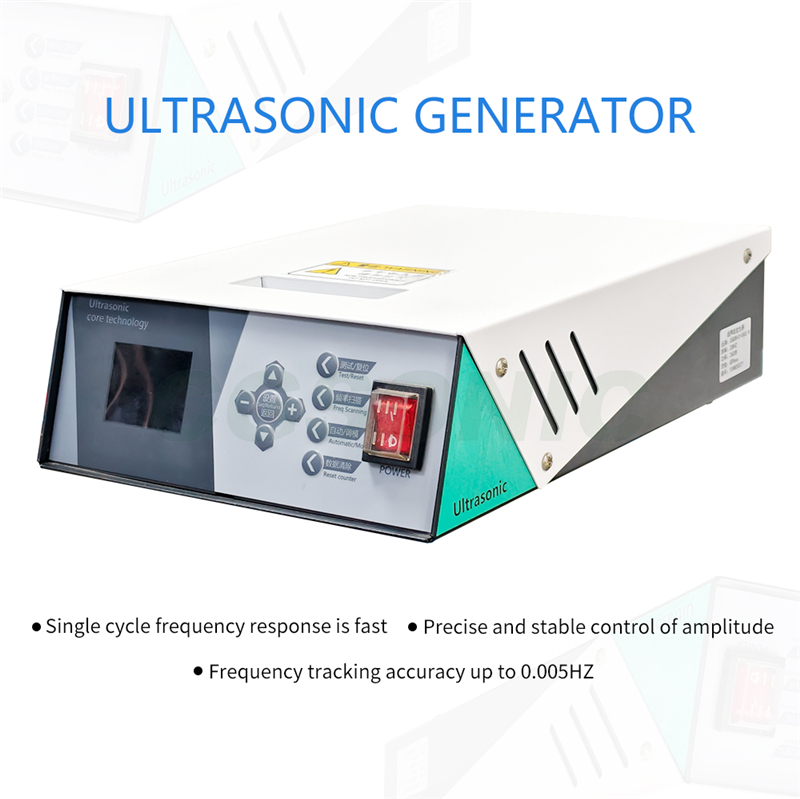

CG00 Series Ultrasonic Generator

Working Principle

The ultrasonic generator converts industrial-frequency power into high-frequency electrical energy through electronic circuits, precisely regulating output frequency, power, and waveform to drive the transducer in producing efficient and stable ultrasonic waves. Equipped with intelligent frequency modulation and adaptive power adjustment functions, it effectively avoids frequency drift and energy loss. Widely used in welding, cleaning, emulsification, medical diagnostics, and other fields, it achieves non-contact energy transfer for precision tasks, enhancing production efficiency and processing outcomes.

Product Introduction

Our ultrasonic generator boasts several standout features:

① Advanced Frequency Modulation and IC Technology: Utilizes cutting-edge frequency modulation circuits and IC technology to significantly reduce working time, improve welding results, save user time costs, and enhance efficiency.

② High-Quality Power Module: Employs premium power modules to greatly improve the safety and lifespan of the electrical box while protecting the ultrasonic transducer's normal operation, reducing equipment failure rates, and lowering maintenance costs.

③ Soft Start Design: Features a unique soft-start circuit to minimize the impact of startup current on the transducer, extending its service life and ensuring stable operation.

④ Digital Signal Processing (DSP) and Microcontroller (MCU): Implements DSP and MCU technologies for generating, controlling, and adjusting high-frequency signals.

⑤ Fully Digital Display: Offers a fully digital display for frequency and power, with stepless adjustment and a timer function. Users can set desired welding times, and any faults are displayed digitally for quick troubleshooting.

⑥ Selectable Work Modes: Provides both continuous and timed operation modes to meet diverse usage needs in various scenarios.

⑦ Elegant Design: The device features a sleek and modern appearance, balancing functionality with aesthetics to win user favor.

⑧ High Stability and Precision: Ensures high frequency stability, precise power control, and supports complex welding process control algorithms. Additionally, functionality can be expanded through software upgrades.

Application Fields

Ultrasonic generators are widely used in plastic welding, metal welding, industrial cleaning, medical fields, food processing, chemical industries, agriculture, environmental management, electronics, and many other sectors.

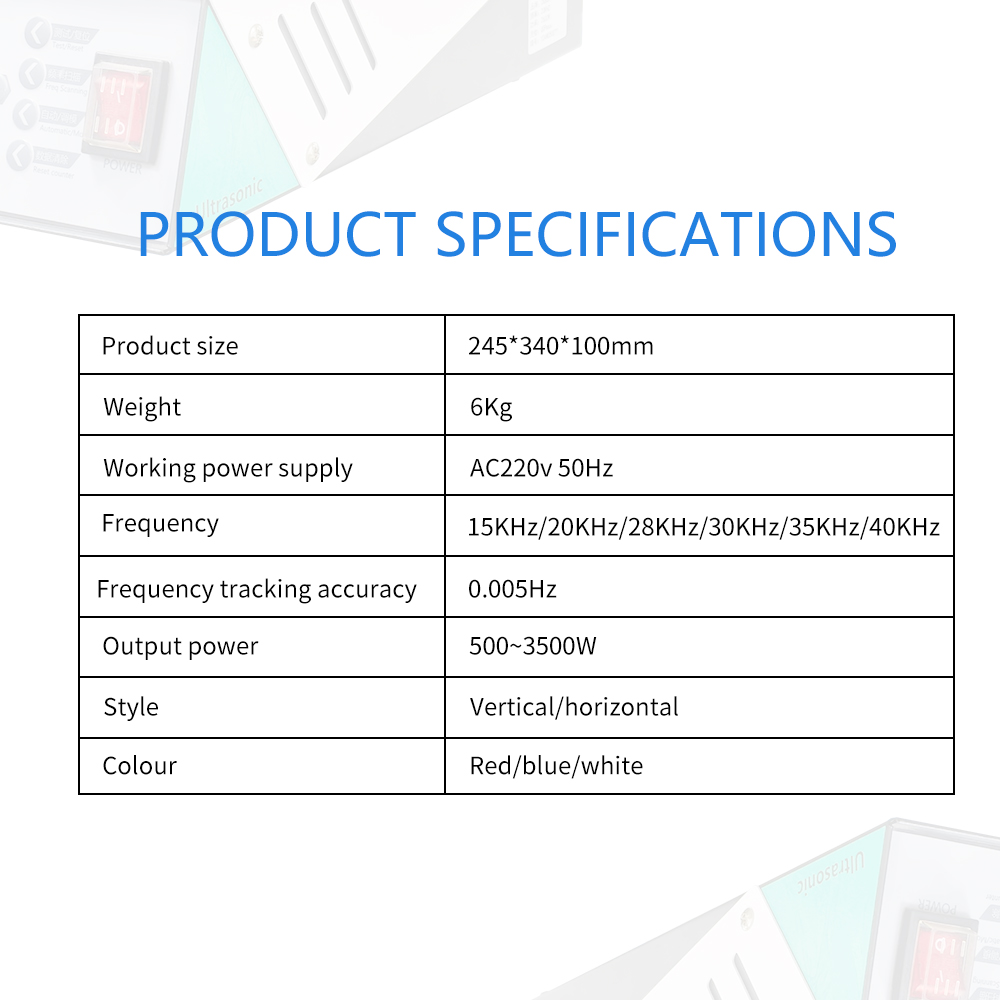

Product Parameters

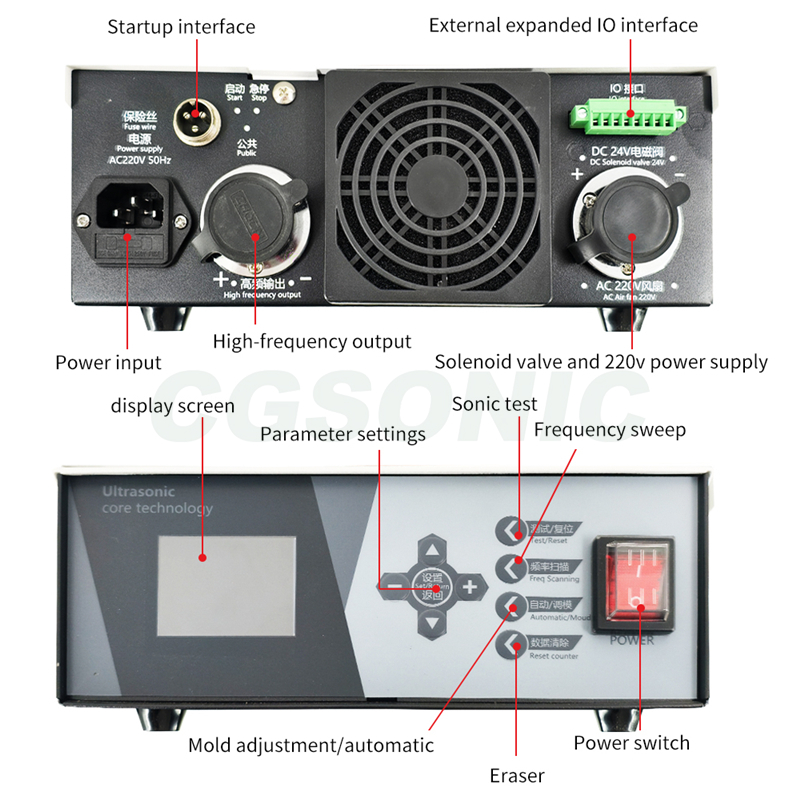

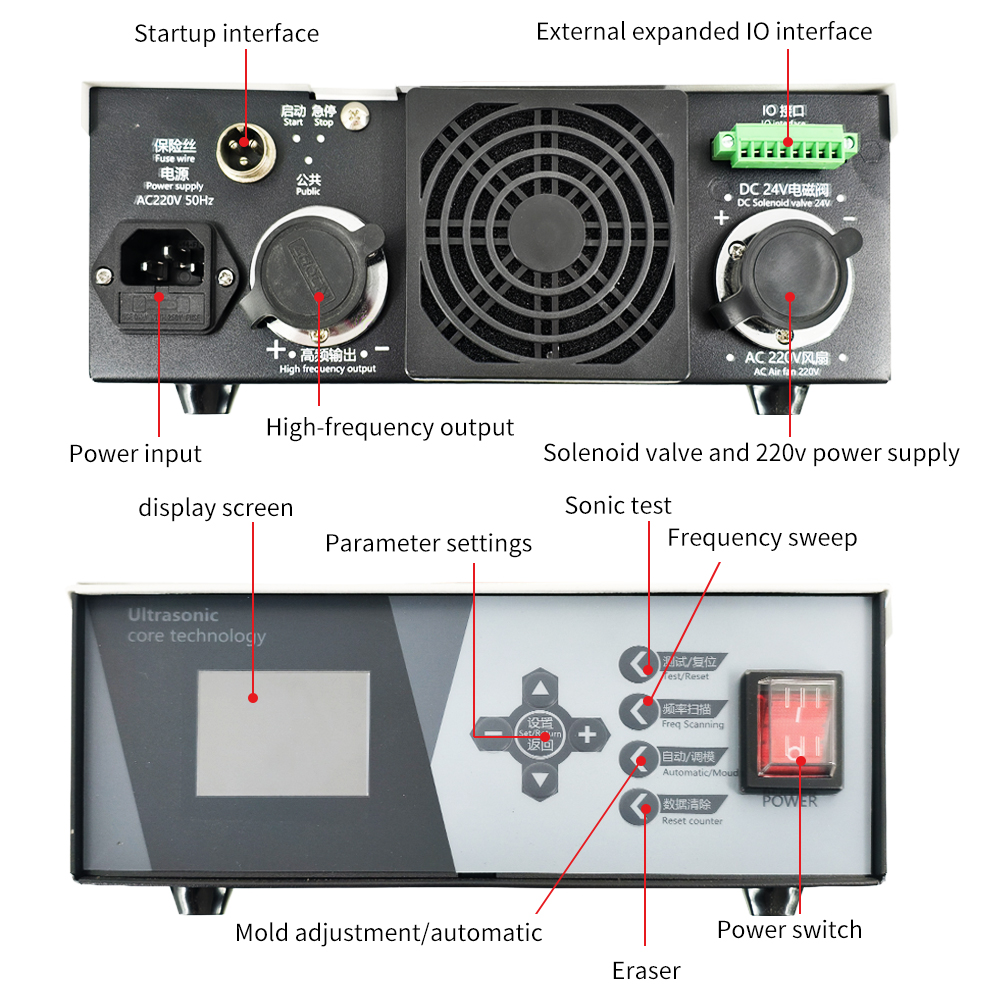

Structural Diagram

Maintenance Guide

Ultrasonic Generator: Regularly wipe the body with a clean, soft cloth to remove dust and stains, avoiding debris entering the interior. Check for loose wiring connections and ensure proper ventilation to prevent overheating and malfunctions.

Transducer and Amplitude Transformer: Inspect for cracks, wear, and loose connections. Replace or tighten components as needed.

Horn Maintenance: Clean surface residues after each use and regularly check for wear. Replace severely worn parts to maintain welding quality.

Control System: Periodically inspect control buttons and displays for proper operation, avoid misuse, and update system software promptly.

Regular Testing: Conduct periodic performance tests on the entire device, such as welding strength and frequency stability, to ensure optimal operation.

After-Sales Service

We offer a 1-year warranty. For any additional questions, we provide online technical support to assist you.