- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

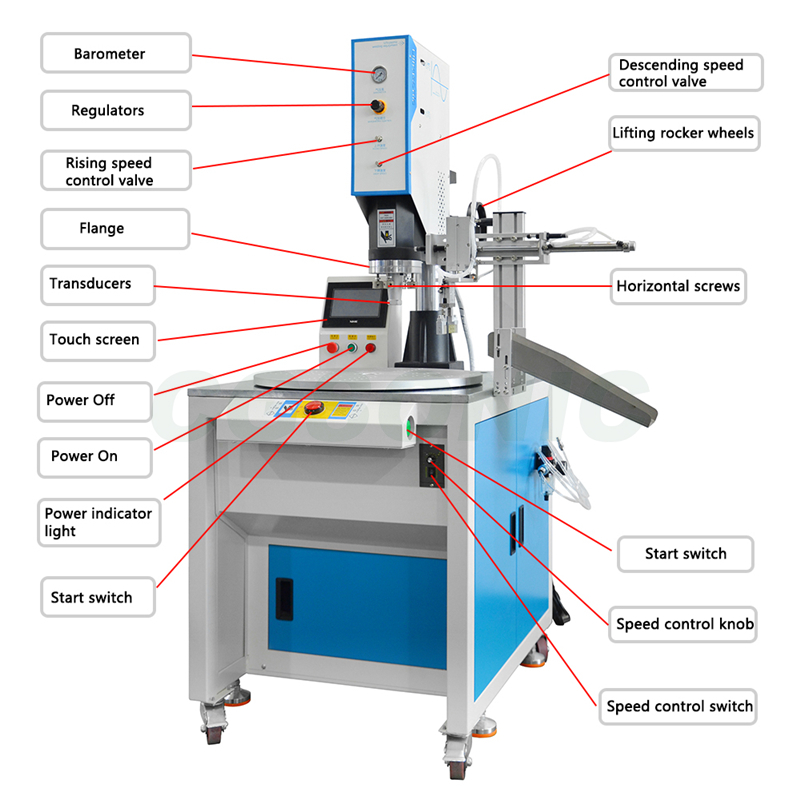

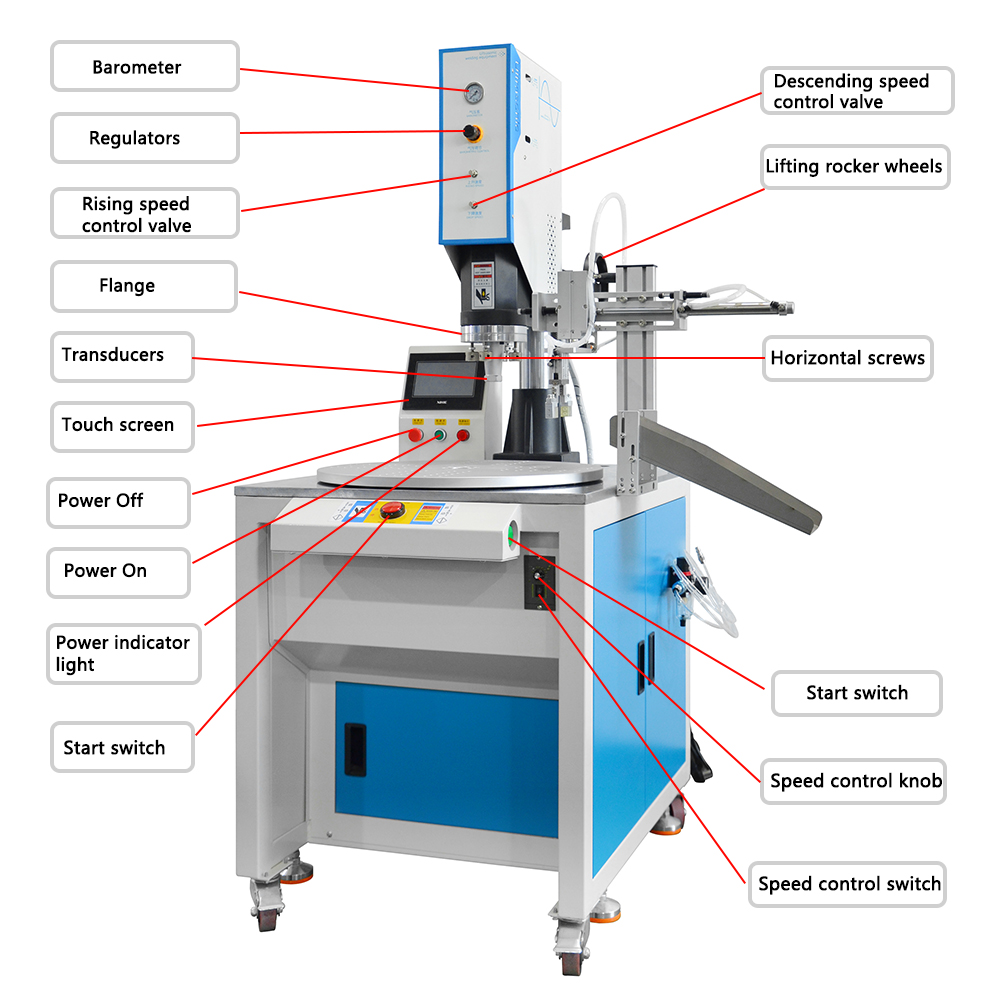

CGZP Ultrasonic Rotary Plastic Welding Machine

Brief Description (Core Features)

1.High Efficiency: Turntable continuous operation for batch production, significantly boosting productivity.

2.Precision Positioning: High-accuracy positioning ensures consistent workpiece alignment.

3.Superior Welding: No filler materials required; high strength, excellent sealing, and minimal damage.

4.Wide Adaptability: Adjustable parameters for diverse materials and product types.

5.User-Friendly: Simple interface for easy operation, reducing labor costs.

6.Energy-Efficient: Low power consumption, meeting green production standards.

7.Stable Performance: Robust design with premium components for reliable operation.

8.Multi-Functional: Integrates processes like riveting and embedding for versatility.

3. Working Principle

The ultrasonic rotary welding machine converts mains electricity into high-frequency electrical signals via the ultrasonic generator. The transducer transforms these signals into mechanical vibrations (ultrasound). The turntable rotates uniformly, moving workpieces sequentially to the welding station. When positioned under the welding head, ultrasonic vibrations transfer to the workpiece, causing molecular friction and localized heating. Upon reaching the melting point, materials fuse under pressure and cool to form a secure bond.

4. Product Introduction

The automatic rotary welding machine generates high-frequency signals converted into ultrasonic vibrations by the transducer, amplified via the horn, and transmitted to the welding mold. The mold transfers vibrations to plastic workpieces, softening and fusing them under pressure. The multi-station turntable enables intermittent feeding for precise, automated continuous welding.

Application Fields

Automotive Industry

Interior Parts: Dashboard panels, door trims, seat components—ensuring aesthetics and durability.

Exterior Parts: Bumpers, light housings, mirror casings—enhancing sealing and weather resistance.

Functional Parts: Filters, fluid tanks—guaranteeing leak-proof performance.

Electronics

Consumer Devices: Phone/tablet cases, charger housings—improving sealing and appearance.

Semiconductor Packaging: Precision welding for chip reliability.

Medical

Disposable Devices: IV bags, blood bags—preventing contamination and leaks.

Equipment Parts: Filters, separation cups—meeting medical-grade standards.

Packaging

Plastic Sealing: Tubes, bottles—ensuring airtight and visually appealing packaging.

Special Packaging: PVC tubes for candies/gifts—creating secure containers.

Toys & Stationery

Toys: Doll limbs, toy car shells—enhancing safety and longevity.

Stationery: Folders, pen cases—improving functionality.

Home Goods

Furniture: Plastic chair/table joints—boosting structural integrity.

Daily Items: Hangers, storage boxes—meeting consumer demands.

New Energy

Batteries: Lithium battery tabs/cases—ensuring performance and safety.

EV Components: Battery housings, controller boxes—high-quality welding.

6. Compatible Molds

Machine maintenance and upkeep

Parameter |

Specification |

Frequency |

15KHz/20KHz/28KHz |

Power |

2000–3500W |

Input Voltage |

AC220V 50/60Hz |

Air Pressure |

0.1–0.7MPa |

Welding Time |

0.01–9.99s |

Amplitude Adjustment |

10%–100% |

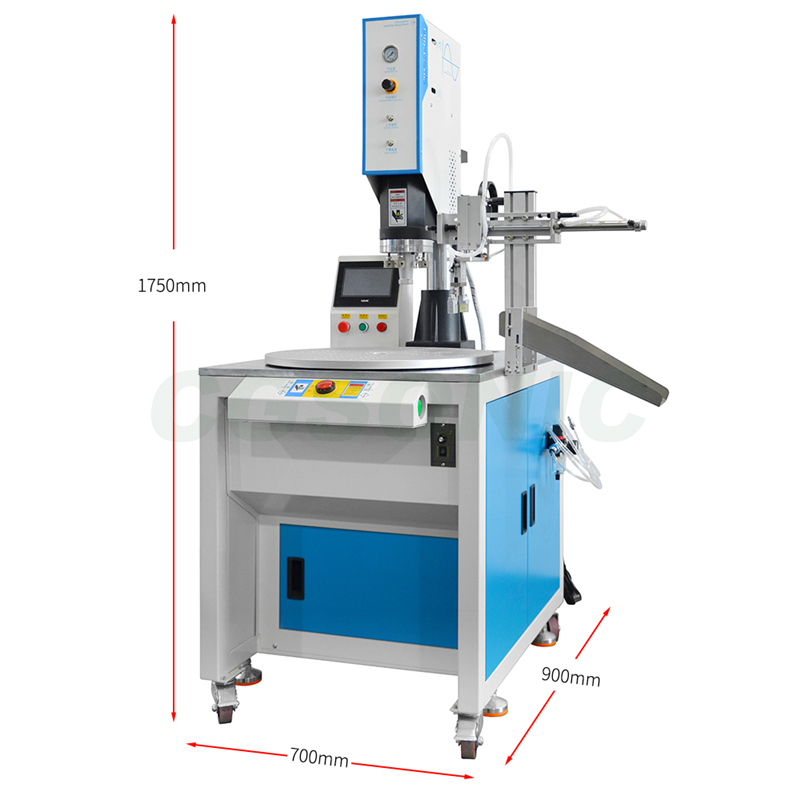

Machine Dimensions |

700×900×1750mm |

Worktable Size |

Ø580×20mm |

Weight |

215kg |

9. Maintenance Guide

1. Cleaning: Wipe the body and turntable regularly to remove debris.

2. Power Check: Inspect cables and grounding before use.

3. Transmission Parts: Lubricate chains/bearings; replace worn components.

4. Ultrasonic System: Check connections, calibrate frequency/power.

5. Welding Head: Clean and replace if worn.

6. Controls: Test buttons/displays; clean circuit boards.

7. Environment: Keep dry and dust-free to protect electronics.

8. Records: Log maintenance details for traceability.

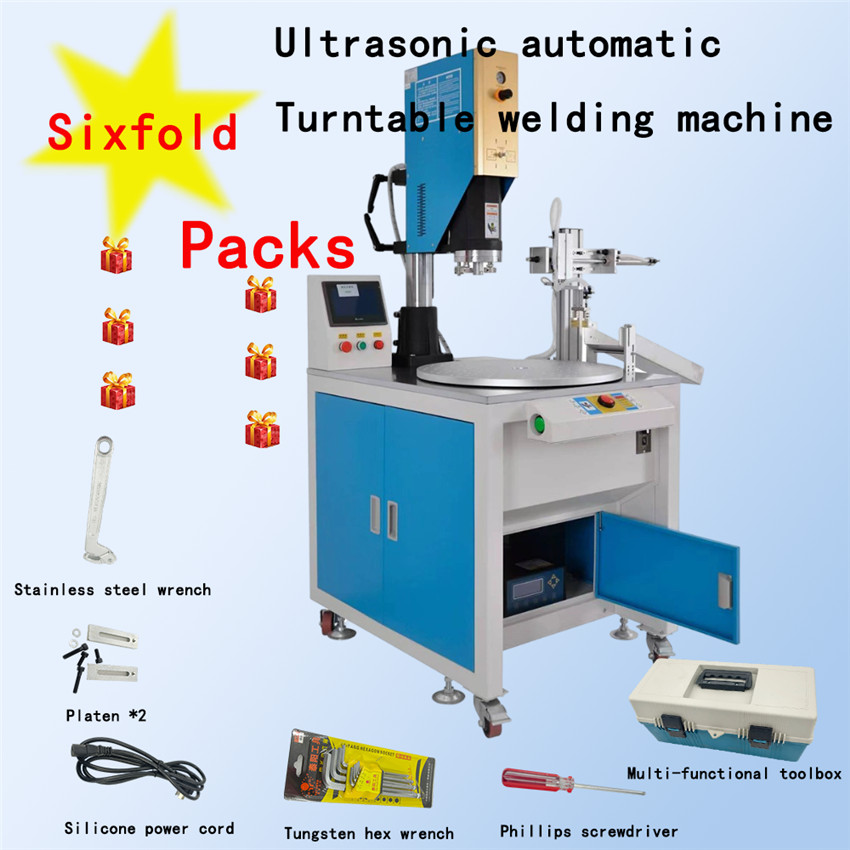

10. After-Sales Service

Our warranty is 1 years, and if you have any other problems about it, we'll provide you online technical support to help you.